A kind of styrene-acrylic latex and its preparation method and application

A styrene-acrylic latex and seed technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as increasing the use cost, affecting the performance of cement slurry, increasing the difficulty of formula design, and reducing the difficulty and use cost. The effect of improving cementing quality and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

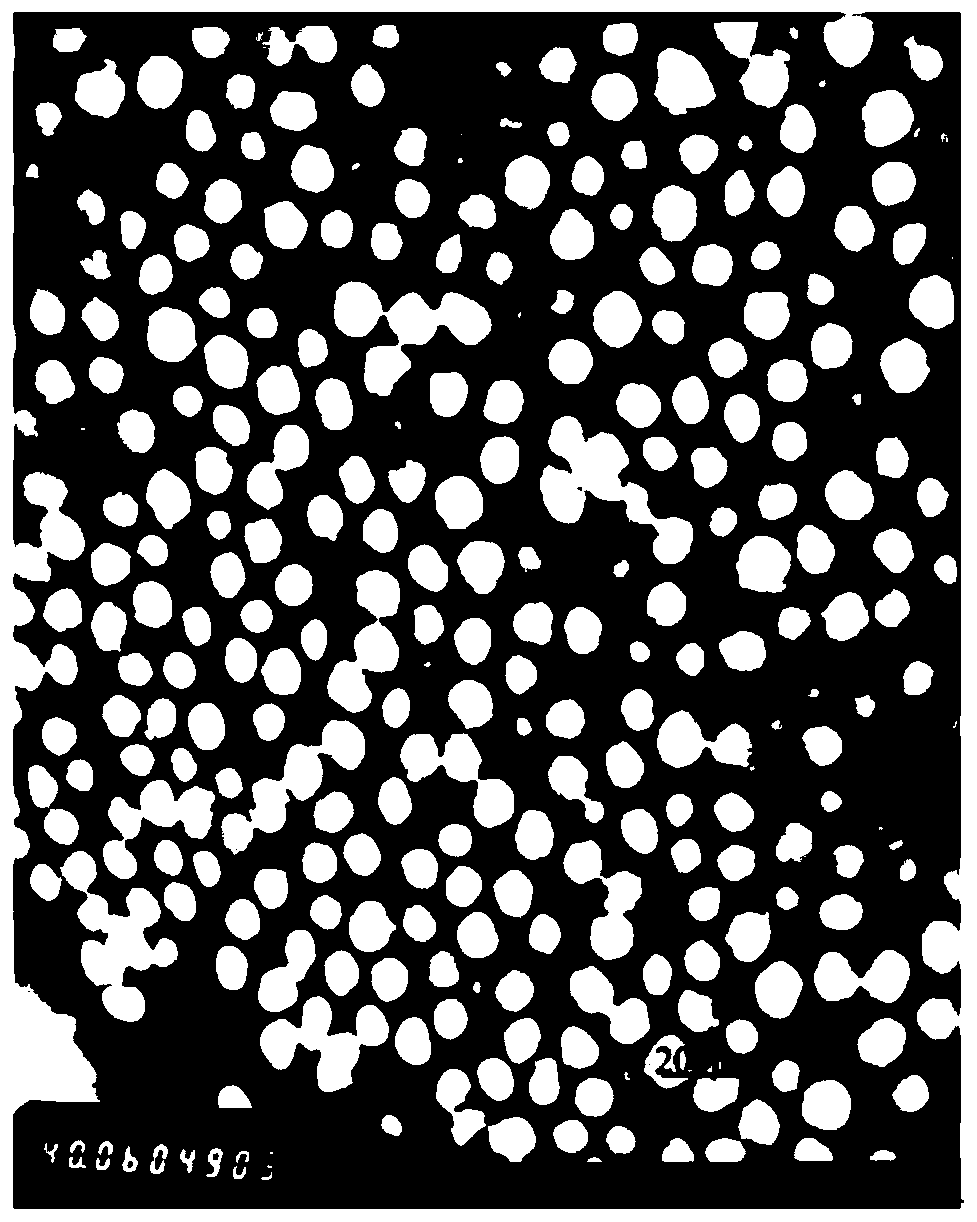

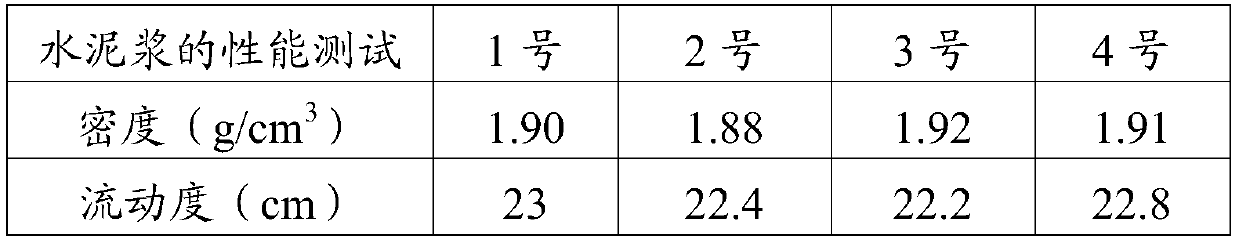

[0030] The preparation method of the above-mentioned styrene-acrylic latex provided in the embodiment of the present invention is to prepare the styrene-acrylic latex through two steps of seed emulsion polymerization and soap-free emulsion polymerization. The styrene-acrylic latex uses the seed emulsion polymerization part as the core, and the soap-free emulsion polymerization as the The shell, which can be evenly dispersed in the cement slurry and maintain a stable state with the cement particles, not only increases the fluidity of the cement slurry, but also hinders the growth of hydration product crystals during the cement hydration process, avoiding the expansion of the cement, Cracking and air channeling, so there is no need to add other soap emulsifiers and stabilizers to stabilize the system, which greatly reduces the difficulty of formula design and the cost of use. At the same time, the toughness and film-forming properties of the latex particles of the styrene-acrylic...

Embodiment 1

[0047]This embodiment provides a kind of styrene-acrylic latex, and this styrene-acrylic latex is prepared by the following method: 2.7g styrene monomer, 2.3g methyl methacrylate monomer, 0.075g sodium acrylate monomer, 0.01g sodium carbonate , 45g of deionized water was added to the reactor, then nitrogen gas was introduced, and the temperature was controlled to be 70°C, then 0.045 potassium persulfate was added, and the reaction was carried out for 90 minutes to obtain the seed emulsion polymerization part, and then 25g of methyl methacrylate was separately Body and 25g ethyl methacrylate monomer mixture, and the mixture of 0.27g potassium persulfate, 0.076g sodium carbonate, 0.58g2-acrylamido-2-methylpropanesulfonic acid monomer is added dropwise to the seed emulsion Polymerize the part, and control the dropping end point to reach at the same time, then raise the temperature to 82°C and keep it warm for 0.4h to obtain the styrene-acrylic latex provided in this example, and t...

Embodiment 2

[0049] This embodiment provides a kind of styrene-acrylic latex, and this styrene-acrylic latex is prepared by the following method: 2.7g styrene monomer, 2.3g ethyl acrylate, 0.075g maleic acid monomer, 0.01g sodium carbonate, 45g Ionized water was added to the reactor, then nitrogen gas was introduced, and the temperature was controlled at 72°C, then 0.045g of ammonium persulfate was added, and the reaction was carried out for 92min to obtain the seed emulsion polymerization part, and then 30g of methyl methacrylate monomer and A mixture of 15g ethyl methacrylate monomer, and a mixture of 0.27g ammonium persulfate, 0.077g sodium phosphate, and 0.86g 2-acrylamido-2-methylpropanesulfonic acid monomer are simultaneously added dropwise to the seed emulsion polymerization part , and control the dropping end point to reach at the same time, then raise the temperature to 88°C and keep it warm for 0.5h to obtain the styrene-acrylic latex provided in this example, and the average part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com