Natural gas horizontal well completion method

一种水平井、天然气的技术,应用在井眼/井部件、钻孔设备和方法、化学仪器和方法等方向,能够解决没有天然气水合物完井技术、无法满足水合物开发、地层成岩性差等问题,达到解决钻压施加困难、稠化时间可调、防止水-气窜的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

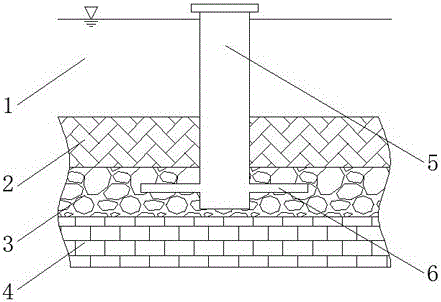

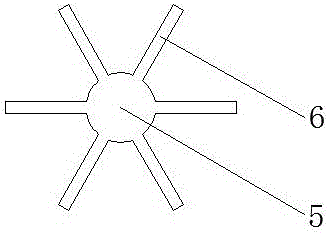

[0034] Embodiment 1: in combination with Figure 1-7 , to further describe the present invention:

[0035] The present invention includes adopting a large-sized drill bit to drill to the target well depth at one time to form a large main borehole 5, and then using radial horizontal well technology to drill multiple horizontal branch boreholes 6 in the natural gas hydrate reservoir. The specific steps are as follows:

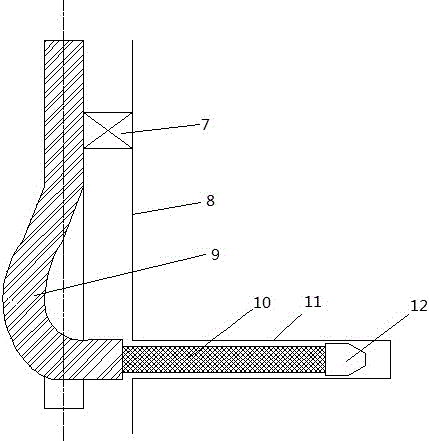

[0036] After the operation of a large main borehole 5 is completed, the downhole skewer 21 is lowered, and the whole set of devices is fixed on the casing 8 at the bottom of the well;

[0037] 2. Lower the build-up guide 9, insert it into the positioning hole 22 of the guide groove 23 of the first horizontal branch wellbore 6, and at the same time, run the high-pressure flexible nozzle into the guiding follow-up screen 10, guide the follow-up screen 10 The front end is equipped with a high-pressure jet drill bit 12, which can drill forward with the help of its o...

Embodiment 2

[0047] Example 2, the difference from Example 1 is that the window sealant used is composed of the following components by weight: 100 parts of G-grade oil well cement, 30 parts of reinforcing agent, 70 parts of hollow microspheres, and 3 parts of early strength agent , 1 part of dispersant, 3 parts of retarder, 1 part of defoamer, 4 parts of fluid loss reducer, 100 parts of water, density 1.2~1.7g / cm -3 ; Wherein the strengthening agent is fly ash and its physical properties are: fineness ≤ 20%, sulfur trioxide ≤ 3.0%; early strength agent is KAl(SO 4 ) 2 ; The dispersant is amino acid sulfonated formaldehyde-acetone condensation polymer, the relative molecular mass is 8000~60000; the retarder is citric acid; the defoamer is tributyl phosphate; the fluid loss reducer is carboxymethyl hydroxyethyl cellulose One of them, the viscosity of 2% aqueous solution at 25°C is 7000~12000mPa·s. The window sealant, that is, the cement slurry system is stable, which can not only meet the...

Embodiment 3

[0048] Example 3, the difference from Example 1 is that the window sealant used is composed of the following components by weight: 100 parts of G-grade oil well cement, 25 parts of reinforcing agent, 40 parts of hollow microspheres, and 3 parts of early strength agent , 1 part of dispersant, 2 parts of retarder, 1 part of defoamer, 3.7 parts of water loss reducer, 80 parts of water; wherein the strengthening agent is ultrafine slag, and the early strength agent is KAl(SO 4 ) 2 ; The dispersant is amino acid sulfonated formaldehyde-acetone condensation polymer; the retarder is citric acid; the defoamer is polyoxyethylene polyoxypropanolamine ether; The viscosity of the aqueous solution is 7000~12000mPa·s.

[0049] The window sealant, that is, the cement slurry system is stable, which can not only meet the special conditions of the natural gas hydrate formation, but also effectively prevent the hydrate layer from sealing shallow water-gas channeling, and has good construction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com