Method for increasing recovery ratio of tight oil reservoir through CO2 foam huff and puff

A tight oil and oil recovery technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of reduced production energy, waste of resources, gas channeling, etc., and achieve the effect of improving oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

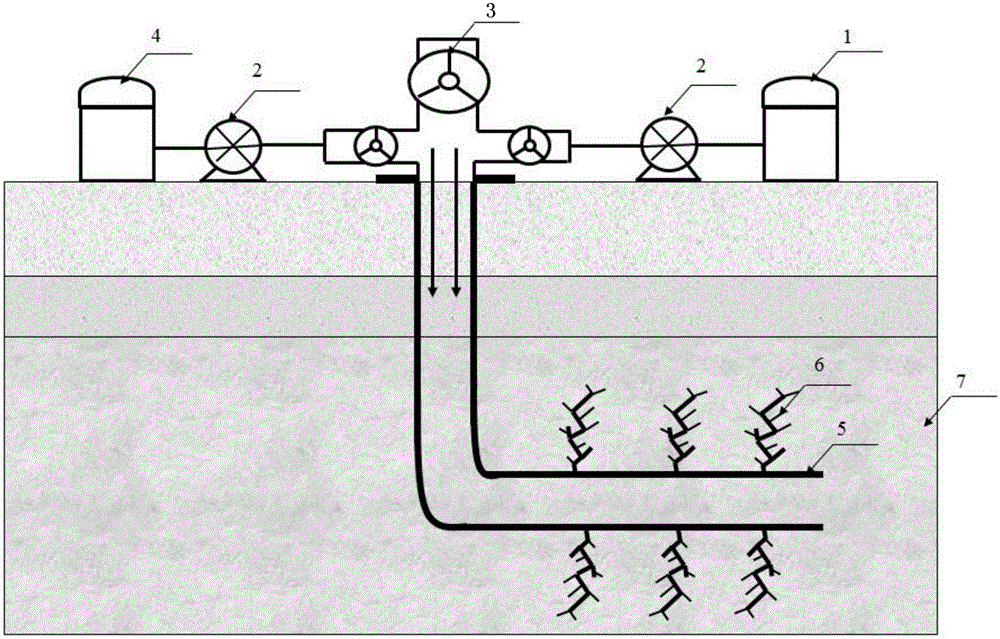

[0007] Technical scheme of the present invention is as follows:

[0008] A tight oil reservoir CO 2 The method for improving recovery by foam stimulation includes the following steps:

[0009] (1) High pressure CO 2 Slug injection: inject 0.01PV to 0.1PV of CO under reservoir conditions 2 The slug is injected into the tight oil reservoir through the wellbore, filling the fractured fractures;

[0010] (2) Surfactant aqueous solution slug injection: The surfactant aqueous solution is fully mixed and then injected into the tight oil layer. The volume of the injected aqueous solution is the same as the CO 2 The volume ratio is 1:2 to 1:1, and the mass concentration of the surfactant aqueous solution is 0.1 to 1.0%;

[0011] (3) Diffusion of soaked wells: After injecting the aqueous surfactant solution into the tight oil layer, the wells are soaked, and the pressure changes during the soaked wells are recorded. During the soaked wells, the CO 2 Mass transfer and diffusion from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com