Method for coal bed methane mining by multi-element thermal fluid foam displacement

A technology of multiple thermal fluids and mining methods, which is applied in the fields of mining fluids, earth-moving drilling, climate sustainability, etc., to achieve the effects of promoting desorption, increasing production pressure difference, and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

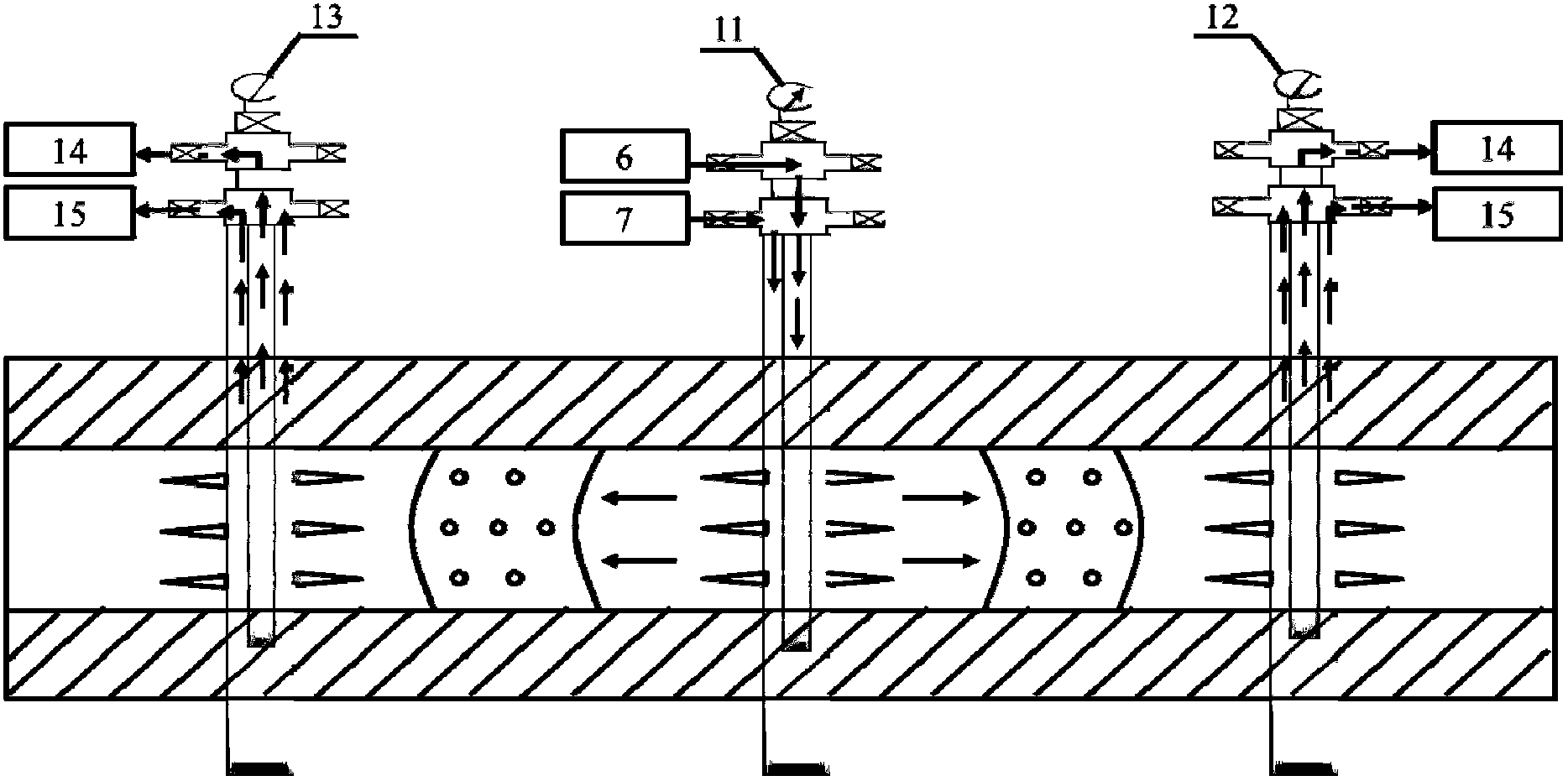

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and a coalbed methane well group at the eastern edge of the Ordos Basin as an example, but the implementation scope of the present invention is not limited.

[0015] The CBM well group is a diamond-shaped well pattern, the center well is a vertical well, and the corner wells are directional wells. The average thickness of the encountered coal seam is 8.87m (the vertical depth in the middle of the coal seam is 480m), the average pressure of the coal seam is 3.60MPa, the component content of carbon dioxide and nitrogen in the coalbed methane in this area is 6.8%, and the critical desorption pressure is about 2.5MPa.

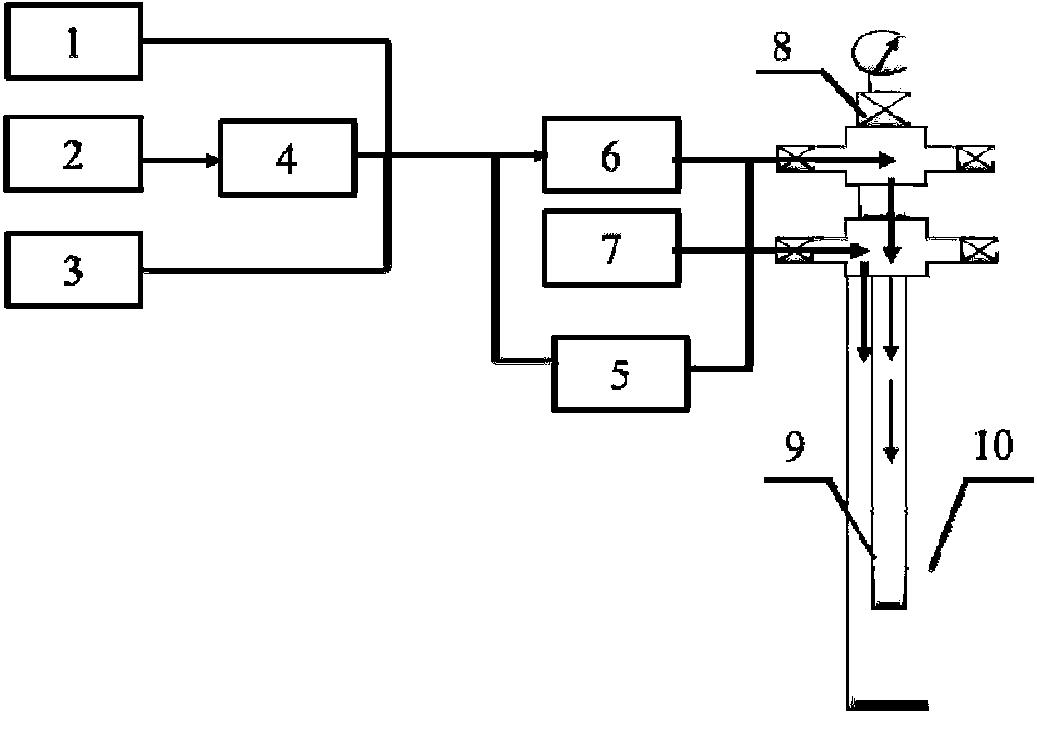

[0016] The central well with low current gas production in this well group was transferred to inject, and the reverse five-point injection-production well pattern was adopted for production. The well row spacing was 300m×250m. The injection process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com