Patents

Literature

42results about How to "Realize gas-liquid separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

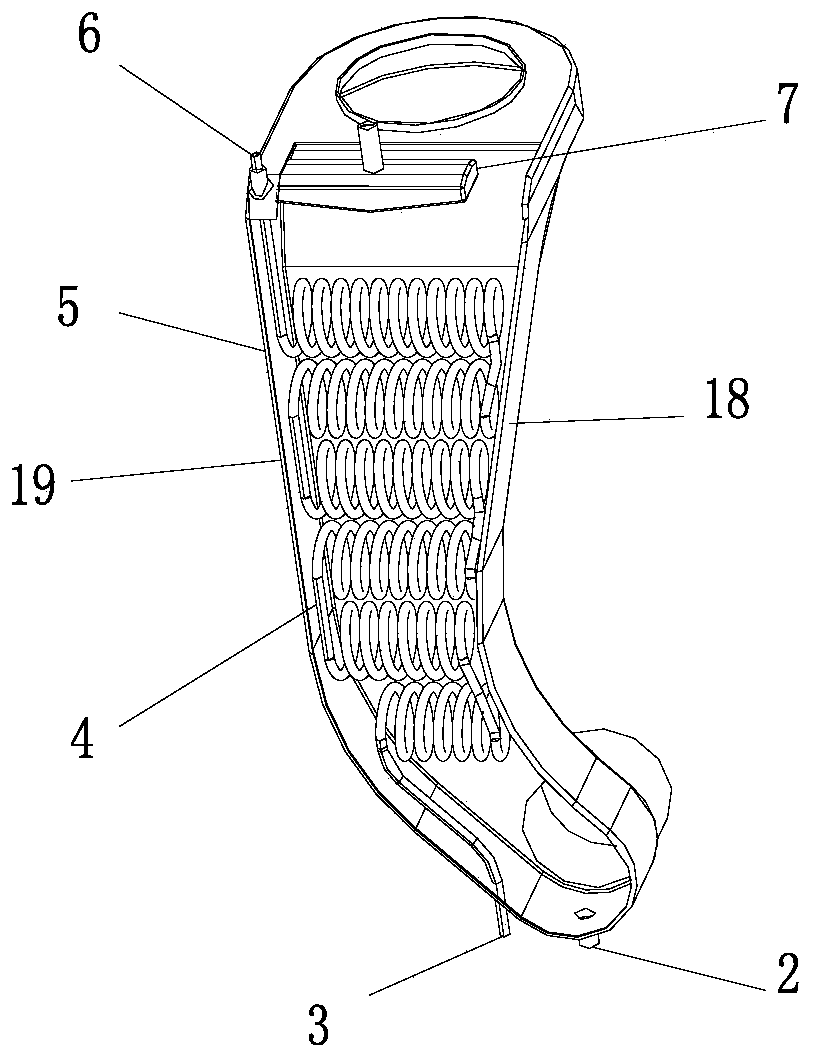

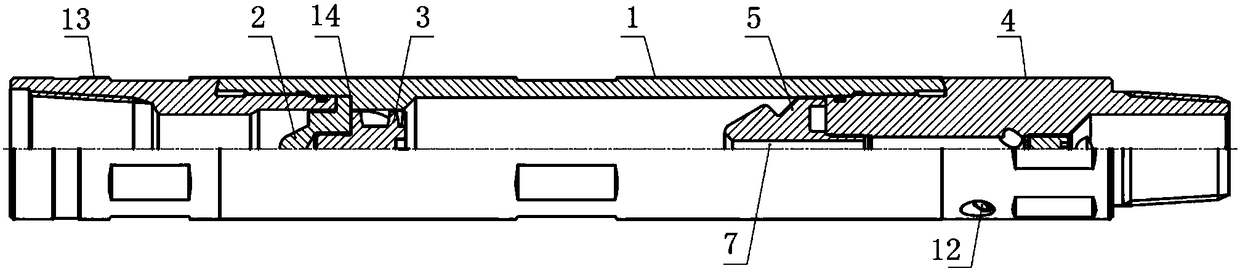

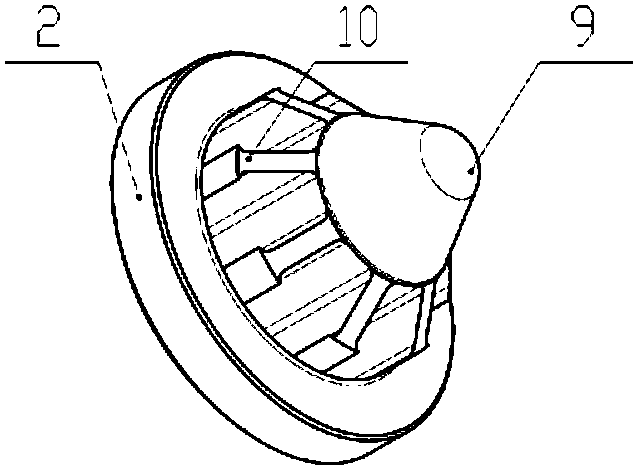

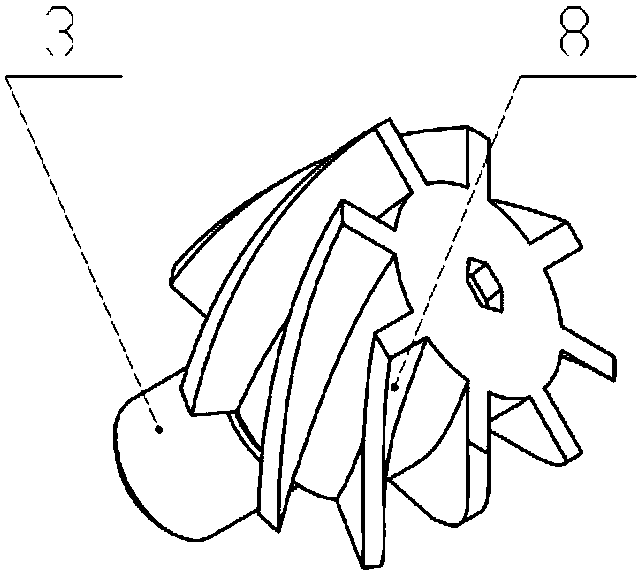

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

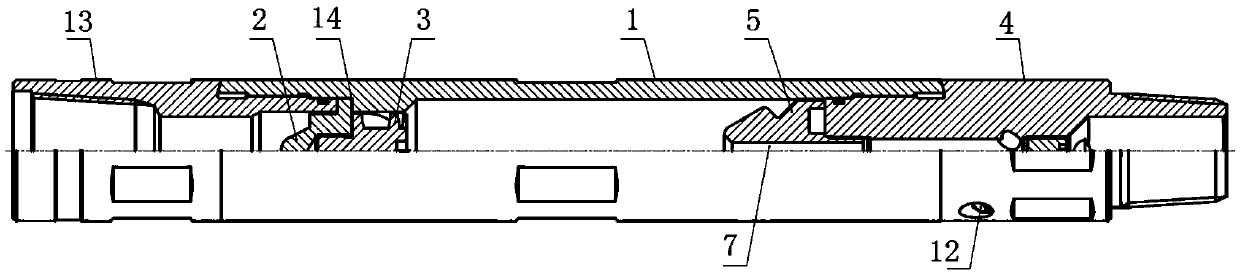

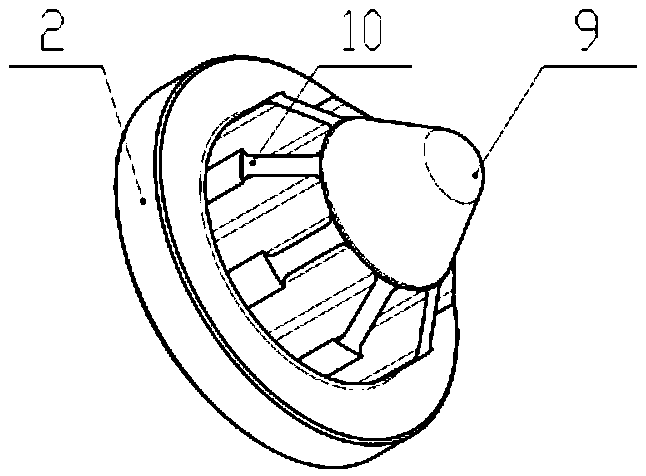

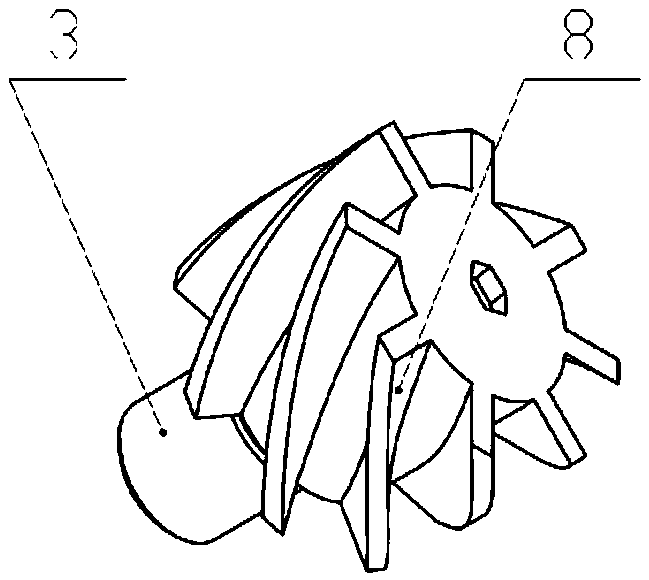

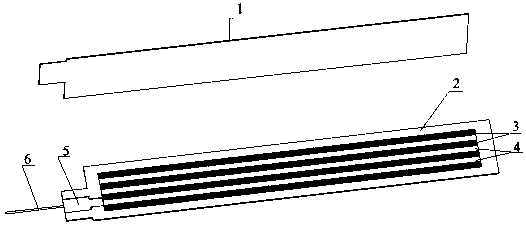

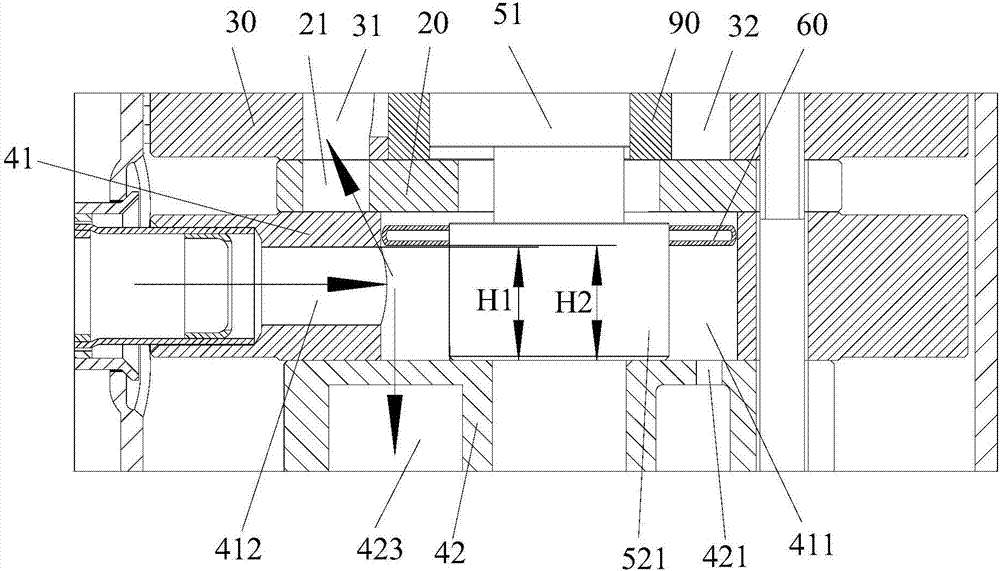

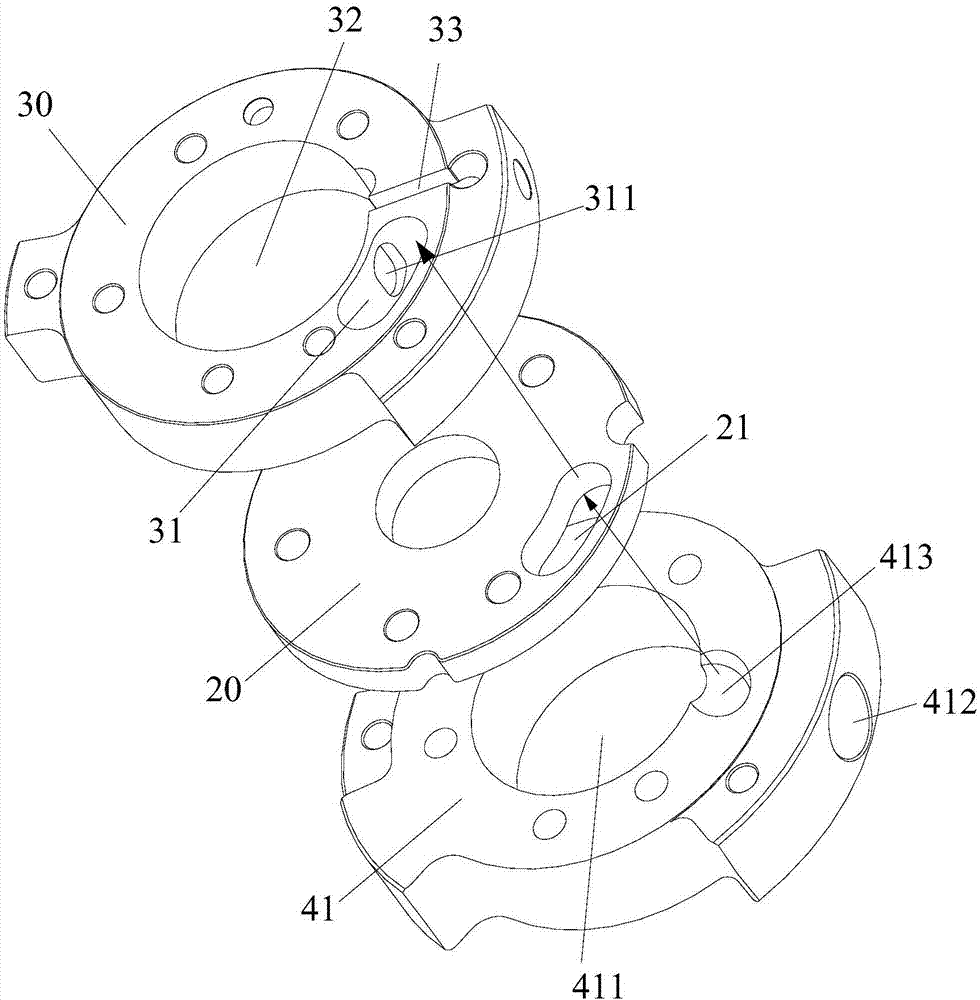

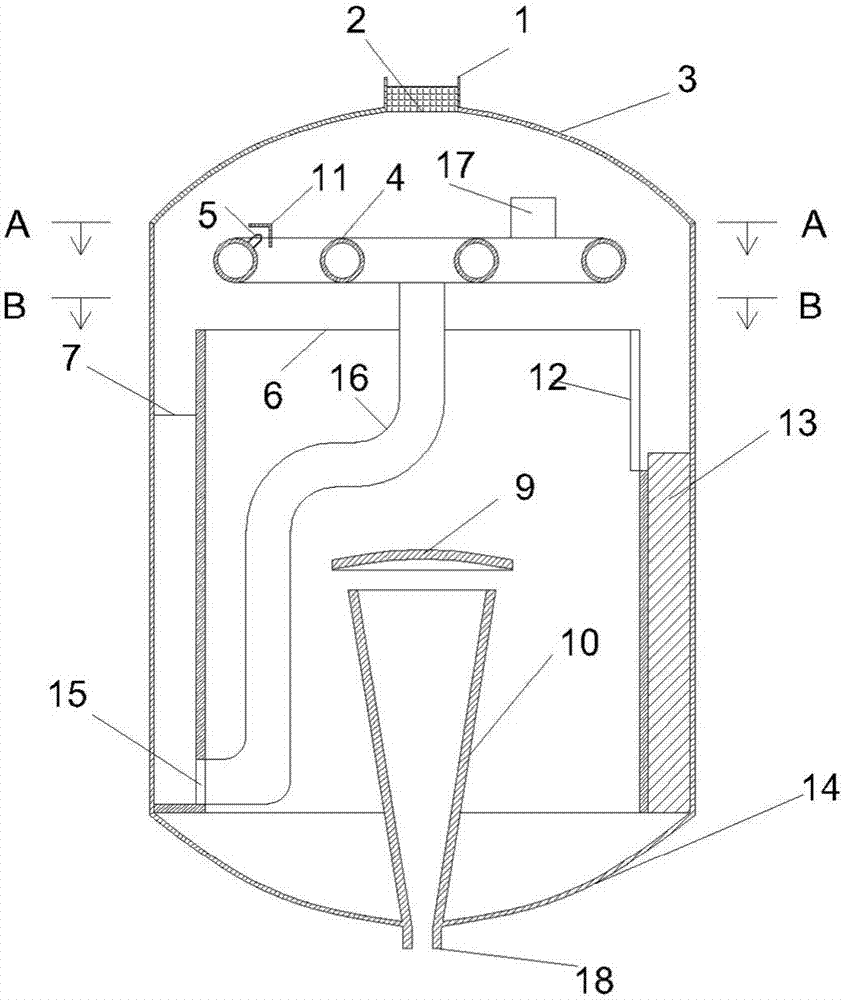

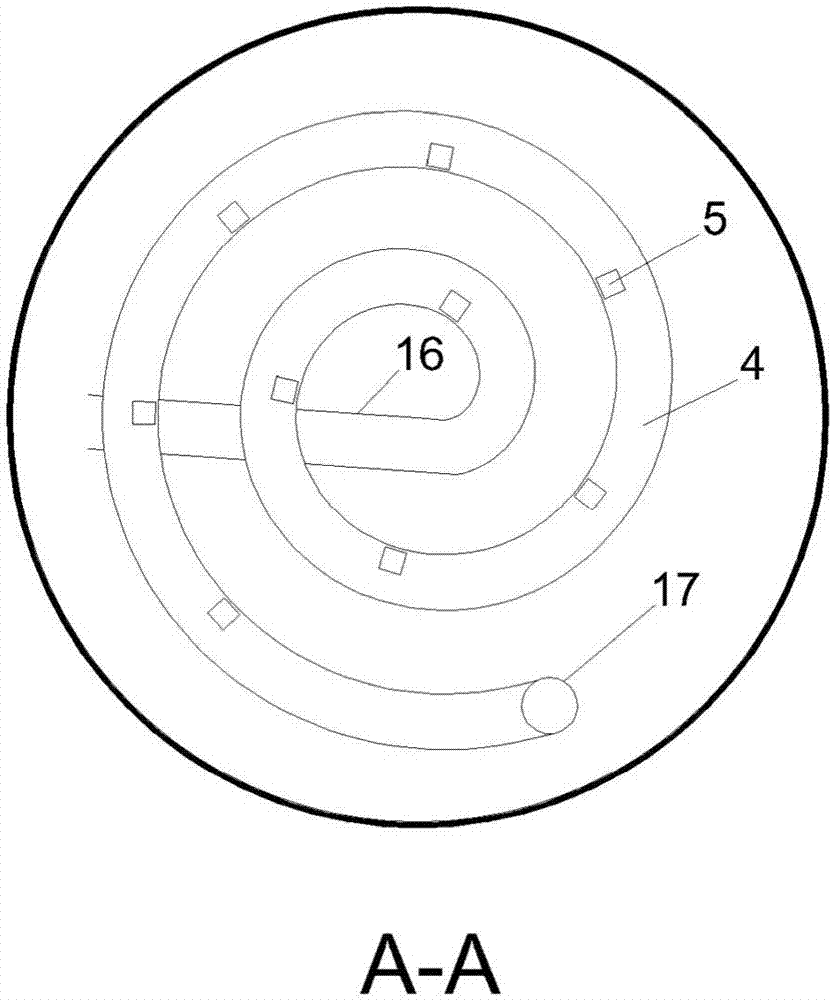

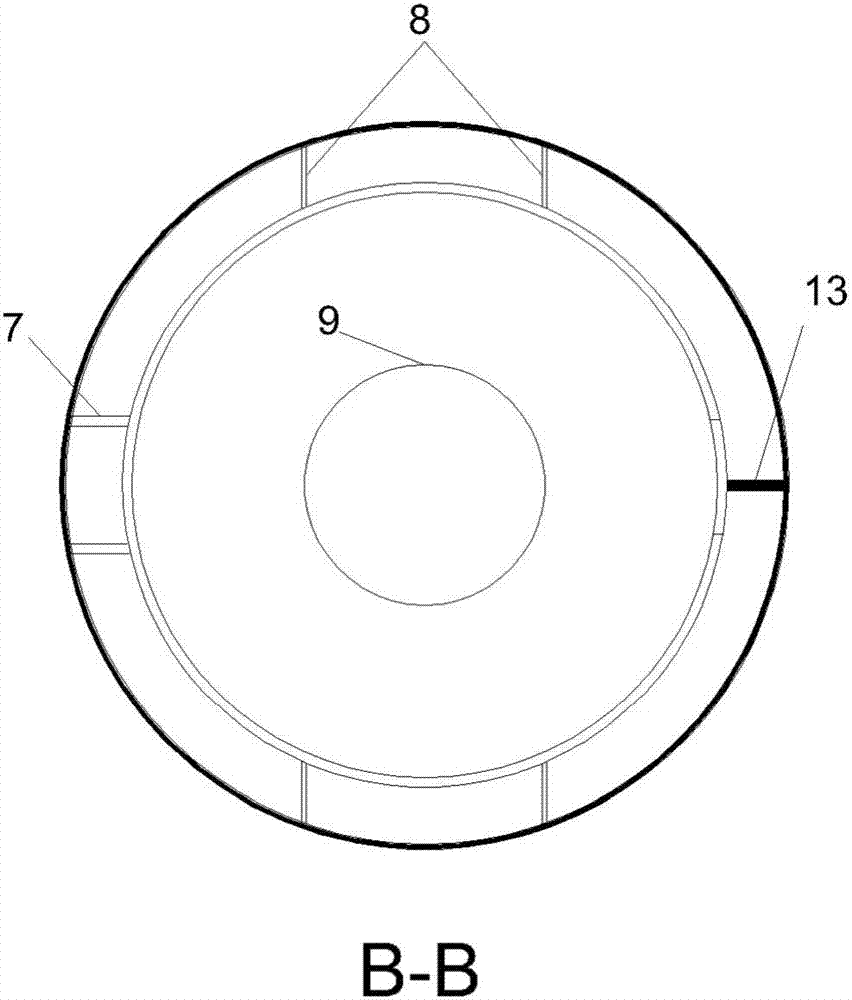

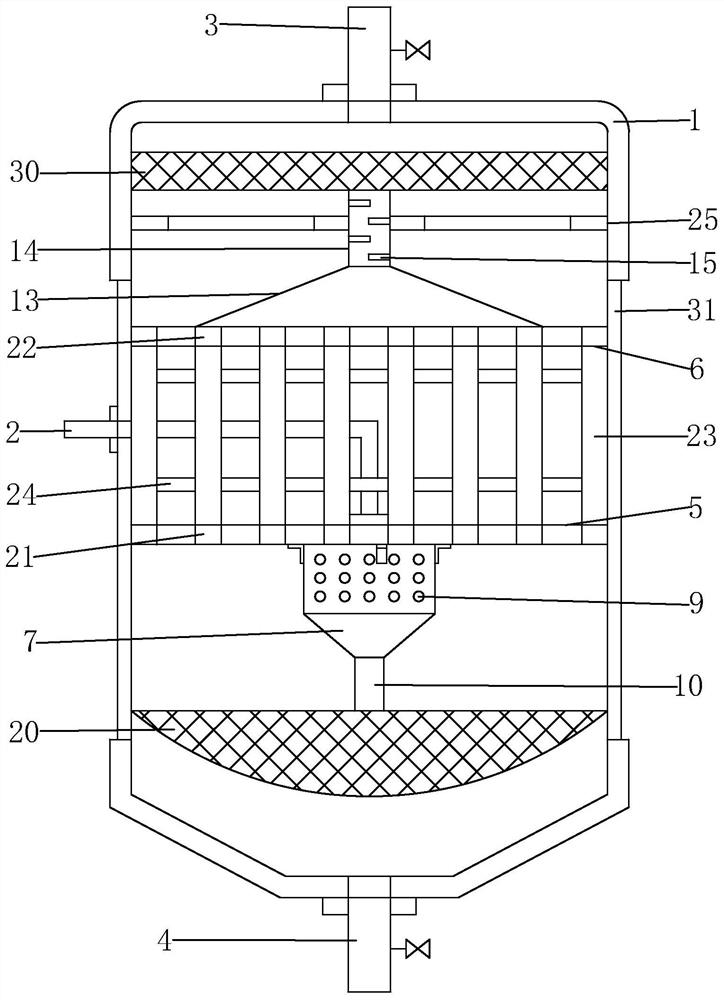

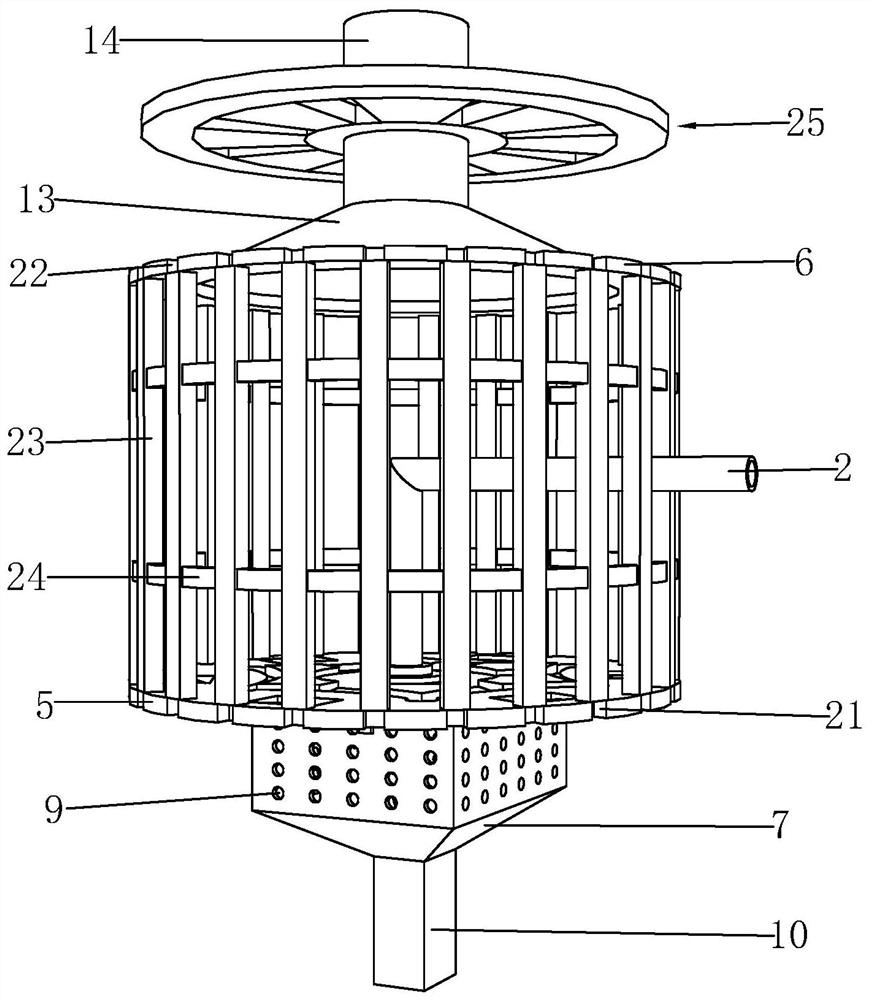

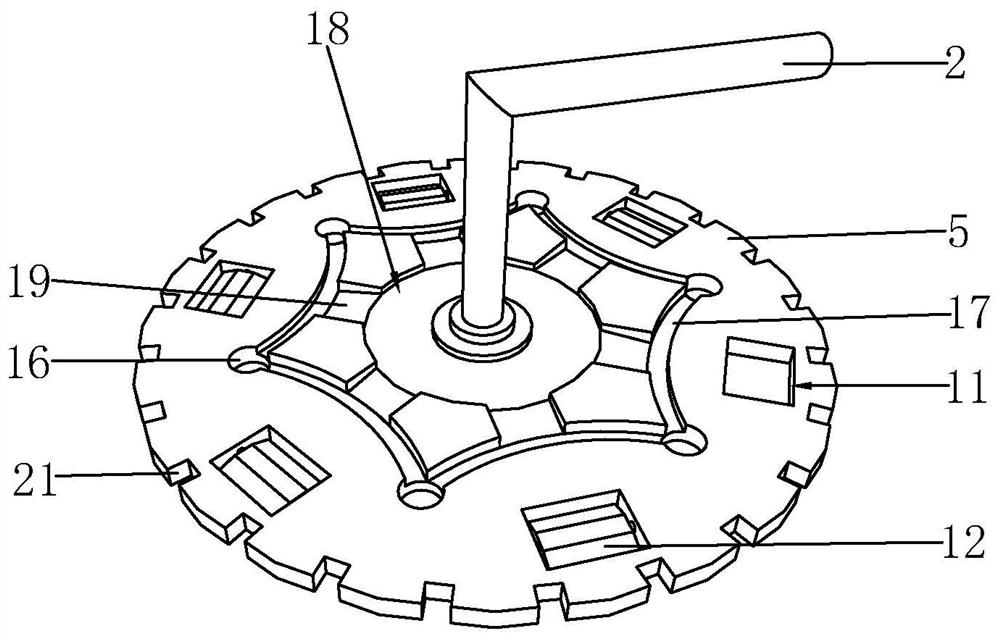

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

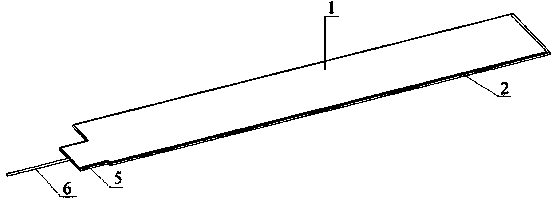

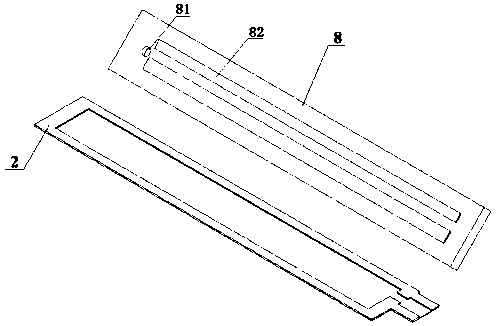

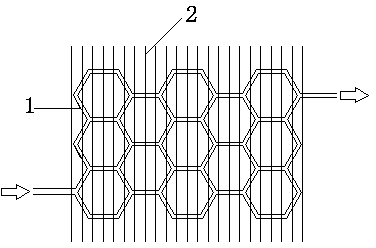

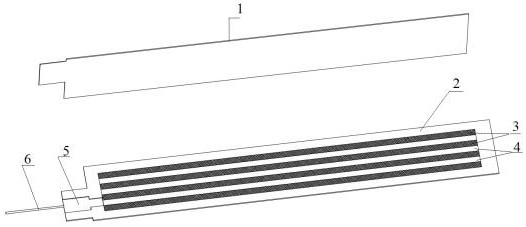

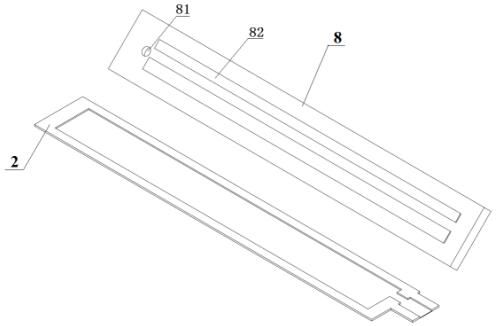

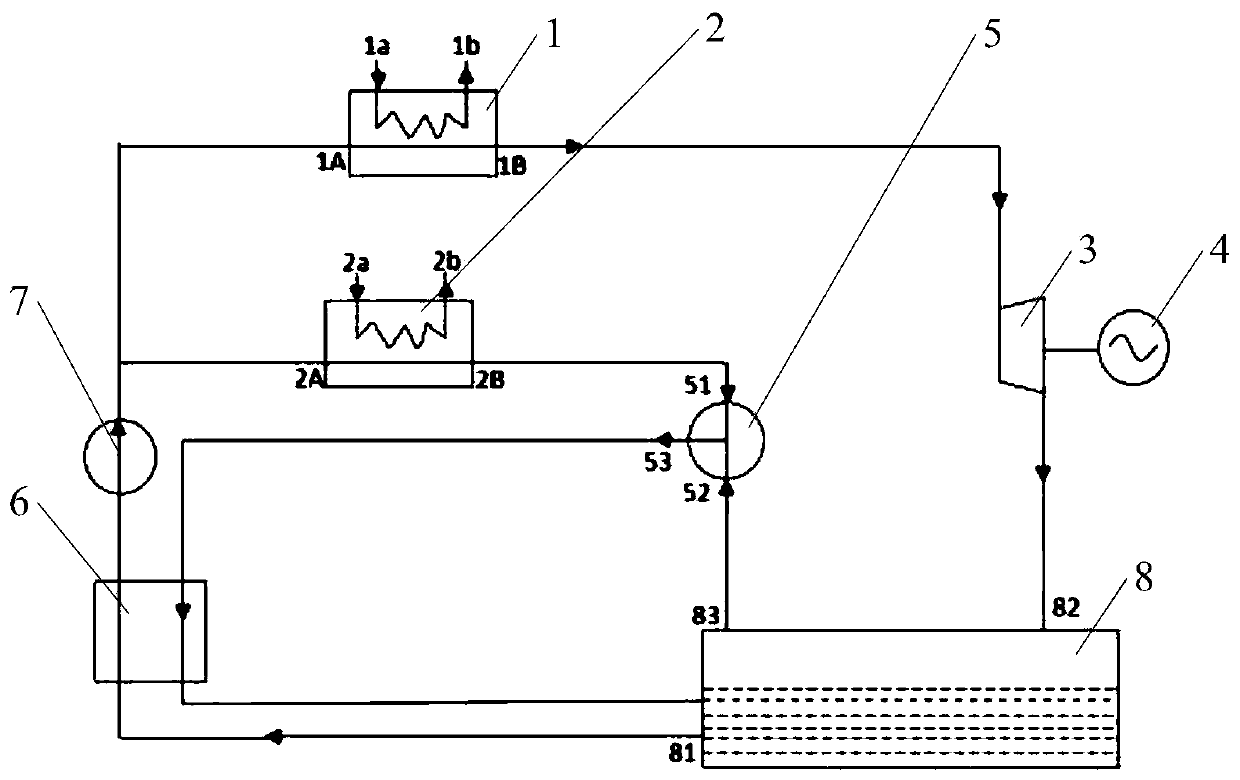

Ultra-thin flat heat pipe and manufacturing process thereof

ActiveCN109443060AIncrease heat transfer limitPrevent collapseIndirect heat exchangersMiniaturizationProcess engineering

The invention relates to the technical field of heat dissipating devices, in particular to an ultra-thin flat heat pipe and a manufacturing process thereof. A bottom plate and a cover plate which arebuckled and packaged are included, the bottom plate is provided with a cavity internally provided with a plurality of capillary structures arranged in parallel, gas flow channels for a heat pipe working medium to flow therein is formed between the adjacent capillary structures, and each capillary structure includes a plurality of liquid flow channels arranged in parallel. A gas working medium flows in the gas flow channels, and a liquid working medium flows in the capillary structures, so that gas-liquid separation of the working media is achieved, the flow resistance is reduced, and the heattransfer limit of the heat pipe is increased; and the ultra-thin flat heat pipe is simple in structure and easy to manufacture, can realize industrial production line production, has strong heat transfer capacity, is small in thickness of heat pipe, can meet the requirement for heat dissipation of electronic devices in a narrow space, meets the needs of integration and miniaturization of electronic components, and has good practicability and applicability .

Owner:GUANGDONG UNIV OF TECH

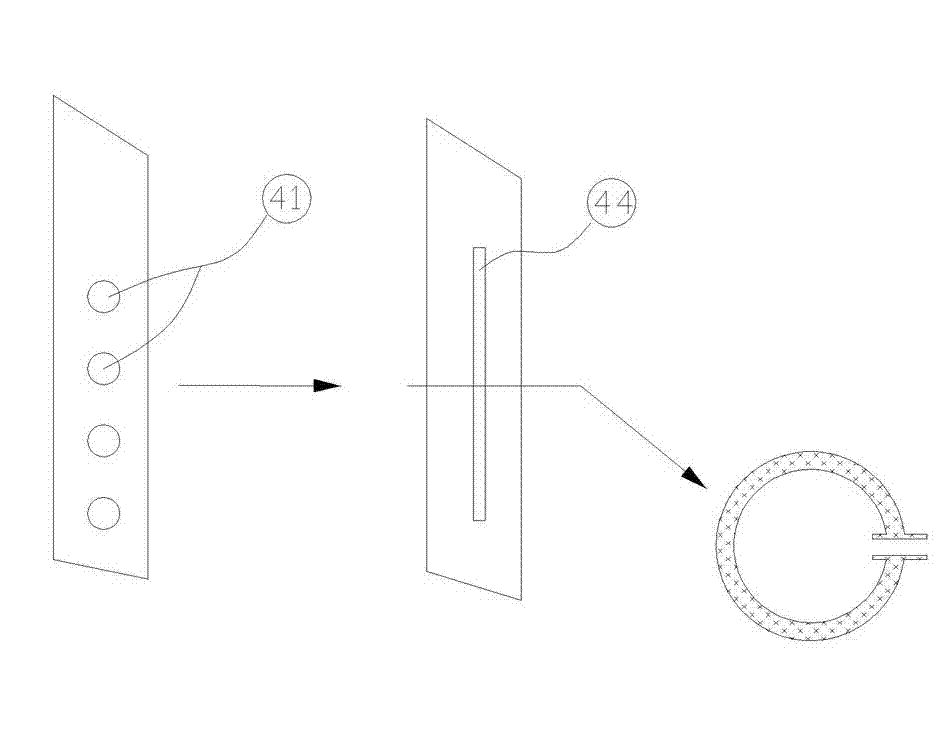

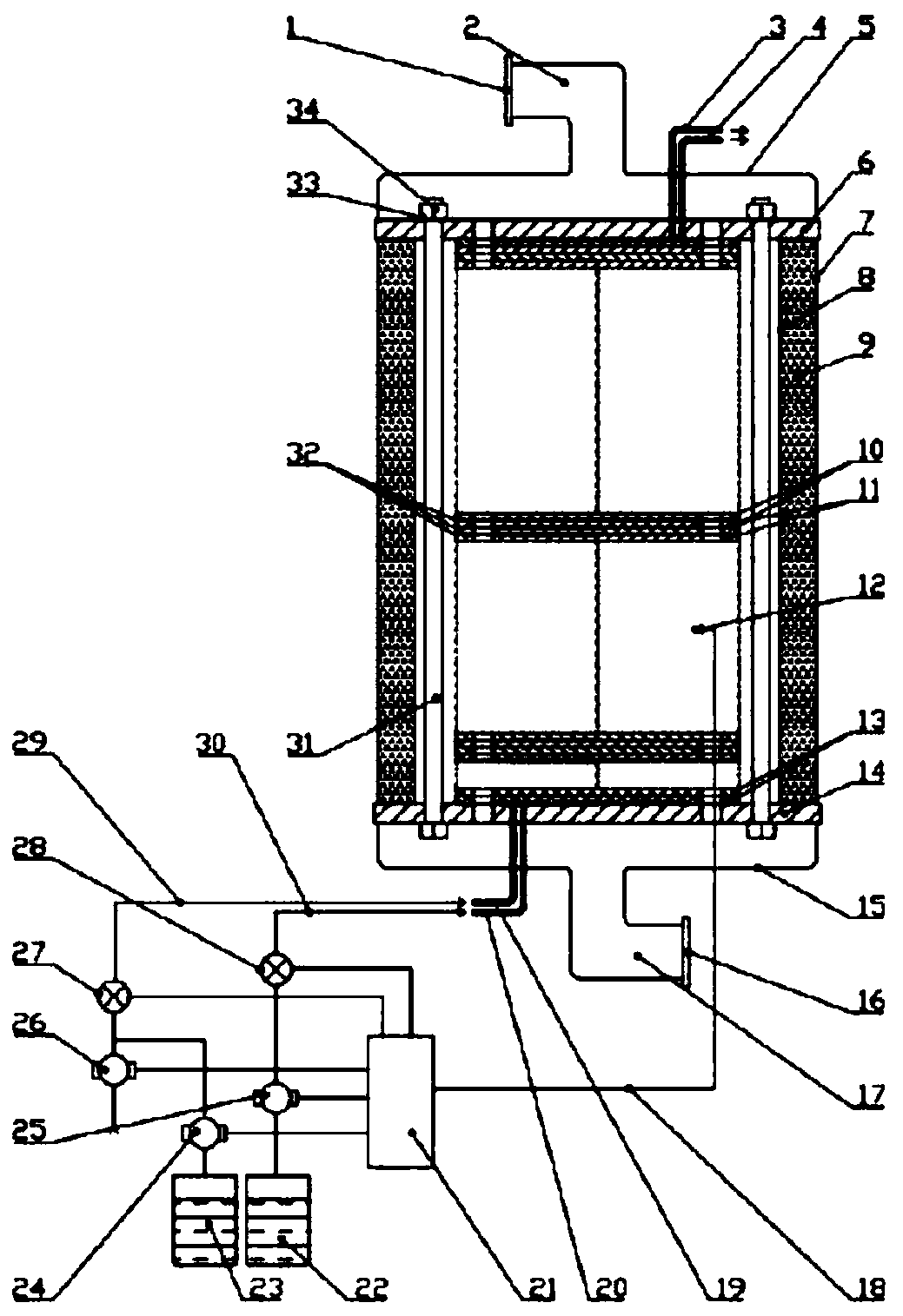

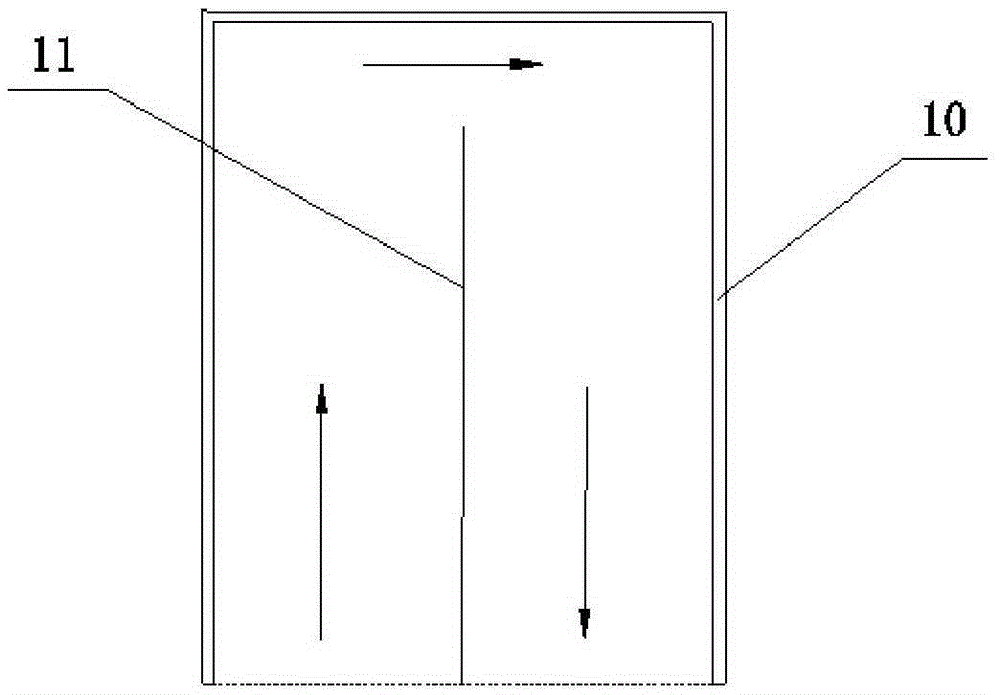

Gas-liquid separating drum for flue gas dewatering, dewatering device and system

InactiveCN106582120ASimple structureEasy maintenanceDispersed particle separationFlue gasEngineering

The invention discloses a gas-liquid separating drum for flue gas dewatering, a dewatering device and a system. A plurality of openings are formed in the wall of the gas-liquid separating drum, liquid drops are thrown to the wall, then transferred to the outer wall of a drum body from the inner wall of the drum body through the openings and separated from gas in flue gas, a flue gas guide device is arranged on the lower portion of the gas-liquid separating drum, the structure of the flue gas guide device is simplified by design of spiral toothed sheets, and running stability of the device is improved. The collected liquid drops are drained by a diversion port in a collecting tank, and liquid is recycled.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

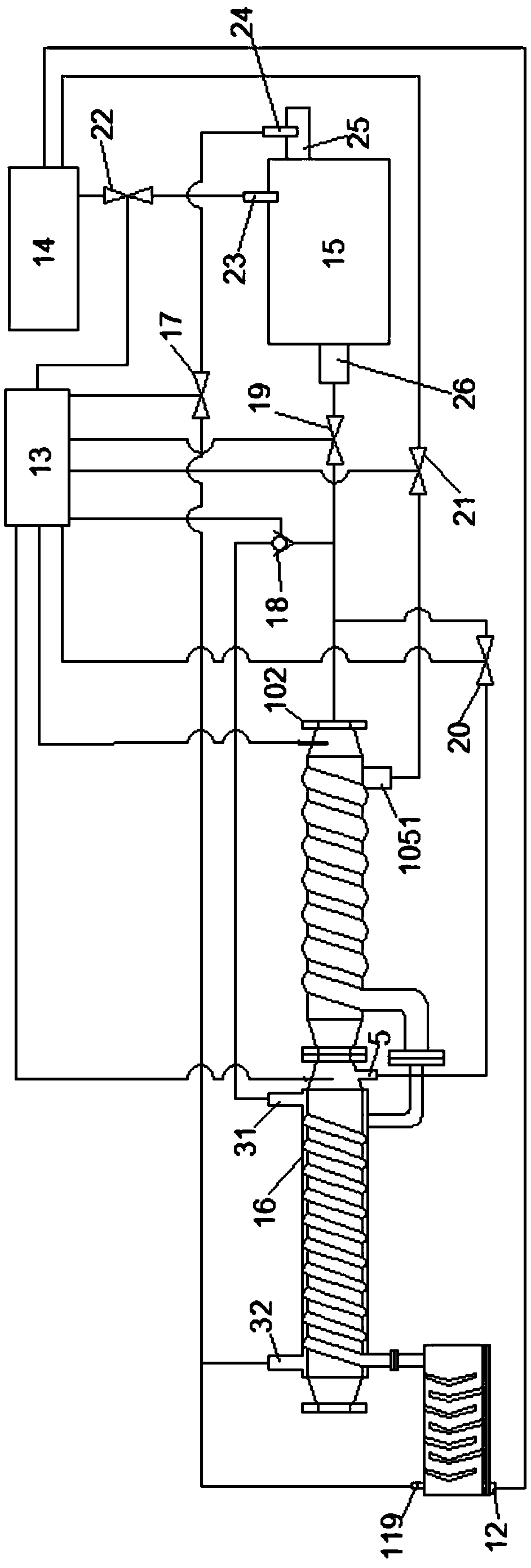

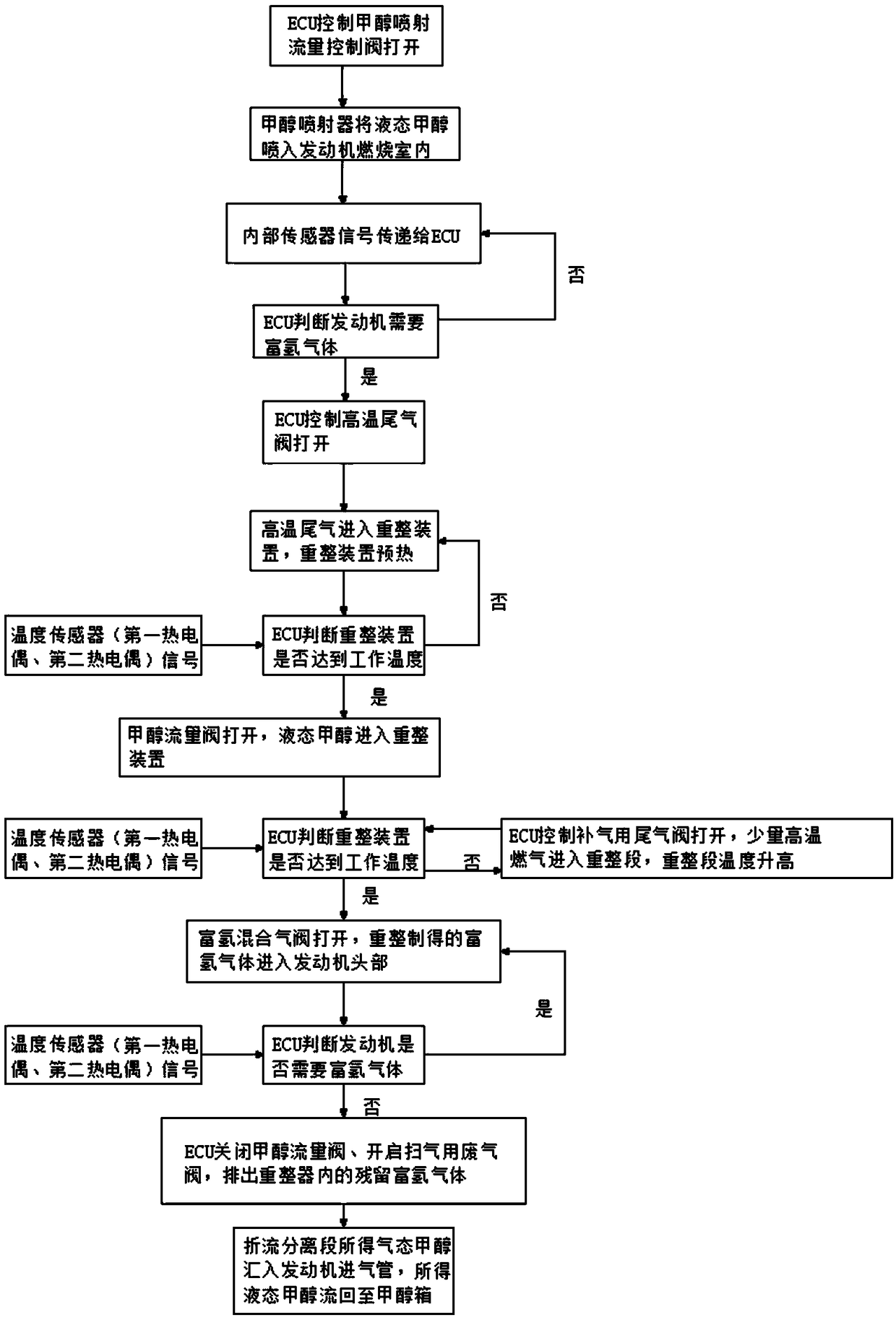

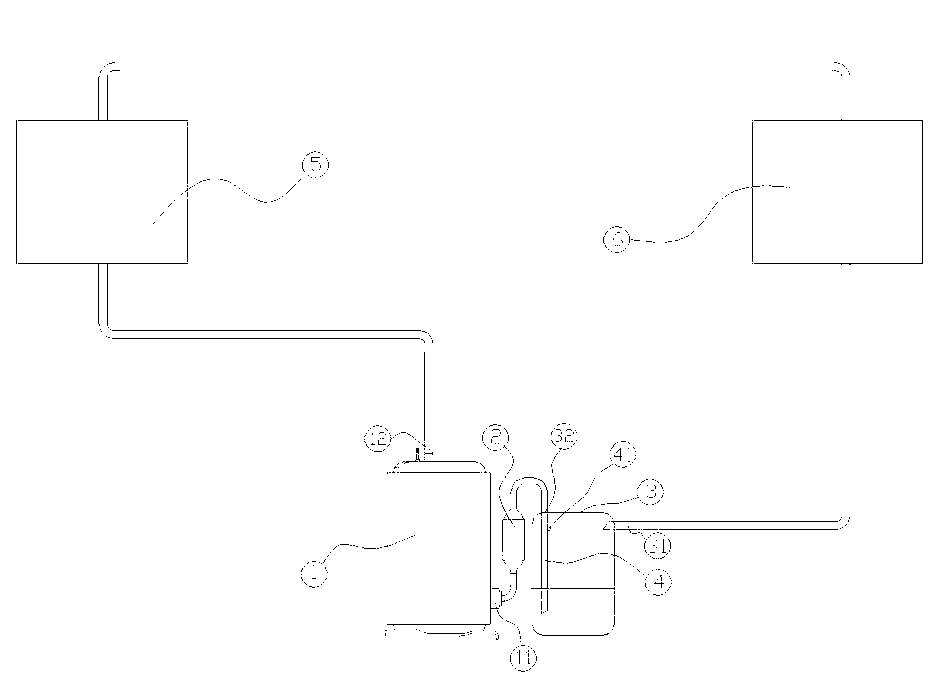

Vehicular methanol online reforming system adopting baffling separation mechanism and control method

PendingCN109319735AImproved combustion and emissions performanceImprove work efficiencyHydrogenNon-fuel substance addition to fuelExhaust gasProcess engineering

The invention discloses a vehicular methanol online reforming system adopting a baffling separation mechanism, wherein an engine is provided with an intake pipe and a vent pipe; a reforming device comprises a reformer, an evaporation section and a baffling separation section; a hydrogen-rich mixed gas valve is connected with a reforming fuel gas outlet and a hydrogen-rich mixed gas ejector througha pipeline; a high-temperature tail gas valve is connected with an evaporation section entrance and the vent pipe through a pipeline; a methanol flow valve is connected with a methanol evaporation pipe entrance and a methanol box through a pipeline; an exit of a waste gas valve for scavenging is connected with a tail gas inlet for scavenging through a pipeline; an entrance of the waste gas valvefor scavenging is communicated with the vent pipe; an ECU is electrically connected with the hydrogen-rich mixed gas valve, the waste gas valve for scavenging, the high-temperature tail gas valve, a tail gas valve for gas supplement, the methanol flow valve and a methanol ejection flow control valve respectively. The vehicular methanol online reforming system adopting a baffling separation mechanism disclosed by the invention achieves aims of realizing vehicular methanol online reforming and splitting methanol fuel into hydrogen-rich combustible gas for a vehicular engine by use of the heat ofhigh-temperature tail gas of the engine and improving the combustion and emission performance of the engine.

Owner:SHENYANG AEROSPACE UNIVERSITY

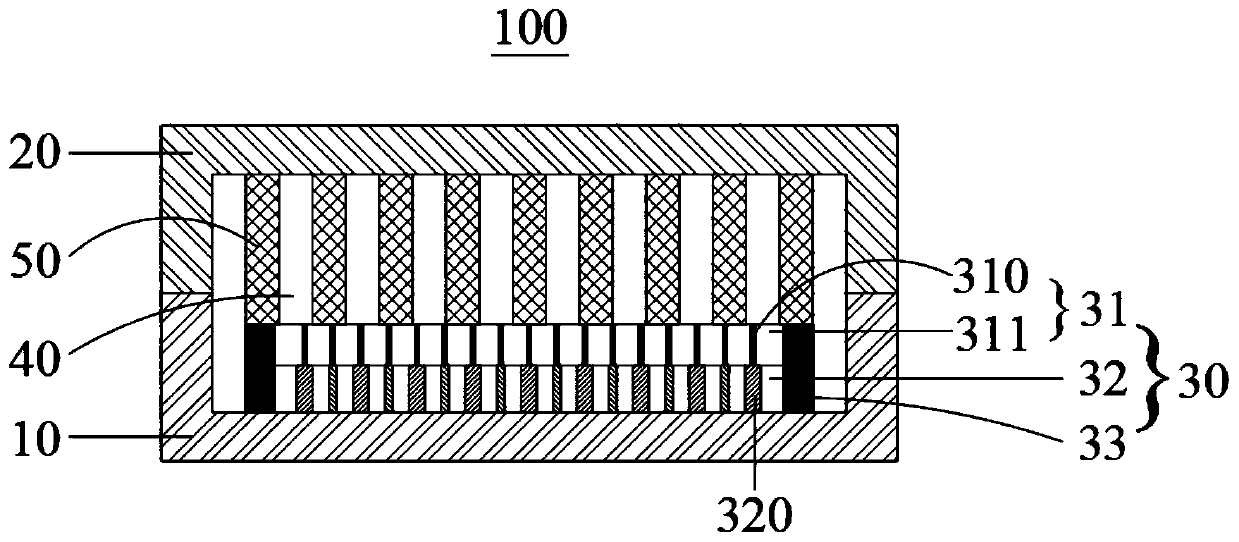

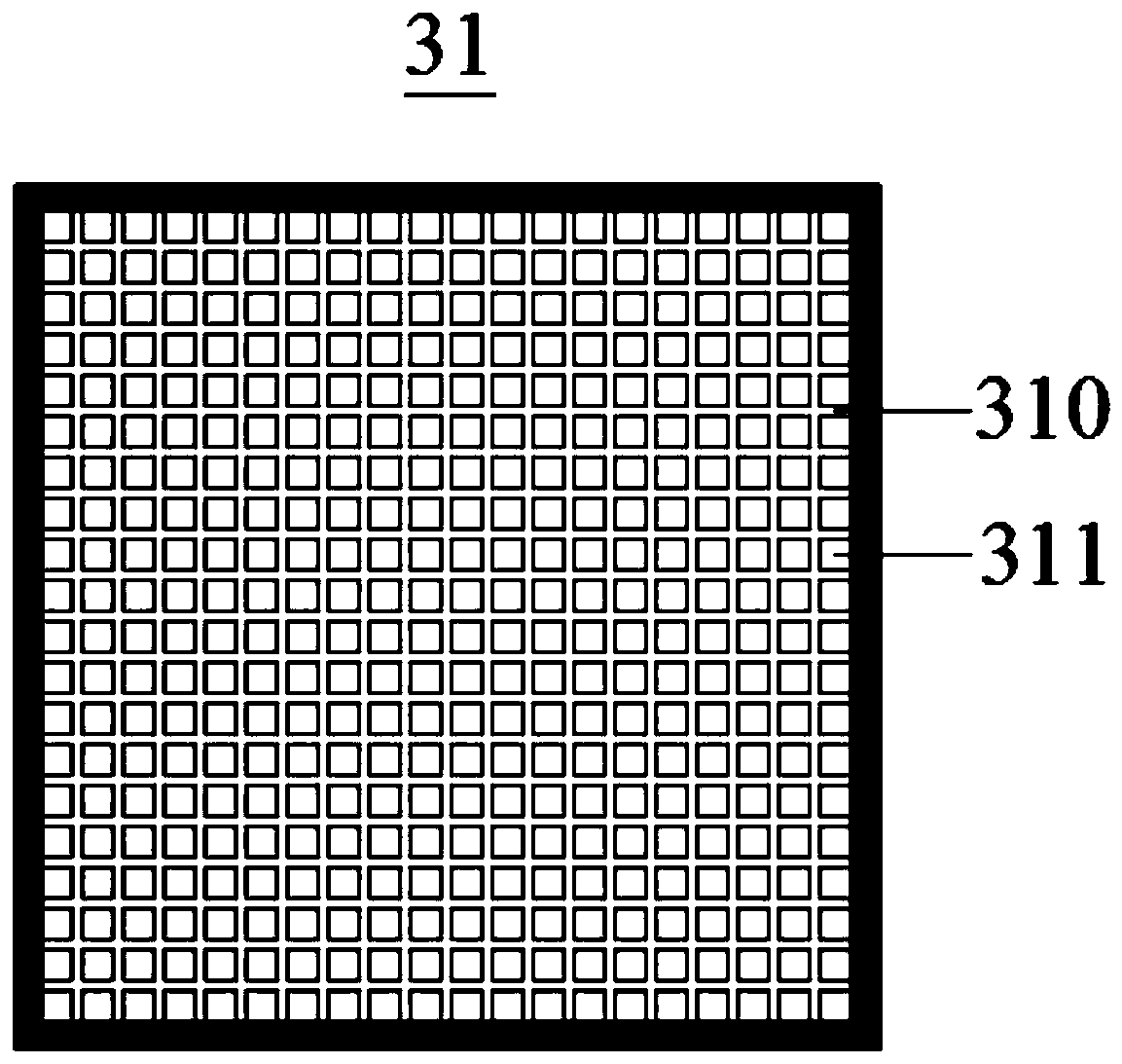

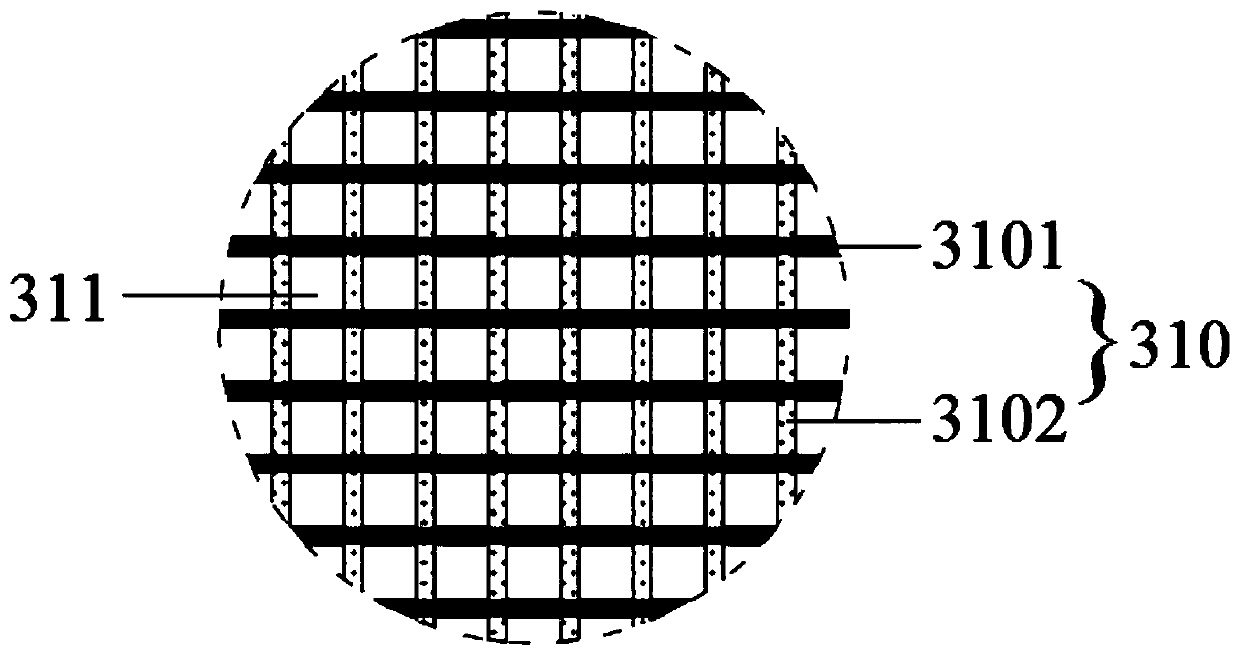

Heat dissipation device, production method of heat dissipation device and electronic equipment

ActiveCN111447793AAvoid interactionGuaranteed performanceCooling/ventilation/heating modificationsEngineeringMechanical engineering

The invention provides a heat dissipation device. The device comprises a first cover plate, a second cover plate, a capillary core and a working fluid. The first cover plate and the second cover plateare covered to form a closed accommodating space; the capillary core is arranged on a surface, close to the accommodating space, of the first cover plate; the working fluid is filled in the accommodating space; the capillary core comprises a supporting layer and a capillary structure layer; and the supporting layer comprises a plurality of supporting strips and a plurality of hollow areas formedby arranging the supporting strips in a staggered mode, the capillary structure layer is arranged between the supporting layer and the first cover plate, the capillary structure layer comprises a plurality of microstructures arranged on the supporting strips at intervals, and a gap between every two adjacent microstructures is less than a transverse size of each hollow area. Each hollow area doesnot generate a capillary acting force on the working fluid so that interaction between the liquid working fluid in the capillary core and the gaseous working fluid in the accommodating space is avoided, gas-liquid separation is achieved, and heat dissipation performance of the heat dissipation device is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A method for promoting liquid-phase water discharge from a gas diffusion layer of a fuel cell

InactiveCN109103463AEnsure gas-liquid balanceGuaranteed normal outflowCell electrodesFuel cellsFiberFuel cells

A method for promoting liquid-phase water discharge from a gas diffusion layer of a fuel cell is provided. The method comprises following steps: at first, an organic material is put in a flow guidinggroove of an electrode plate, a hollow tubular array is grown on the surface of the organic material, and then carbon fibers are arranged between the array layers for filling and hydrophobic treatmentis performed to form a structure in which the hydrophobic hollow tubular array is directly connected with a metal electrode plate flow guide groove, so that the liquid phase water in the gas diffusion layer of the fuel cell can be discharged in a timely manner. The method provided by the invention provides a good liquid flow channel for the gas diffusion layer, thereby effectively suppressing water flooding inside the gas diffusion layer, simultaneously separating gas from liquid in the gas diffusion layer, ensuring the concentration of fuel gas, and ensuring the durability of the gas diffusion layer and even the whole fuel cell.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

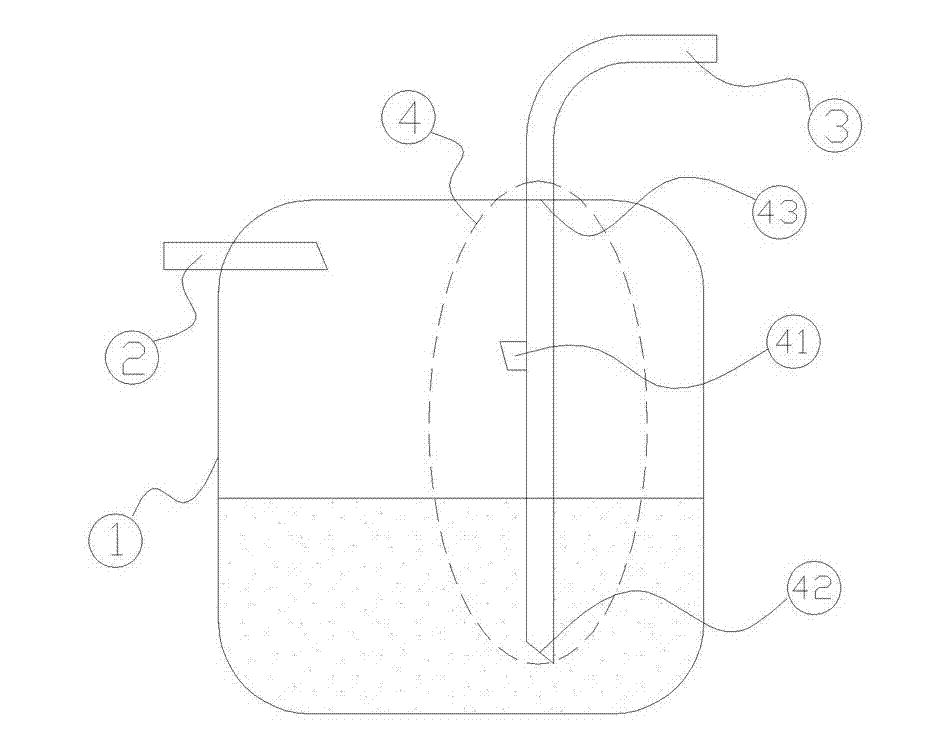

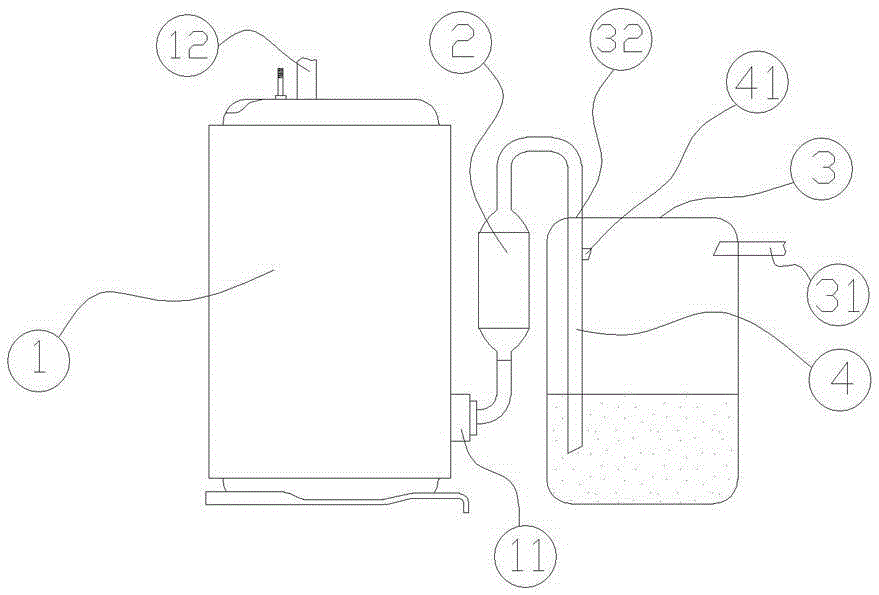

Two-phase flow liquid storage flow stabilizer

InactiveCN102967093ASimple structureSingle performanceRefrigeration componentsThermodynamicsStraight tube

The invention provides a two-phase flow liquid storage flow stabilizer, which comprises a liquid storage tank, a refrigerant inflow port, a refrigerant outflow port and a gas-liquid two-phase flow distribution pipe in the liquid storage tank, wherein the liquid storage tank is a high-pressure-resistant sealed container, of which the outer surface is provided with a thermal insulating layer; two externally connected interfaces of the two-phase flow liquid storage flow stabilizer are the refrigerant inflow port and the refrigerant outflow port respectively; the gas-liquid two-phase flow distribution pipe is a straight pipe and mainly comprises two ports and a backflow hole in the gas-liquid two-phase flow distribution pipe; and the function of the two-phase flow liquid storage flow stabilizer is to store an actuating medium, realize gas-liquid separation of the actuating medium and reasonably set the flow ratio between a liquid actuating medium to a gas actuating medium in a circulation loop to form a stable actuating medium two-phase flow in the circulation loop.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

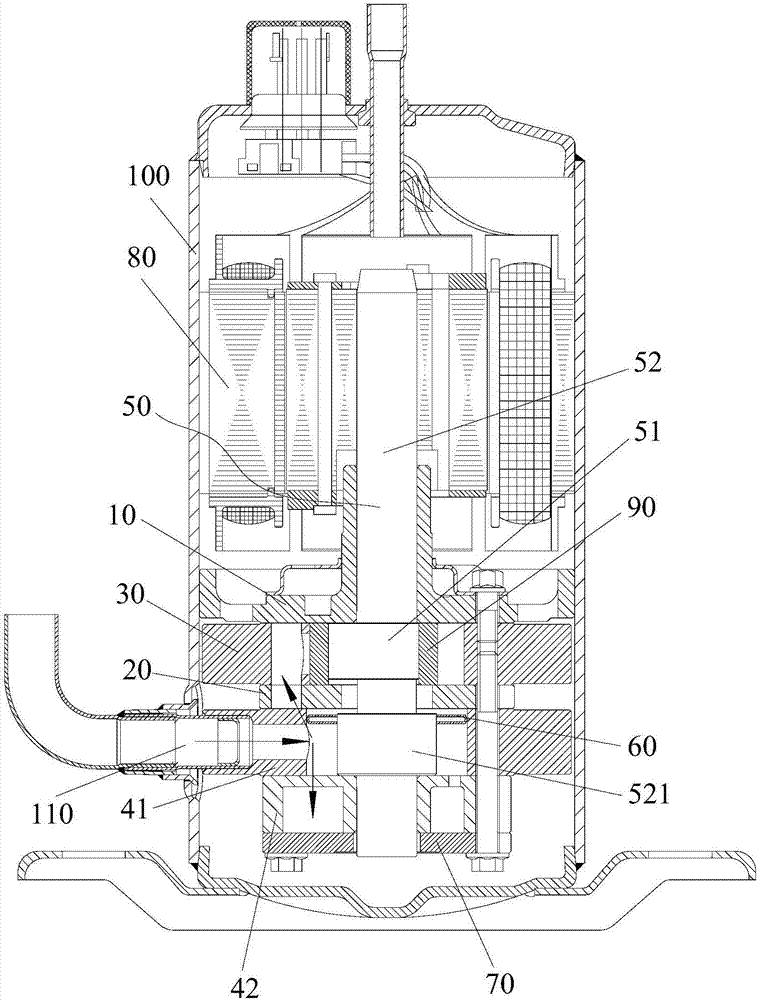

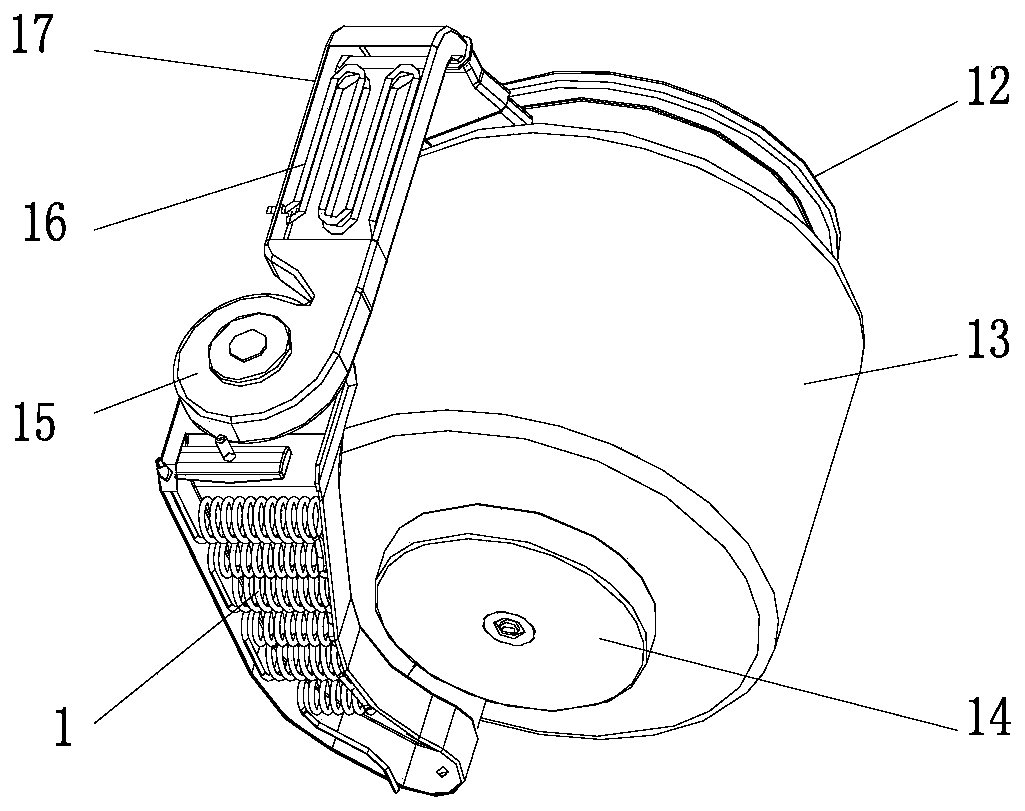

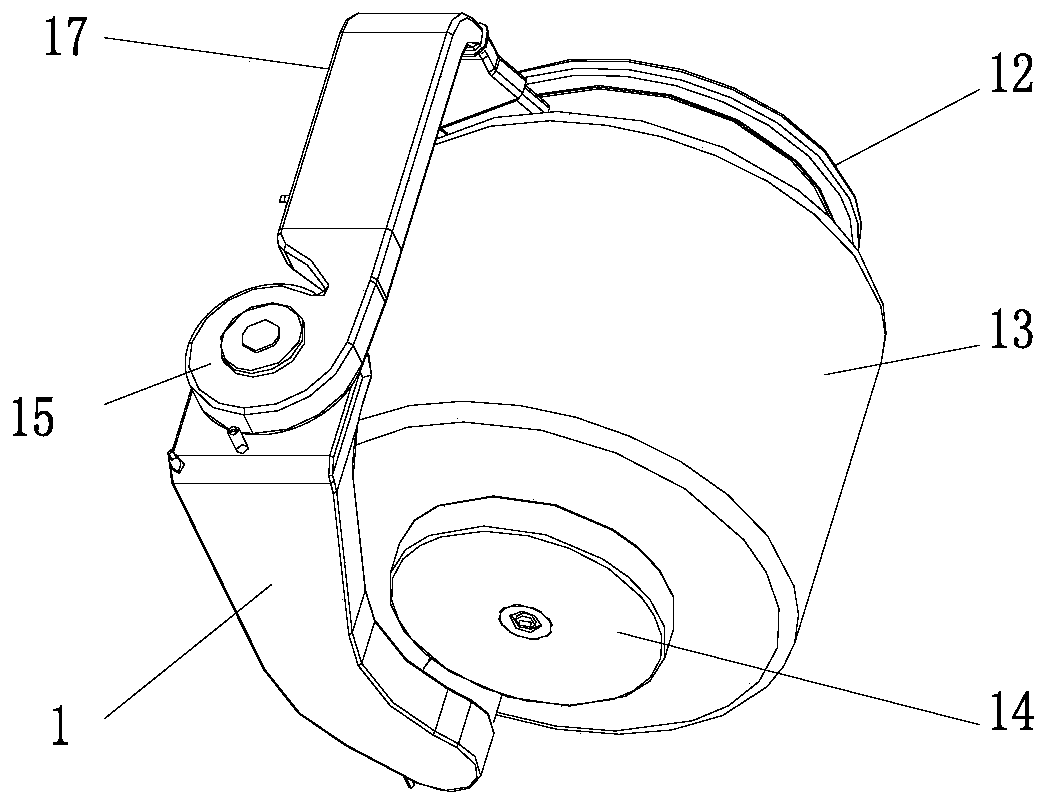

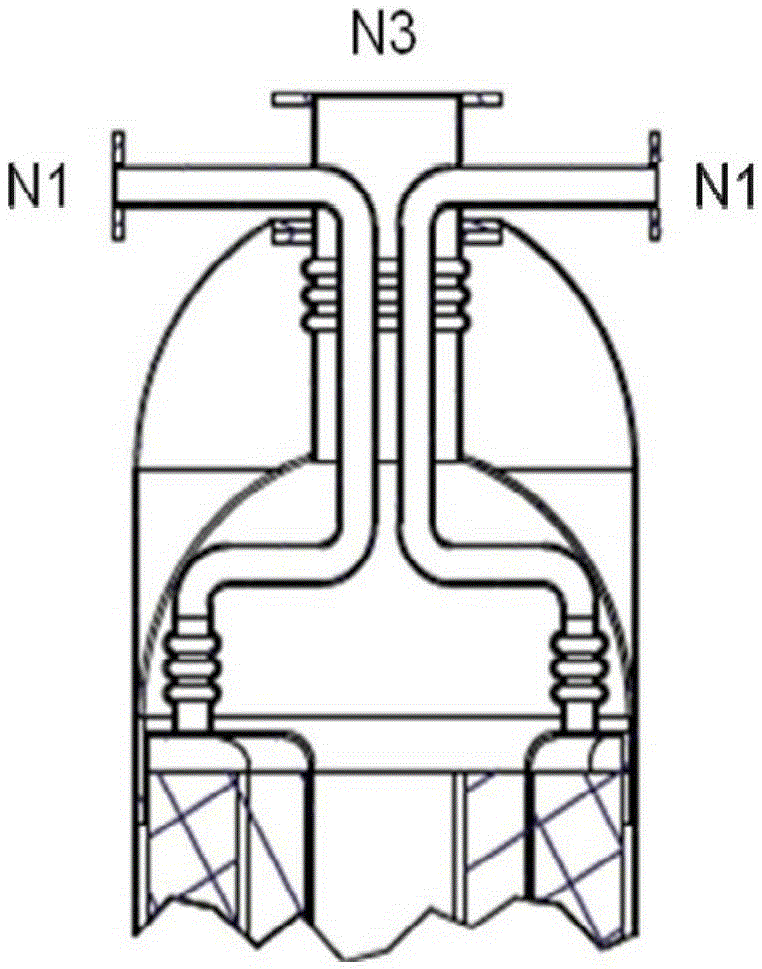

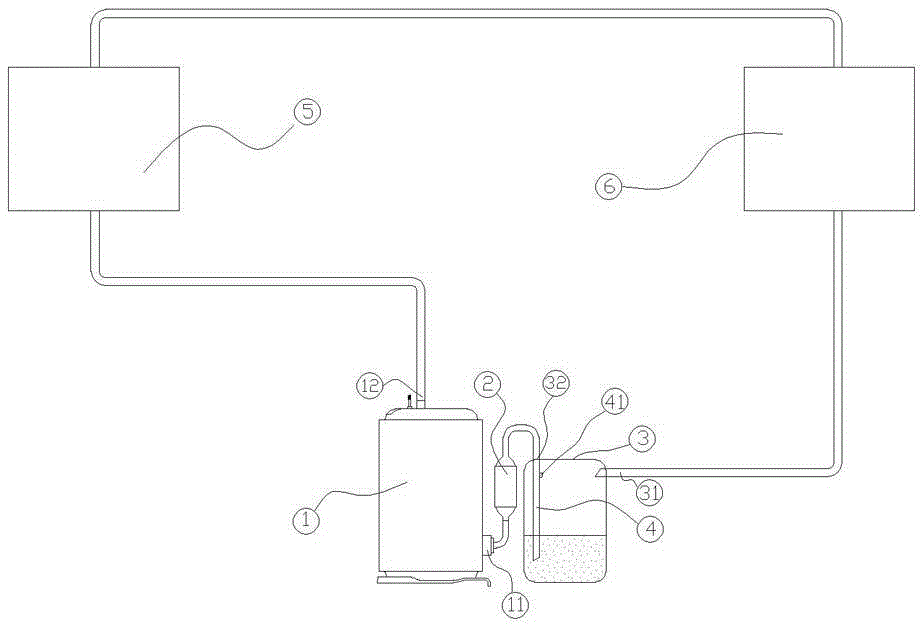

Fluid machine and heat exchange device with fluid machine

PendingCN107975475AGuaranteed uptimeReduce vibrationRotary/oscillating piston combinations for elastic fluidsDispersed particle separationEngineering

The invention provides a fluid machine and a heat exchange device with the fluid machine. The fluid machine comprises a rotating shaft, a gas and liquid separation assembly and an air cylinder; the gas and liquid separation assembly is provided with a separation cavity, at least one part of the rotating shaft penetrates into the separation cavity and can rotate relative to the separation cavity, amixed refrigerant enters the separation cavity and is subject to gas and liquid separation under the rotating effect of the rotating shaft, and gas obtained after gas and liquid separation enters theair cylinder. The problems that in the prior art, in the running process of the fluid machine, vibration and noise are large are effectively solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

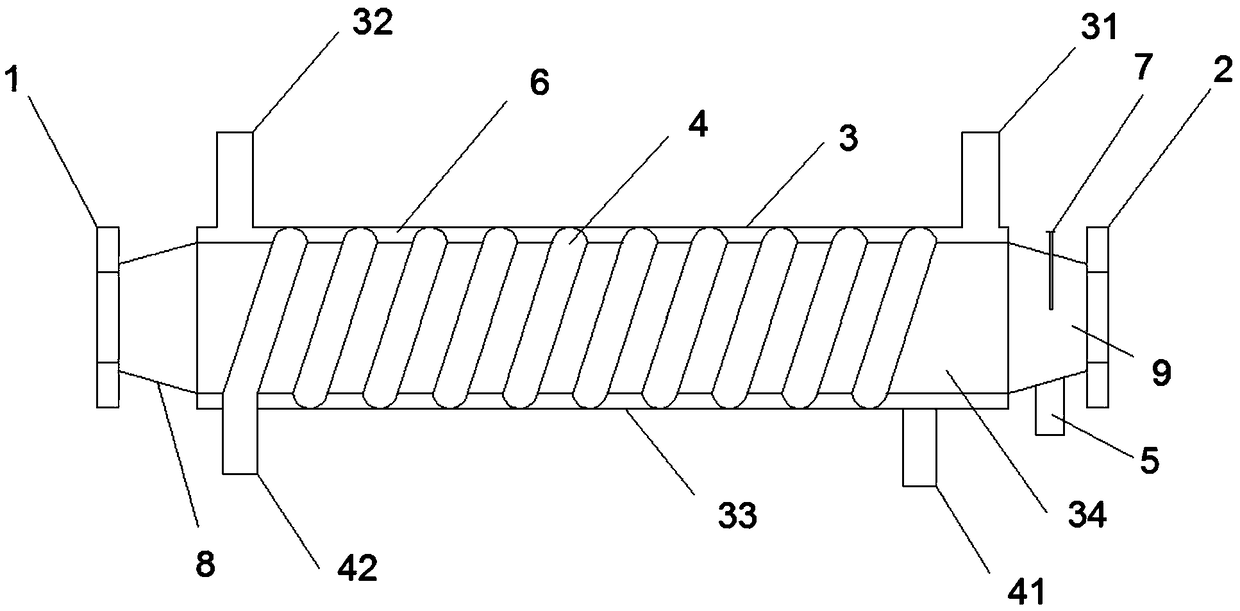

A high-efficiency condenser and a washing machine with the condenser

ActiveCN107815812BShorten drying timeImprove sanitationWashing machine with receptaclesTextiles and paperCondensation processThermodynamics

The invention discloses a high-efficiency condenser and a washing machine with the same. The condenser is of a cavity structure with a wider upper part and a narrower lower part, and the lower part isbent to one side. The condenser comprises a shell, heat exchange tubes, a spray box, and a condensed water outlet. An air inlet is formed in the lower part of the shell and is connected to an outer cylinder of the washing machine, an air outlet is formed in the top of the shell and is connected with a fan in a drying air duct, the side with a smaller curvature radius of the lower bending part isthe inner side, and the side with a larger curvature radius is the outer side; the heat exchange tubes are disposed in the shell for heat exchange with hot humid air, hollowed and wound into multiplerows of cylindrical spring-shaped heat exchange tubes arranged above and below; the spray box is disposed above the heat exchange tubes for flushing wire scraps on the heat exchange tubes; the condensed water outlet is located at the bottom of the condenser for discharging condensed water in the condenser and is connected to a drain pipe of the washing machine. The condenser and the washing machine realize gas-liquid separation of a condensing process; besides, through the setting of the change of the density, outer diameter and inner diameter of the heat exchange tubes, the heat exchange is more fully achieved and the condensing efficiency is improved, thus the drying efficiency of a washing and drying machine is improved.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

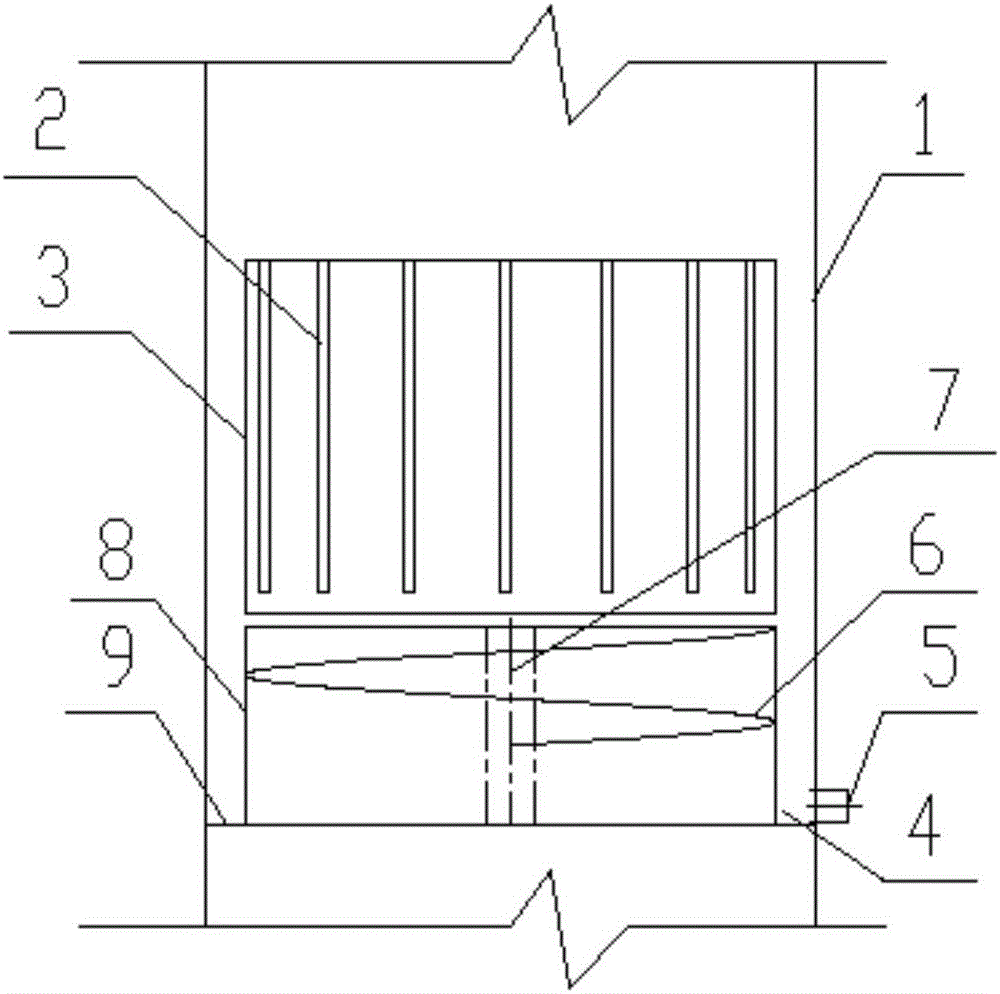

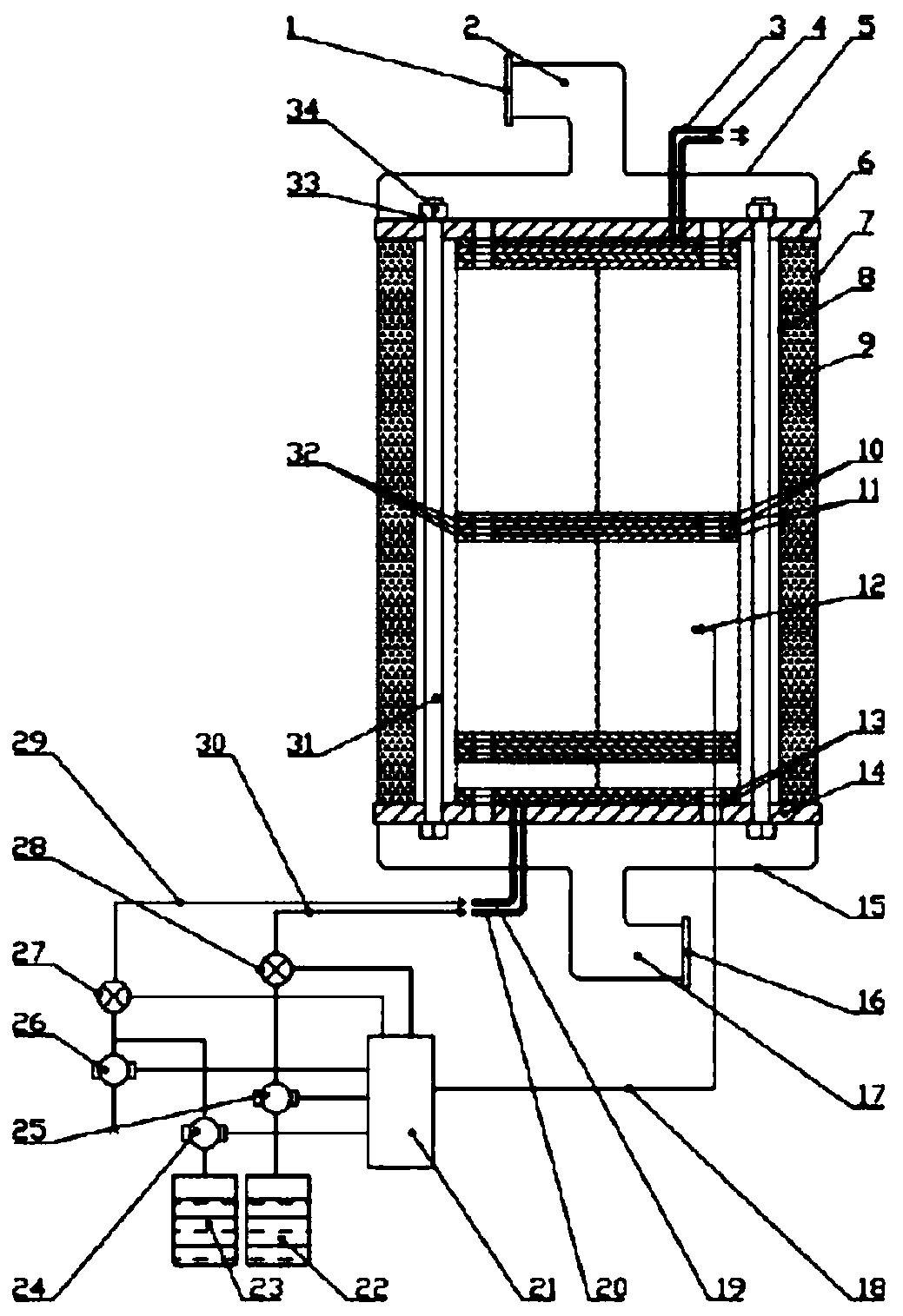

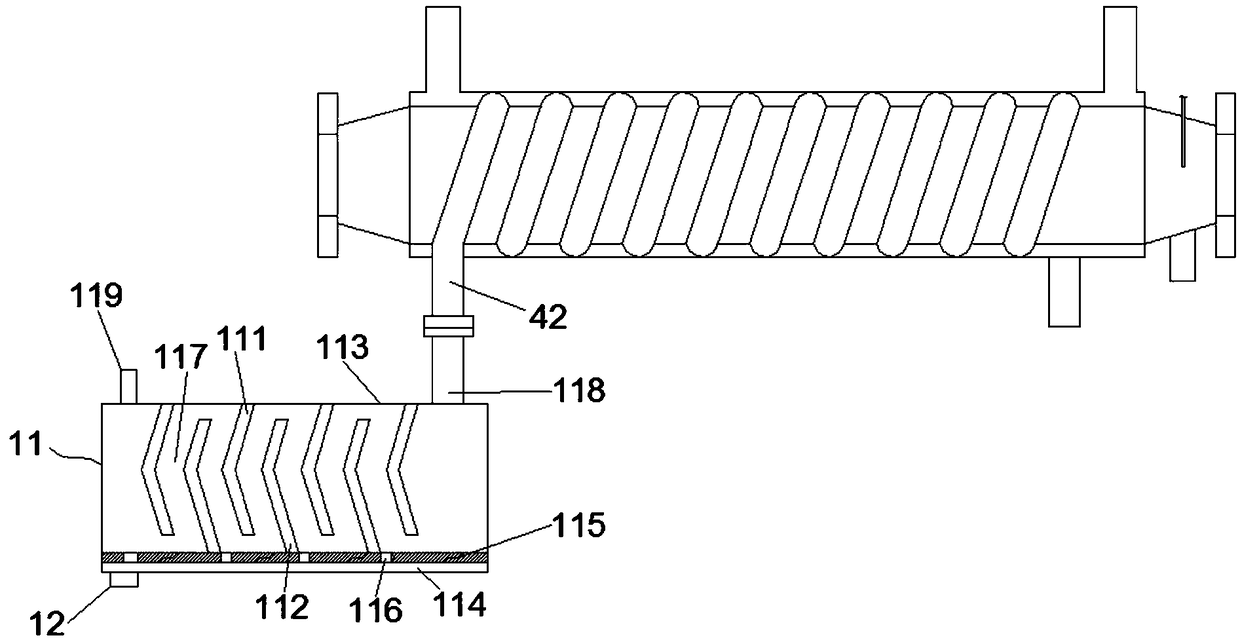

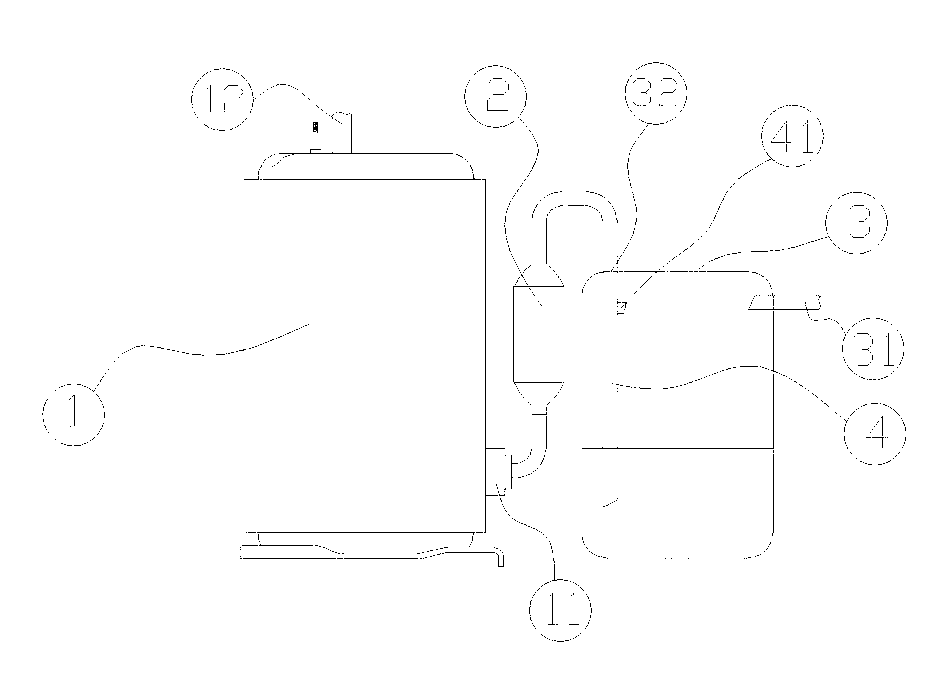

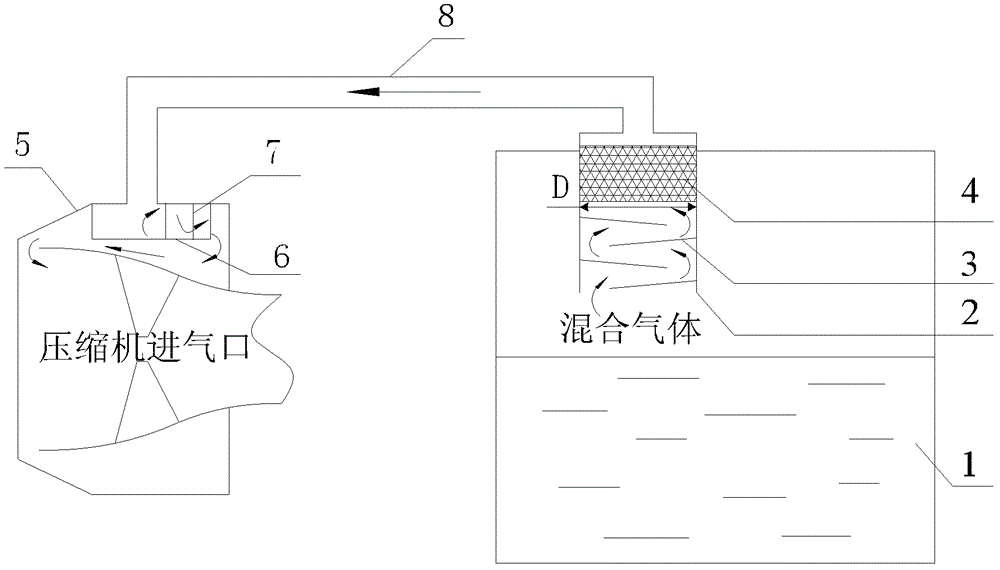

On-line methanol reformer using baffle separation mechanism and engine exhaust gas

PendingCN109179321ARealize gas-liquid separationImprove work efficiencyHydrogenNon-fuel substance addition to fuelEngineeringMethanol

The invention discloses an on-line methanol reformer using a baffle separation mechanism and engine exhaust gas. The on-line methanol reformer comprises a separation section and a reformer. The separation section comprises a separation plate. The separation plate is horizontally assembled on the inner wall of the separation section casing. A liquid collection chamber is formed between the lower part of the separation plate and the inner wall of the separation section casing. The separation plate is provided with a plurality of liquid collecting holes. The top of the inner wall of the separation section casing is fixedly provided with a plurality of upper cooling baffles. The upper surface of the separation plate is fixedly provided with a plurality of lower cooling baffles. The upper cooling baffles and the lower cooling baffles are arranged at intervals. The upper cooling baffles and the lower cooling baffles form an S-shaped cooling and separation channel in the separation section casing. Two sides of the top of the separation section casing are respectively provided with a methanol mixture inlet and a gaseous methanol outlet. The bottom of the separation section casing is provided with a liquid methanol outlet. The on-line methanol reformer can fast realize the gas-liquid separation of the methanol mixture discharged from the reformer and improve the work efficiency of the reformer.

Owner:SHENYANG AEROSPACE UNIVERSITY

Air cushion furnace gas-liquid quenching spray nozzle structure and gas-liquid cooperative quenching system

PendingCN111826504AGuaranteed cooling effectPrevents the risk of inflow into air system ductsFurnace typesHeat treatment furnacesSpray nozzleWater flow

The invention belongs to the field of metal heat treatment, and discloses an air cushion furnace gas-liquid quenching spray nozzle structure and a gas-liquid cooperative quenching system. An air floating spray nozzle adopted at present generally only considers the circulation of single-phase gas, and is mainly suitable for a gas quenching area, while the water quantity in a water mist area is large, if the traditional gas quenching spray nozzle is still adopted, the risk that the water mist flows into an air duct along a lower-layer gas nozzle can be caused, after long-term operation, water isprone to accumulating in the air duct so as to accelerate structural corrosion, and if the water accumulation amount is large and the arrangement position of a fan is low, the possibility of water flowing into the fan is further achieved so as to threaten the safety operation of the system. The air cushion furnace gas-liquid quenching spray nozzle structure is improved, and comprises an air inletchamber, a nozzle, and a waterproof cover, a gas-liquid separation cavity and a drainage groove formed in the bottom of the gas-liquid separation cavity different from the traditional air floating spray nozzle, gas circulation can be guaranteed, so that the float of an aluminum plate is achieved, and liquid evaporation cooling is accelerated; and accumulated water can be effectively discharged, so that the operation risk of the gas quenching system is reduced.

Owner:BEIJING AVIATION FEIFANG MACHINERY EQUIP FACTORY

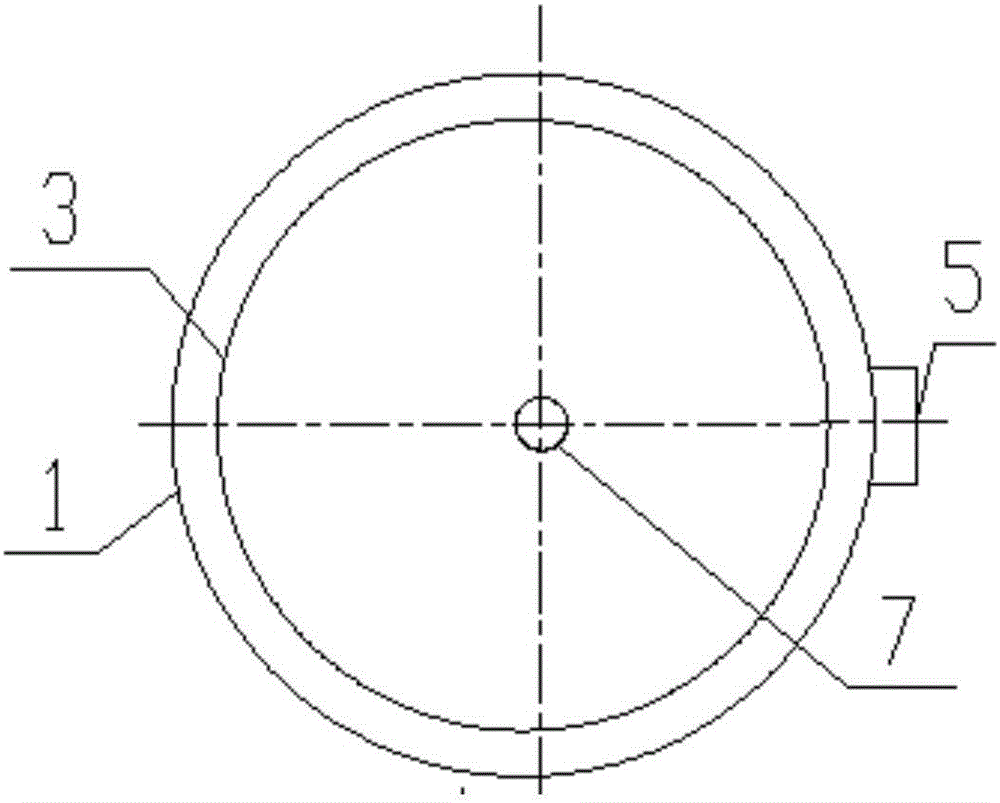

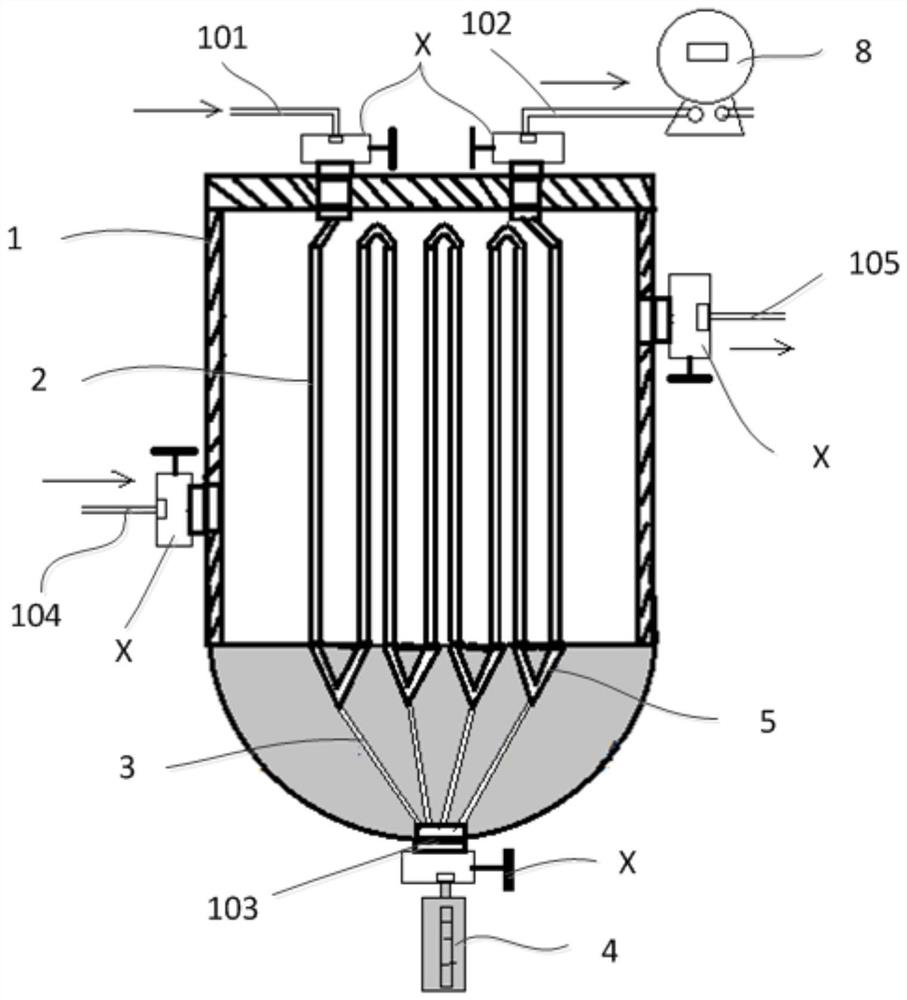

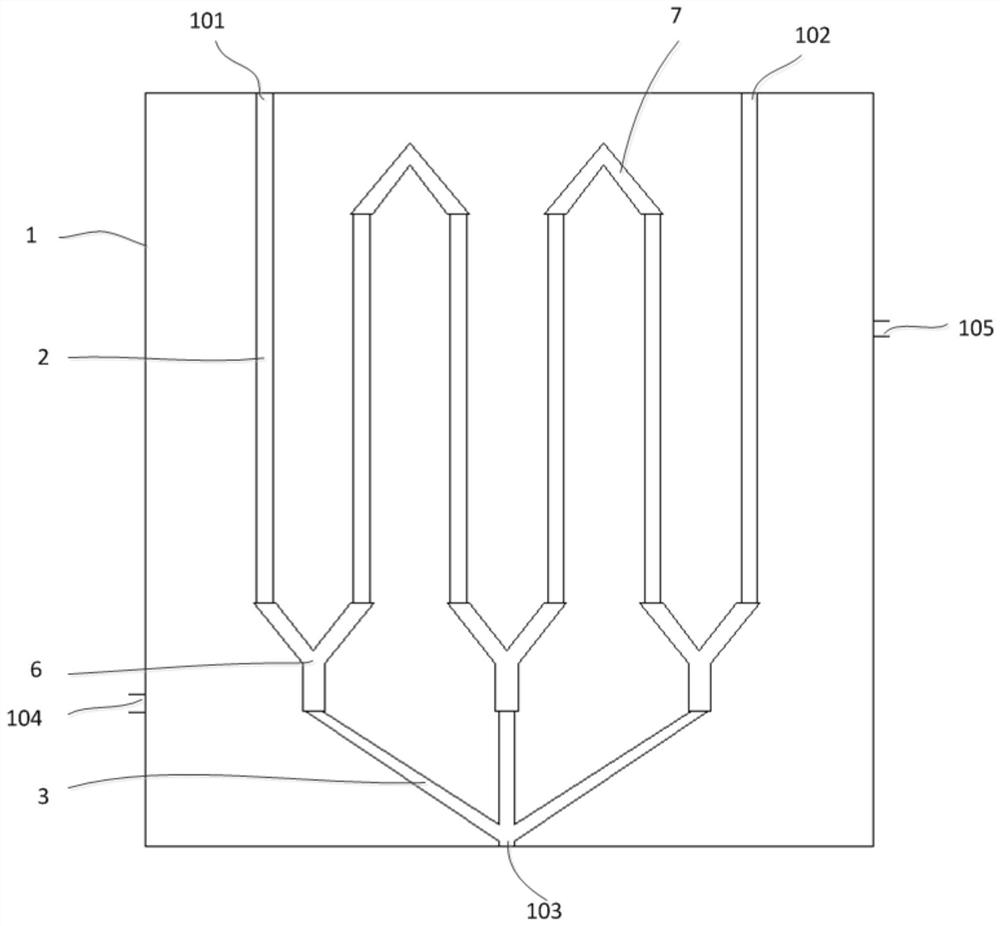

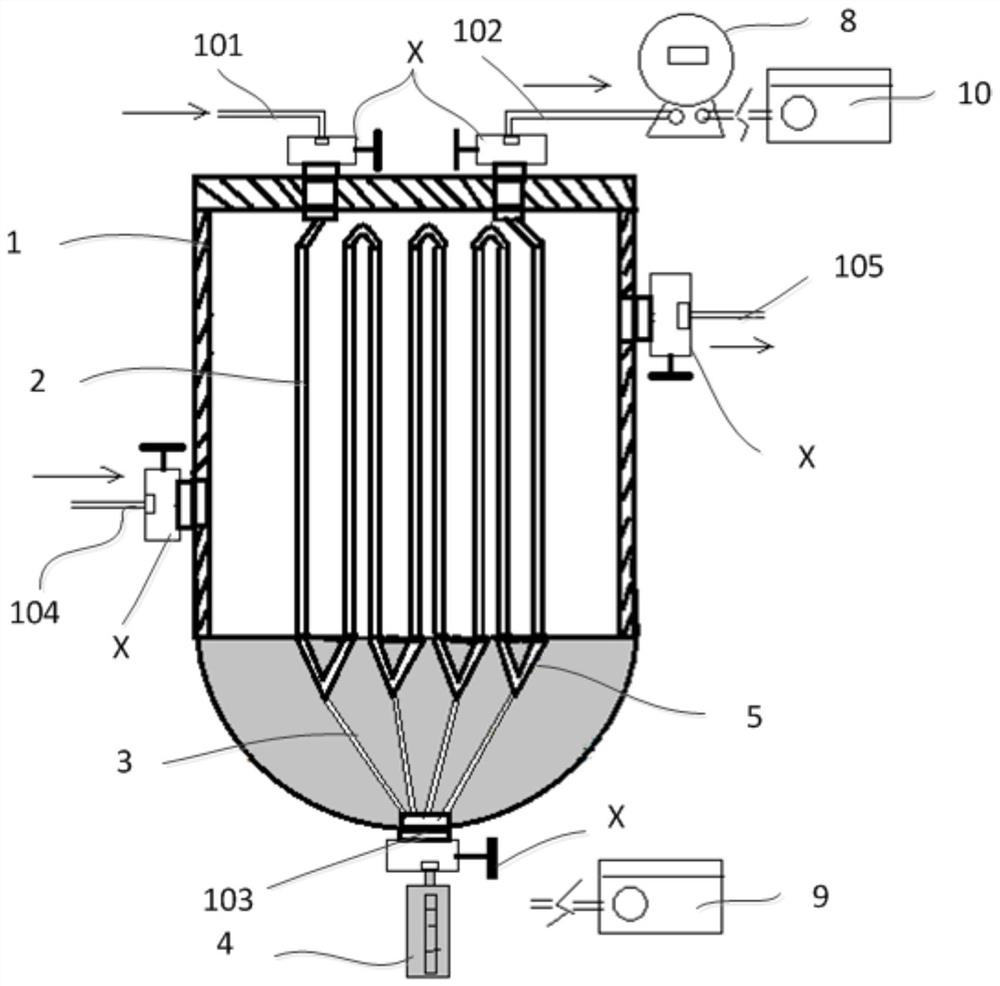

Novel all-welding plate shell type heat exchanger

InactiveCN105258536AFlexible structureIncrease the heat exchange areaLaminated elementsStationary plate conduit assembliesGas phaseEngineering

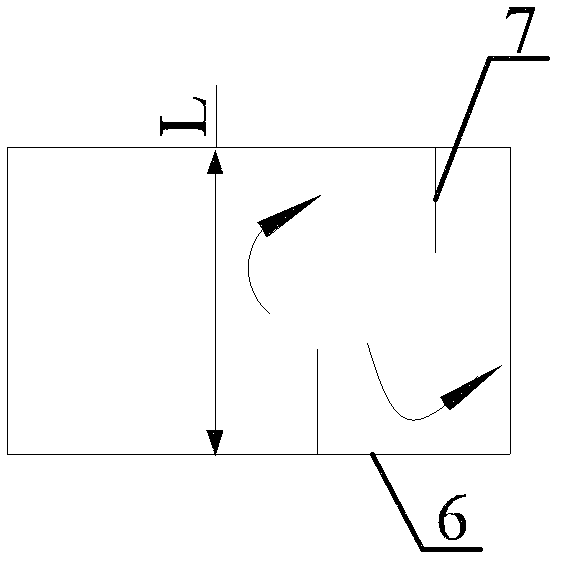

The invention relates to a novel all-welding plate shell type heat exchanger. The novel all-welding plate shell type heat exchanger comprises a shell (1), a heat exchange plate pair body (7), a plate pass heat exchange fluid inlet, a plate pass heat exchange fluid outlet, a shell pass heat exchange fluid inlet, a shell pass heat exchange fluid gas phase outlet and a shell pass heat exchange fluid liquid phase outlet, wherein the plate pass heat exchange fluid inlet, the plate pass heat exchange fluid outlet, the shell pass heat exchange fluid inlet, the shell pass heat exchange fluid gas phase outlet and the shell pass heat exchange fluid liquid phase outlet are formed in the shell (1); the heat exchange plate pair body (7) is installed in the shell (1) and formed by heat exchange plate pairs (3), each heat exchange plate pair (3) forms a plate pass cavity by welding a plurality of contacts on two metal plates, and the plate pass cavities allow plate pass heat exchange fluid to circulate therein; shell pass cavities are formed between the heat exchange plate pairs (3) and between the heat exchange plate pairs (3) and the shell (1) and allow shell pass heat exchange fluid to circulate therein; and the heat exchange plate pair body (7) is of one of a cuboid structure, a cylinder structure or a spiral cylinder structure. Compared with the prior art, the novel all-welding lamella heat exchanger has the beneficial effects of being high in heat exchange efficiency, small in land occupation, flexible and changeable in structure, large in heat exchange area, compact in heat exchange system and low in pressure reduction.

Owner:ATHCO ENG SHANGHAI CO LTD

Compressor

ActiveCN103017415ARealize gas-liquid separationImprove work efficiencyCompressorInsulation layerStraight tube

The invention provides a compressor, which comprises a compressor machine body consisting of a compressor housing, a motor and a pump body, a filter, a liquid storage pot arranged on one side of the compressor machine body through a bracket and a gas-liquid two-phase flow distribution pipe positioned inside the liquid storage pot; the liquid storage pot is a high pressure resistant sealed container provided with a heat insulation layer on the outer surface, and comprises two external ports which are respectively a refrigerant outflow port and a refrigerant inflow port; the gas-liquid two-phase flow distribution pipe positioned inside the liquid storage pot is a straight pipe with two opened ends, and a gas return hole is formed on the straight pipe; and the liquid storage pot and the gas-liquid two-phase flow distribution pipe positioned inside the liquid storage pot have the functions of storing working mediums, realizing gas-liquid separation of the working mediums, and reasonably distributing the flow-rate ratio of liquid working medium and gas working medium entering the compressor machine body so as to form stable two-phase flow of working mediums in a refrigeration cycle loop.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

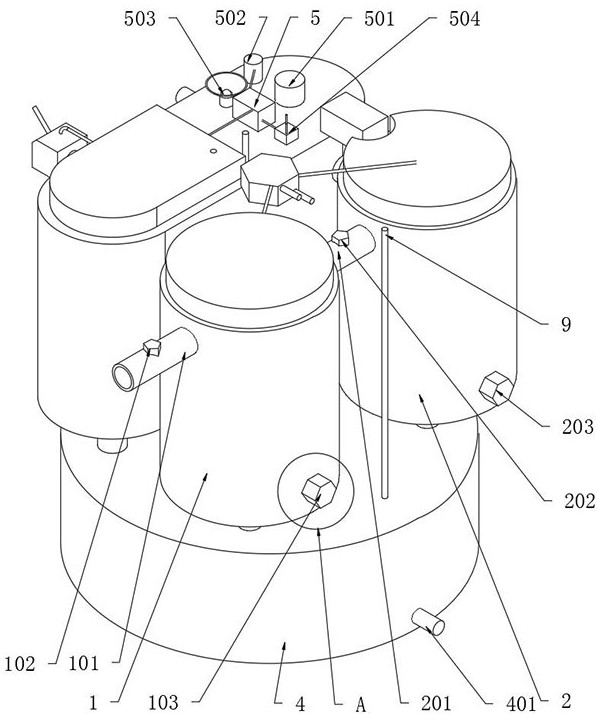

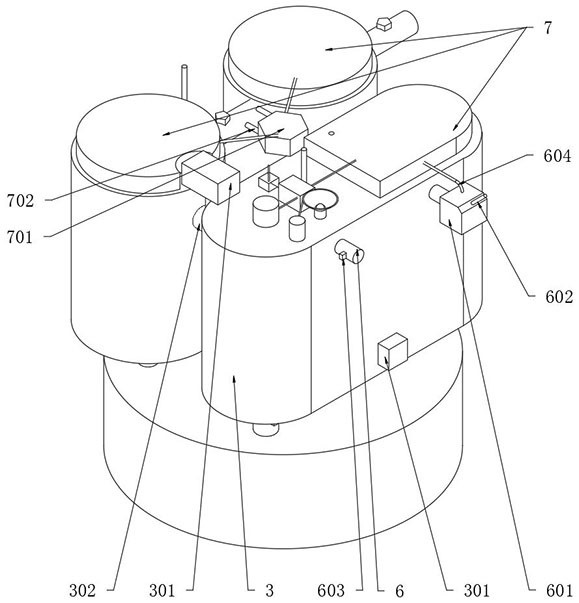

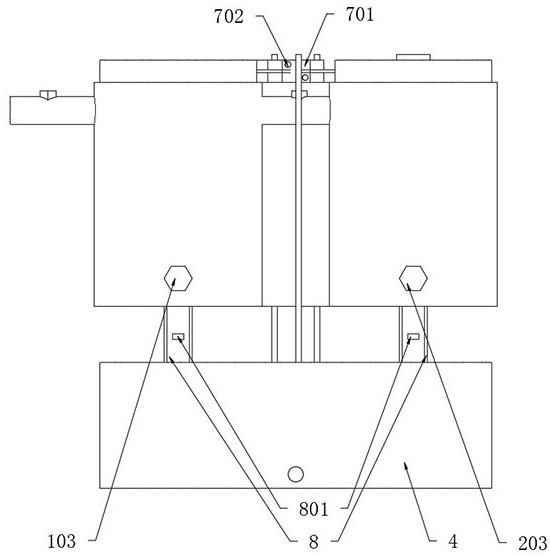

Gas-liquid multistage separation device for gas bearing experiment for incoming flow of pump

ActiveCN107050931ARealize gas-liquid separationExtension of timeLiquid degasification arrangementsSpray nozzleEngineering

The invention discloses a gas-liquid multistage separation device for a gas bearing experiment for incoming flow of a pump. The gas-liquid multistage separation device comprises a tank as well as a first-stage separation part, a second-stage separation part and a third-stage separation part which are arranged in the tank, wherein the first-stage separation part is arranged in upper space of an inner chamber of the tank, the second-stage separation part is arranged on the peripheral surface of the inner wall of the tank and connected with the first-stage separation part through a water pipe, and the third-stage separation part is arranged at the bottom of the tank; the first-stage separation part comprises a spiral pipe, spray nozzles and baffle plates; the second-stage separation part comprises an annular chamber, inlet baffle plates, gas-liquid separation plates and an outlet baffle plate; the third-stage separation part comprises a liquid separation plate and a conical diversion pipe which is big end up. The gas-liquid multistage separation device adopts compact mechanism, is high in separation efficiency and can effectively solve the problem about fluid degassing in experiments and engineering.

Owner:ZHEJIANG SCI-TECH UNIV

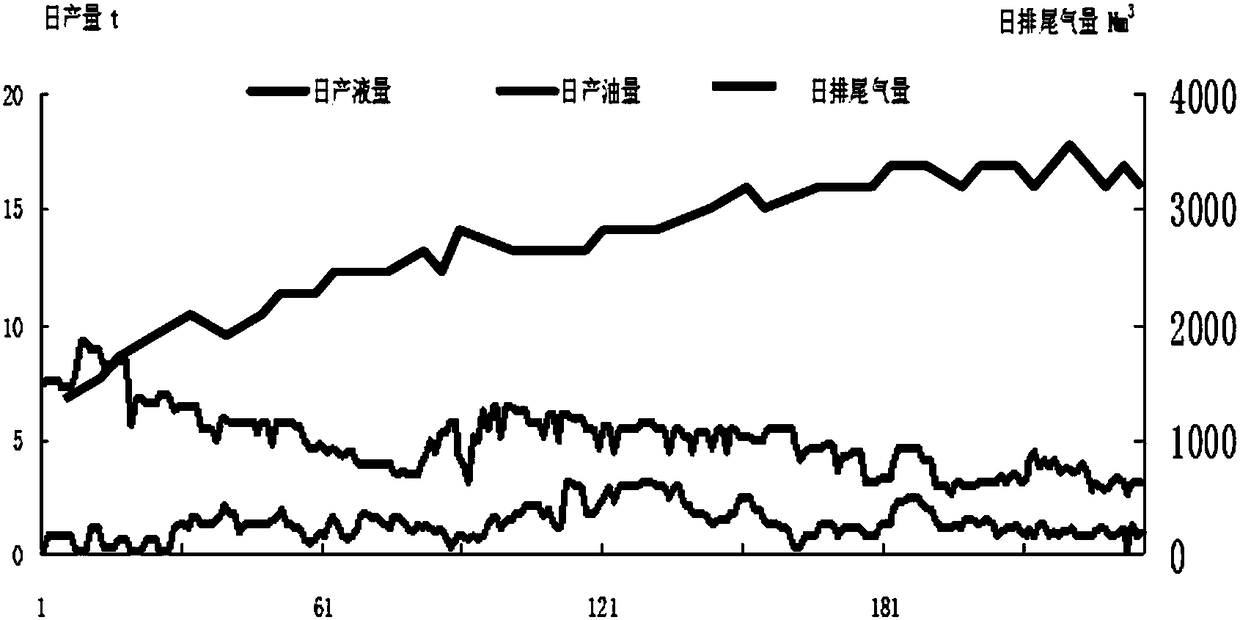

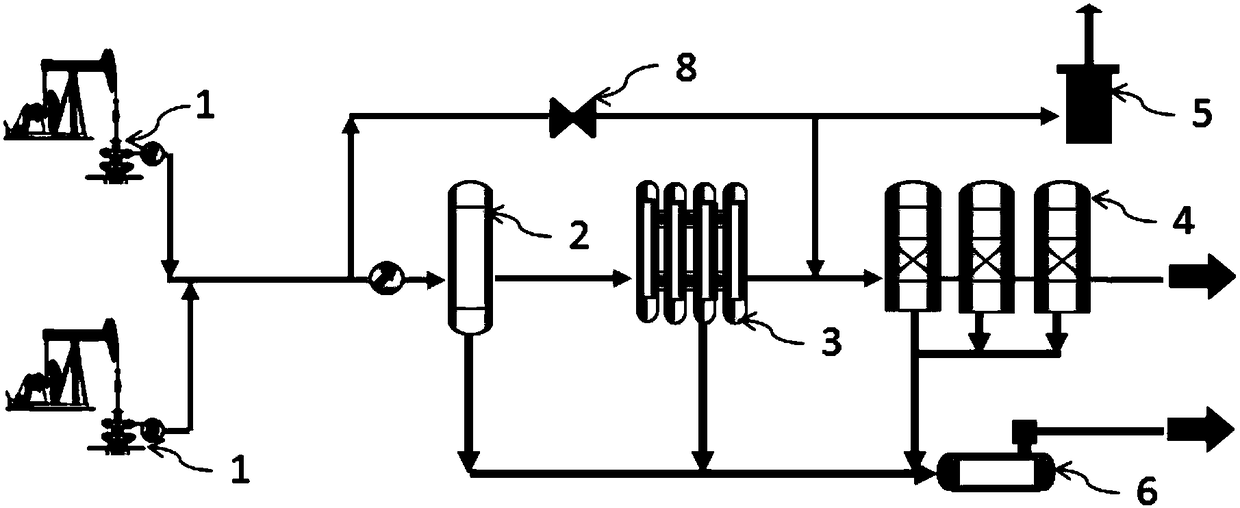

Treatment system and treatment method for fireflooding high exhaust gas well

InactiveCN108392958ARealize gas-liquid separationEnsure safetyGas treatmentDispersed particle separationExhaust gasWater content

The invention discloses a treatment system and a treatment method for a fireflooding high tail gas well and relates to the technical field of thickened oil fireflooding oil wells. The treatment systemfor the fireflooding high tail gas well comprises a cyclone gas-liquid separator communicated with an oil extraction wellhead, an air cooler connected with the cyclone gas-liquid separator as well asa desulfurizing tower and a plurality of desulfurizing tanks connected with the air cooler, wherein the cyclone gas-liquid separator is used for reducing the water content of tail gas inputted fromthe oil extraction wellhead; the inlet end of the cyclone gas-liquid separator can be communicated with the outlet end of the air cooler; the plurality of desulfurizing tanks are connected in parallel. According to the application, the problems of effusion and freeze blockage of a tail gas pipeline and failure of a desulfurization agent caused by water logging can be solved; meanwhile, the purification degree of the tail gas is improved.

Owner:PETROCHINA CO LTD

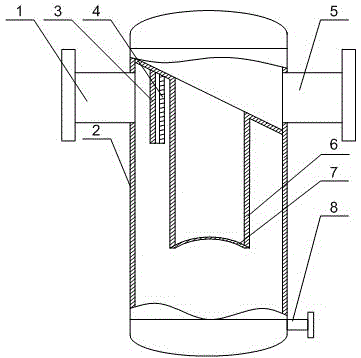

Gas-liquid separation device for single-well booster set

InactiveCN105080272ARealize gas-liquid separationAvoid deactivationCombination devicesEngineeringKinetic energy

The invention discloses a gas-liquid separation device for a single-well booster set. The gas-liquid separation device comprises a tank body, wherein a gas inlet and a gas outlet are formed in two sides of the tank body; a filtering core barrel is arranged in the tank body; the gas inlet is opposite to the side wall of the filtering core barrel; the top end of the filtering core barrel is inclined and is opposite to the gas outlet; a separation filtering net which is bent in the direction of pointing to the top end along the bottom end of the filtering core barrel is arranged at the bottom end of the filtering core barrel. The gas-liquid separation device also comprises a flow blocking plate and a water absorbing plate, wherein the flow blocking plate is opposite to the gas inlet; a gap is formed between the flow blocking plate and the water absorbing plate; liquid moves upwards after direction changing, so that the distance, entering the interior of the filtering core barrel, of the liquid is increased, namely kinetic energy of rest liquid cannot move upwards continuously after the consumption that the kinetic energy is converted into potential energy after direction changing or upward moving, and falls down to the bottom of the tank body directly, so that the gas-liquid separation of mixtures is finally realized, a condition that the residual liquid enters the booster set to cause the halt of the booster set when the residual liquid is conveyed from the gas outlet is avoided, and simultaneously the separation treatment capacity of the booster set is improved.

Owner:CHENGDU ZHENGSHENG ENERGY TECH DEV CO LTD

a compressor

ActiveCN103017415BRealize gas-liquid separationImprove work efficiencyCompressorInsulation layerStraight tube

Owner:BEIJING FULLLINK OREITH TECH CO LTD

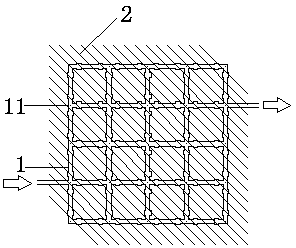

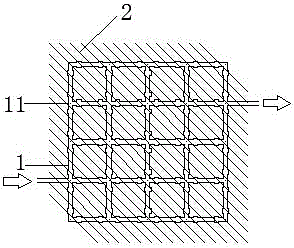

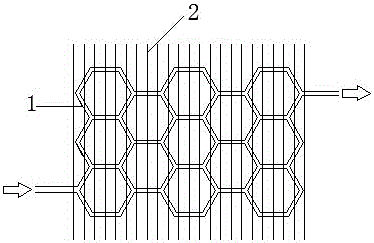

Gas-liquid separation evaporator

ActiveCN104034095ALow flow resistanceRealize gas-liquid separationEvaporators/condensersEngineeringHeat sink

The invention provides a gas-liquid separation evaporator comprising transmission tubes and radiating fins. The transmission tubes are in a multi-way mesh structure. The radiating fins are distributed in parallel and are fastened to the transmission tube. The transmission tubes are bellows; joints of the transmission tubes are connected through multi-way connectors. The multi-way mesh structure allows gas-liquid separation, and heat exchange area can be increased effectively, heat dissipation is quickened. The gas-liquid separation evaporator has the advantages that gas-liquid flow resistance can be reduced effectively and cooling efficiency is improved.

Owner:佛山市顺德区君胜电器实业有限公司

A kind of ultra-thin flat heat pipe and its manufacturing process

ActiveCN109443060BIncrease heat transfer limitPrevent collapseIndirect heat exchangersManufacturing technologyProcess engineering

The present invention relates to the technical field of heat dissipation devices, and more specifically relates to an ultra-thin flat heat pipe and its manufacturing process, including a bottom plate and a cover plate snap-fitted and packaged, and the bottom plate is provided with concave holes with several capillary structures arranged in parallel. In the cavity, a gas flow channel for the flow of the working fluid of the heat pipe is formed between adjacent capillary structures, and the capillary structure includes several liquid flow channels arranged in parallel. The gas working medium flows in the gas flow channel, and the liquid working medium flows in the capillary structure, so as to realize the gas-liquid separation of the working medium, reduce the flow resistance, and improve the heat transfer limit of the heat pipe; and the invention has simple structure and simple manufacture, and can It realizes industrial assembly line production, and has strong heat transfer capacity. The thickness of the heat pipe is small, which can meet the heat dissipation of electronic devices in narrow spaces, and meet the needs of integration and miniaturization of electronic components. It has good practicability and applicability. .

Owner:GUANGDONG UNIV OF TECH

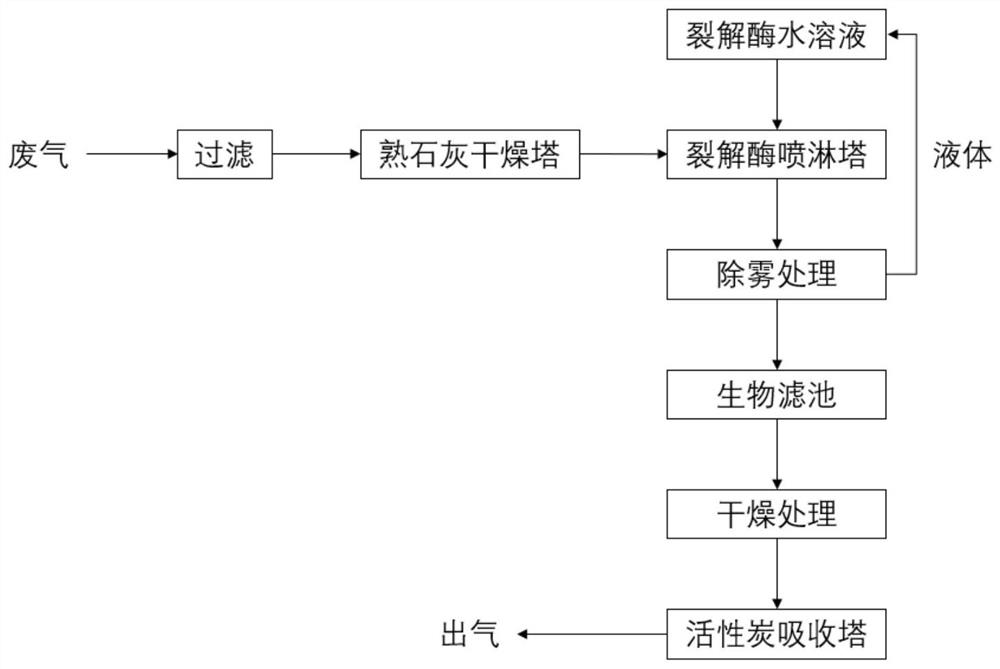

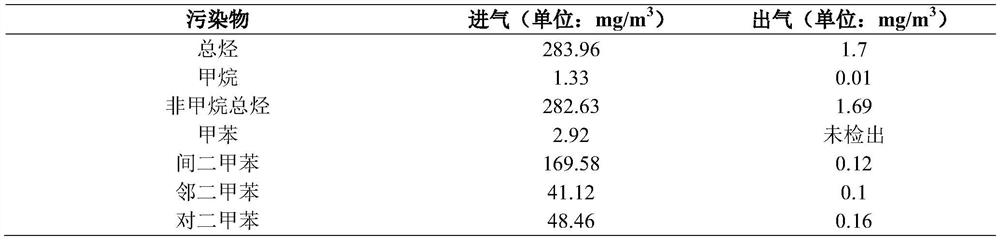

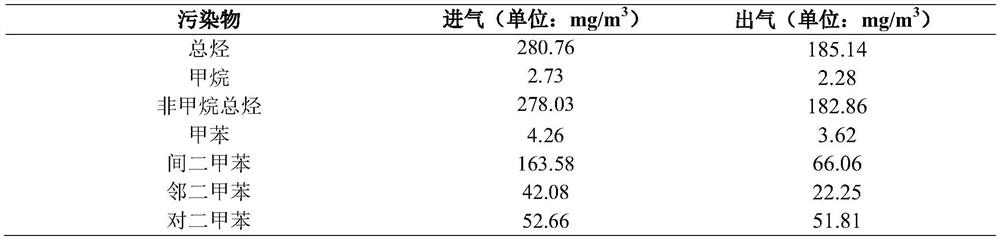

Treatment method of waste gas containing organic pollutants

PendingCN114053864AWell mixed contactFully degradedGas treatmentDispersed particle separationActivated carbonOrganomercurial lyase

The invention discloses a treatment method of waste gas containing organic pollutants, and belongs to the technical field of waste gas treatment. The treatment method comprises the following steps: 1) introducing the waste gas subjected to particle removal by filtration into a slaked lime absorption tower, and removing acidic pollutants contained in the waste gas; 2) introducing the gas treated in the step 1) into a spray tower, and spraying water mist containing lyase in the spray tower to remove organic pollutants contained in the waste gas; 3) carrying out demisting treatment on the gas discharged from the spray tower in the step 2), and introducing the gas into a biological filter; and 4) treating the gas treated in the step 3) through a drying tower, and introducing the treated gas into an activated carbon absorption tower. After lyase is added into water, the lyase is sprayed out in a water mist manner, so that the water mist containing the lyase is fully mixed and contacted with the waste gas, and organic matters in the waste gas are more fully degraded.

Owner:青岛万慧源环保科技有限公司

Gas-liquid separation device and method, crude oil extraction system and crude oil detection system

PendingCN111965265AAchieve separationQuickly know the volumeComponent separationPetrochemicalHigh pressure gas

The invention belongs to the technical field of petrochemical equipment, and relates to a gas-liquid separation device for fluid obtained by extracting crude oil light dydrocarbon through high-pressure gas, which comprises a shell, at least two fluid introduction pipelines, a liquid drainage pipeline and a liquid collector. The shell is provided with a fluid inlet, a gas outlet, a liquid outlet, acondensing medium inlet and a condensing medium outlet. The at least two fluid introduction pipelines and the liquid drainage pipeline are positioned in the shell. All the fluid introduction pipelines are communicated in sequence, the included angle between each fluid introduction pipeline and the horizontal plane is greater than 0 degree and less than or equal to 90 degrees, the lower end of each fluid introduction pipeline is communicated with the upper end of the liquid drainage pipeline, the upper end of a first fluid introduction pipeline in the at least two fluid introduction pipelinesis communicated with the fluid inlet, and the upper end of a last fluid introduction pipeline is communicated with the gas outlet. The lower end of the liquid drainage pipeline, the liquid outlet andthe liquid collector are sequentially communicated. The gas-liquid separation device can quickly realize gas-liquid separation under the condition of high pressure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil producing well casing gas recovery device

InactiveCN113389526ARealize gas-liquid separationImprove performancePV power plantsFluid removalControl cellEnergy conservation

The invention relates to the field of oil producing well casing gas recovery, in particular to an oil producing well casing gas recovery device. The device comprises a liquid storage unit, a control unit is arranged on the upper end face of the liquid storage unit, an output unit is arranged at one side of the liquid storage unit, an energy storage unit is arranged at the upper portion of the control unit, and an energy-saving unit is arranged at the upper portion of the energy storage unit. A three-stage settling tank is adopted, gas-liquid separation in casing gas is achieved, a pressure pump is arranged to enable casing gas and liquid in a third collecting tank to have pressure, and higher efficiency is obtained during recycling; a thermoelectric generator and a liquid conveying pipe are arranged, compressed casing gas is converted into electric energy to be stored through a storage battery, external equipment is connected, the use range of the casing gas is widened, and energy conservation and emission reduction are achieved; and a solar panel is adopted to realize environmental protection, and an inverter is arranged to change the electric energy voltage generated by the solar panel and the thermoelectric generator according to requirements, so that the output electric energy obtains a wider application range under the action of the inverter.

Owner:山东辛丁技术有限公司

Gas-liquid separation evaporator

ActiveCN104034095BLow flow resistanceRealize gas-liquid separationEvaporators/condensersNetwork structureEngineering

The invention provides a gas-liquid separation evaporator; the evaporator comprises a transmission tube and a heat sink, the transmission tube is a multi-connected mesh structure, the heat sink is distributed in parallel, and is clamped on the transmission tube Corrugated pipes are used for the transmission pipes, and the nodes between the transmission pipes are connected by multi-pass connectors. The multi-pass network structure can realize gas-liquid separation, effectively increase the heat exchange area, and speed up heat dissipation. The evaporator can effectively Reduce vapor-liquid two-phase flow resistance and improve refrigeration efficiency.

Owner:佛山市顺德区君胜电器实业有限公司

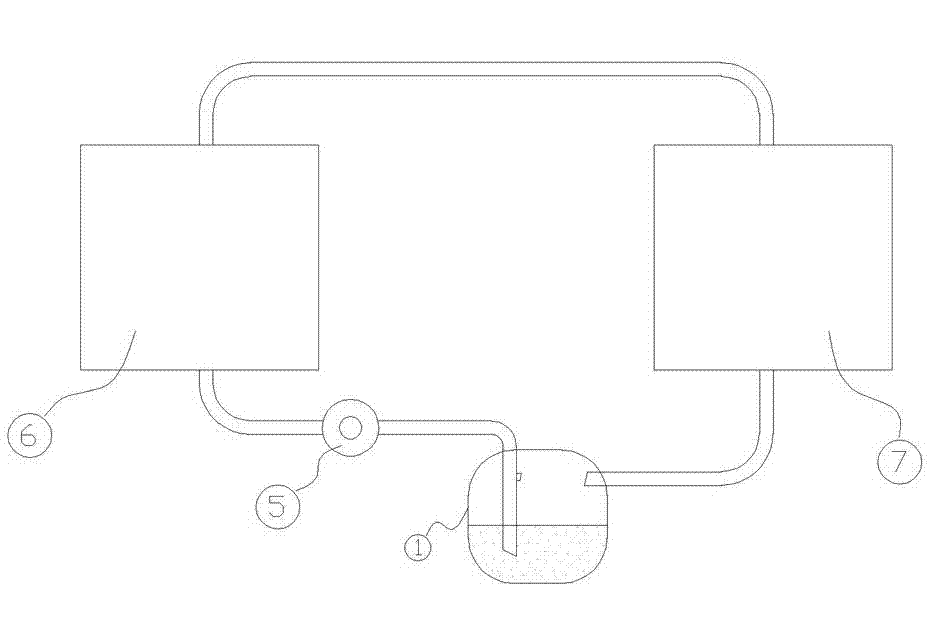

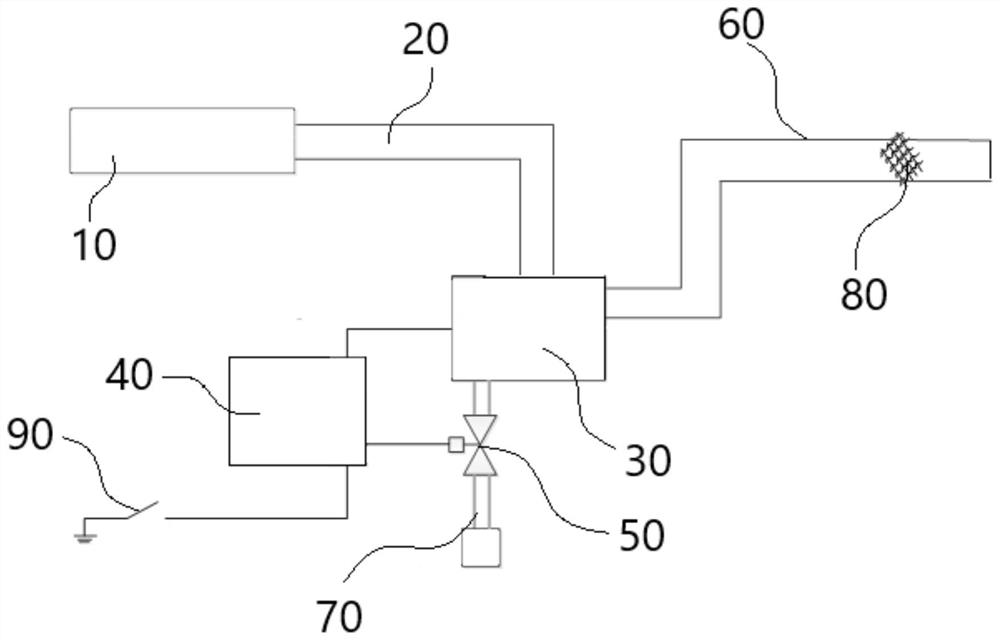

Fuel cell automobile tail gas water-vapor separation and emission system and control method thereof

PendingCN112164811ARealize gas-liquid separationAvoid influencePropulsion by batteries/cellsFuel cellsExhaust gasProcess engineering

The invention relates to the technical field of fuel cell vehicles, in particular to a fuel cell vehicle tail gas and water vapor separation and emission system and a control method thereof. The tailgas and water vapor separation and emission system comprises a fuel cell stack, a tail gas conveying pipe, a water tank, a fuel cell control unit, a first control switch, an exhaust pipe and a drain pipe, one end of the tail gas conveying pipe is communicated with the tail gas output end of the fuel cell stack, and the other end of the tail gas conveying pipe is communicated with a gas inlet of the water tank; the exhaust pipe is communicated with a gas outlet of the water tank, a filter unit is arranged at one end, far away from the water tank, of the exhaust pipe, the filter unit is used forfiltering gas, the drain pipe is communicated with a water outlet of the water tank, and the first control switch is arranged on the drain pipe and used for connecting or disconnecting the drain pipe. Liquid separated by the system is collected in a centralized mode, regular and fixed-point drainage is conducted, and the problem that in the prior art, tail gas is discharged at will, and consequently the road surface environment is affected is solved.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

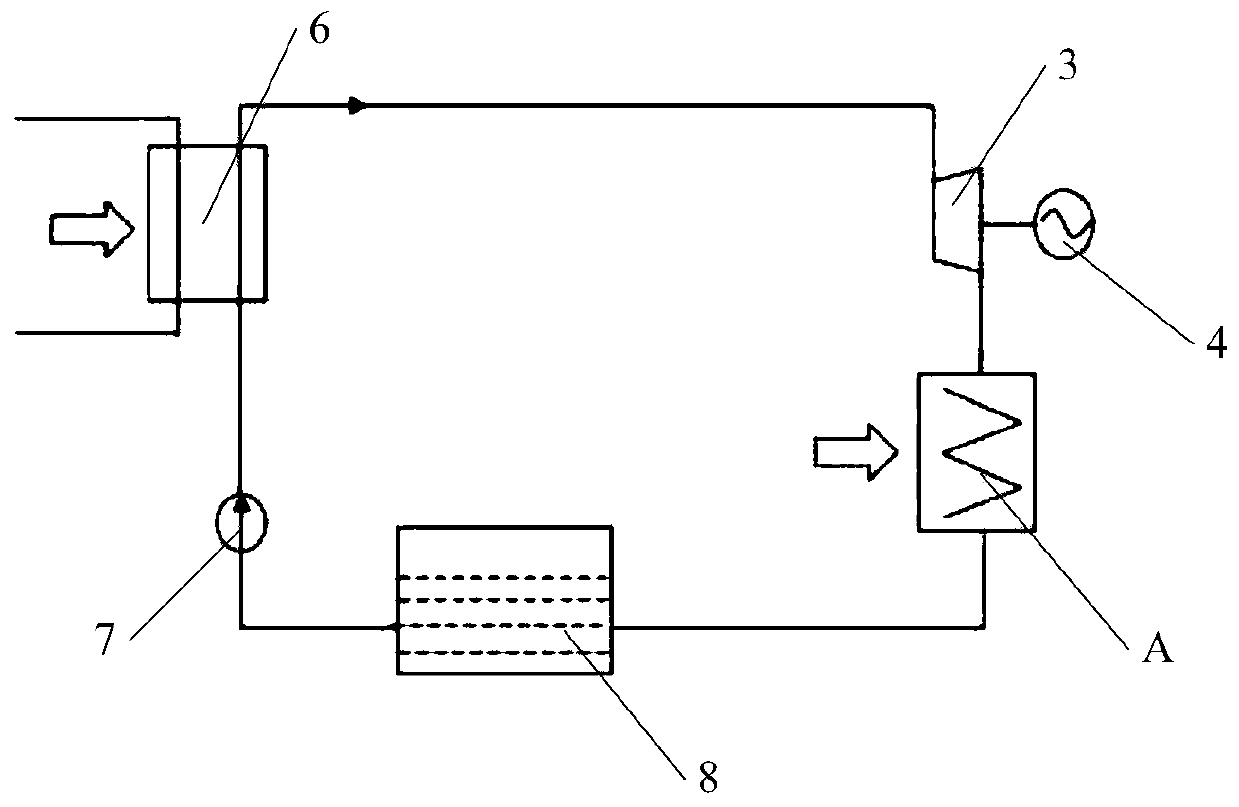

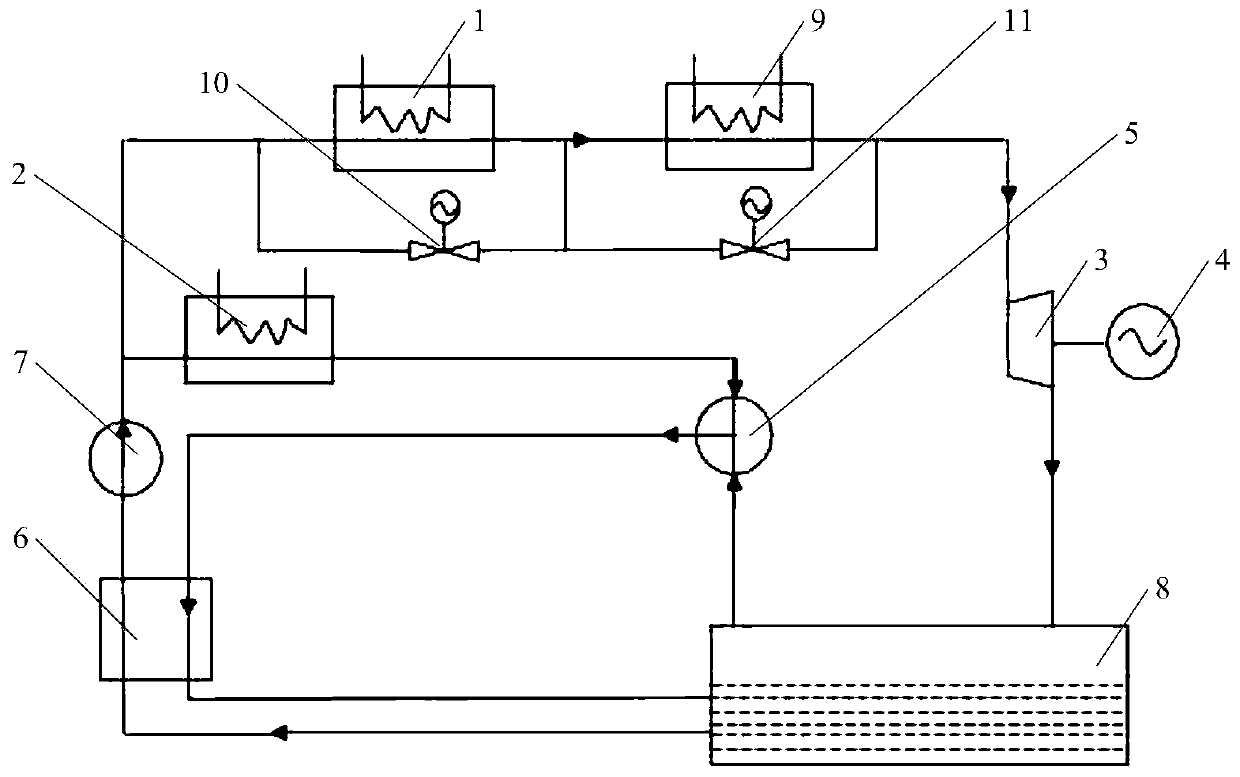

Low-parameter heat recovery system

PendingCN109763870ALow costImprove work efficiencyHeat recovery systemsSteam engine plantsElectricityLiquid storage tank

The invention discloses a low-parameter heat recovery system which comprises a main circulation system for generating electricity or doing work and an auxiliary circulation system for acquiring and maintaining low-temperature energy, and low-temperature working medium fluid and external recovered waste heat form a temperature difference by controlling the main circulation system and the auxiliarycirculation system to achieve electricity generating and work doing; the main circulation system includes a liquid storage tank, a working medium pump, a regenerator, a first heat exchanger, a steam turbine and a generator which are connected in sequence; the auxiliary circulation system includes a second heat exchanger connected with the regenerator and further comprises a steam turbine, a liquidstorage tank, a jet heat pump and a regenerator which are connected in sequence, the second heat exchanger is also connected to the jet heat pump, and the regenerator is connected to the liquid storage tank; and both the first heat exchanger and the second heat exchanger are connected to external recovered waste heat. Compared with a conventional heat engine, the main circulation system is assisted by auxiliary circulation, and continuous and stable heat work conversion is changed under the condition that no external cold source is needed for cooling dead steam.

Owner:潘彦伯

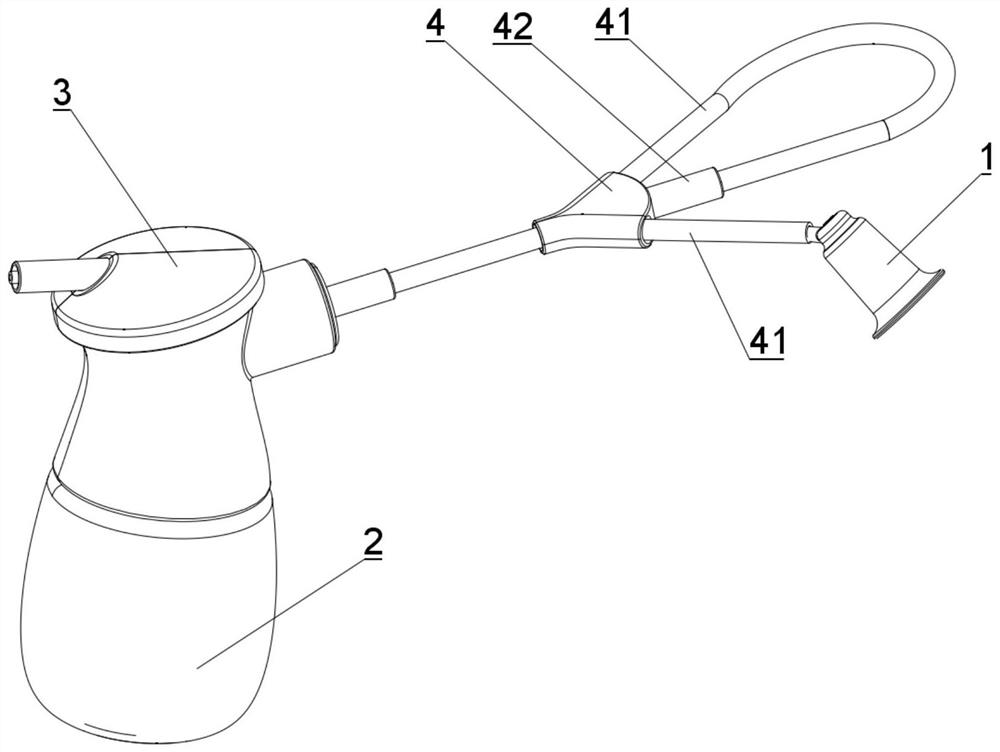

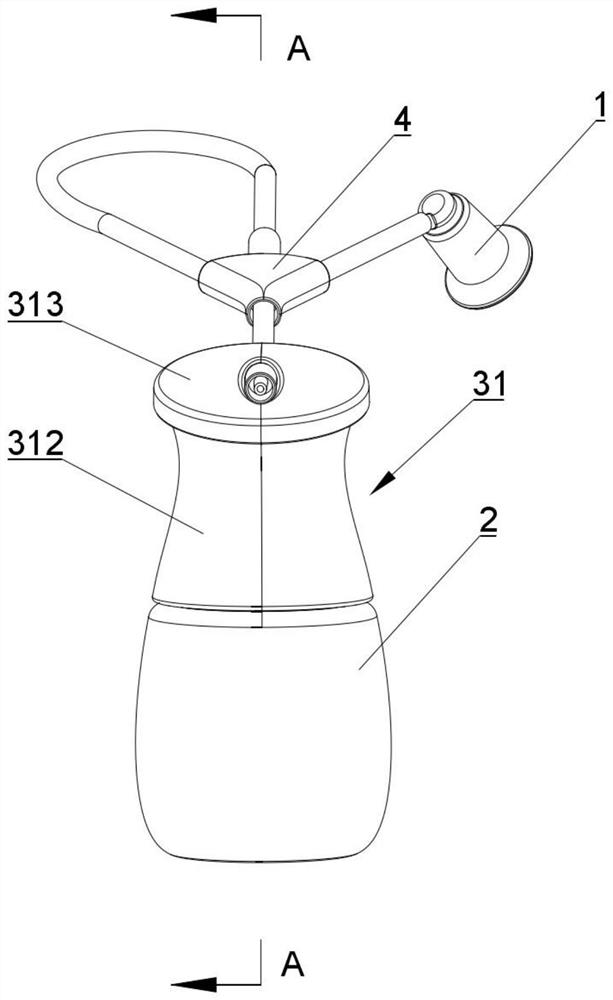

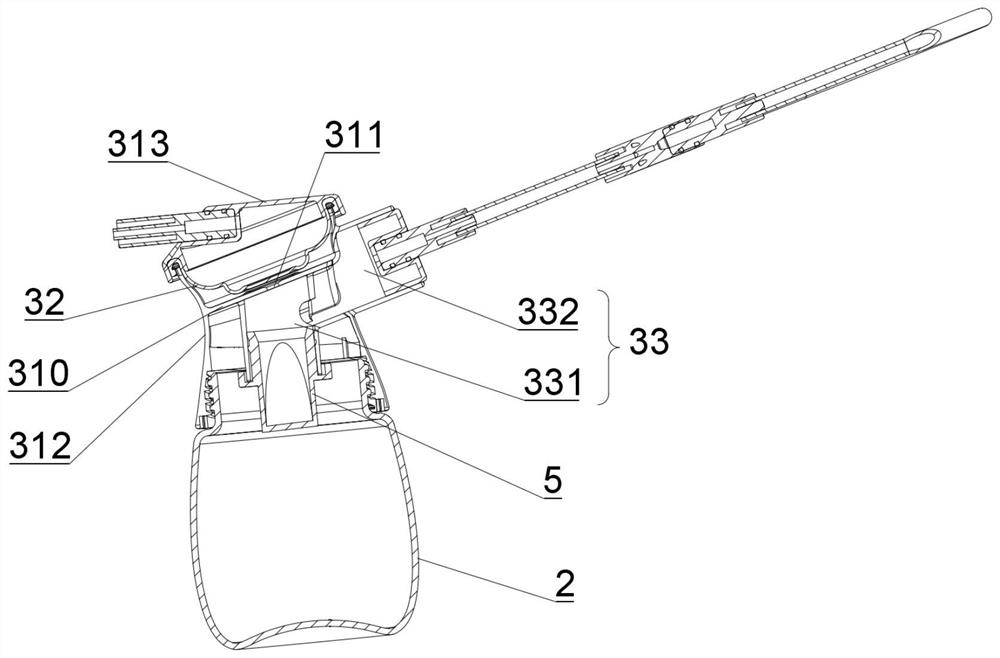

Nipple corrector

The invention relates to the technical field of medical instruments, and discloses a nipple corrector. The nipple corrector comprises a nipple correction cover and a liquid storage tank; an air-liquid separation device is arranged at a tank opening of the liquid storage tank; the air-liquid separation device comprises a shell, a flexible deformation structure and a flow guide passage; the shell is divided into a first cavity and a second cavity which communicate with each other; the flexible deformation structure is arranged in the first cavity, and a sealing cavity is formed between the flexible deformation structure and the inner wall of the shell; the sealing cavity is communicated with an air extracting pump; the air extracting pump extracts air to enable the flexible deformation structure to be deformed; the flow guide passage is formed in the second cavity; one end of the flow guide passage extends out of the shell and is communicated with the nipple correction cover; and the other end of the flow guide passage is connected and disconnected with the liquid storage tank through a control valve. When the nipple corrector is used for correcting nipples, air-liquid separation is implemented, and liquid is prevented from being pumped into the air extracting pump.

Owner:上海贝立安特智能科技有限公司

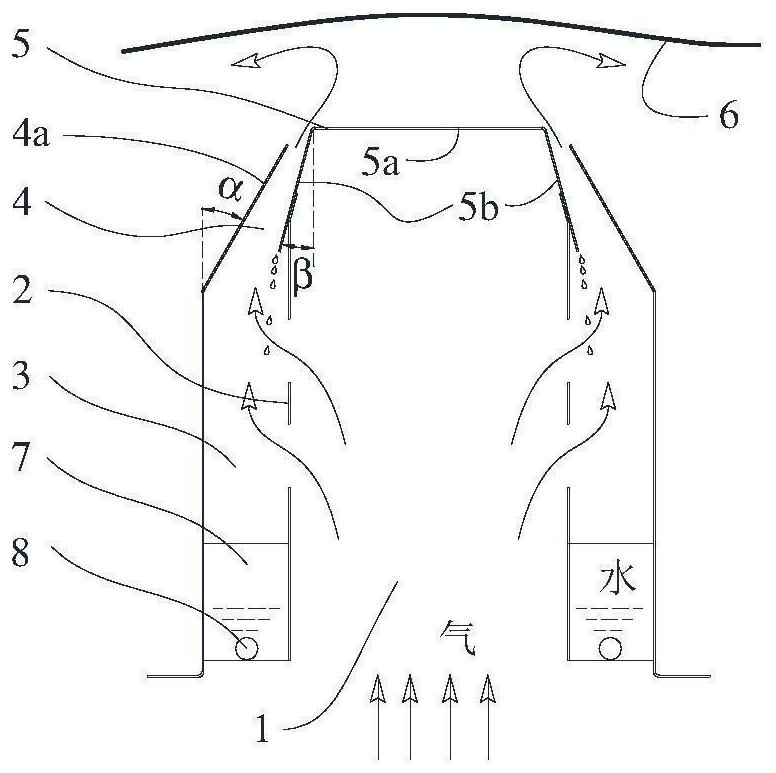

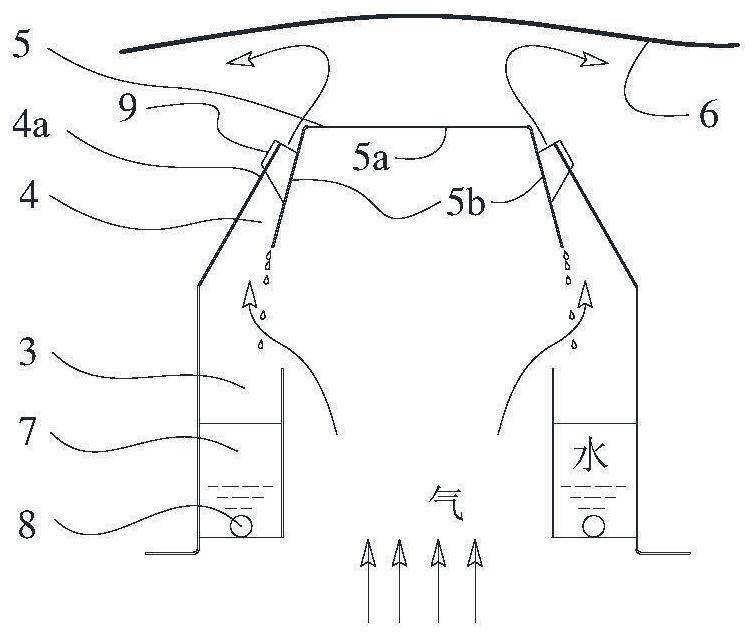

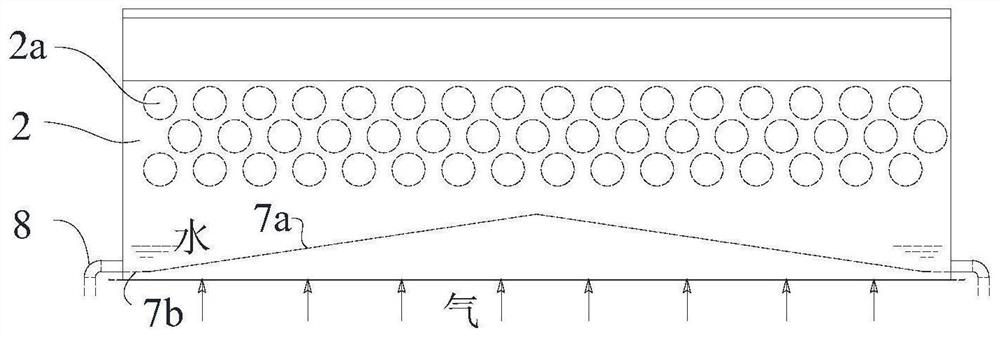

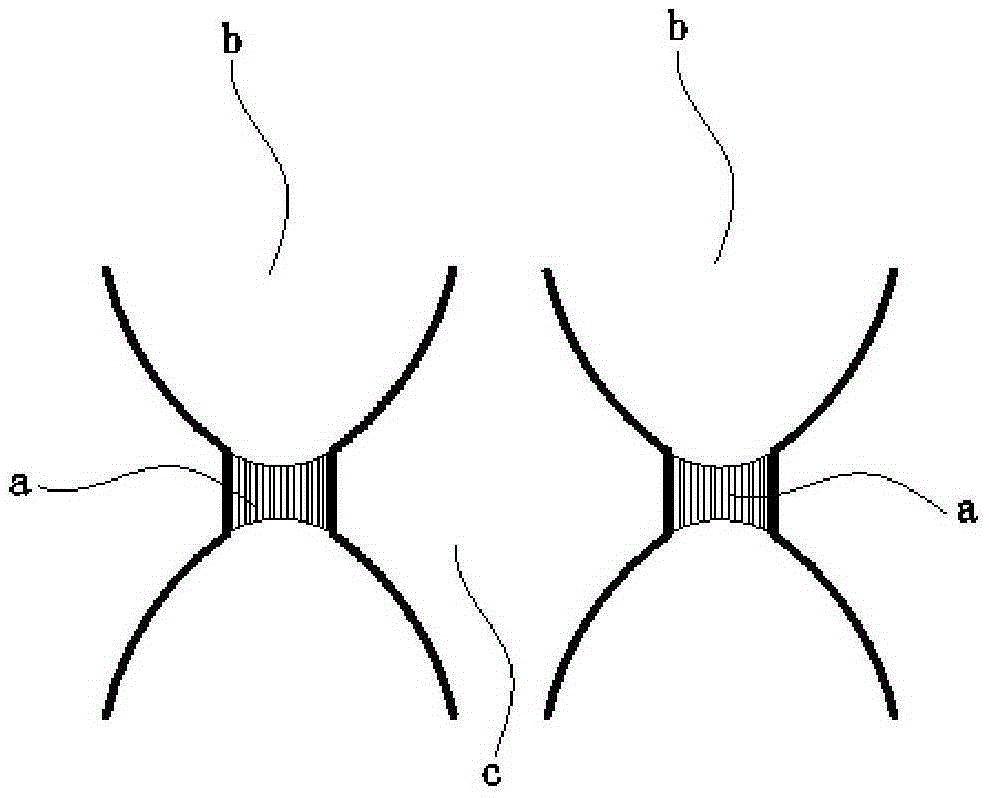

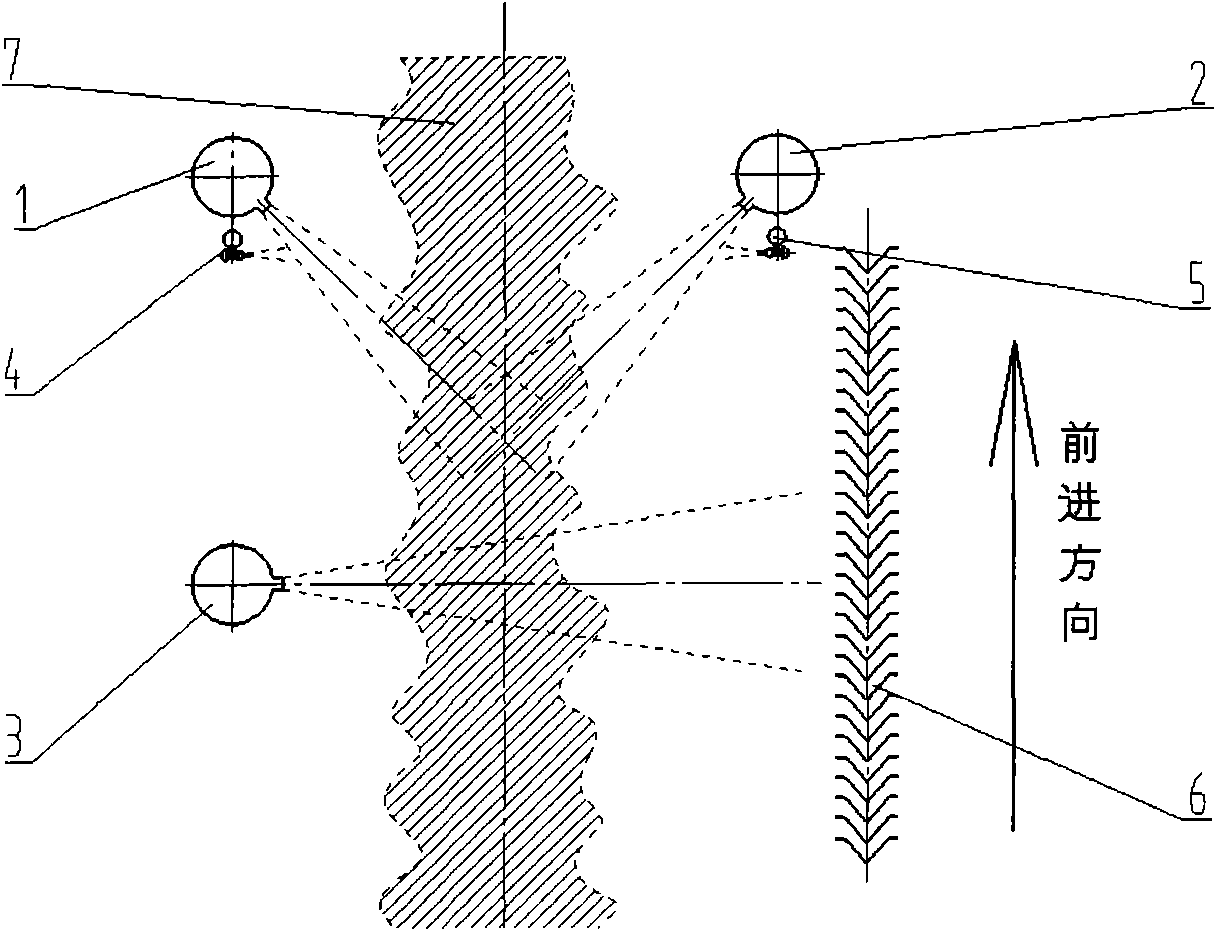

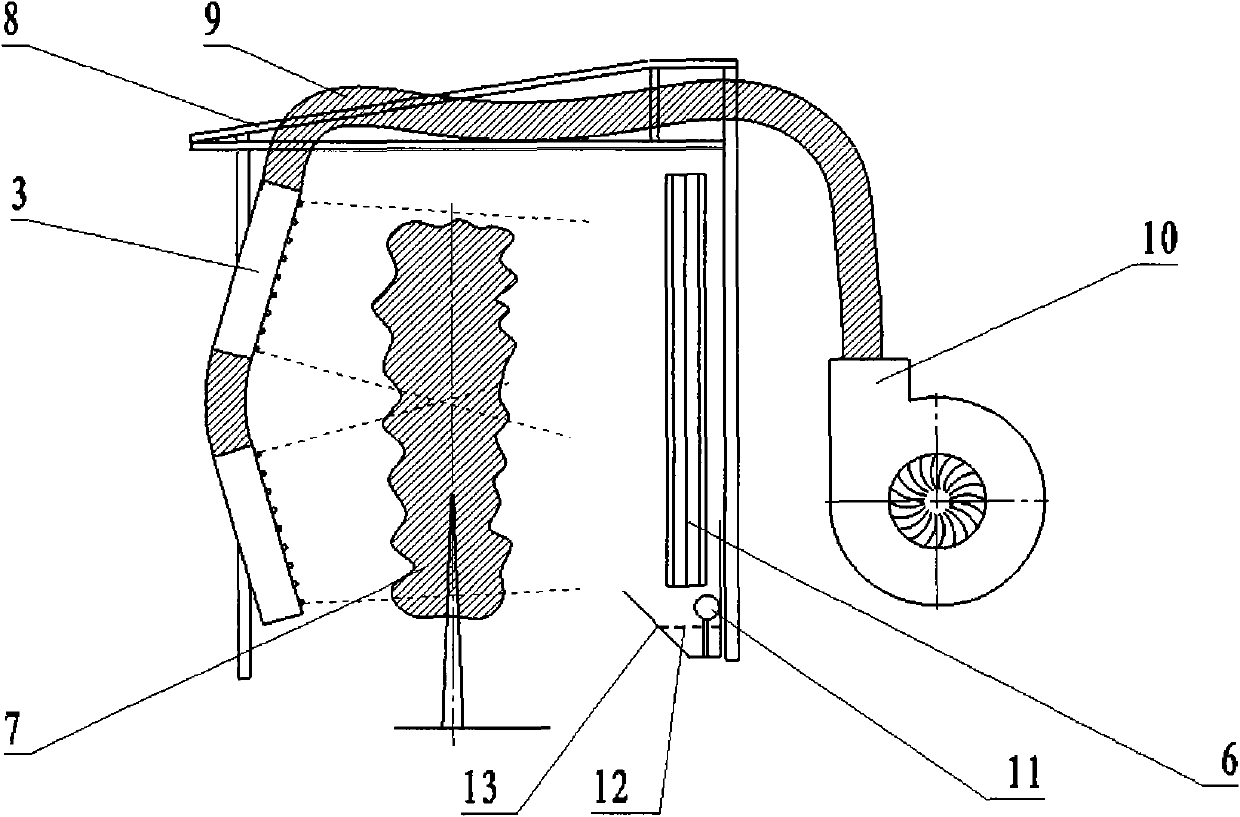

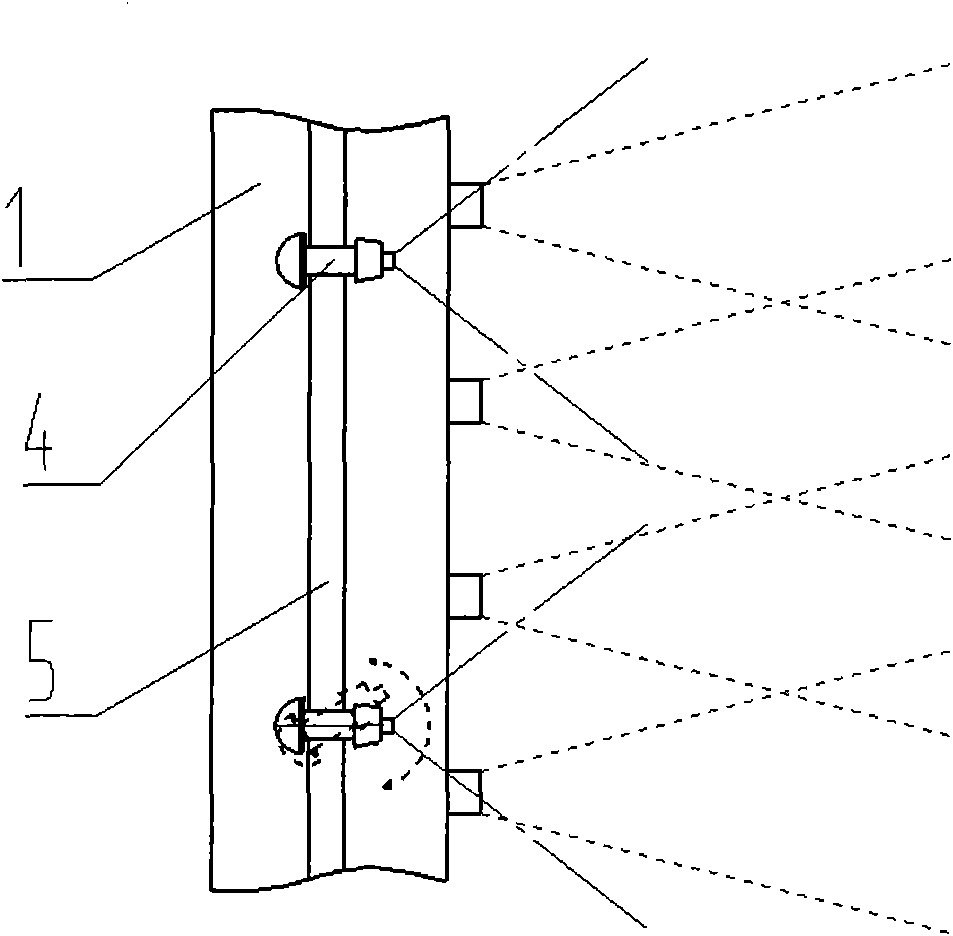

Air-assisted grid circulating spraying system

InactiveCN102165944BLight structureImprove stabilityInsect catchers and killersSpray nozzleAgricultural engineering

The invention relates to the technical field of agricultural equipment for plant protection, and particularly discloses an air-assisted grid circulating spraying system, which comprises a machine body of a medicine spraying machine, an air-assisted device, a grid interception device, a frame, a fan, a spray rod and a spray nozzle, wherein the frame is in an 'n' shape; the air-assisted device is arranged on the frame; one side of the frame is arranged on the machine body of the medicine spraying machine; the grid interception device is arranged on the machine body of the medicine spraying machine; and the fan is arranged on the machine body of the medicine spraying machine and is connected with the air-assisted device through an air pipe. The air-assisted grid circulating spraying system has a simple structure and is convenient to install, and the effect of the air-assisted spraying system is enhanced greatly; and active directional interception is realized, and liquid medicine which does not operate is recovered, so the waste of the liquid medicine is reduced greatly, the application value is high, and the air-assisted grid circulating spraying system is suitable to be popularizedwidely in the technical field of agricultural plant protection.

Owner:CHINA AGRI UNIV

A compressor gas-liquid separation structure

ActiveCN102900709BRealize gas-liquid separationHigh separation precisionPump componentsPumpsEngineering

Owner:GREE ELECTRIC APPLIANCES INC

A wet steam vapor-liquid two-phase separation device

The invention discloses a vapor-liquid two-phase separation device for wet steam. A support plate and a liquid baffle are respectively provided. The liquid baffle is located above the support plate. A separation bucket is provided on the bottom surface of the support plate. One end of the air intake pipe passes through the support plate and extends into the separation bucket. The sides of the separation bucket are evenly distributed. There is a flow hole, the bottom of the separation bucket is provided with a liquid outlet pipe, a fixed channel is distributed around the support plate, a spoiler is movably connected in the fixed channel, there are gaps distributed on the outer circumference of the support plate, and the liquid baffle There are diversion openings distributed on the outer circumference of the outer circumference, a conduit is arranged between the diversion opening and the gap, an air collecting hood is arranged on the liquid baffle, and an air outlet pipe is arranged on the top of the air collecting hood. The invention has stable structure, multiple separation, good separation effect and reliable use.

Owner:杭州量创科技咨询有限公司

Downhole gas-liquid separation device and its working method

ActiveCN105536299BReduce in quantitySimple structureLiquid degasificationSeparation devicesCENBOLBarrel Shaped

Owner:JEREH ENERGY SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com