Patents

Literature

38 results about "Methanol reformer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

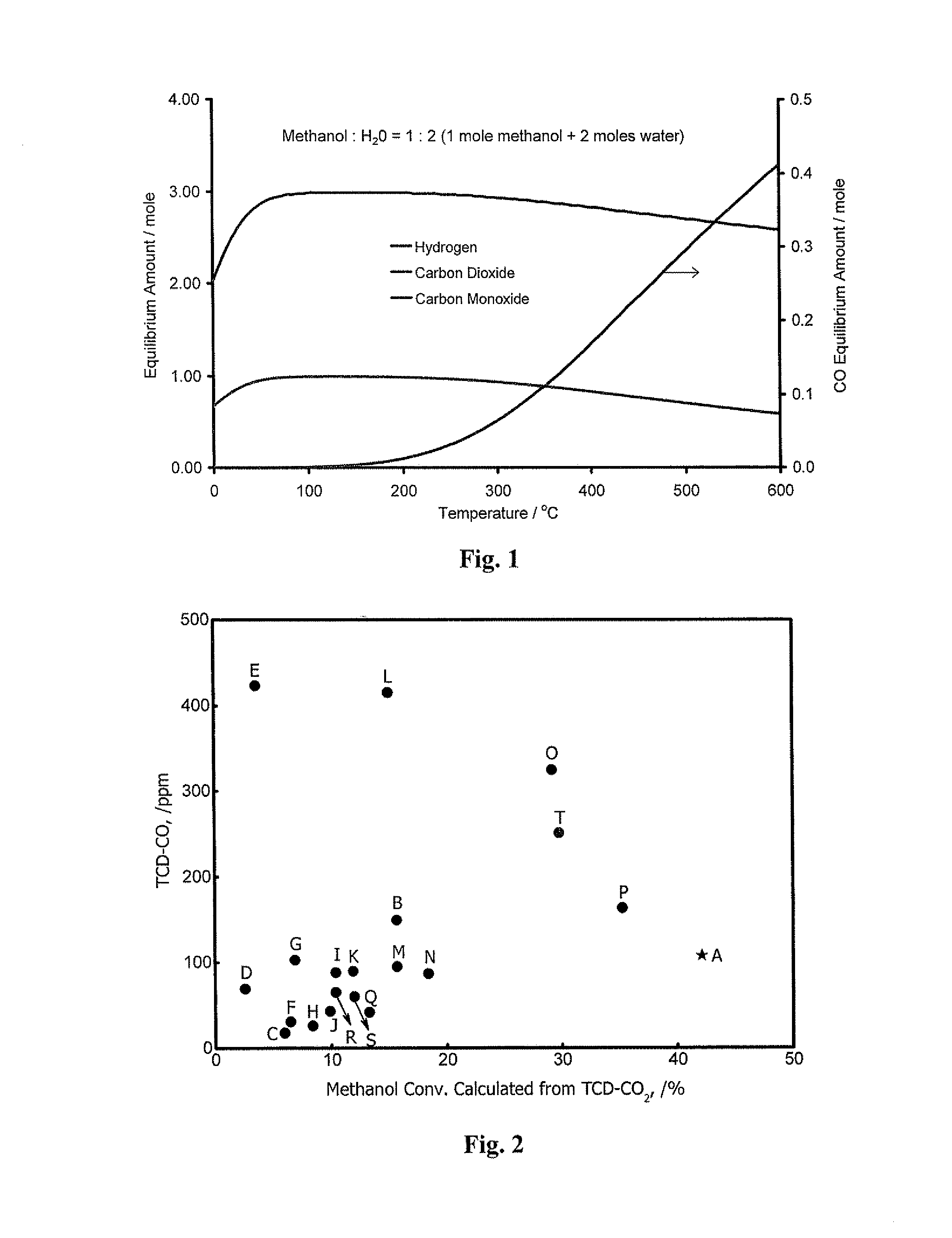

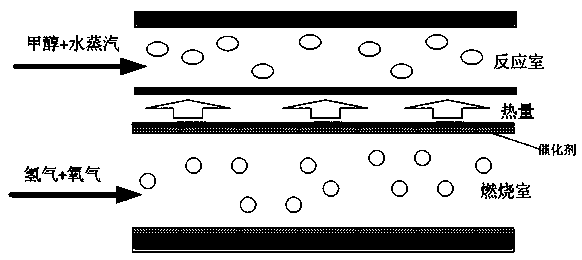

A methanol reformer is a device used in chemical engineering, especially in the area of fuel cell technology, which can produce pure hydrogen gas and carbon dioxide by reacting a methanol and water (steam) mixture. CH₃OH₍g₎+H₂O₍g₎ ⟶ CO₂+3 H₂ ΔHR ₂₉₈⁰=49.2 kJ/mol

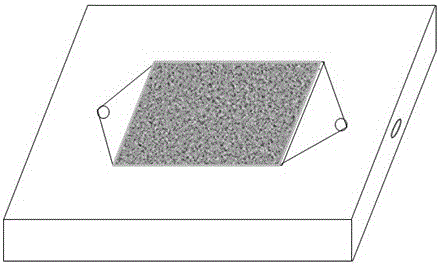

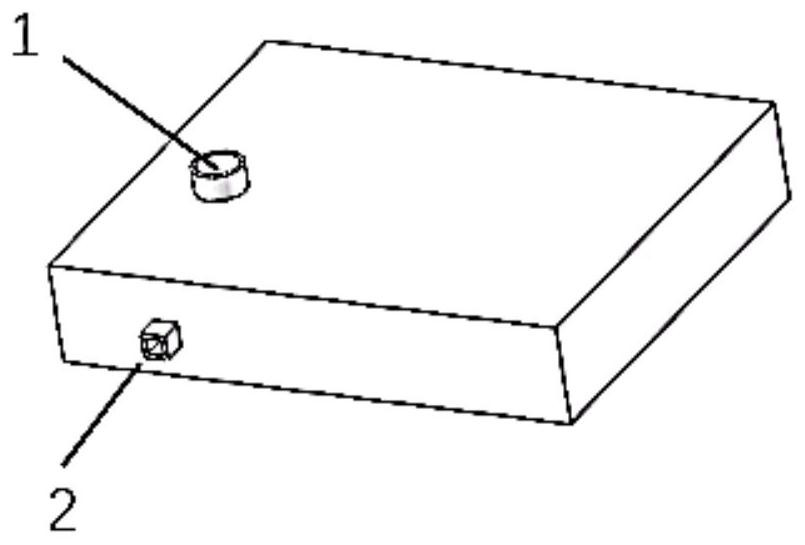

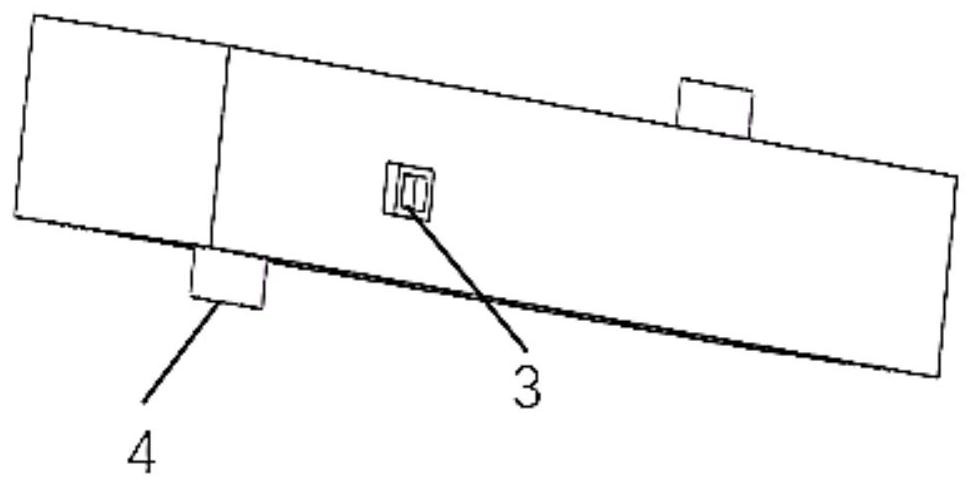

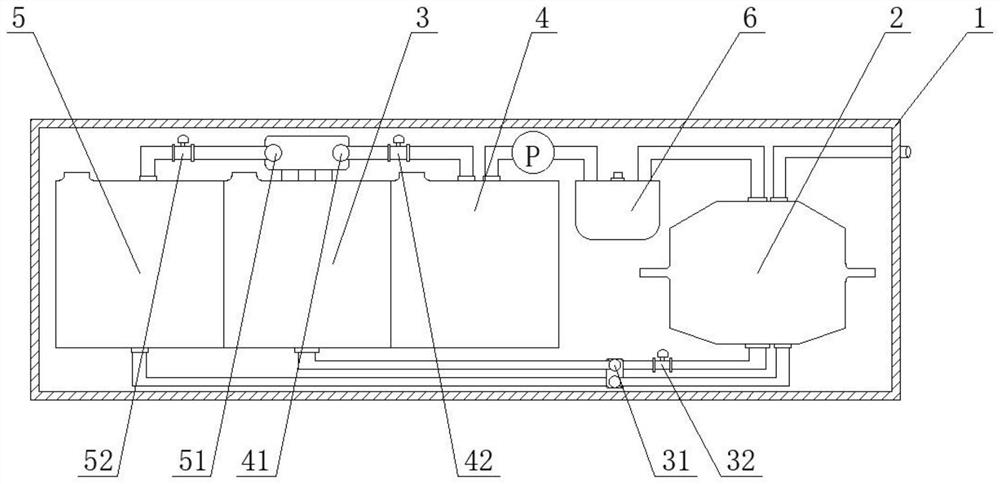

MEMS (Micro-Electromechanical Systems) methanol reforming fuel cell system

ActiveCN103943873AChange fuel supplyImprove securityReactant parameters controlSustainable buildingsLithiumMicroelectromechanical systems

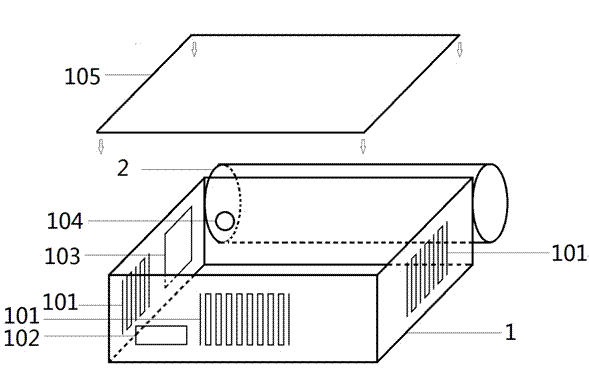

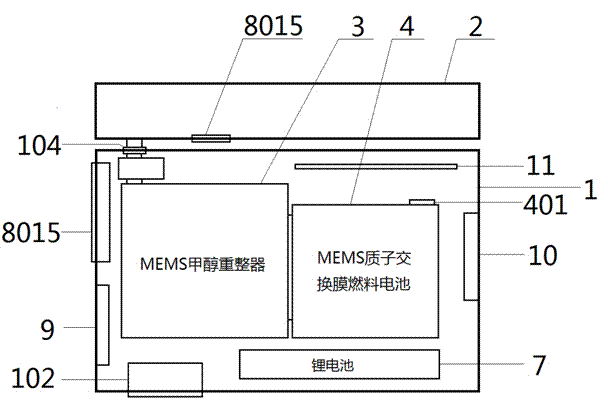

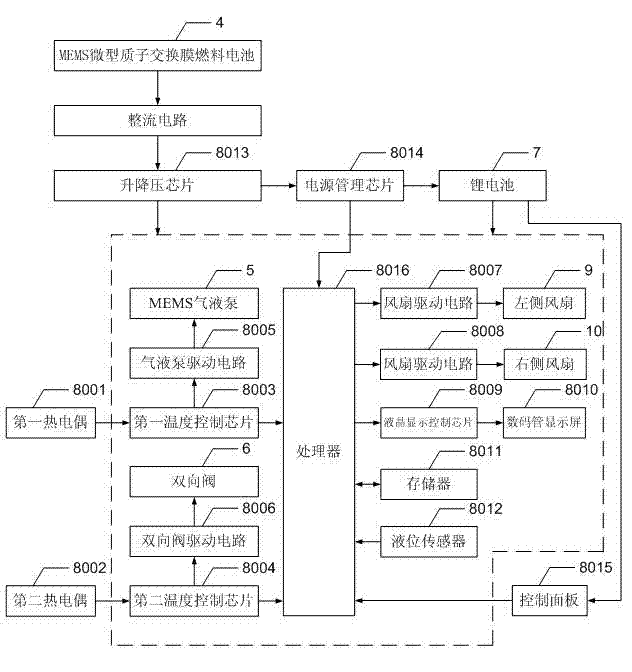

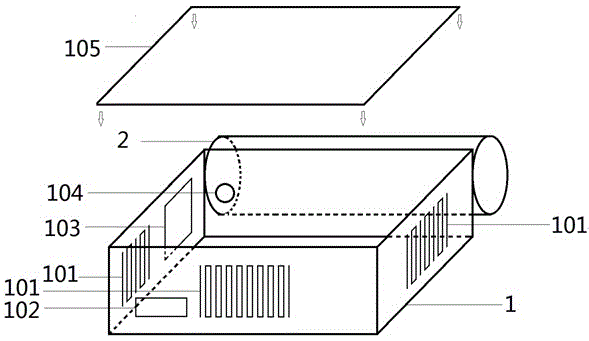

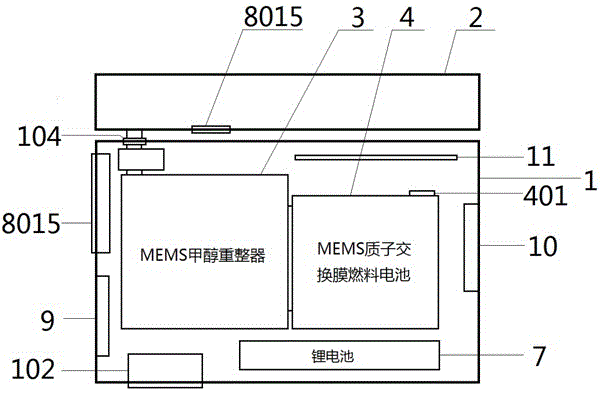

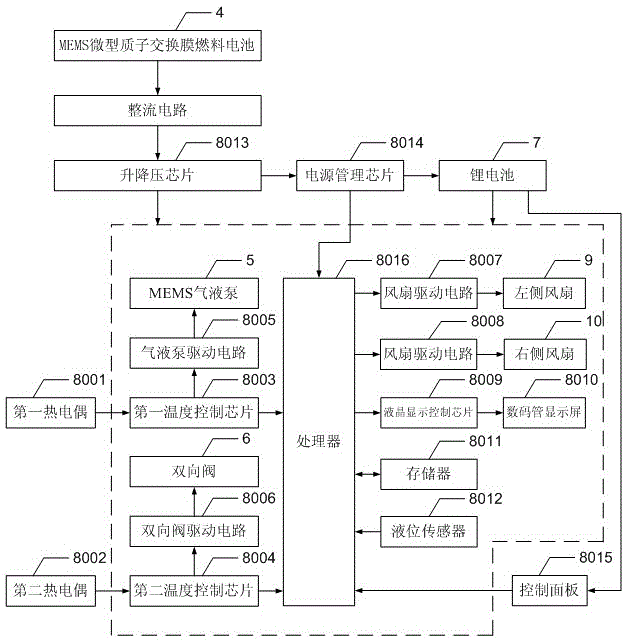

The invention discloses an MEMS (Micro-Electromechanical Systems) methanol reforming fuel cell system, belongs to the field of methanol reforming fuel cells and aims to solve the problems of a traditional methanol reforming fuel cell system. The MEMS methanol reforming fuel cell system comprises a shell, a liquid storage bottle, an MEMS methanol reformer, an MEMS proton exchange membrane fuel cell, an MEMS air-liquid pump, a bi-directional valve, a lithium cell, a managing system, a left side fan and a right side fan, wherein the shell is in a cuboid shape, the liquid storage bottle is arranged on the outer surface of the back side of the shell, the MEMS methanol reformer, the MEMS proton exchange membrane fuel cell, the MEMS air-liquid pump, the bi-directional valve, the lithium cell, the managing system, the left side fan and the right side fan are arranged in the shell, an input port of the MEMS methanol reformer is communicated with a methanol outlet of the liquid storage bottle by virtue of a pipeline, the MEMS air-liquid pump and the bi-directional valve are arranged on the pipeline, an output port of the MEMS methanol reformer clings to an anode input port of the MEMS proton exchange membrane fuel cell tightly, and the contact position is sealed by a sealing material.

Owner:HARBIN INST OF TECH

Method for fuel methanol of igniting type engine

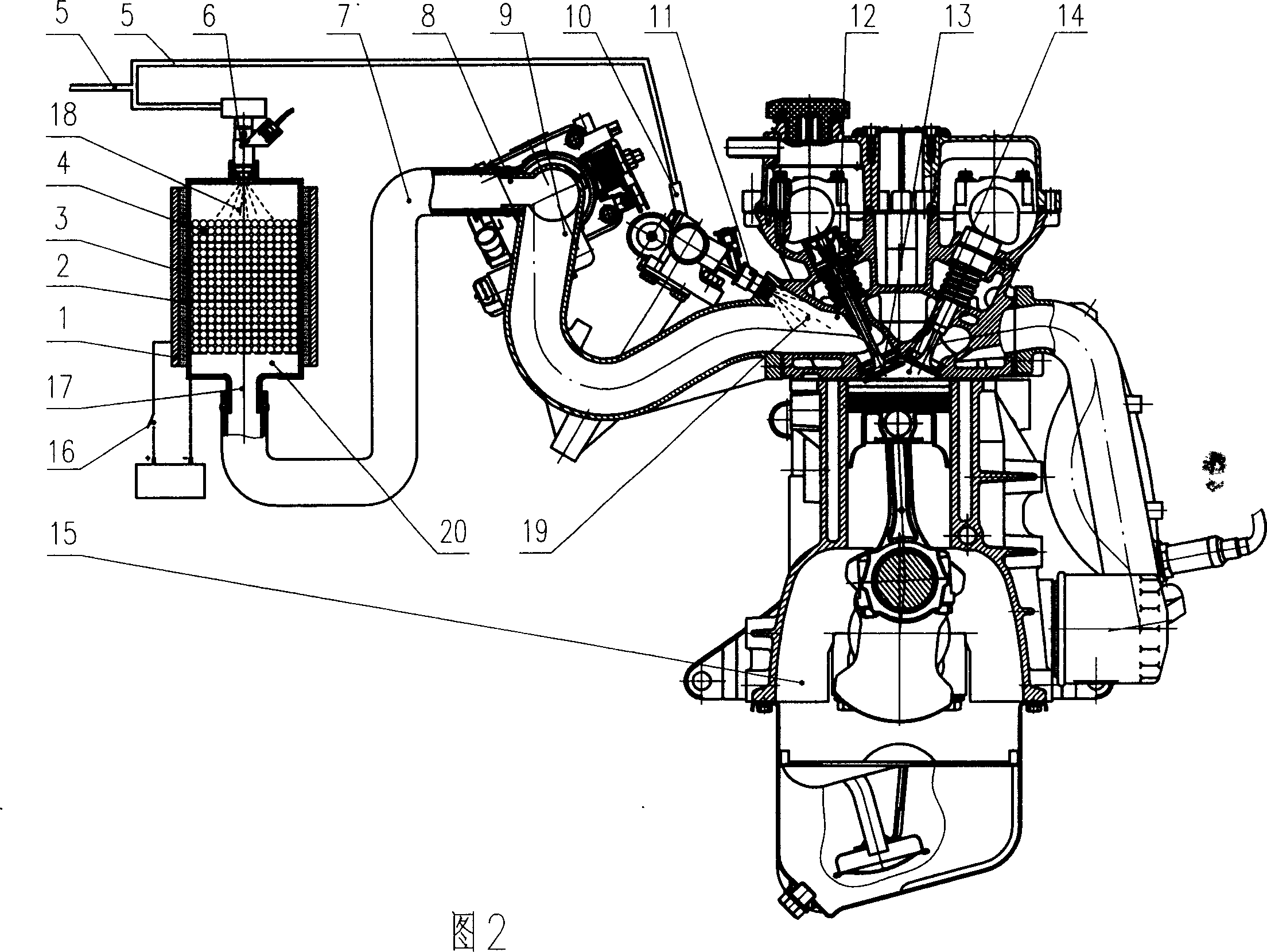

InactiveCN1821558AImprove cold start performanceReduce consumption rateInternal combustion piston enginesGaseous engine fuelsHydrogenNitrogen

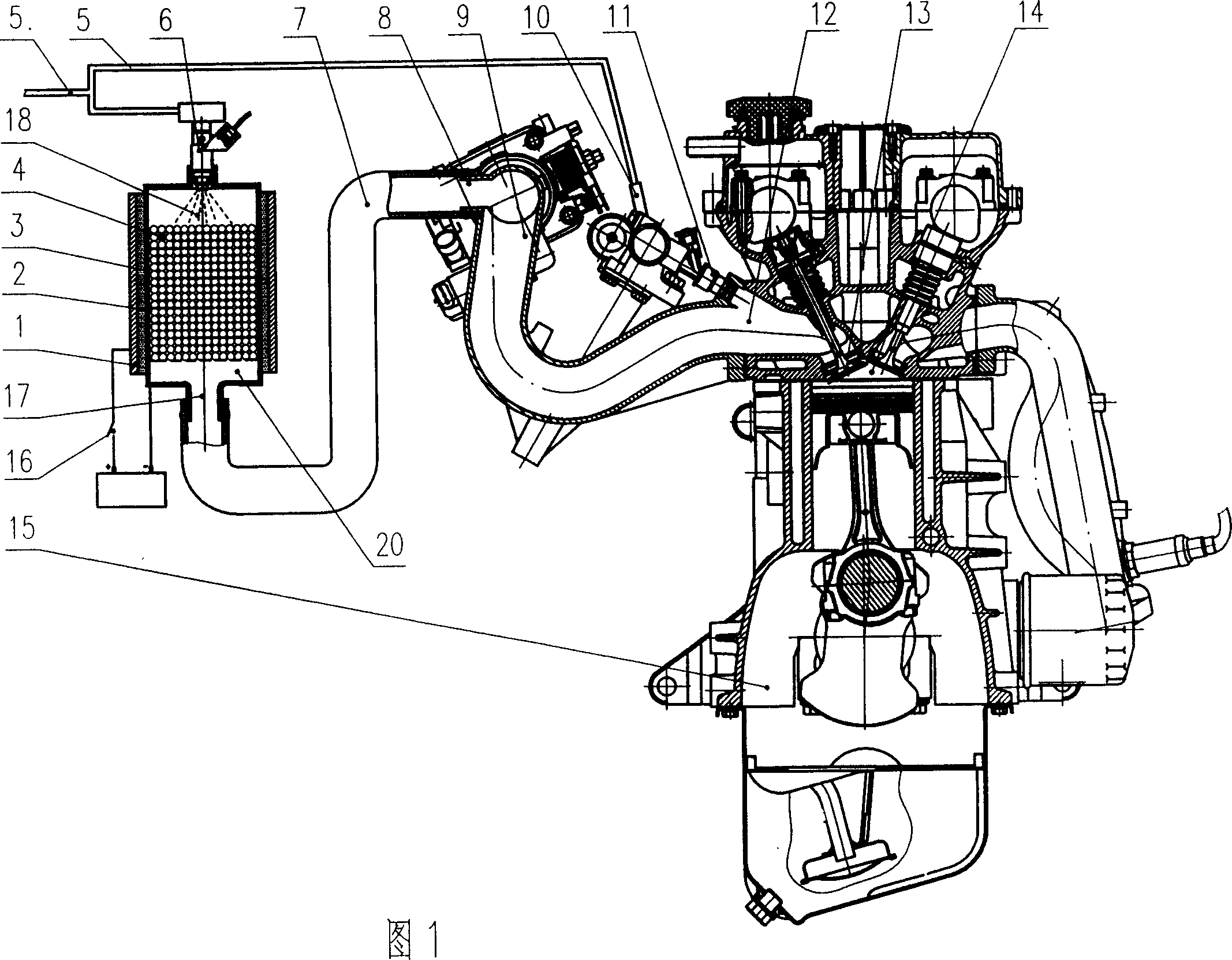

The method of burning methanol in an ignition type engine includes the following steps: 1. heating methanol reforming catalyst inside the methanol reformer with electrothermal PTC element and maintaining the temperature at 200-300 deg.c; 2. jetting methanol into the reformer for reaction to produce reformed methanol gas containing hydrogen and CO; 3. mixing the reformed methanol gas and air inside the inlet manifold to form mixed inflammable gas; 4. starting the engine to burn the mixed inflammable gas; and 5. jetting more methanol to form mixed inflammable gas essential for the engine in raised load, so as to make the engine burn mixed gas of nitrogen, CO, methanol and air. The present invention improves the cold start performance of engine burning methanol, eliminates formaldehyde exhaust pollution, raises the burning efficiency, lowers the furl consumption, reduces exhaust pollution and saves petroleum resource.

Owner:郑国璋

Foamed metal aluminum surface modification catalyst carrier, preparation method of the carrier, and method for preparing alcohol type reforming catalysts by utilizing carrier

ActiveCN103846109AThickness is easy to controlComposition is easy to controlHydrogenCatalyst carriersElectrolytic agentAluminate

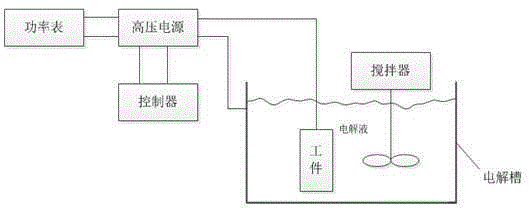

The invention discloses a foamed metal aluminum surface modification catalyst carrier, a preparation method of the carrier, and a method for preparing alcohol type reforming catalysts by utilizing the carrier. The carrier is prepared from a foamed metal aluminum framework and a porous oxide ceramic membrane growing by modification on the surface of the framework. The method comprises the following steps: putting porous foamed aluminum as a positive pole into an electrolyte containing 5-20g of aluminate, silicate and fluorozirconate per milliliter, and applying direct or alternating voltages to perform microarc oxidation, thereby forming a layer of oxidized ceramic membrane, and carrying the catalyst on the surface of the ceramic membrane as a substrate, thereby obtaining the alcohol type reforming catalysts. The problems such as insufficient contact of reaction gas with the catalyst, low utilization rate of the catalyst, and the negative effects of the catalyst framework on the catalyst in the existing methyl alcohol reformer can be effective solved and the generation of carbon monoxide is reduced to a certain degree.

Owner:HARBIN INST OF TECH

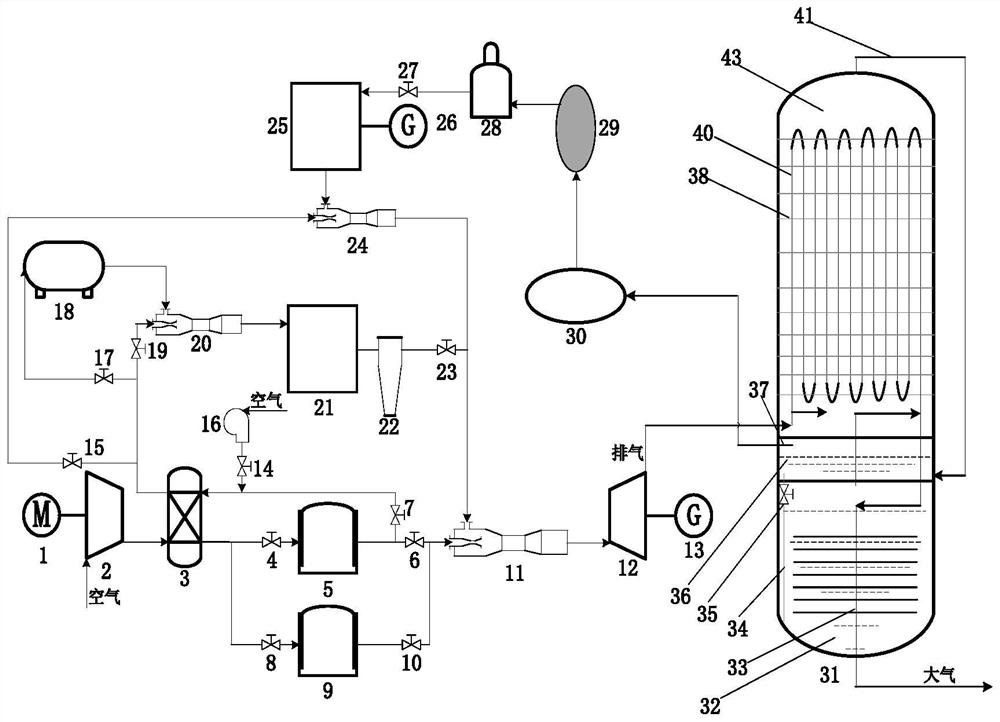

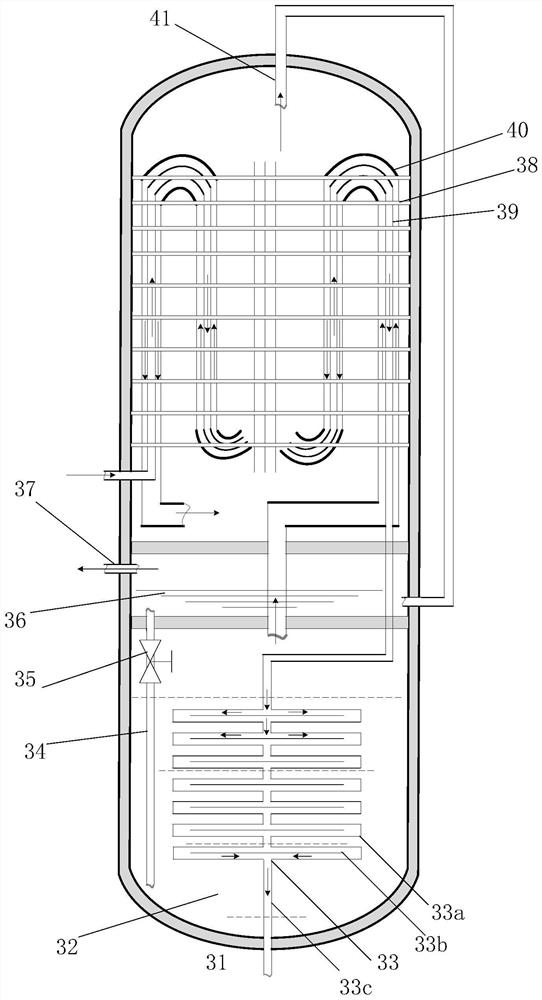

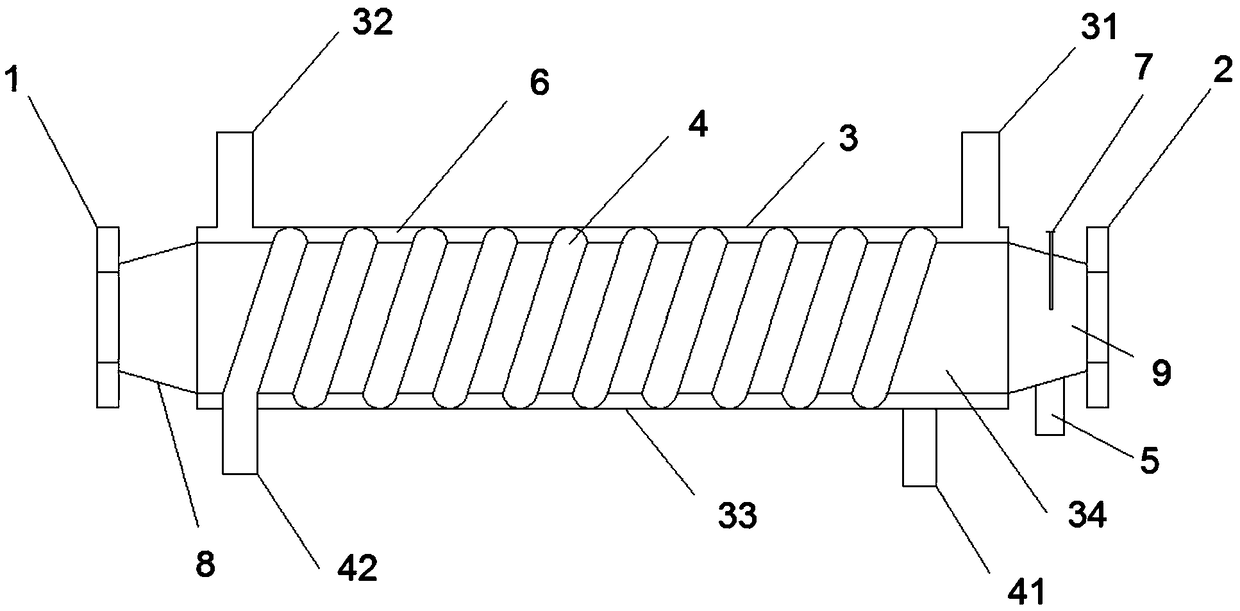

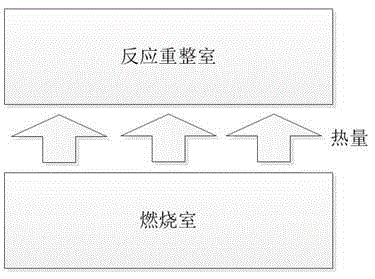

Composite compressed air energy storage system and method for coupling methanol reformer with internal combustion engine

ActiveCN114483290AMake full use of high temperature heat dissipationMake the most of heat removalHydrogenInternal combustion piston enginesMethanol waterCombustor

The composite compressed air energy storage system comprises a compressed air energy storage unit, a methanol steam reforming unit, a low-dust combustor unit and an internal combustion engine power generation unit which are mutually coupled, and low-grade compression heat, high-temperature exhaust heat of the internal combustion engine and exhaust heat of an expansion machine are fully utilized; exhaust gas of the expansion machine firstly passes through the methanol steam reaction inner pipe to provide energy for methanol reforming reaction, and then passes through the disc-shaped heat exchanger to evaporate a methanol aqueous solution to generate methanol steam, so that stepped utilization of high-temperature exhaust gas energy of the expansion machine is realized, and the energy utilization efficiency is improved; an external heat source of the reactor is avoided while high-temperature exhaust is utilized, so that the system efficiency is further improved; the mixed gas generated by the reforming reaction passes through the low-concentration methanol aqueous solution in the methanol removal chamber, methanol in the mixed gas is absorbed, heat of the mixed gas is absorbed at the same time, recycling of the methanol and the heat is achieved, and the economical efficiency of hydrogen production through methanol steam reforming is improved.

Owner:XI AN JIAOTONG UNIV

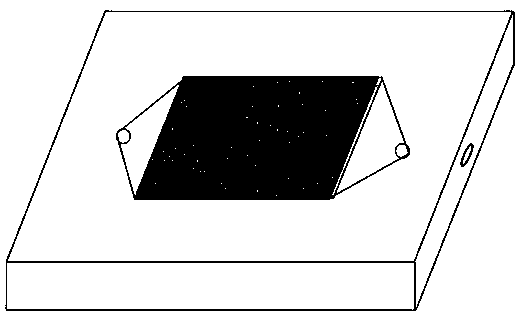

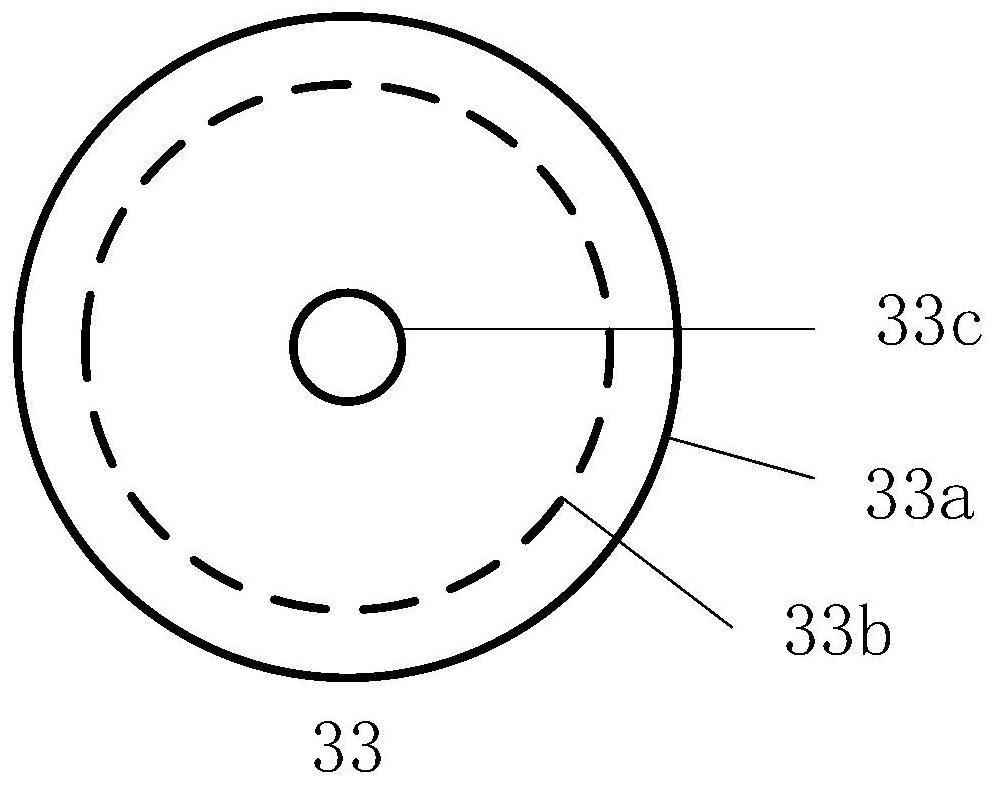

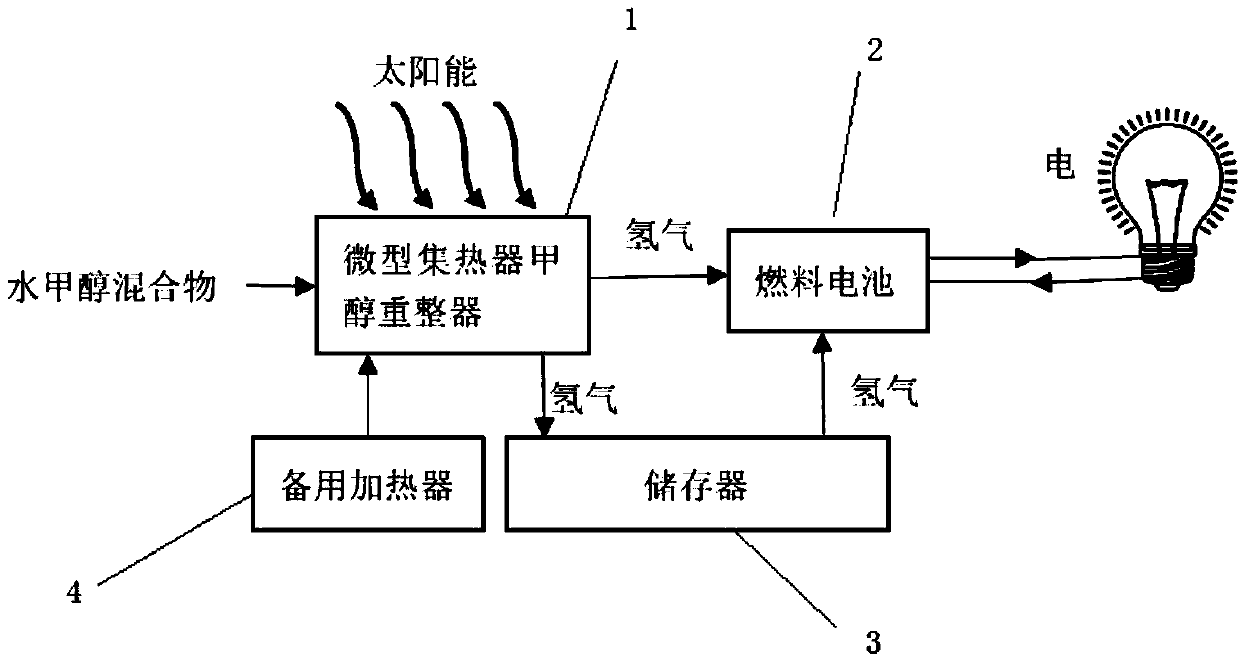

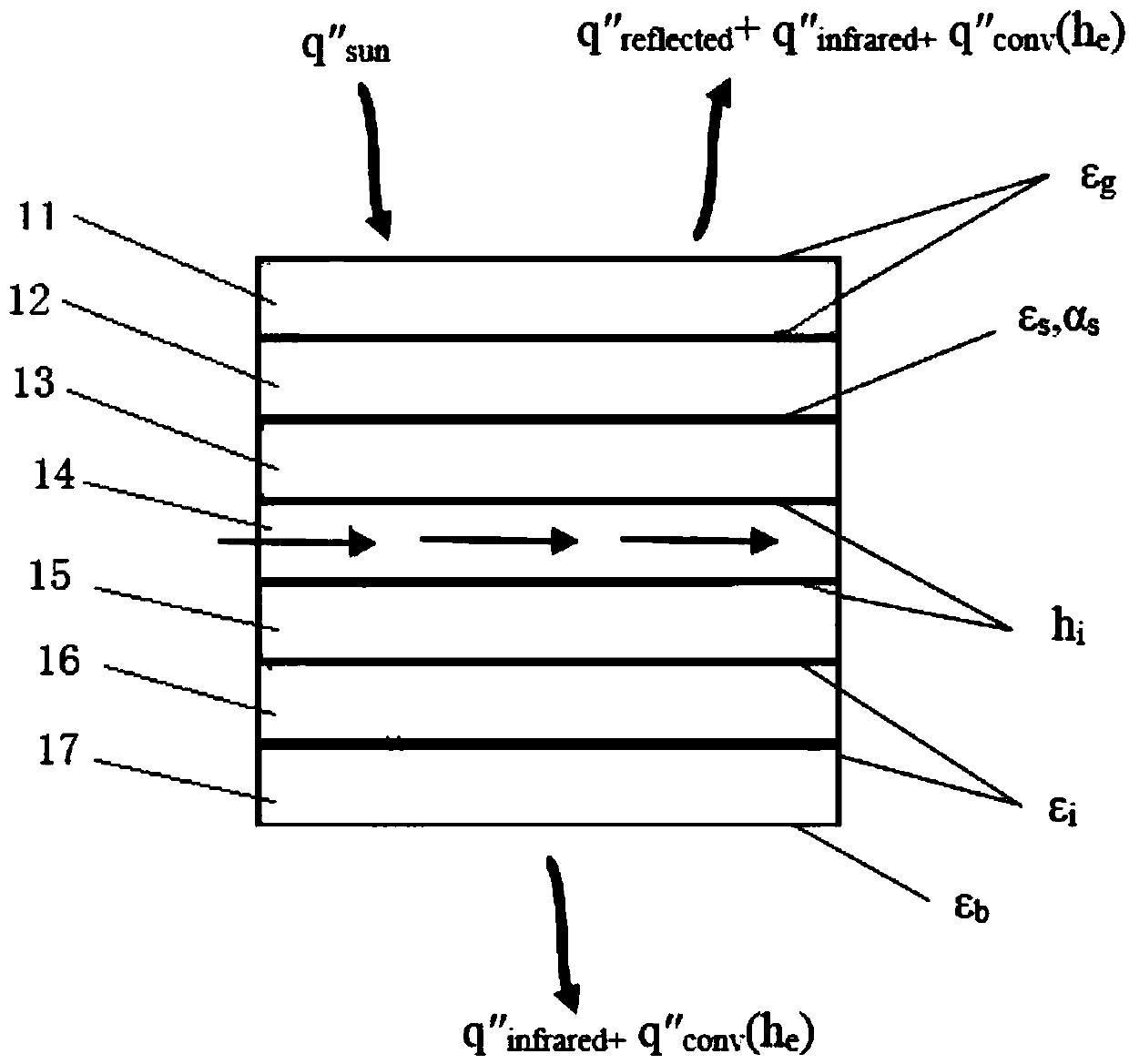

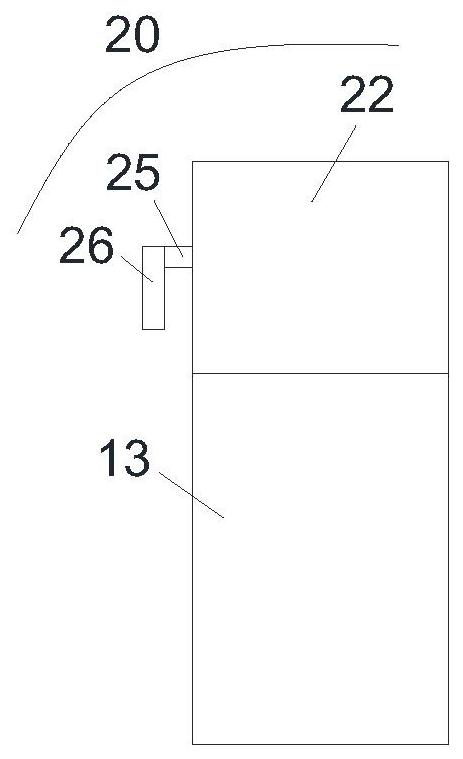

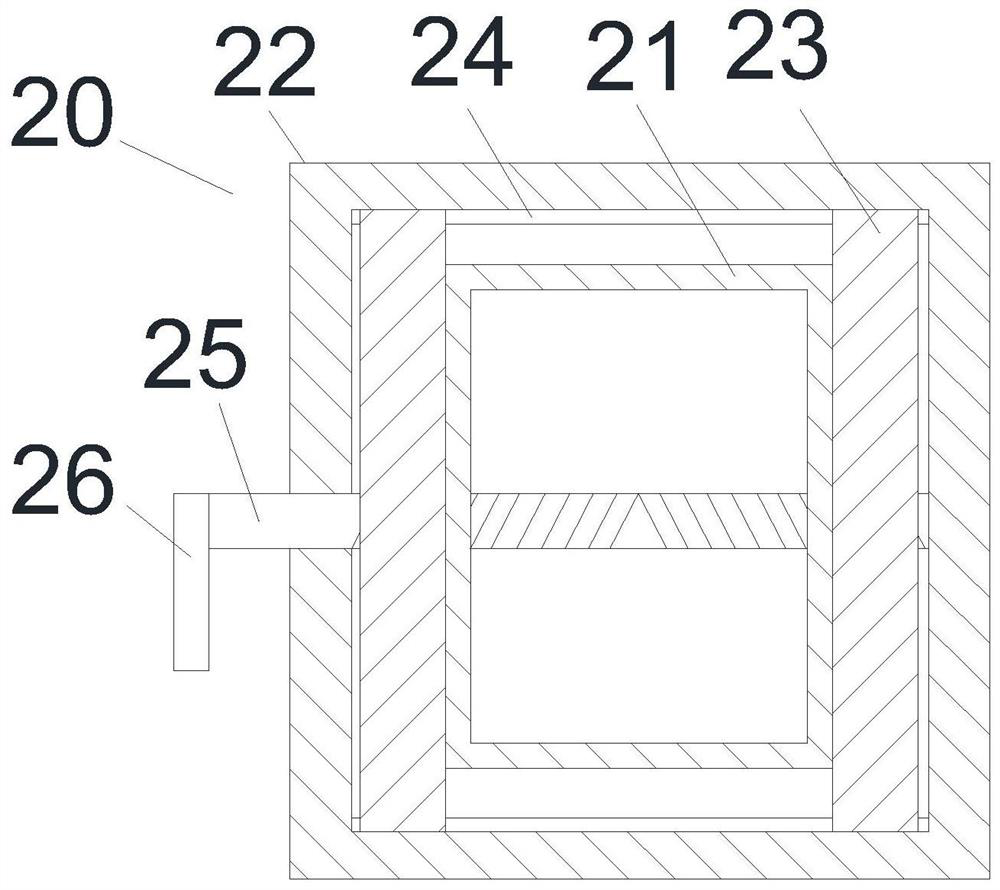

Minitype solar-energy heat collection device for methanol reforming hydrogen fabrication

PendingCN108036523AImprove hydrogen production efficiencyReduce consumptionSolar heating energyHydrogenElectricityHydrogen

The invention provides a minitype solar-energy heat collection device for methanol reforming hydrogen fabrication. The minitype solar-energy heat collection device comprises a minitype heat collectormethanol reformer, a fuel cell and a storage device, a hydrogen output mouth of the minitype heat collector methanol reformer is connected with the fuel cell and the storage device correspondingly, the hydrogen output mouth of the storage device is connected with the fuel cell, the minitype heat collector methanol reformer comprises a minitype heat collector and a methanol reformer which is connected with the minitype heat collector, and the minitype heat collector is a flat solar-energy heat collector. The minitype solar-energy heat collection device for the methanol reforming hydrogen fabrication has the beneficial effects that the green, environment-friendly and renewable solar energy is taken as the external heat source to provide heat required for the reaction for the methanol reformer, so that the consumption of electricity and other energy can be reduced, the energy utilization rate is increased, the overall efficiency of hydrogen fabrication of the methanol reformer is improved, and the application cost is lowered.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

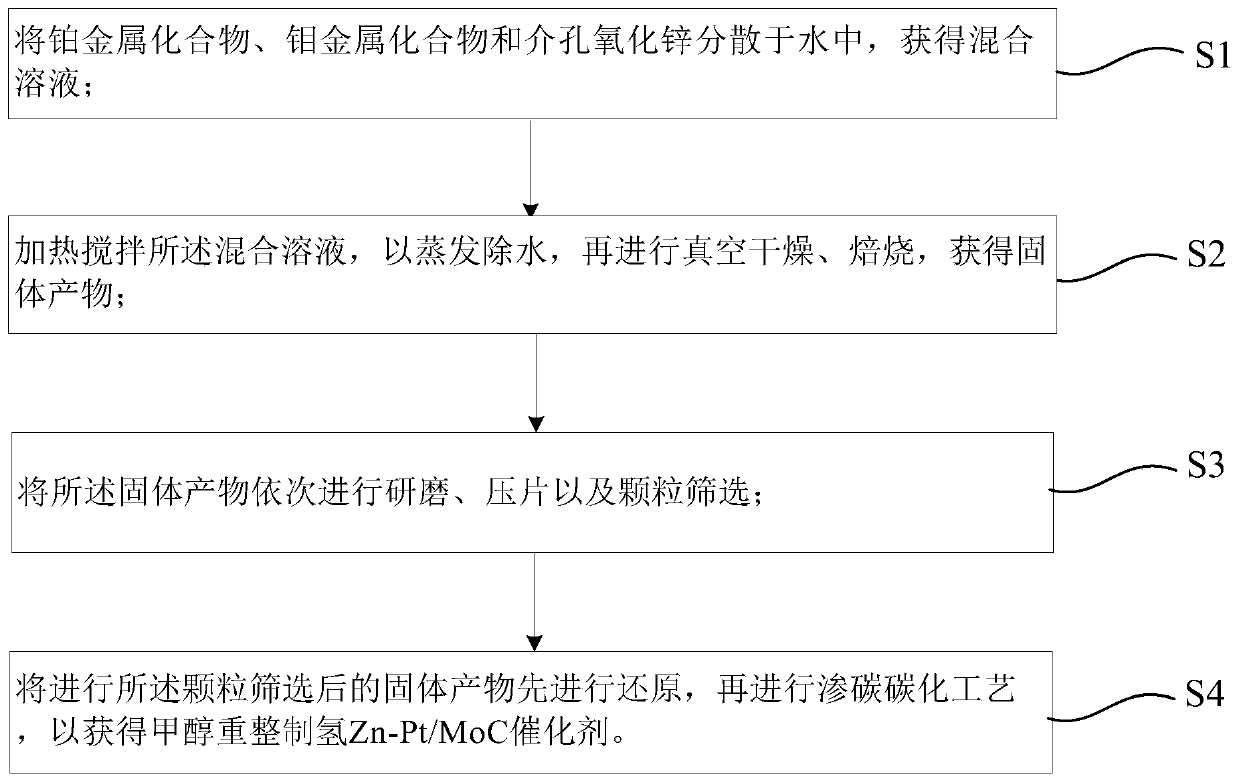

Catalyst for hydrogen production by methanol reforming and preparation method of catalyst

ActiveCN110075889AHigh reforming hydrogen production activityImprove reaction stabilityHydrogenPhysical/chemical process catalystsWater vaporVacuum drying

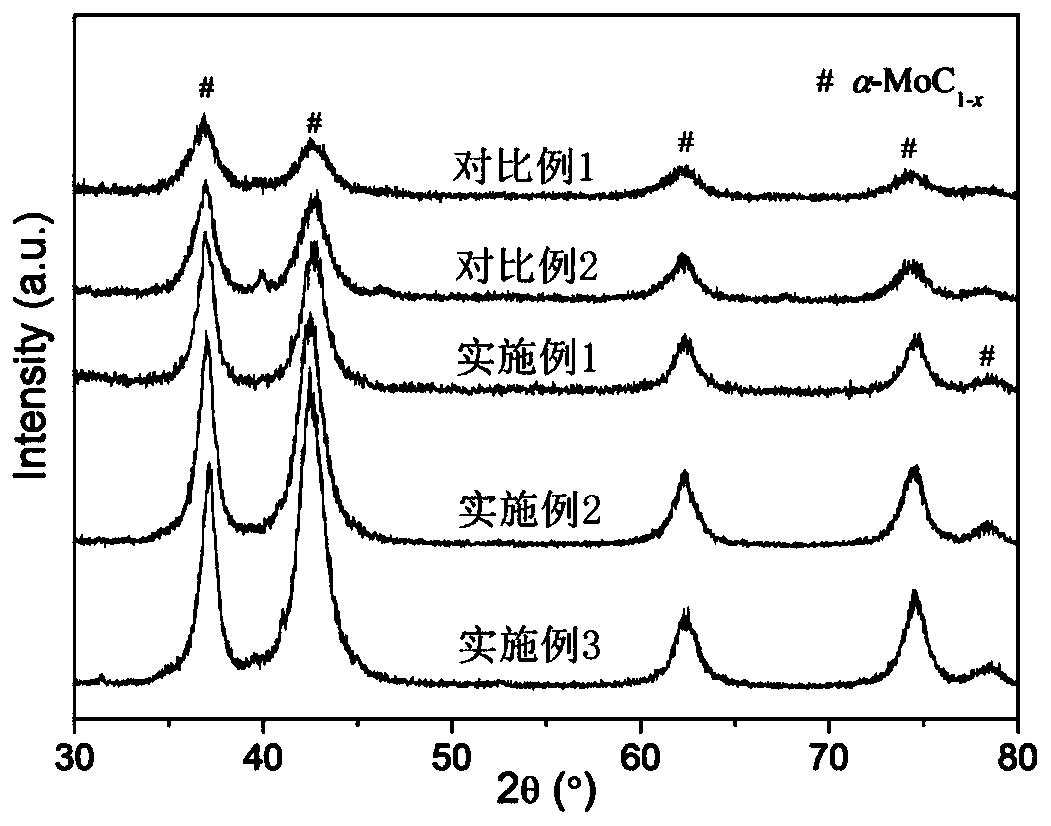

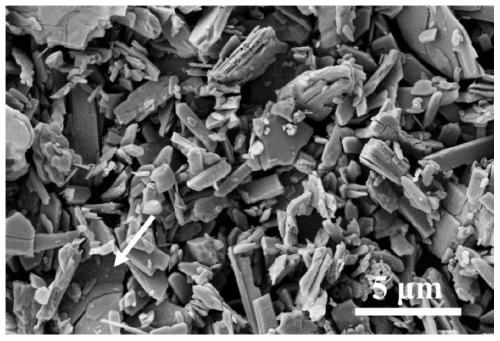

The invention provides a catalyst for hydrogen production by methanol reforming and a preparation method of the catalyst. The preparation method at least comprises the following steps: firstly, dispersing platinum metal compounds, molybdenum metal compounds and mesoporous zinc oxide in water to obtain a mixed solution; then, heating and stirring the mixed solution to evaporate and remove water, and performing vacuum drying and roasting to obtain a solid product; grinding and sheeting the solid product, and performing particle screening; finally, reducing the solid product after particle screening and then performing carburizing and carbonizing to obtain the Zn-Pt / MoC catalyst for hydrogen production by methanol reforming. The catalyst obtained with the preparation method can efficiently and stably catalyze methanol steam reforming to produce hydrogen under the conditions of low temperature and normal pressure (120-160 DEG C, 1 atm), and no byproduct carbon monoxide is generated in thereaction process, so that the catalyst has good application prospect.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Steam Reforming Of Methanol

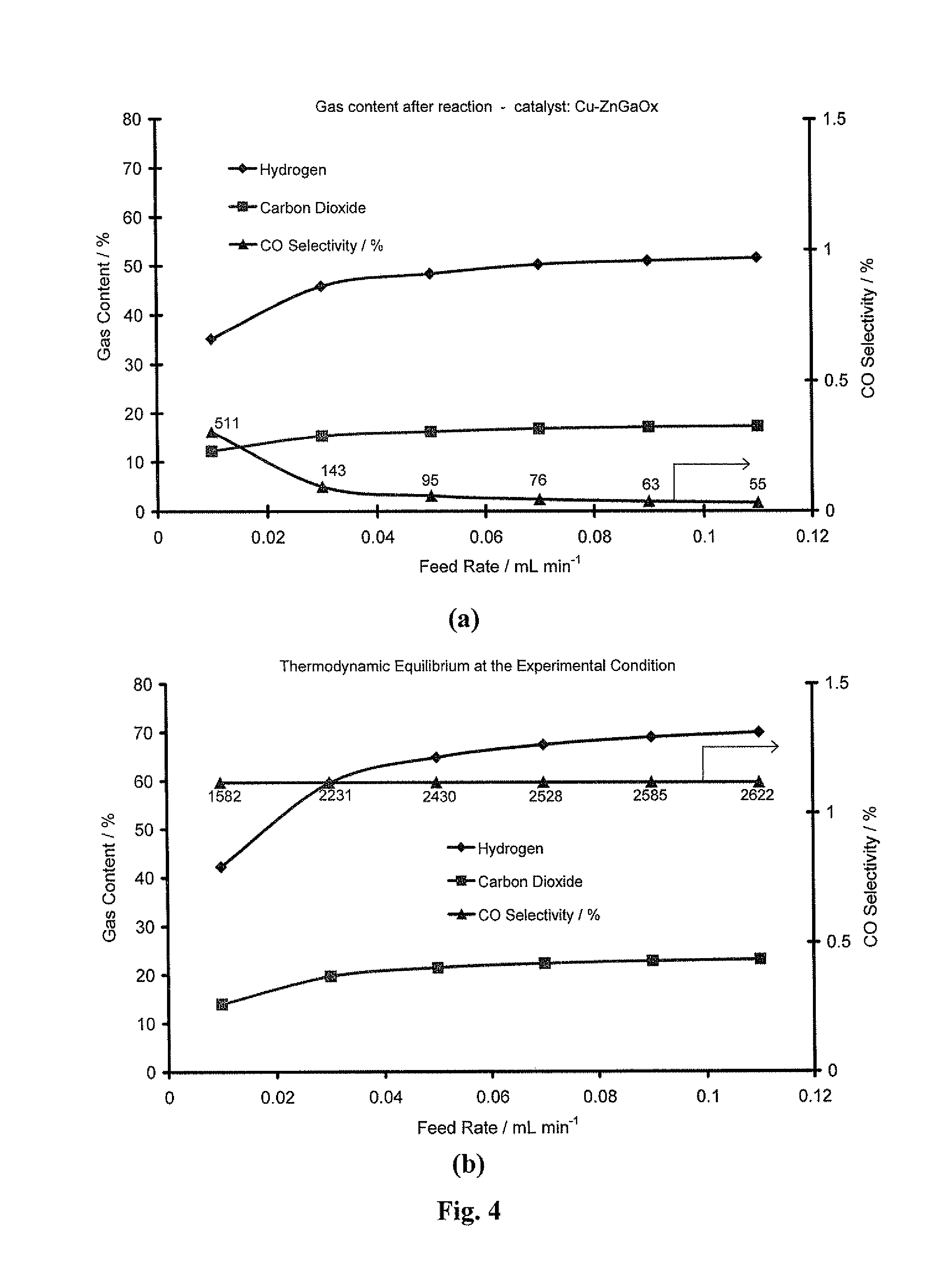

InactiveUS20140308597A1Organic compound preparationHeterogenous catalyst chemical elementsWater vaporGas phase

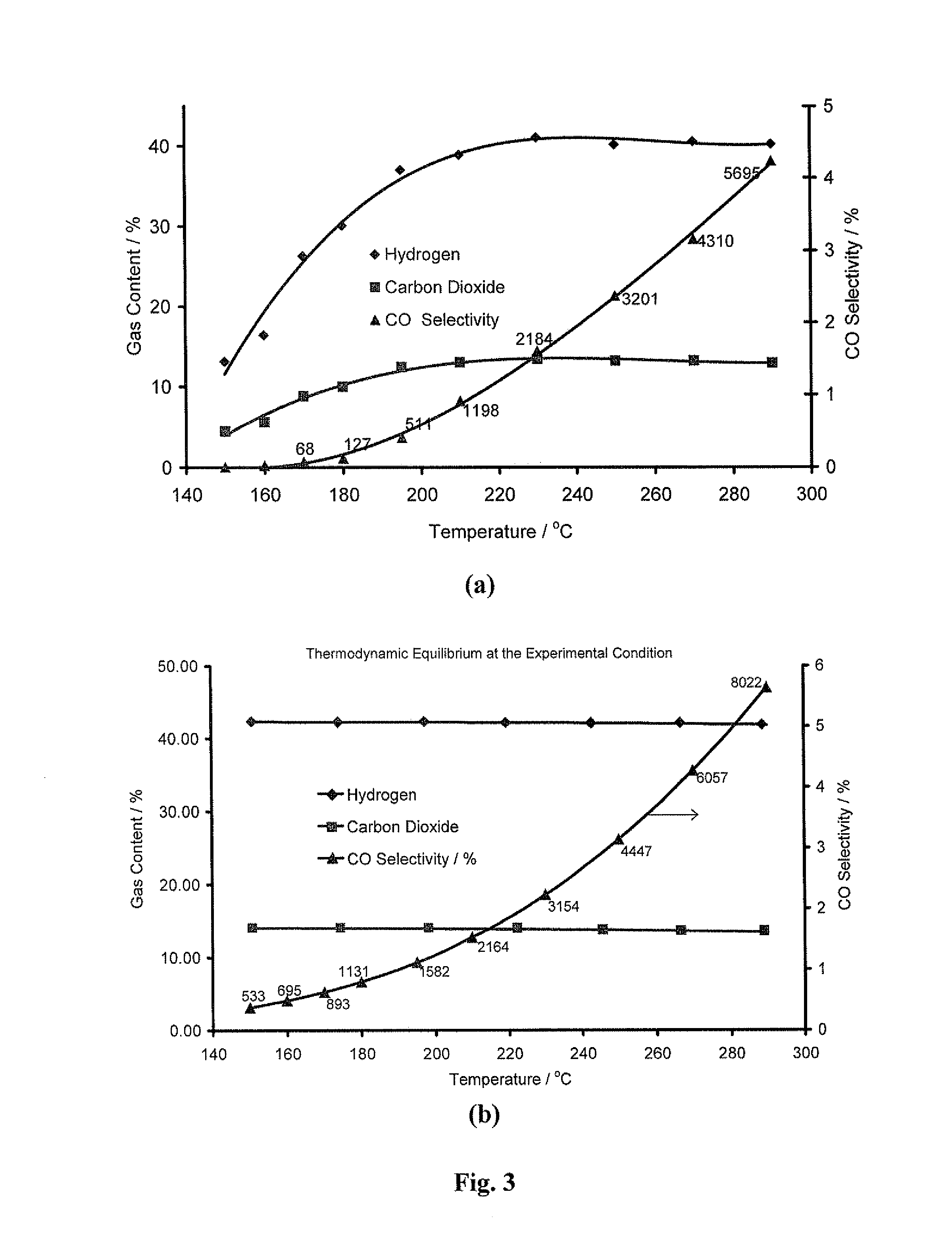

The invention provides a process for producing H2 by steam reforming of methanol, which process comprises contacting a gas phase comprising (a) CH3OH and (b) H20 with a solid catalyst, which solid catalyst comprises a mixed metal oxide, which mixed metal oxide comprises copper, zinc and gallium, wherein the atomic percentage of copper relative to the total number of metal atoms in the oxide is from 20 at. % to 55 at. %. The solid catalyst itself is also an aspect of the present invention, as is a process for producing the catalyst, which process comprises: (1) a co-precipitation step, comprising contacting: (a) a solution of copper nitrate, zinc nitrate and gallium nitrate, wherein the atomic percentage of copper relative to the total number of metal atoms in said solution is from 20 at. % to 55 at. %, with (b) a metal carbonate, to produce a co-precipitate comprising said copper, zinc and gallium; (2) a separation step, comprising separating the co-precipitate from solution; (3) a calcination step, comprising calcining the co-precipitate by heating the co-precipitate in air; and, optionally, (4) a reduction step, comprising heating the calcined product in the en presence of H2. Further provided is the use of the catalyst of the invention in a process for producing H2 by steam reforming of methanol. Additionally, the invention provides a fuel cell system comprising a fuel cell, such as a proton exchange membrane (PEM) fuel cell, and a methanol reformer comprising a catalyst of the invention. Portable electronic devices comprising a fuel cell system of the invention are also provided. A further aspect of the invention is the use of a catalyst of the invention in a process for producing methanol by the hydrogenation of carbon dioxide. Thus, the invention further provides a process for producing methanol by the hydrogenation of carbon dioxide, which process comprises contacting a gas phase comprising (a) C02 and (b) H2, with a catalyst of the invention.

Owner:OXFORD UNIV INNOVATION LTD

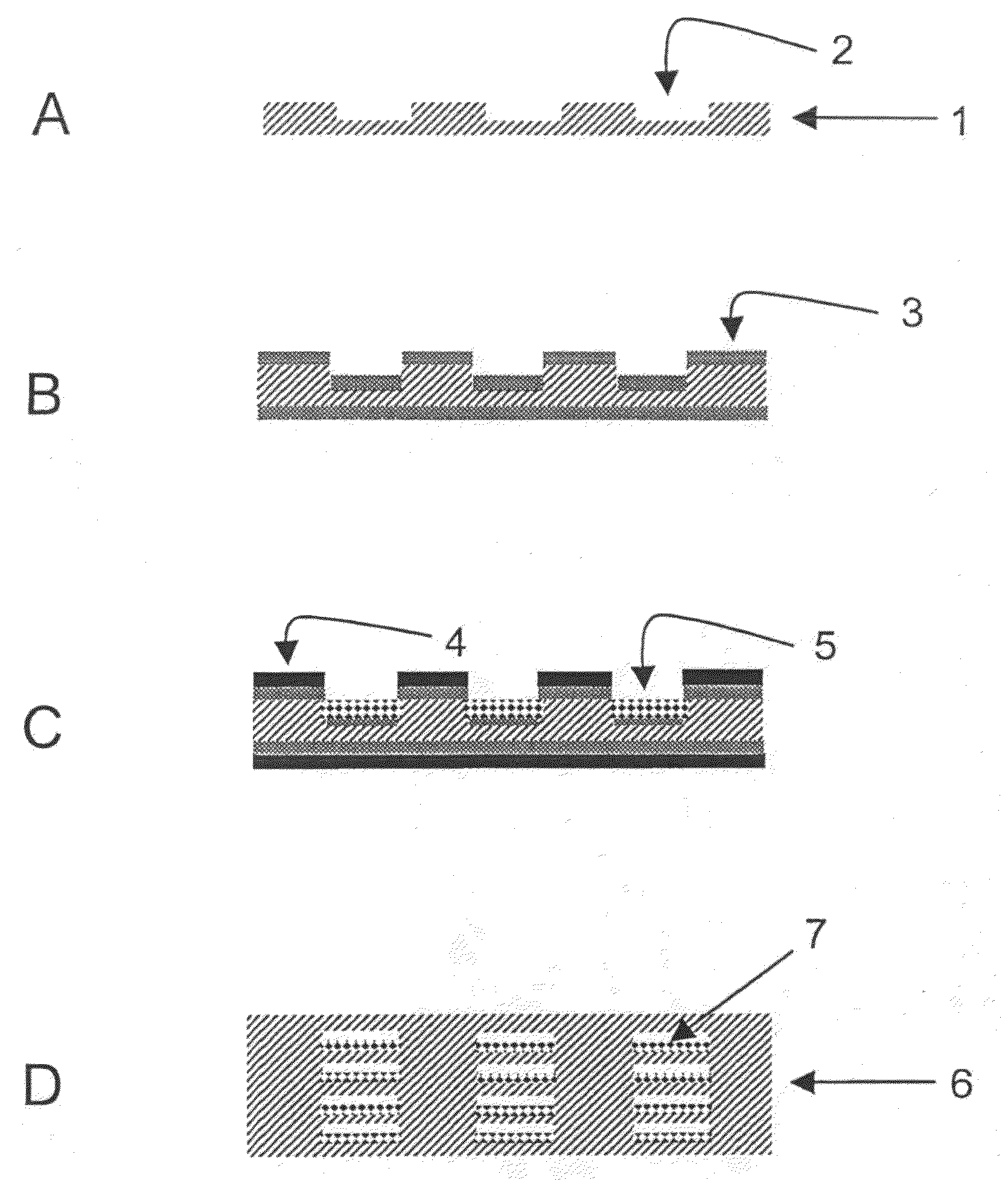

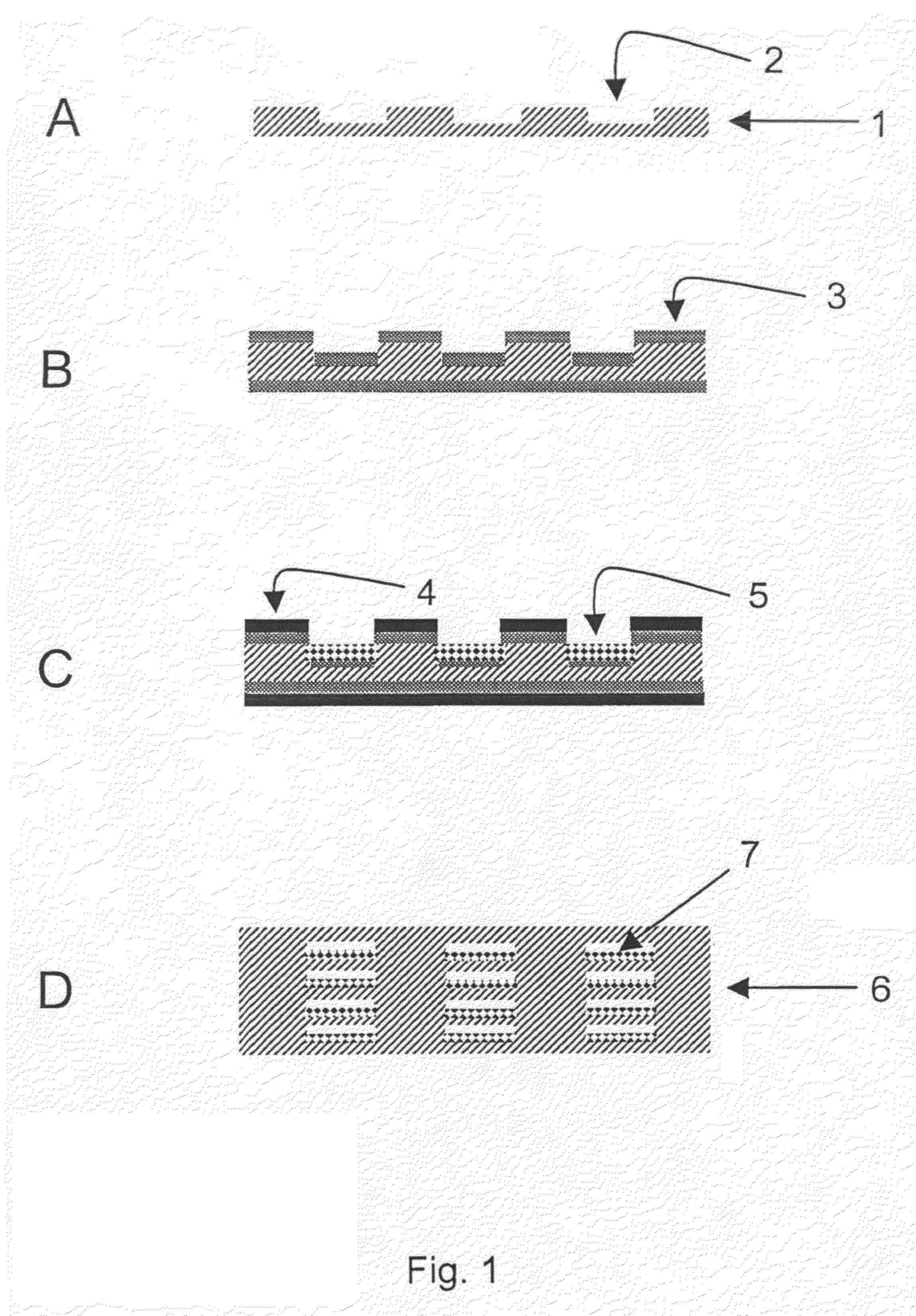

Process for manufacturing a microreactor and its use as a reformer

InactiveUS7909987B2Avoid affecting efficiency of catalystIncrease flexibilityHydrogenPhysical/chemical process catalystsMicroreactorMicro structure

For manufacturing micro-structured reactors with passageways loaded with catalyst using the pre-coat method, a method is provided which comprises the following method steps: a) producing reactor layers having bonding areas as well as passageway areas in which the passageways are formed, b) applying at least one bonding layer onto the reactor layers in the bonding areas, c) loading the reactor layers in the passageway areas with the catalyst and d) bonding the reactor layers, the bonding layer being applied and masked before the reactor layers are loaded with the catalyst. As a result, it is ensured that the efficiency of the catalyst will not be affected during manufacturing. The reactor may be used as a methane and methanol reformer in particular.

Owner:ATOTECH DEUT GMBH

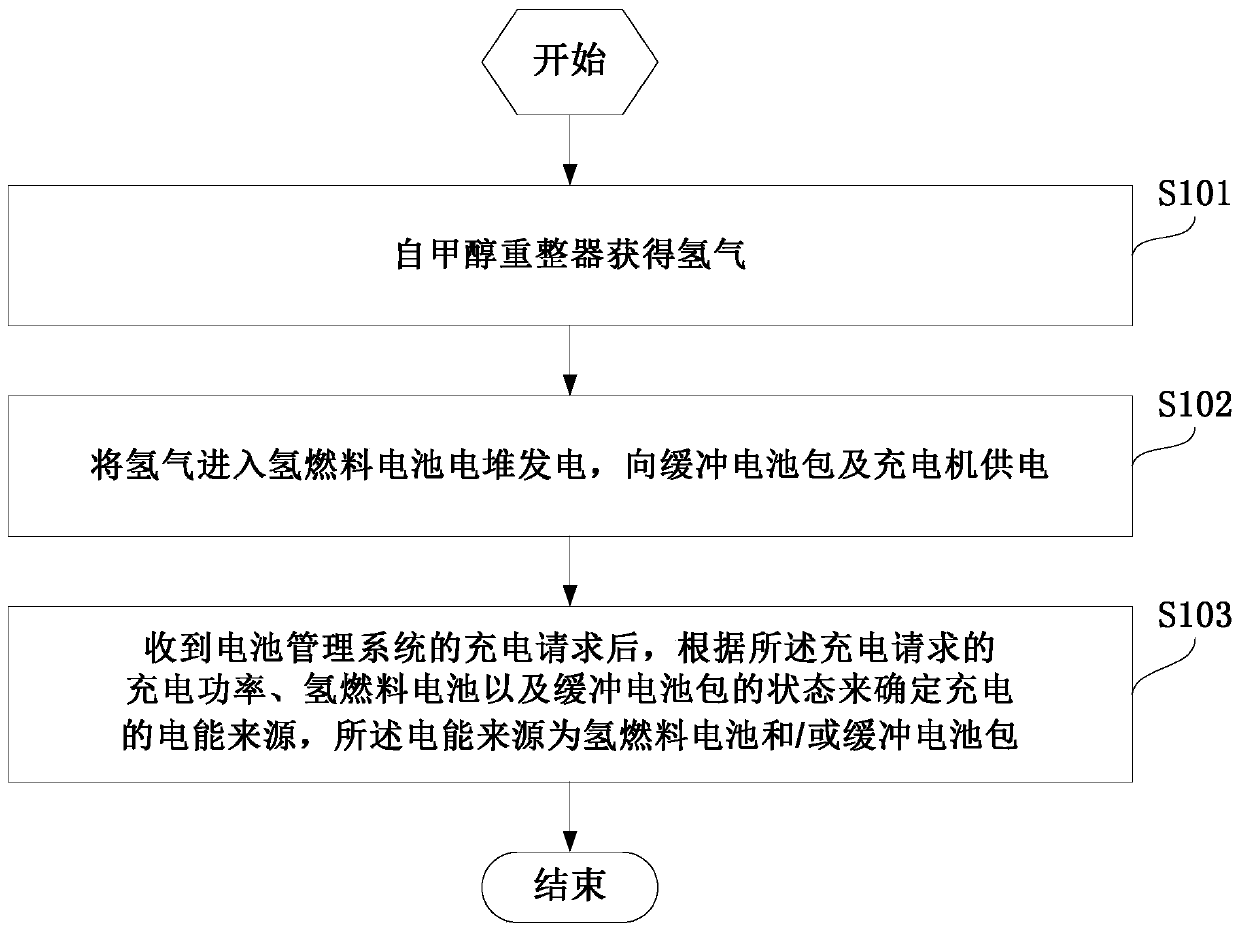

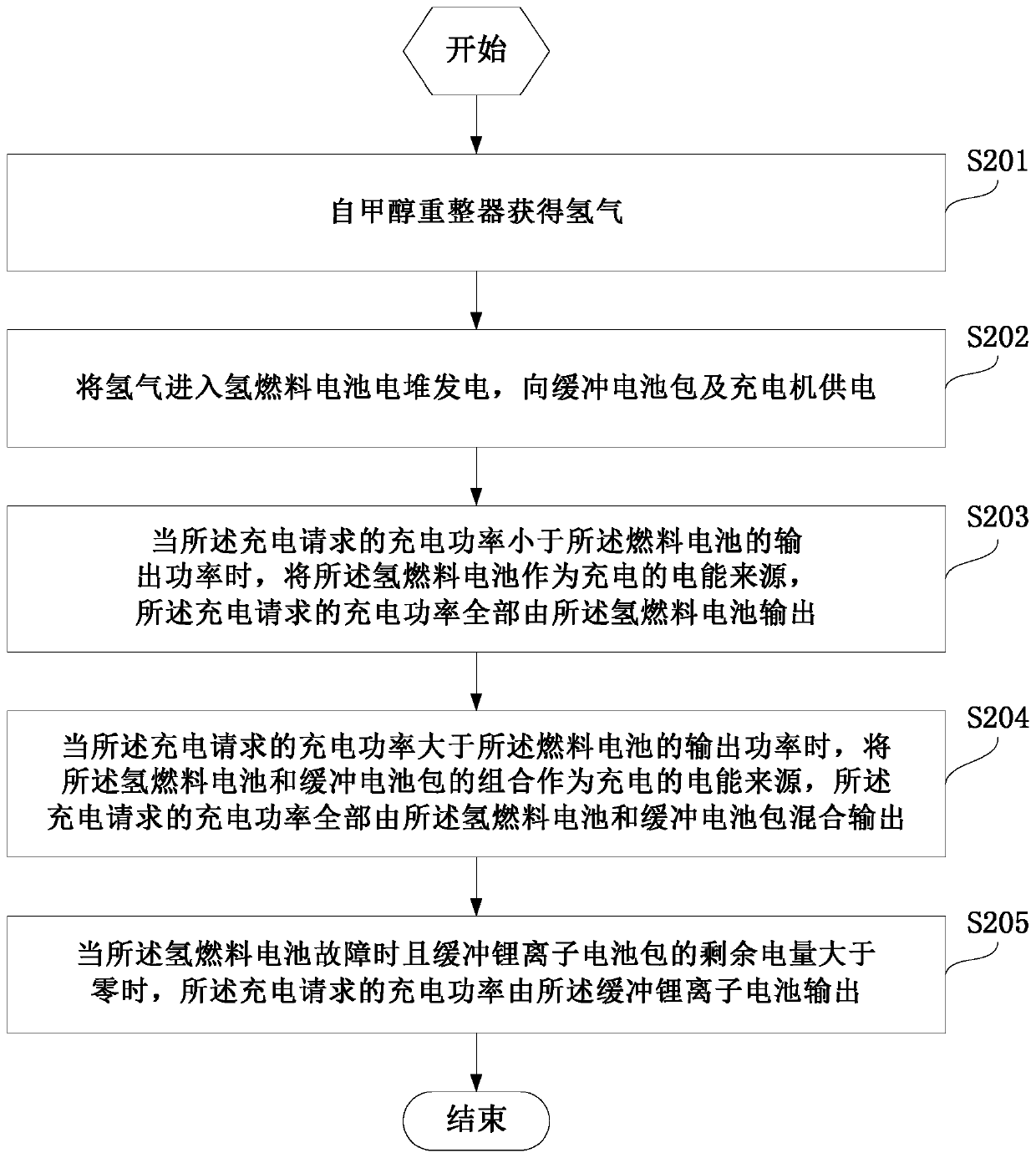

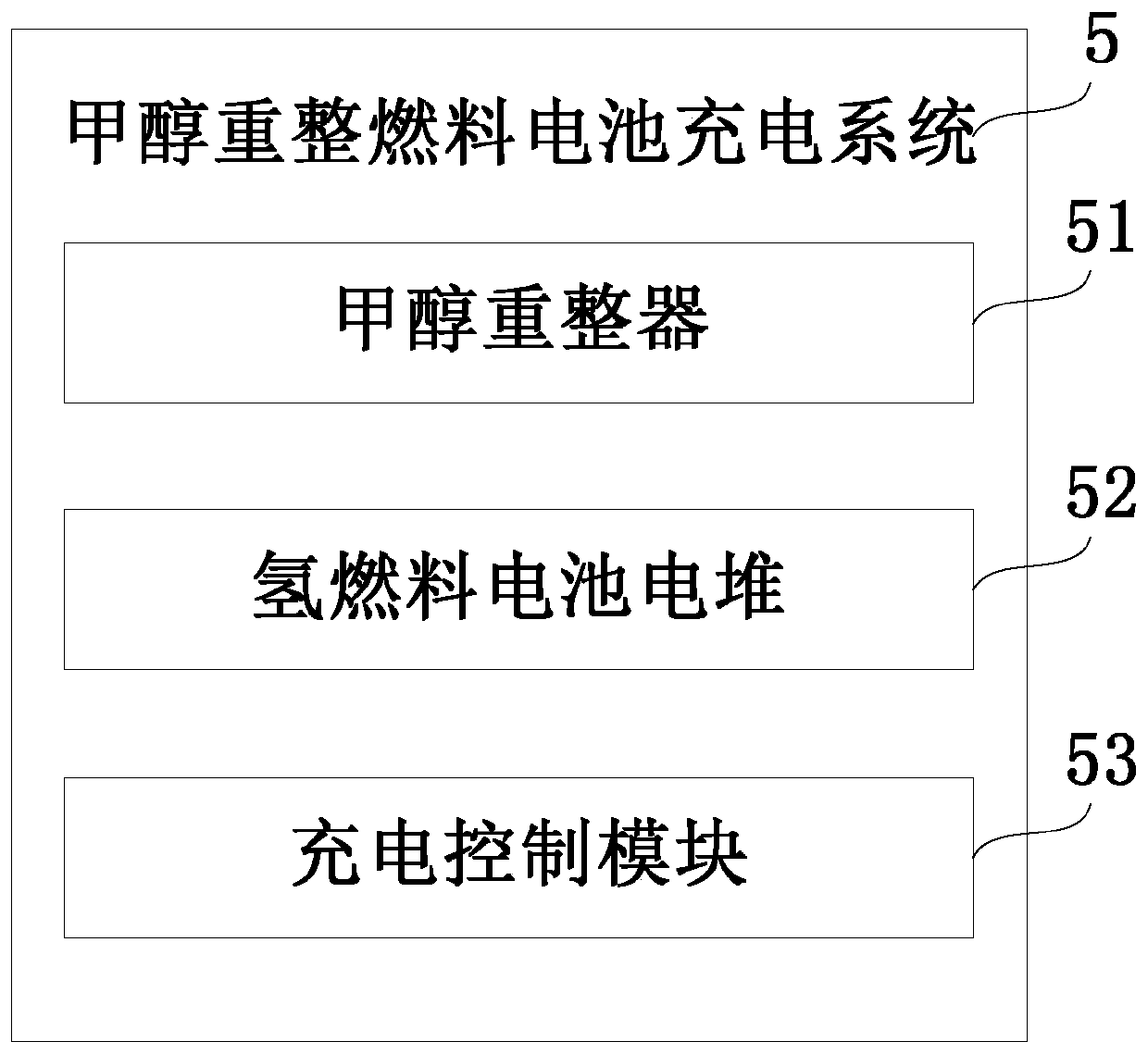

Methanol reforming fuel cell charging method, system and equipment, and storage medium

InactiveCN109733237AStable output powerIncrease profitCharging stationsSecondary cells charging/dischargingElectricityHydrogen fuel cell

The invention provides a methanol reforming fuel cell charging method, system and equipment, and a storage medium. The methanol reforming fuel cell charging method comprises the following steps: obtaining hydrogen from a methanol reformer; introducing hydrogen into a hydrogen fuel cell stack to generate electricity, and supplying electricity to a buffer cell pack and a charger; and after a charging request of a battery management module is received, determining a charging electric energy source according to the charging power of the charging request and the states of the hydrogen fuel cell andthe buffer battery pack, wherein the electric energy source is the hydrogen fuel cell and / or the buffer battery pack. The charging power is high, output power is stable, the utilization rate is high,the cost is moderate, and the methanol reforming fuel cell charging method can be applied both in a fixed mode and in a movable mode, so that the application scene is wide.

Owner:AIWAYS AUTOMOBILE CO LTD

Preparation method of platinum catalyst by taking porous foaming aluminum as carrier for methyl alcohol reformer combustion chamber

ActiveCN103949244AFully contactedImprove output efficiencyCell electrodesMetal/metal-oxides/metal-hydroxide catalystsElectrolytic agentAluminate

The invention discloses a preparation method of a platinum catalyst by taking porous foaming aluminum as a carrier for a methyl alcohol reformer combustion chamber. The preparation method comprises the following steps: placing porous foaming aluminum as an anode into electrolyte containing one or two of aluminate, silicate, fluoroziconate and sodium hypophosphite, carrying out micro-arc oxidation treatment by applying a direct-current or alternating-current voltage for 10-120 minutes, forming a layer of porous oxidation ceramic membrane on the surface of the foaming aluminum, and loading the Pt based catalyst on the surface of the ceramic membrane serving as a substrate, thereby obtaining the Pt based catalyst for the methyl alcohol reformer combustion chamber. According to the invention, the problems of insufficient contact of hydrogen and platinum in the existing methyl alcohol reformer combustion chamber, low catalyst utilization ratio, adverse effect to the catalyst by a catalyst framework and the like are solved.

Owner:HARBIN INST OF TECH

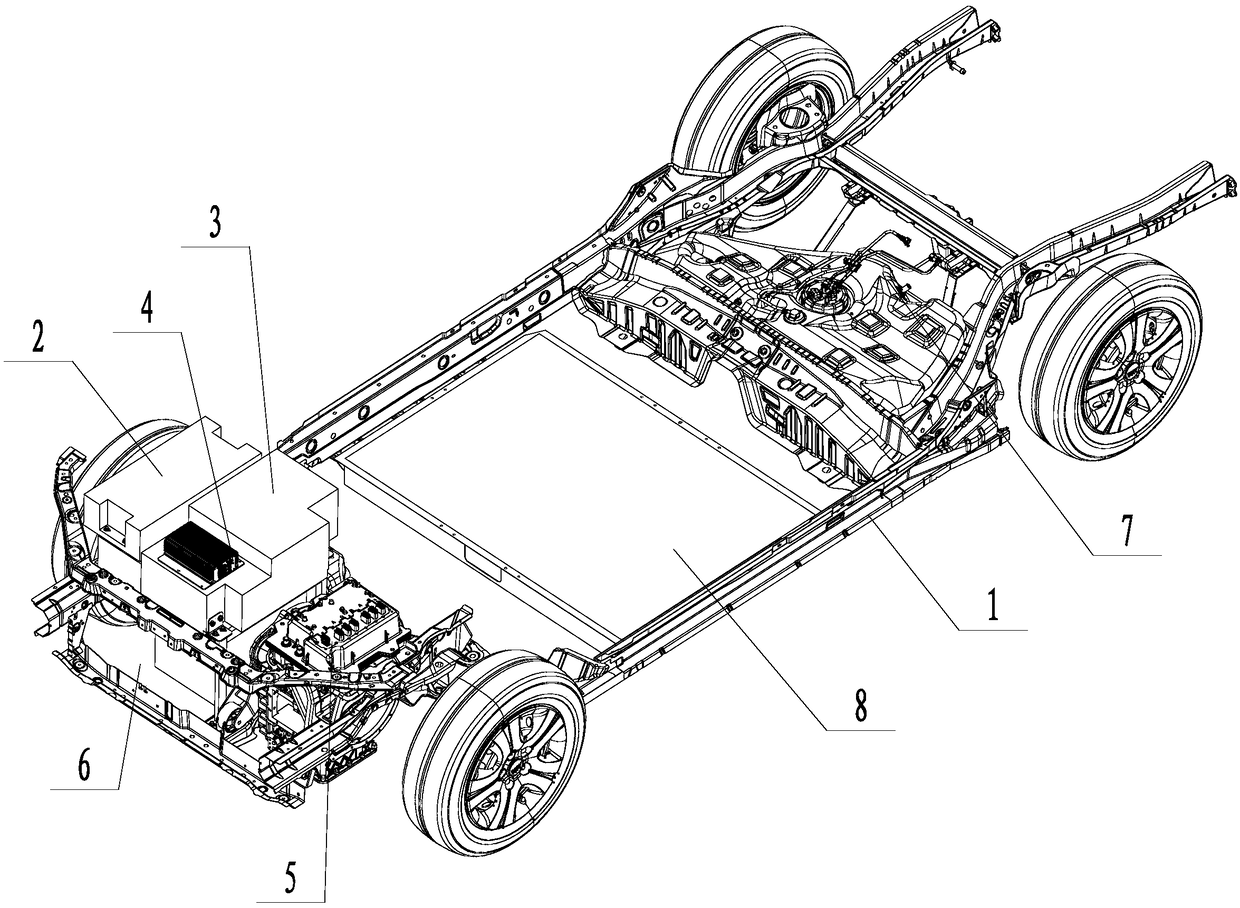

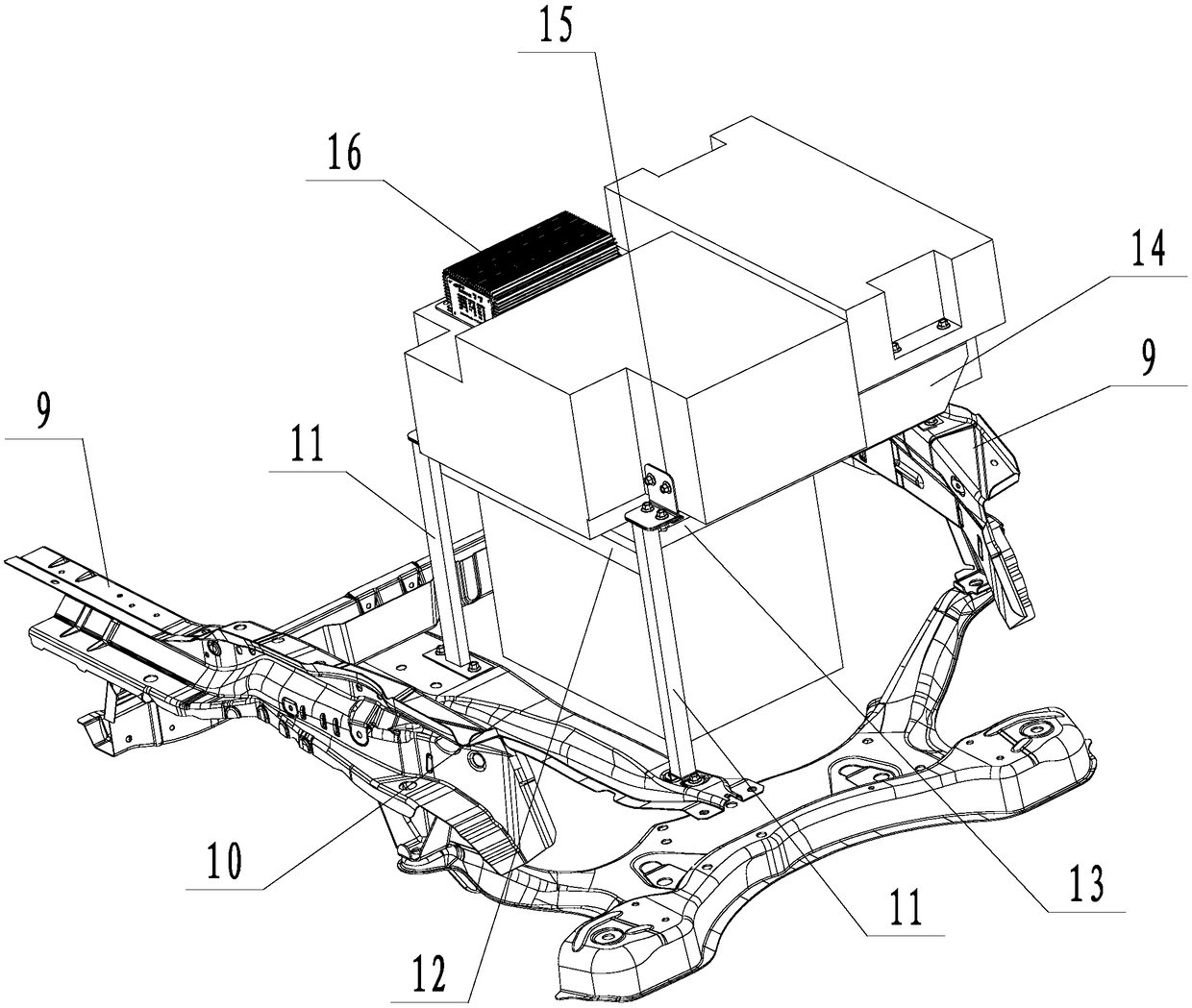

Fuel cell hydrogen powered automobile

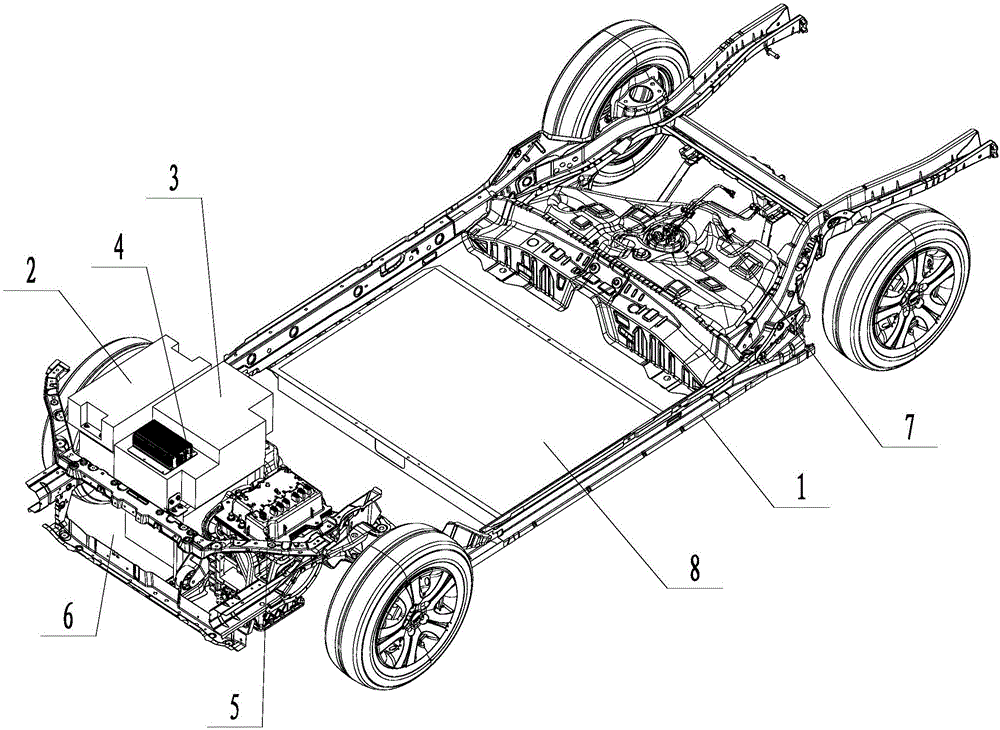

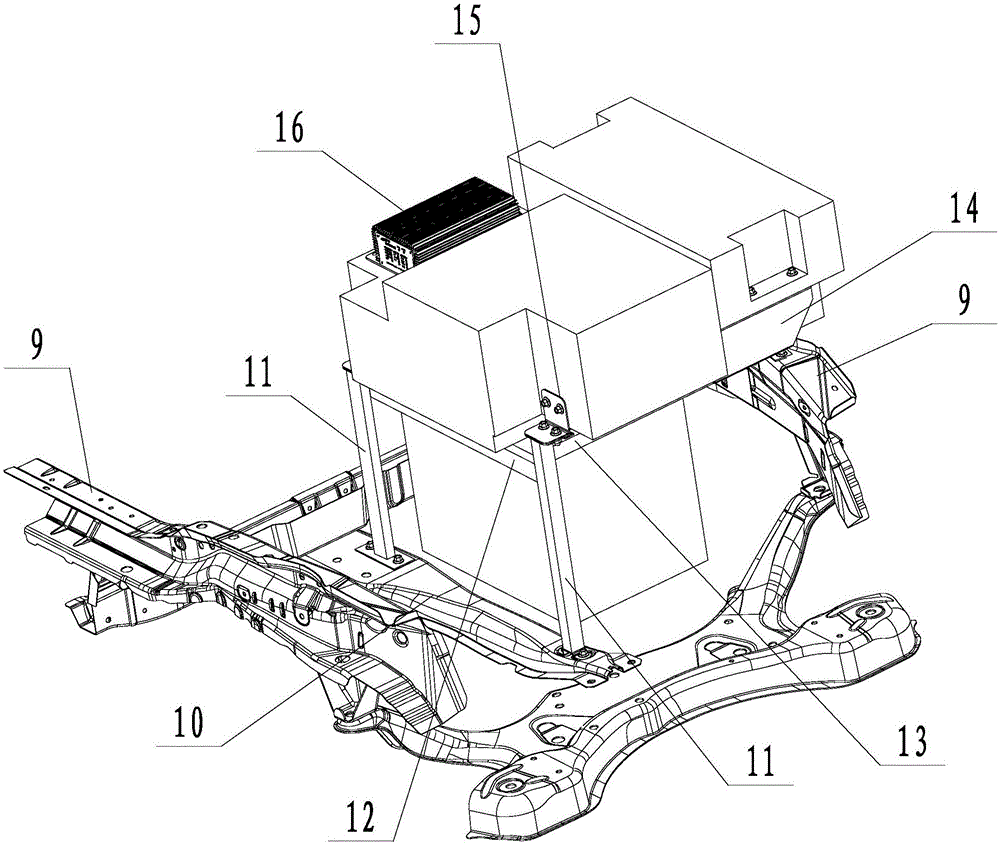

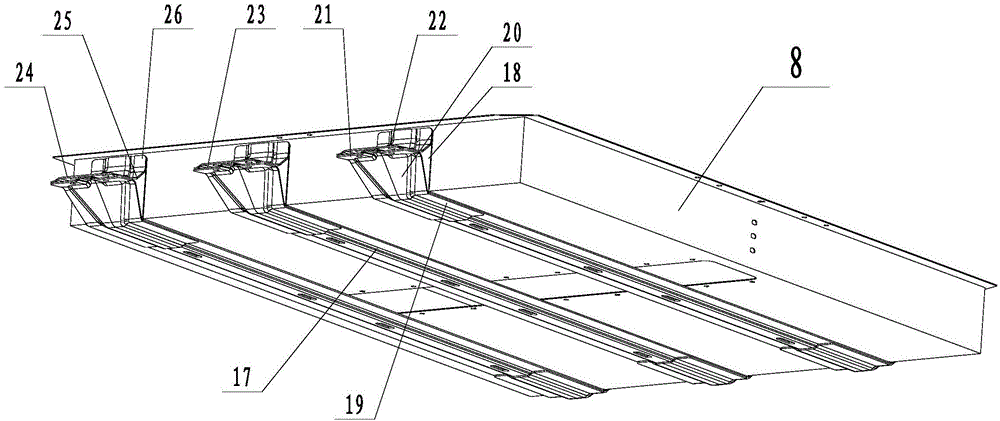

ActiveCN106585395AEasy to assembleFirmly connectedUnderstructuresPropulsion by batteries/cellsPower batteryMotor drive

The invention discloses a fuel cell hydrogen powered automobile. The objective of the invention is to solve the problems of incontinence in hydrogen feeding, hidden security hazards in use, low structural compactness and inconvenient assembly of an existing hydrogen fuel powered automobile. The fuel cell hydrogen powered automobile of the invention comprises a frame; the front end of the frame is provided with a hydrogen production by methanol reformer, a fuel cell, a DC / DC converter, a motor driving system and an automobile heat dissipation system; the rear end of the frame is provided with a methanol tank; the frame is provided with a lithium-ion power battery near the middle portion of the frame; the methanol tank is connected with the hydrogen production by methanol reformer through a pipeline; the hydrogen production by methanol reformer provides hydrogen for the fuel cell; and the fuel cell is connected in parallel with the lithium-ion battery through the DC / DC converter so as to provide power for the motor driving system. According to the fuel cell hydrogen powered automobile of the invention, the hydrogen production by methanol reformer installed on the automobile is adopted to provide hydrogen, and so that the feeding of hydrogen is not required, and a hydrogen tank can be omitted, and the automobile is more secure and reliable in a use process. The fuel cell hydrogen powered automobile has the advantages of highly compact structure, convenient assembly and reliable connection.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

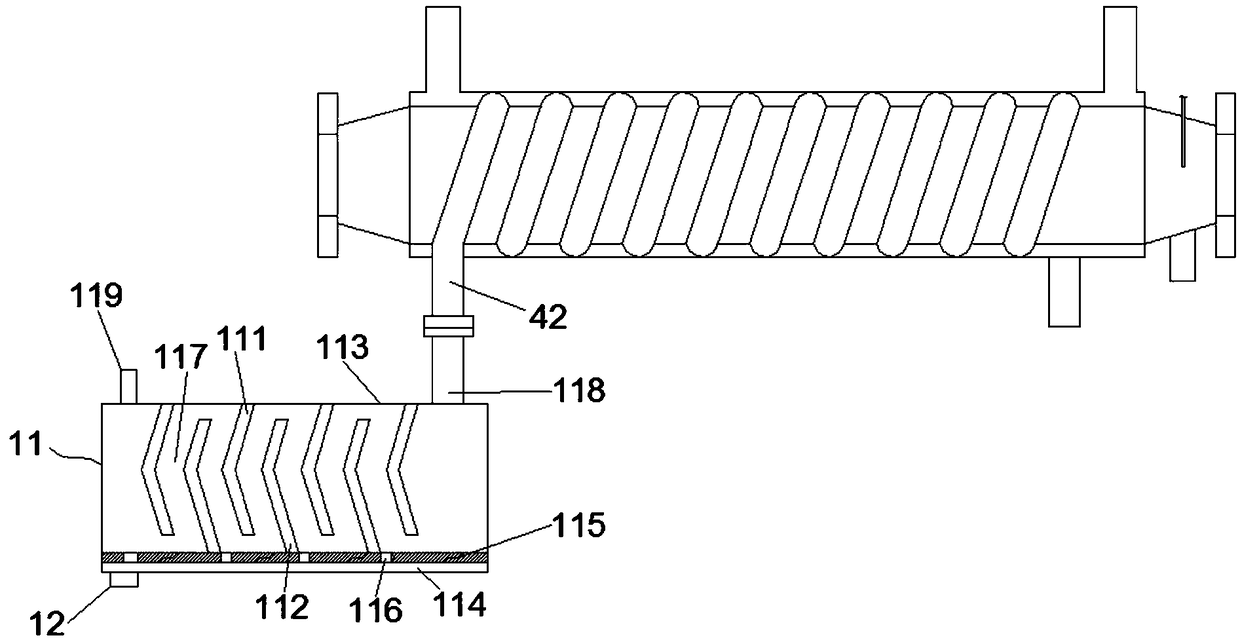

On-line methanol reformer using baffle separation mechanism and engine exhaust gas

PendingCN109179321ARealize gas-liquid separationImprove work efficiencyHydrogenNon-fuel substance addition to fuelEngineeringMethanol

The invention discloses an on-line methanol reformer using a baffle separation mechanism and engine exhaust gas. The on-line methanol reformer comprises a separation section and a reformer. The separation section comprises a separation plate. The separation plate is horizontally assembled on the inner wall of the separation section casing. A liquid collection chamber is formed between the lower part of the separation plate and the inner wall of the separation section casing. The separation plate is provided with a plurality of liquid collecting holes. The top of the inner wall of the separation section casing is fixedly provided with a plurality of upper cooling baffles. The upper surface of the separation plate is fixedly provided with a plurality of lower cooling baffles. The upper cooling baffles and the lower cooling baffles are arranged at intervals. The upper cooling baffles and the lower cooling baffles form an S-shaped cooling and separation channel in the separation section casing. Two sides of the top of the separation section casing are respectively provided with a methanol mixture inlet and a gaseous methanol outlet. The bottom of the separation section casing is provided with a liquid methanol outlet. The on-line methanol reformer can fast realize the gas-liquid separation of the methanol mixture discharged from the reformer and improve the work efficiency of the reformer.

Owner:SHENYANG AEROSPACE UNIVERSITY

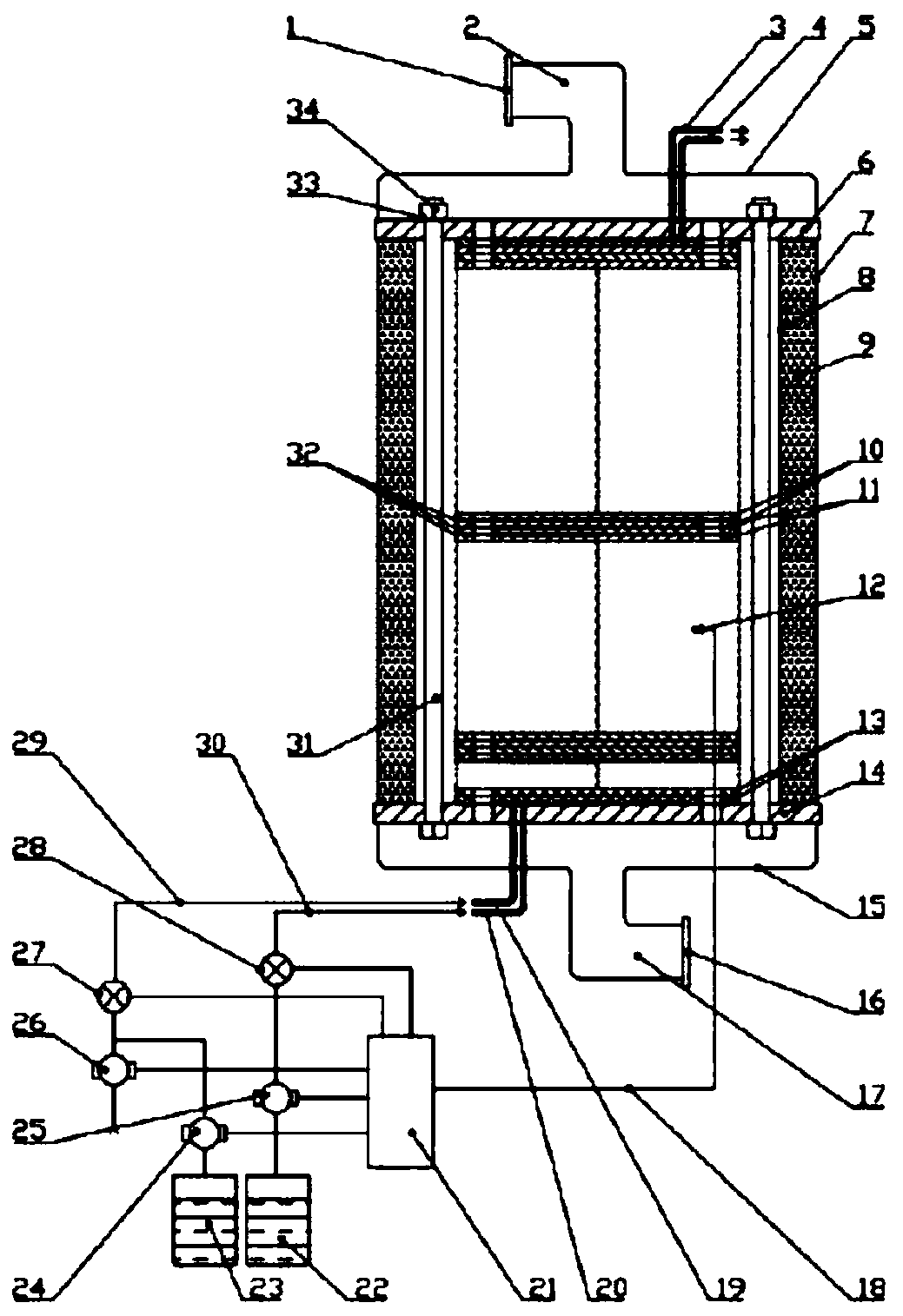

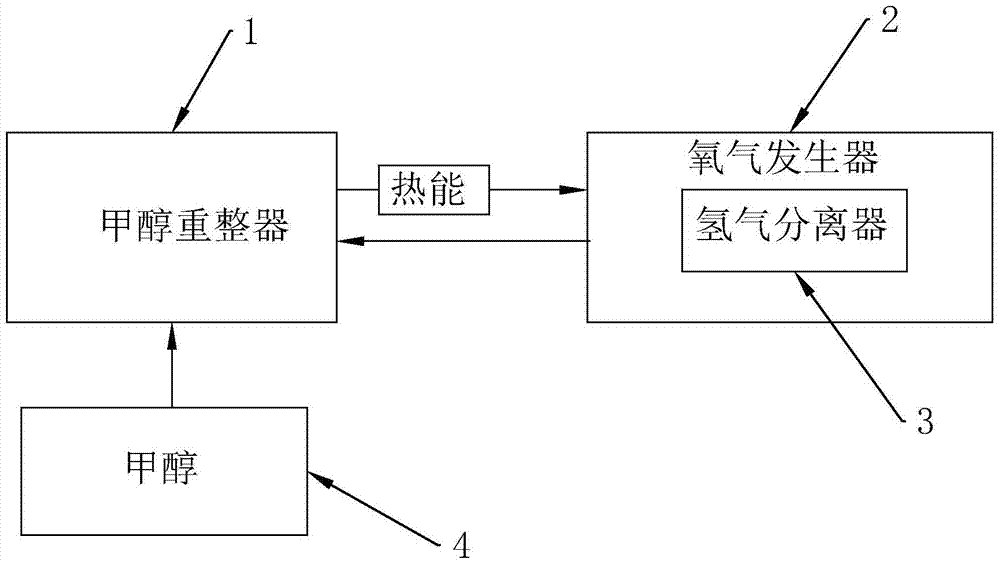

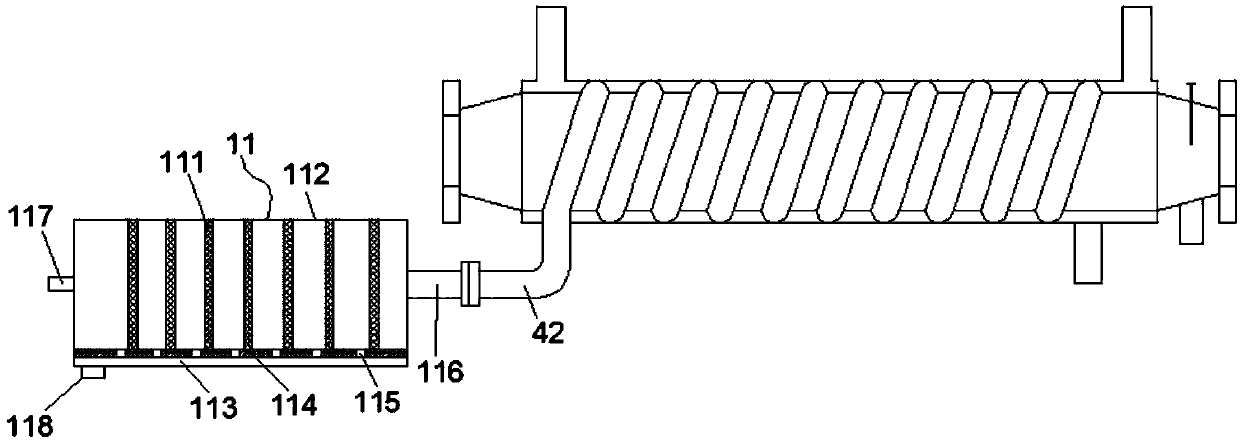

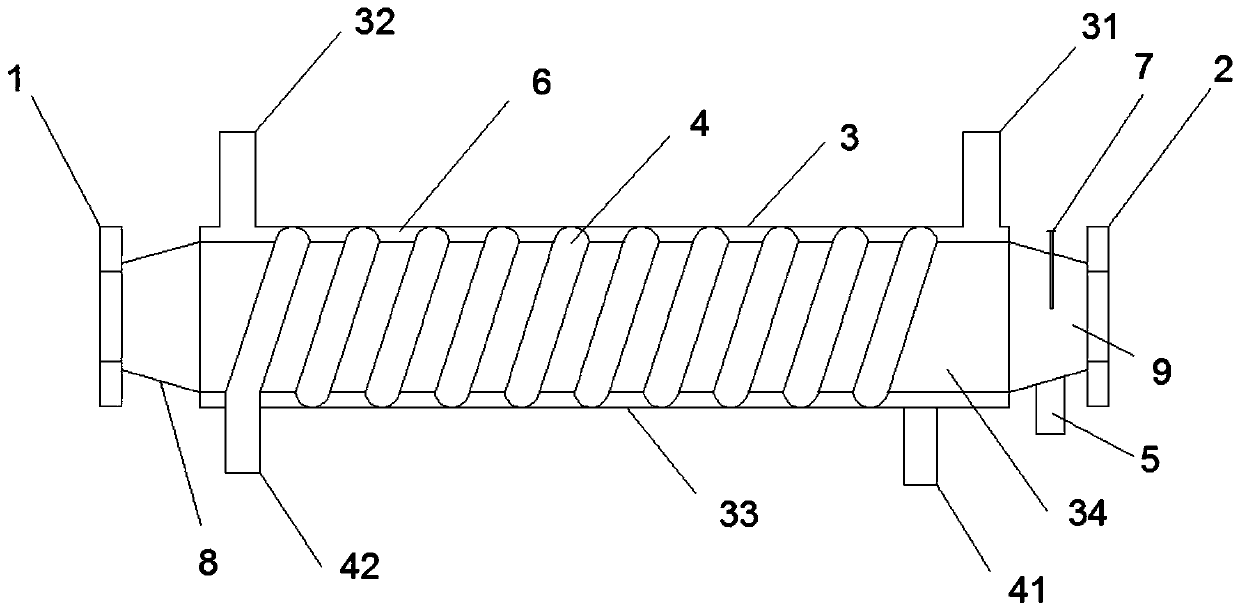

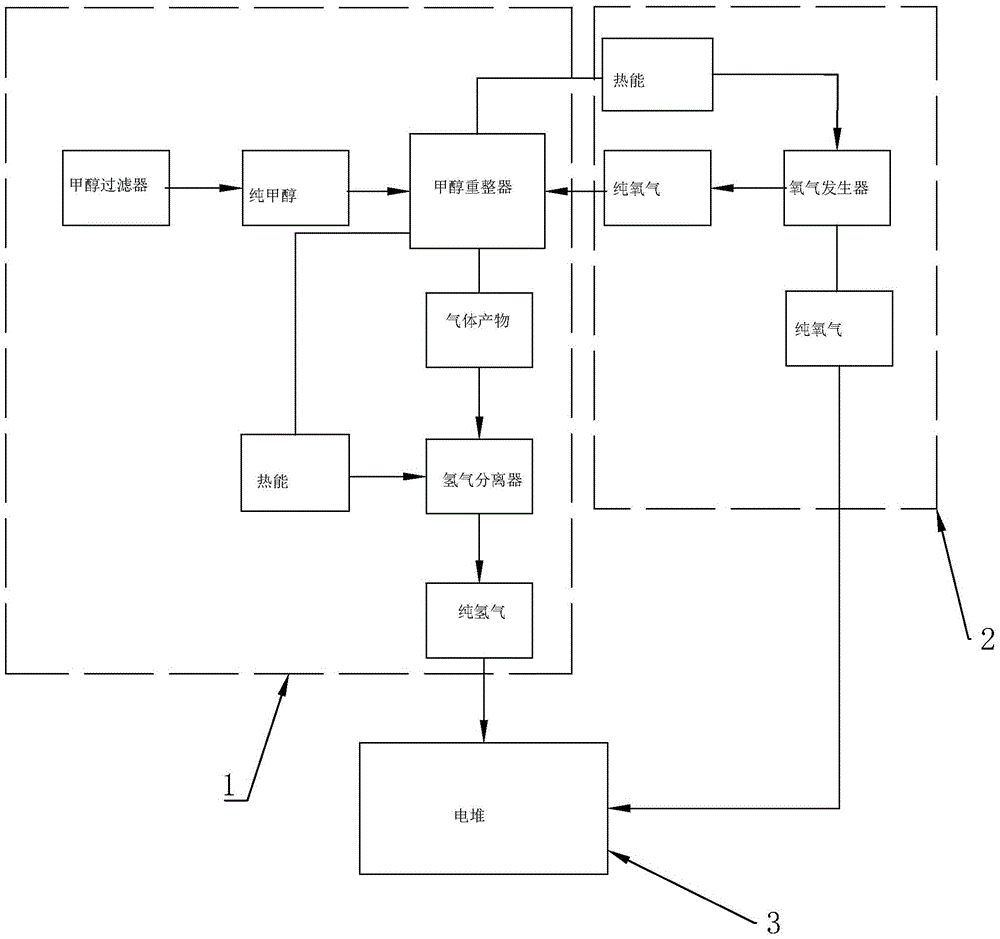

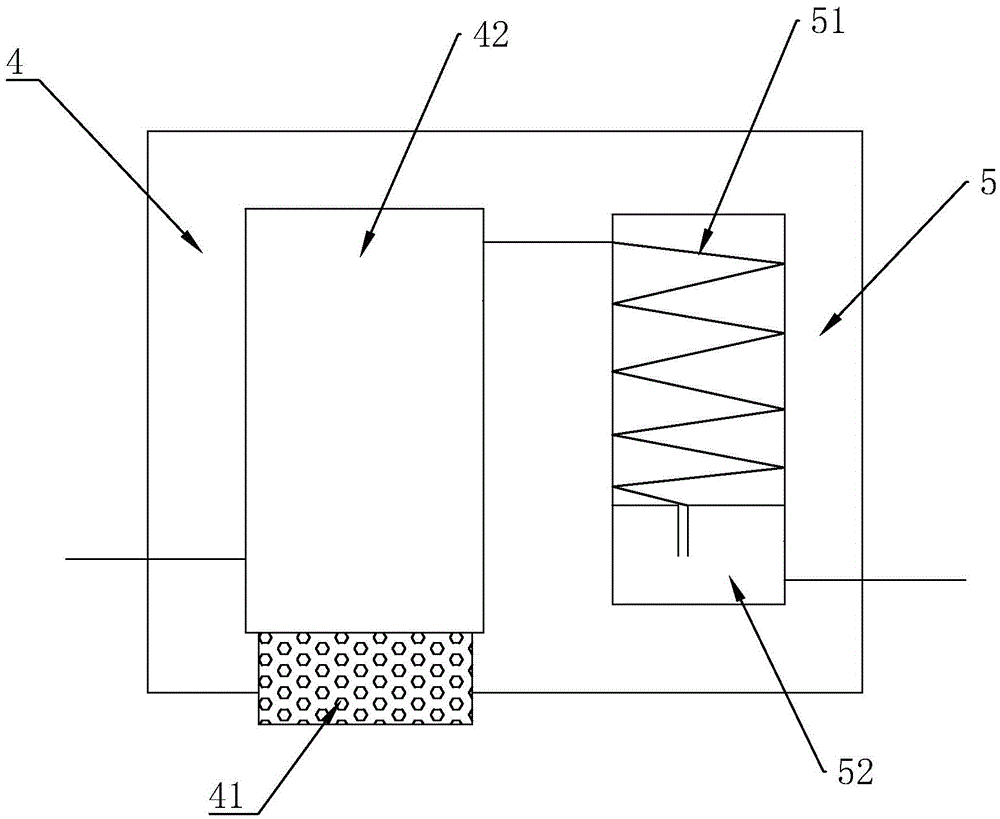

Hydrogen purifying module of pure hydrogen and pure oxygen high-temperature battery system

InactiveCN107010596AIncrease costLow efficiencyHydrogen/synthetic gas productionSpecific gas purification/separationPartial oxidationHydrogen

The invention discloses a hydrogen purifying module of a pure hydrogen and pure oxygen high-temperature battery system. The hydrogen purifying module adopts the technical scheme that the hydrogen purifying module comprises a methanol reformer, an oxygen generator and a hydrogen generator, wherein the oxygen generator is connected with the methanol reformer; the hydrogen separator is arranged in the oxygen generator; the methanol reformer utilizes methanol raw material and oxygen produced by the oxygen generator to generate part of oxidizing and oxidizing reforming reaction; the oxygen generator uses heat produced by the reaction of the methanol reformer to purify the hydrogen and oxygen; the methanol raw material is filtered pure methanol, and a palladium composite film is arranged in the hydrogen separator. The hydrogen purifying module has the advantages that the hydrogen separator is arranged in the oxygen generator, the heat of the reforming reaction is utilized, and the hydrogen and oxygen are separated and purified; the efficiency is high, the cost is low, and the energy-saving and environment-friendly effects are realized.

Owner:上海博氢新能源科技有限公司

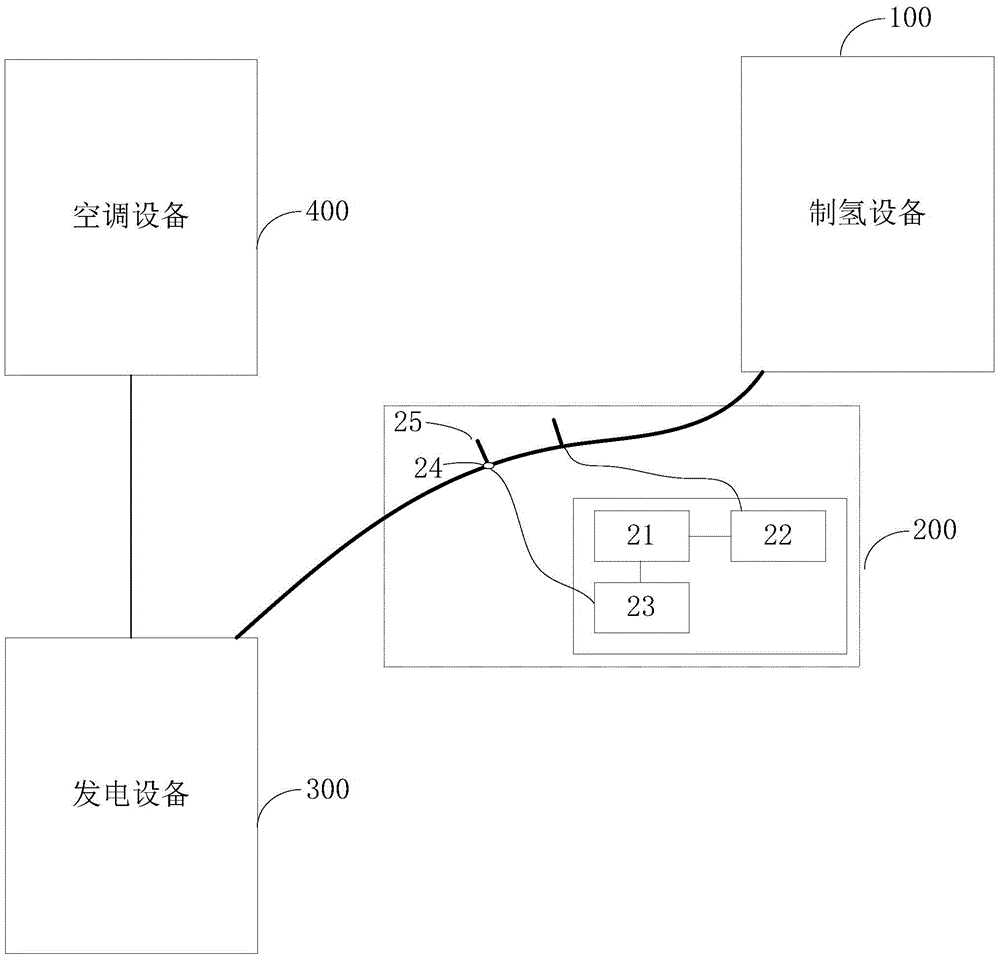

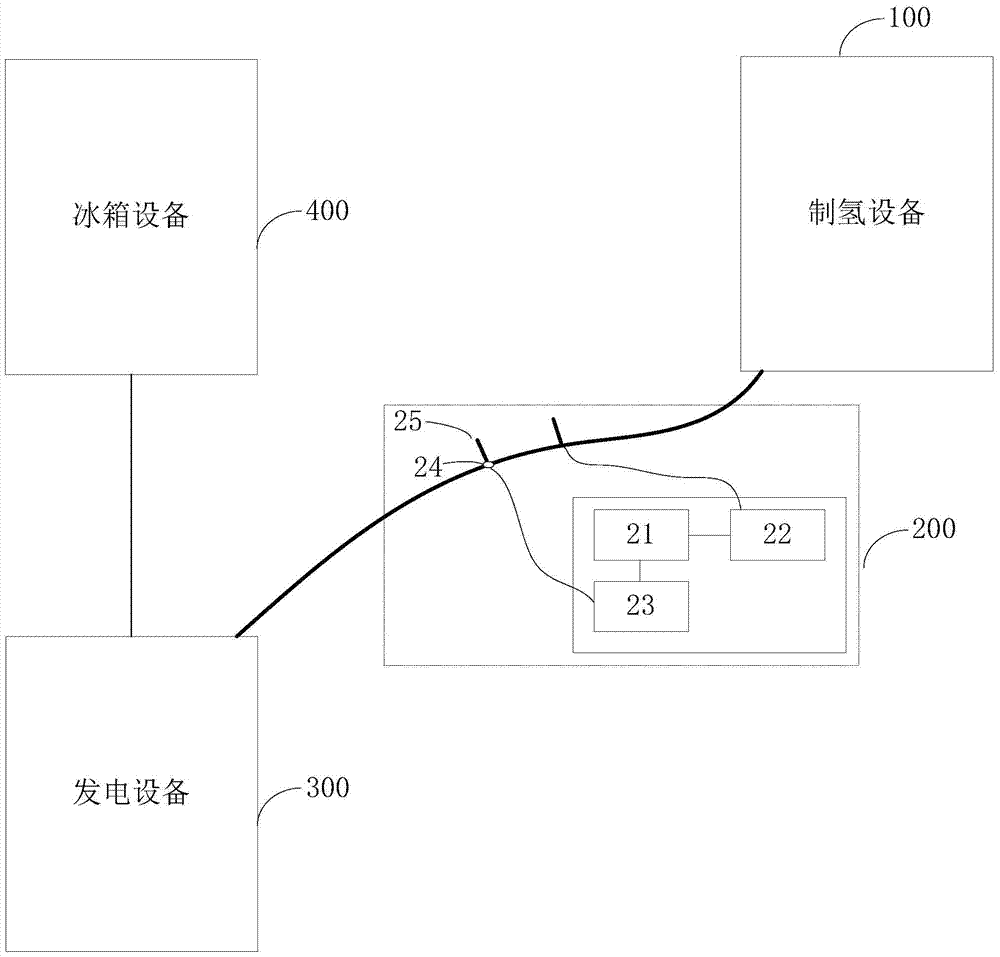

A methanol water reforming power generation air conditioning system and control method

The invention discloses an air-conditioning system with methanol liquid reforming and power generating functions and a control method. The air-conditioning system comprises hydrogen generation equipment, power generation equipment and air-conditioning equipment. The hydrogen generation equipment generates hydrogen by means of reforming methanol liquid, the generated hydrogen is delivered to the power generation equipment for generating power, and generated electric energy is supplied to the air-conditioning equipment, so that the air-conditioning equipment can run; the movable air-conditioning equipment without outdoor units comprises a connecting pipeline, a compressor, an exhaust fan, an electric heater, an evaporator, an air-cooled finned condenser and a ventilating system, and the connecting pipeline is used for extending to an outdoor environment; the ventilating system comprises an enclosed hood, a heat exchange chamber, an air supply pipeline, a fresh air supplementing device and a fan and is used for extracting outdoor air and delivering cooled air into an indoor environment. The air-conditioning system with the methanol reforming and power generating functions and the control method for the air-conditioning system have the advantage that the air-conditioning system can run without extra power sources.

Owner:SHANGHAI HYDROGEN MOBILE REFRMER INSTR

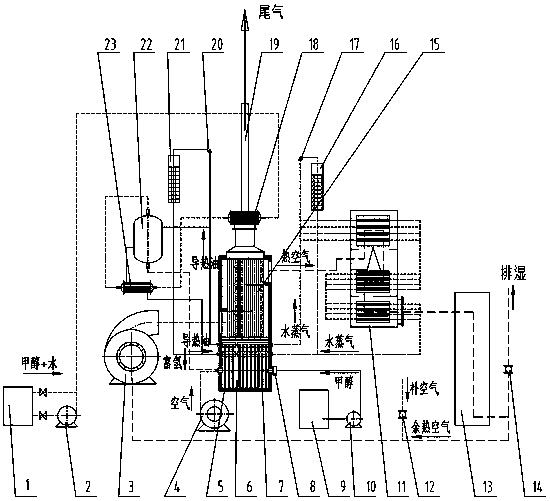

Methanol reforming produced hydrogen-rich gas combustion heat supply device

The invention relates to a methanol reforming produced hydrogen-rich gas combustion heat supply device, and belongs to the technical field of agricultural machinery. The device comprises a heat conduction oil heat exchange tube, a hydrogen-rich gas combustion furnace, a steam heat exchange tube, a steam / air heat exchanger, a flue gas heat exchanger, a flue gas / methanol + water preheater and a methanol reformer, wherein the methanol reformer is used for conveying prepared hydrogen-rich gas into the hydrogen-rich gas combustion furnace through a pipeline, the steam heat exchange tube and the heat conduction oil heat exchange tube are arranged at the lower part of the hydrogen-rich gas combustion furnace in parallel, the steam heat exchange tube is connected with the steam / air heat exchanger;and the heat conduction oil heat exchange tube is connected with the methanol reformer through a pipeline, the flue gas heat exchanger is positioned at the upper part of the hydrogen-rich gas combustion furnace, and the steam / air heat exchanger is located at the position of an air inlet of a drying box. The hydrogen-rich gas is produced by reforming of methanol, heat is produced through hydrogen-rich gas combustion, heat energy is provided for a drying machine, the heat utilization rate is greatly improved, pollutant emission is avoided, the device is green and environment-friendly, meanwhile, the hydrogen gas can be generated instantly and combusted instantly, and so that safety and reliability are achieved.

Owner:玉溪新天力农业装备制造有限公司

Online methanol reformer adopting screen separating mechanism and utilizing engine exhaust

PendingCN109437103ARealize gas-liquid separationImprove work efficiencyHydrogenInternal combustion piston enginesProcess engineeringFlange

The invention discloses an online methanol reformer adopting a screen separating mechanism and utilizing engine exhaust. The online methanol reformer adopting the screen separating mechanism and utilizing the engine exhaust comprises a separating section; the separating section comprises condensation nets, a separating section shell, a liquid collecting cavity and an isolating plate; the isolatingplate is horizontally assembled on the inner wall of the separating section shell; the liquid collecting cavity is formed between the position below the isolating plate and the inner wall of the separating section shell; a plurality of liquid collecting holes are formed in the isolating plate; a plurality of the condensation nets are vertically arranged between the position above the isolating plate and the inner wall of the separating section shell; a methanol mixture inlet and a gaseous methanol outlet are respectively formed in the two sides of the separating section shell; a liquid methanol outlet is formed in the bottom of the bottom of the separating section shell; the liquid methanol outlet communicates with the liquid collecting cavity; the methanol mixture inlet communicates witha reforming methanol outlet of a reformer through a flange; according to the online methanol reformer adopting the screen separating mechanism and utilizing the engine exhaust, the separating sectionis arranged and the condensation nets are vertically arranged in the separating section, so that gas-liquid separating of the methanol mixture discharged from the reformer can be realized quickly; the separated liquid methanol flows back to a methanol box for storing; and the work efficiency of the reformer is improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

Pure-hydrogen and pure-oxygen high-temperature battery system

InactiveCN105552414ATake advantage ofImprove power generation efficiencyFuel cell heat exchangeFinal product manufactureHydrogenFuel cells

The invention discloses a pure-hydrogen and pure-oxygen high-temperature battery system. In the technical scheme, the pure-hydrogen and pure-oxygen high-temperature battery system comprises a pure-hydrogen generation module, a pure-oxygen generation module and a high-temperature proton exchange membrane electric stack, wherein the pure-hydrogen generation module comprises a methyl pump, a methyl filter, a methyl reformer and a hydrogen separator which are sequentially connected, the pure-oxygen generation module comprises an oxygen generator connected with the methyl reformer, the hydrogen separator and the oxygen generator are respectively connected with the high-temperature proton exchange membrane electric stack, and the methyl filter is arranged in the pure-hydrogen generation module and used for filtering methyl water. With the pure-hydrogen and pure-oxygen high-temperature battery system, pure hydrogen and pure oxygen are obtained by using residual heat generated in the methyl reformer, so that the pure-hydrogen and pure-oxygen high-temperature battery system can be applied into a vehicle-mounted fuel cell, and the power generation efficiency of the fuel cell is greatly improved.

Owner:BOYUAN FUEL CELL SHANGHAI

A fuel cell power source and electric vehicle

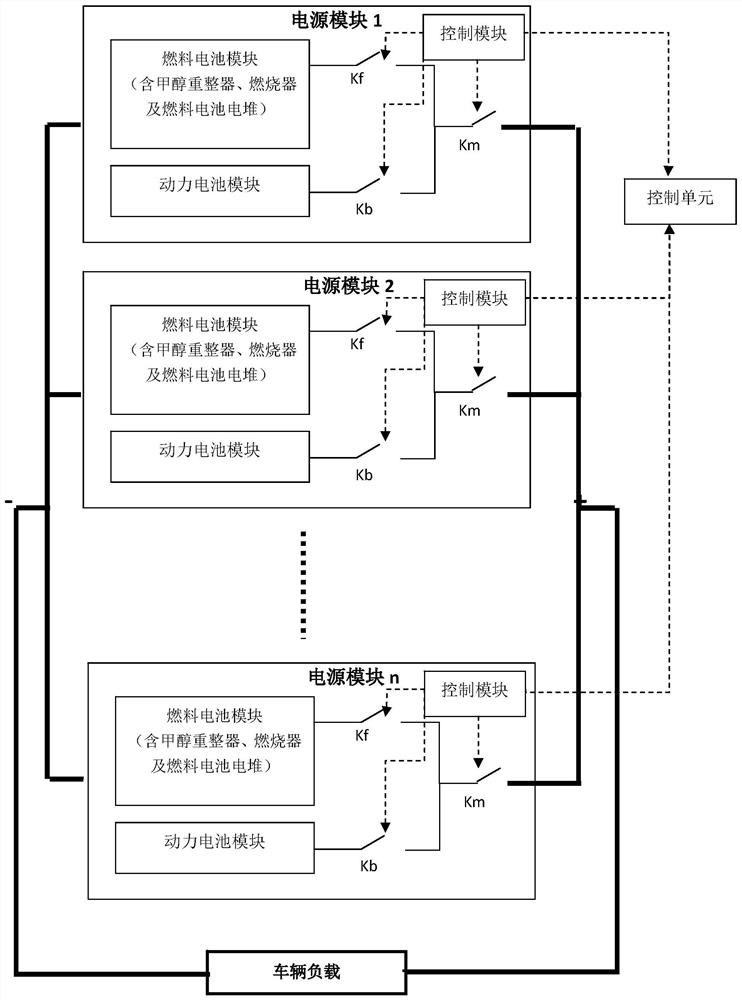

The invention discloses a fuel cell power supply, comprising n parallel power supply modules, where n is a positive integer greater than 1; each power supply module is composed of an independent fuel cell module and a power battery module in parallel, with a control module and a The controllable switch; the fuel cell module contains the methanol reformer, the burner and the fuel cell stack, and the control module controls the switch for regulating the output of the power module. The present invention also provides an electric vehicle provided with a fuel cell power source. When the vehicle is running, the switch Km of any power supply module can be controlled to adapt to the target power required by the vehicle according to the power requirements of the vehicle. The switches Kf and Kb can also be adjusted according to the state of the battery SOC and the power generation state of the fuel cell module, so as to achieve the power required by the vehicle at the same time. According to the different battery temperature, the switch Kf of any power module can be controlled to heat the battery to keep the temperature of the battery balanced.

Owner:陈俊霖

Preparation method of platinum catalyst supported by porous aluminum foam used in combustor of methanol reformer

ActiveCN103949244BFully contactedImprove output efficiencyCell electrodesMetal/metal-oxides/metal-hydroxide catalystsElectrolytic agentAluminate

The invention discloses a preparation method of a platinum catalyst by taking porous foaming aluminum as a carrier for a methyl alcohol reformer combustion chamber. The preparation method comprises the following steps: placing porous foaming aluminum as an anode into electrolyte containing one or two of aluminate, silicate, fluoroziconate and sodium hypophosphite, carrying out micro-arc oxidation treatment by applying a direct-current or alternating-current voltage for 10-120 minutes, forming a layer of porous oxidation ceramic membrane on the surface of the foaming aluminum, and loading the Pt based catalyst on the surface of the ceramic membrane serving as a substrate, thereby obtaining the Pt based catalyst for the methyl alcohol reformer combustion chamber. According to the invention, the problems of insufficient contact of hydrogen and platinum in the existing methyl alcohol reformer combustion chamber, low catalyst utilization ratio, adverse effect to the catalyst by a catalyst framework and the like are solved.

Owner:HARBIN INST OF TECH

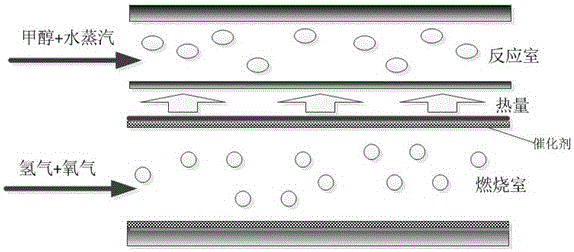

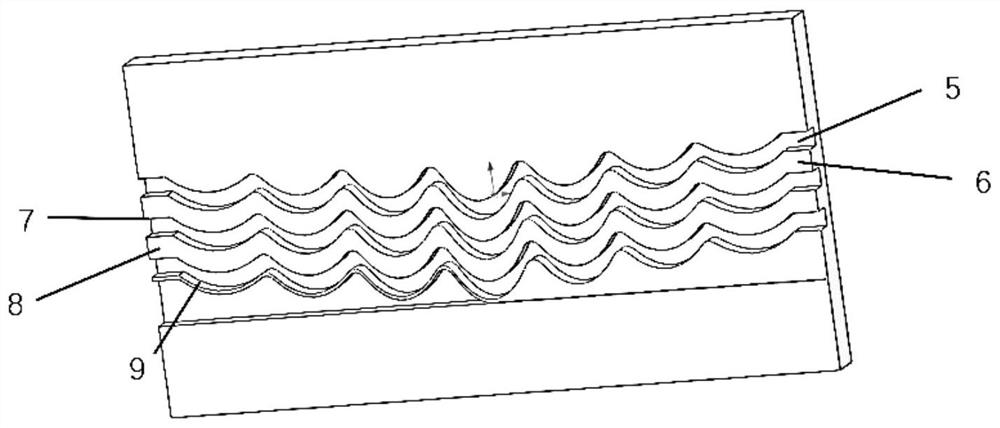

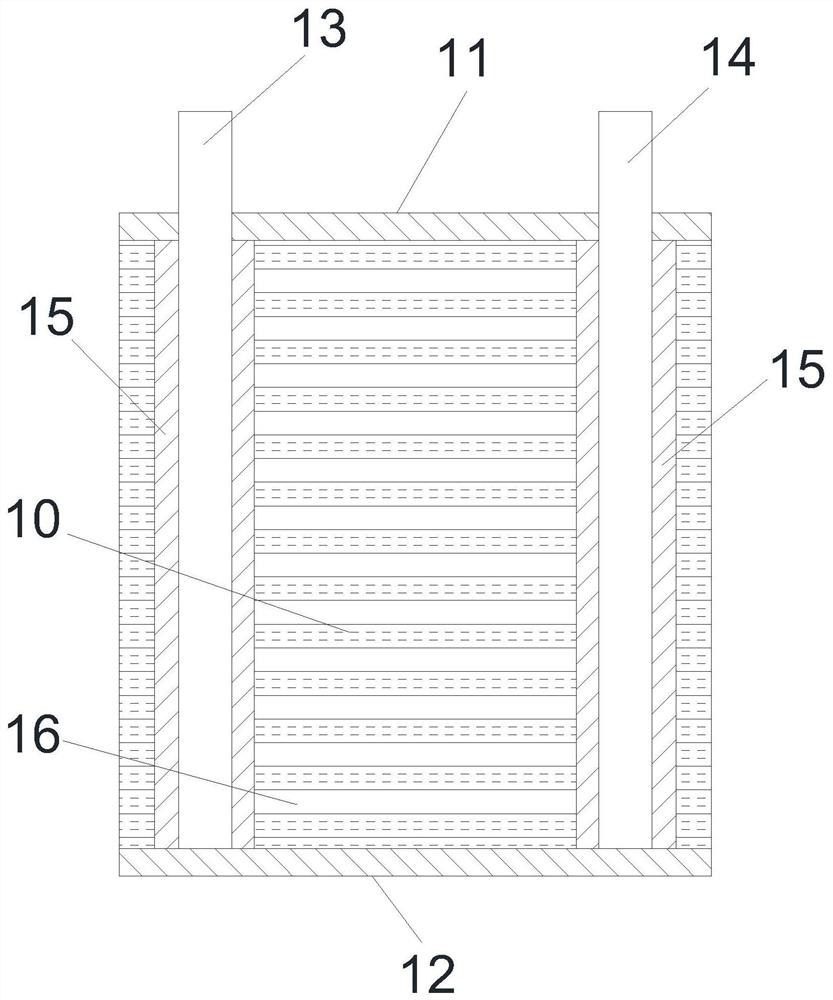

Novel methanol reformer

PendingCN114212754AIncrease the reaction contact areaImprove heat transfer performanceHydrogenHydrogen/synthetic gas productionCatalytic reformingMethanol water

The invention discloses a novel methanol reformer, and relates to the field of industrial equipment, and the methanol reformer comprises an alcohol water input port, a hydrogen-rich gas output port, a methanol air inlet, a reaction tail gas outlet, a cavity, a heat transfer plate and a catalyst layer. The cavity comprises three layers of runners, namely an upper-layer preheating treatment runner, a middle-layer methanol catalytic combustion runner and a lower-layer methanol catalytic reforming runner; the preheating treatment flow channel is used for receiving a methanol water solution conveyed through the methanol water input port and preheating the methanol water solution to generate methanol water vapor; the methanol catalytic combustion flow channel is used for providing heat for the preheating treatment flow channel and the methanol catalytic reforming flow channel; the methanol catalytic reforming flow channel is used for reforming methanol steam to produce hydrogen; each flow channel is of a snakelike flow channel structure, and the longitudinal direction of each flow channel is of a symmetrical increasing wave function. The problem of low utilization rate of the existing methanol reformer catalyst can be effectively solved, and the methanol steam reforming efficiency is improved.

Owner:JIANGSU UNIV +1

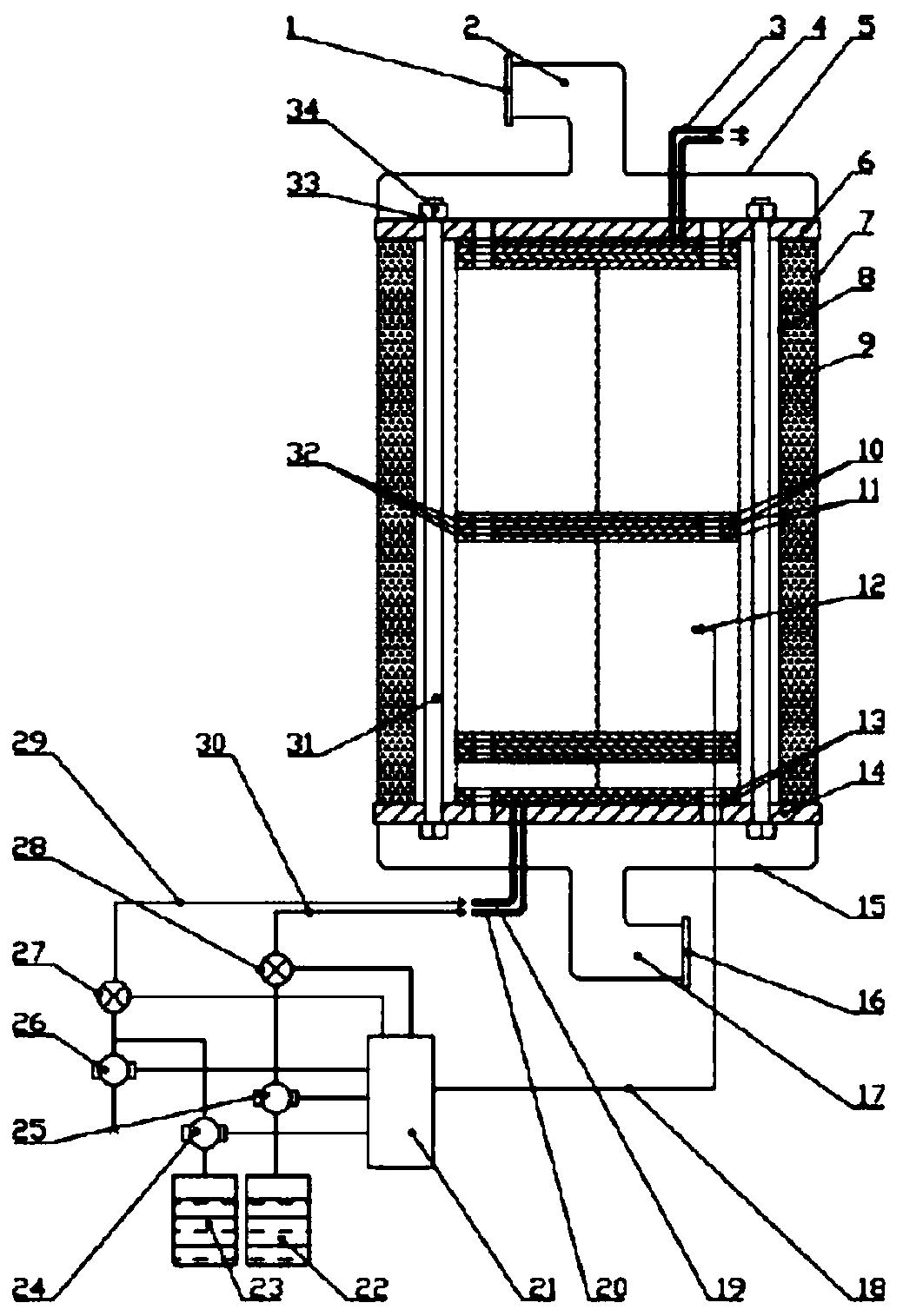

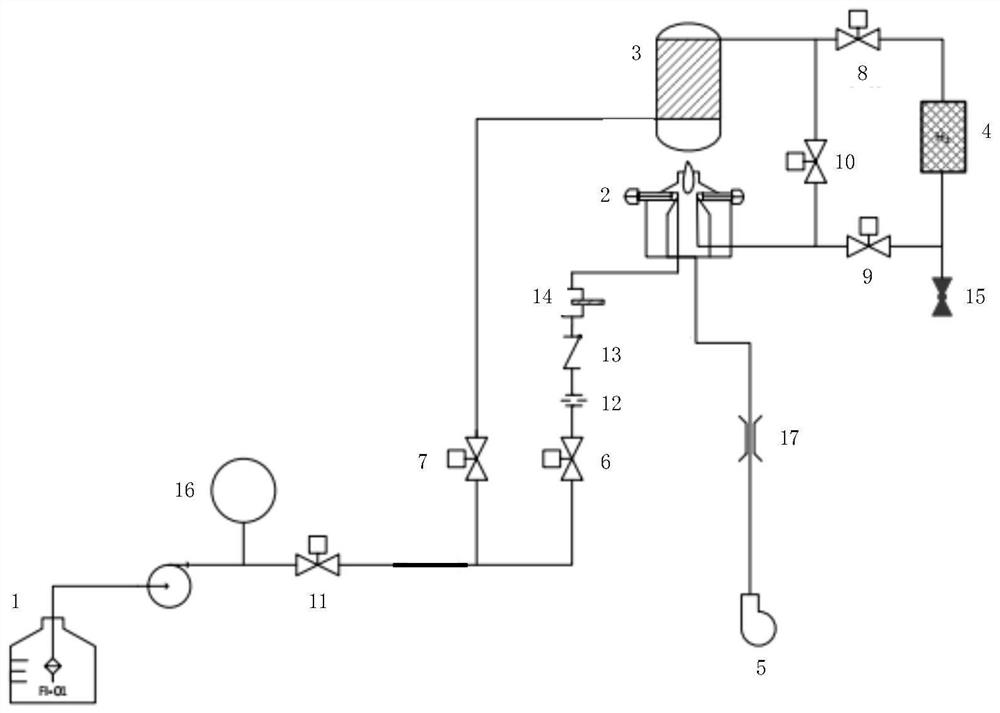

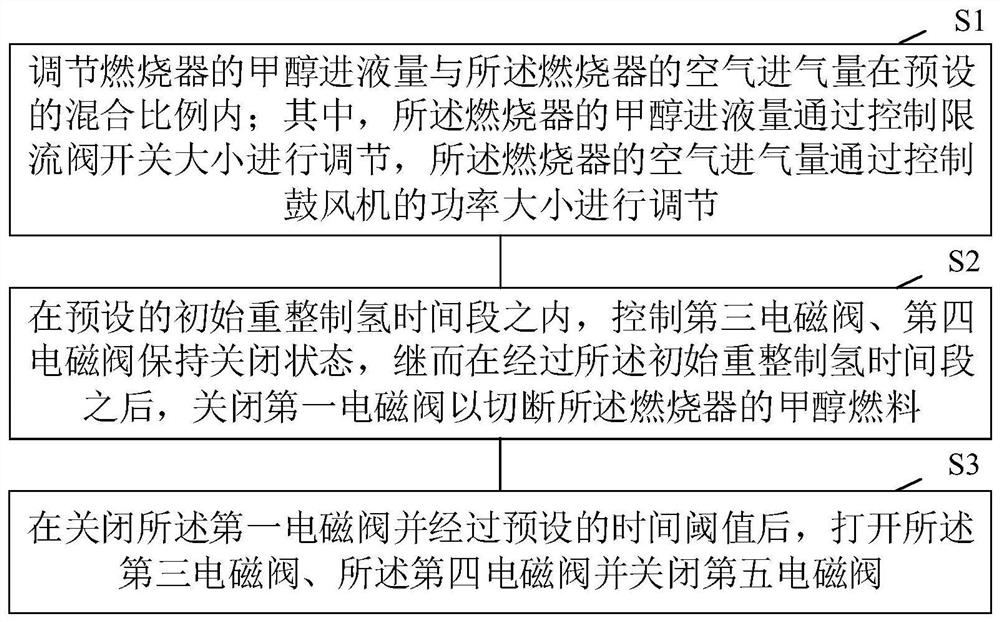

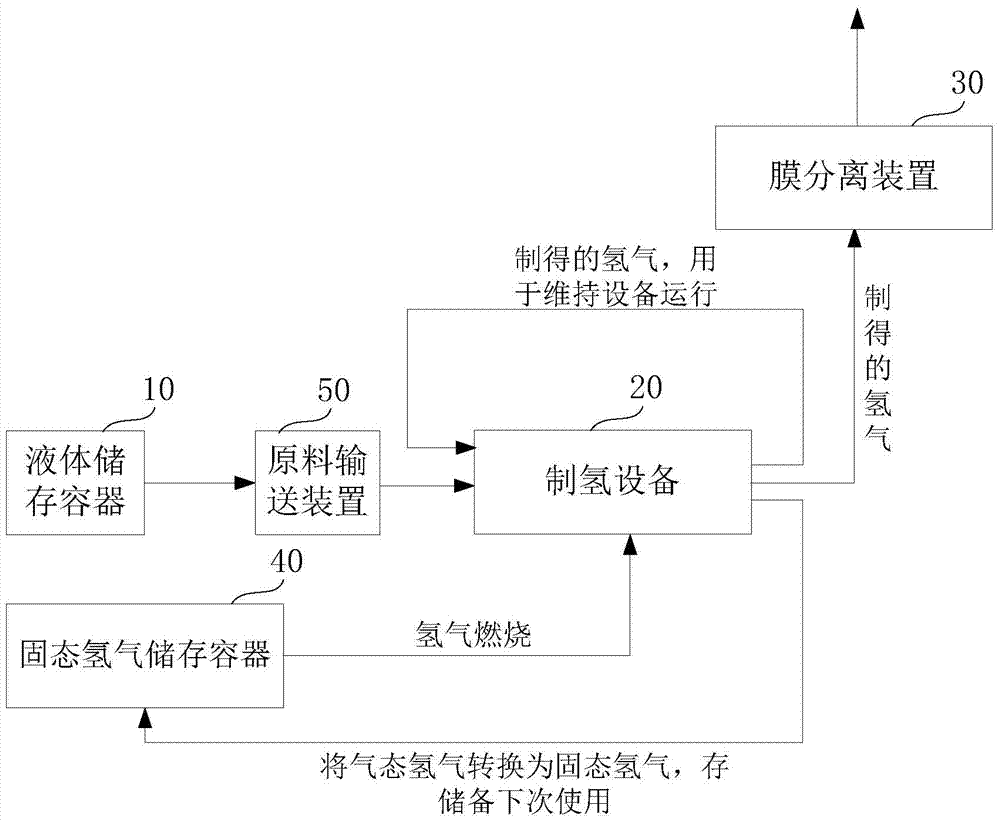

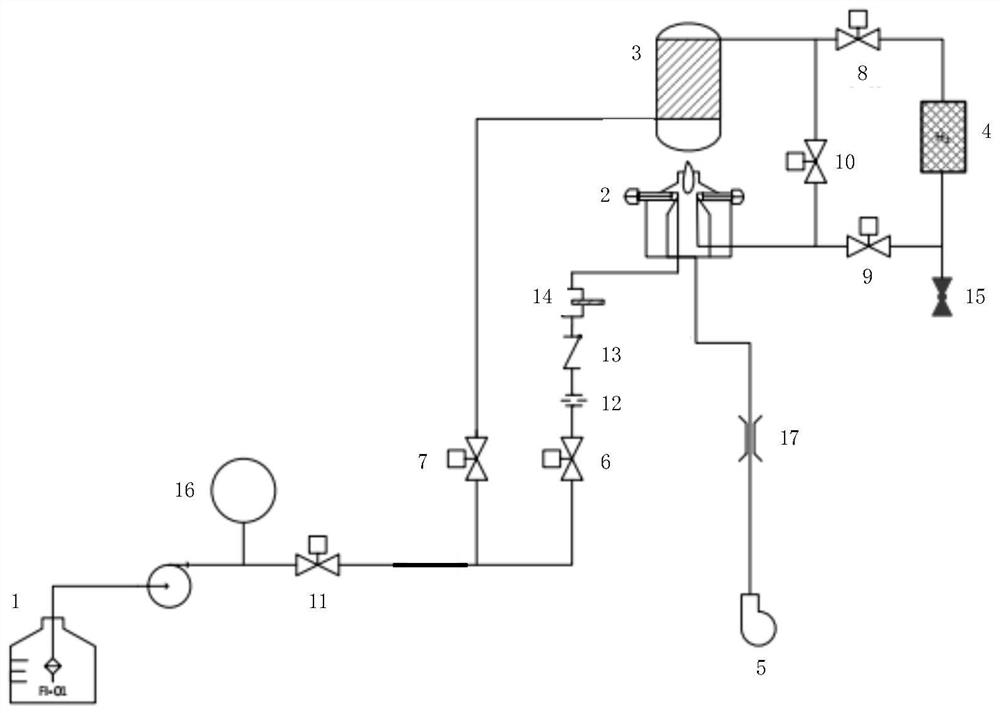

Methanol-water fuel reforming hydrogen production system and control method thereof

ActiveCN112310450ASimplify the way of liquid supplySwitch freelyFuel cellsMethanol waterThermodynamics

The invention provides a methanol-water fuel reforming hydrogen production system and a control method thereof. The system comprises a methanol supply device, a combustor, a reformer, a fuel cell, anair blower and a controller. According to a fuel supply pipeline, a liquid can be supplied to the methanol reformer while a methanol fuel is supplied to the combustor, and a liquid supply mode of thereforming hydrogen production device is simplified; besides, by arranging a hydrogen recovery pipeline and a control method for freely switching combustion reactants, free switching between methanol water combustion and hydrogen combustion can be achieved, and stable control can be achieved in the switching process; and therefore, the methanol-water reforming hydrogen production system can be intelligently controlled, an energy utilization rate is increased, and the heat balance of the system is maintained.

Owner:摩氢科技有限公司

Preparation method of catalyst in combustor of micro-methanol reformer

ActiveCN103949245BExtended service lifeImprove bindingCell electrodesMetal/metal-oxides/metal-hydroxide catalystsOxide ceramicElectrolytic agent

The invention discloses a method for preparing a catalyst for a combustion chamber of a micro-methanol reformer. The steps of the method are as follows: the combustion chamber of the reformer with a flow field is used as an anode, placed in an electrolyte, and a DC or AC voltage is applied to the catalyst. The flow field is processed to form a layer of porous oxide ceramic film on the surface of the flow field, and then use it as a carrier to load the reforming catalyst Pt. The present invention adopts the micro-arc oxidation technology to directly grow the oxide ceramic film containing Al2O3 in situ on the surface of the flow field, and then use it as a carrier to deposit Pt. The catalyst prepared by the present invention can effectively solve the problem of existing methanol reformer combustion chamber There are problems such as poor adhesion of the catalyst, small contact area between the reaction gas and the catalyst, and low utilization of the catalyst.

Owner:HARBIN INST OF TECH

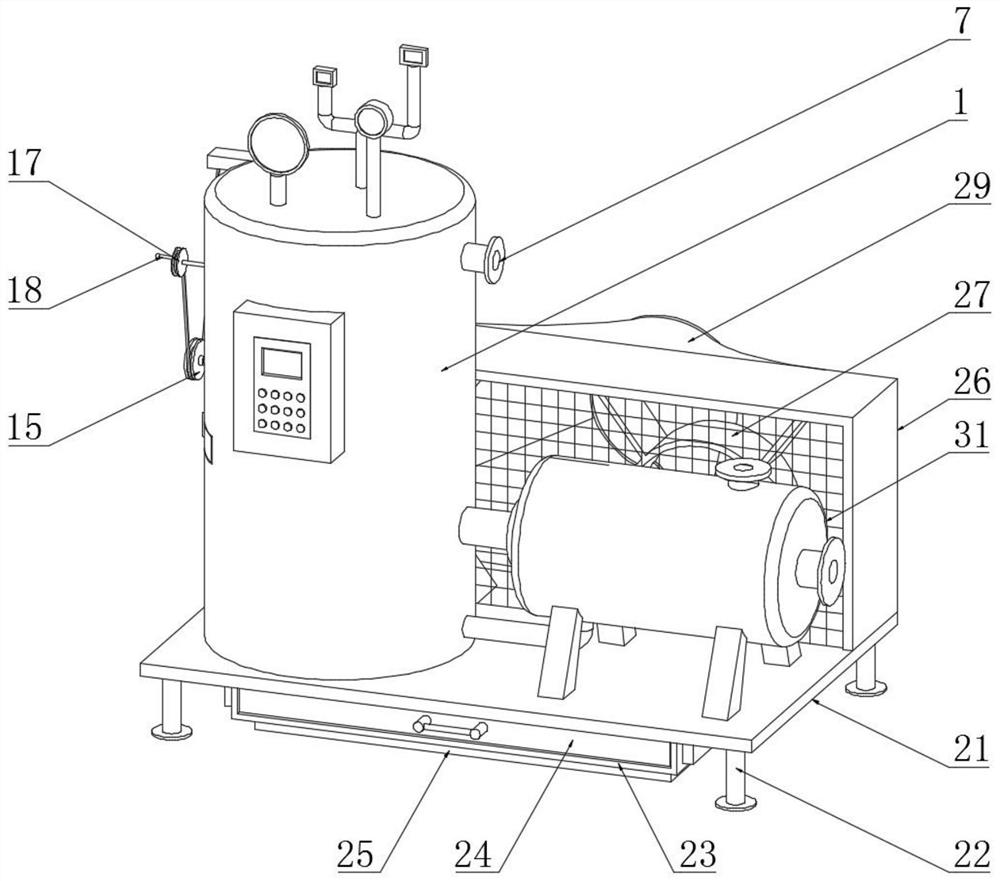

Self-heating type methanol reforming hydrogen production device based on fractal structure and control method thereof

ActiveCN114735650AUnique heat and mass transport propertiesImprove energy utilizationHydrogenThermodynamicsMethanol fuel

The invention discloses a self-heating type methanol reforming hydrogen production device based on a fractal structure and a control method of the self-heating type methanol reforming hydrogen production device. The self-heating type methanol reforming hydrogen production device comprises a shell, a methanol reformer, a methanol solution blending tank, a methanol fuel tank, a water tank and a fuel bubbler. The methanol reformer is connected with the methanol fuel tank through the fuel bubbler, the methanol reformer is respectively connected with the methanol solution blending tank and the water tank, and the methanol solution blending tank is respectively connected with the methanol fuel tank and the water tank. The methanol reformer comprises a reformer shell, a methanol catalytic combustion unit, a methanol steam reforming unit and a condensing unit; the control method comprises the steps of system debugging, working condition parameter determination, preheating starting, methanol solution preparation, hydrogen production operation, reaction water recovery, hydrogen production working condition switching, shutdown, control system improvement and the like. The self-heating methanol reformer has the beneficial effects that the self-heating methanol reformer is designed on the basis of a fractal network structure, and the heat and mass transport characteristic of the self-heating methanol reformer can be well suitable for volume increasing reactions such as methanol reforming.

Owner:JIANGSU UNIV

mems methanol reforming fuel cell system

ActiveCN103943873BChange fuel supplyImprove securityElectricity cogenerationReactant parameters controlLithiumContact position

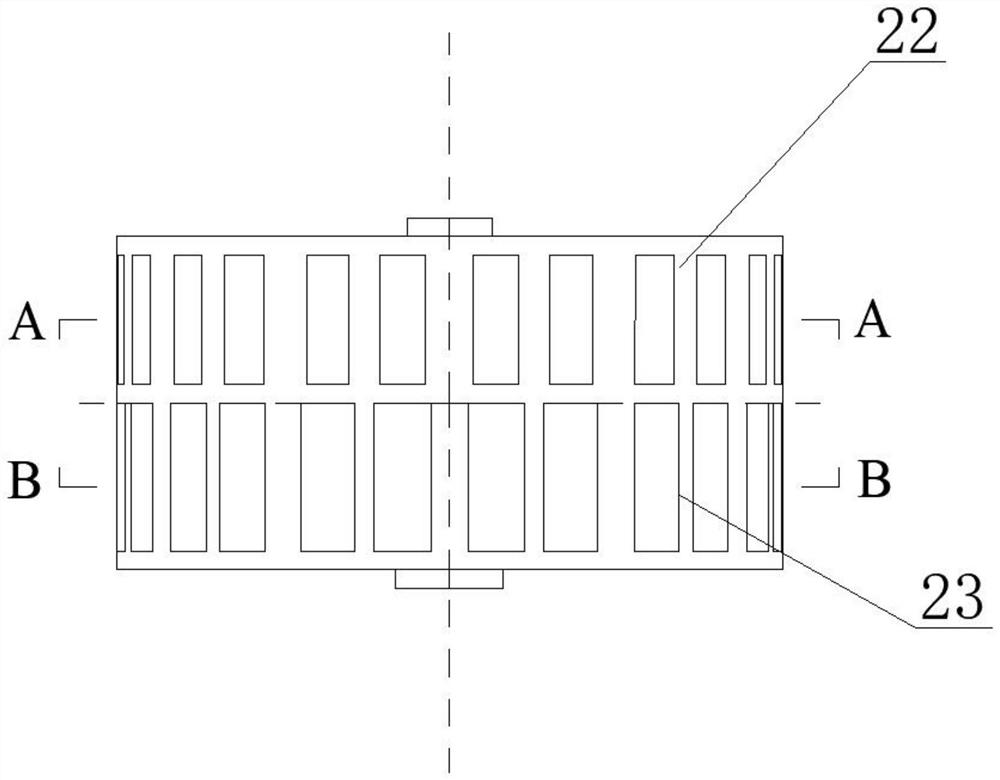

The invention discloses an MEMS (Micro-Electromechanical Systems) methanol reforming fuel cell system, belongs to the field of methanol reforming fuel cells and aims to solve the problems of a traditional methanol reforming fuel cell system. The MEMS methanol reforming fuel cell system comprises a shell, a liquid storage bottle, an MEMS methanol reformer, an MEMS proton exchange membrane fuel cell, an MEMS air-liquid pump, a bi-directional valve, a lithium cell, a managing system, a left side fan and a right side fan, wherein the shell is in a cuboid shape, the liquid storage bottle is arranged on the outer surface of the back side of the shell, the MEMS methanol reformer, the MEMS proton exchange membrane fuel cell, the MEMS air-liquid pump, the bi-directional valve, the lithium cell, the managing system, the left side fan and the right side fan are arranged in the shell, an input port of the MEMS methanol reformer is communicated with a methanol outlet of the liquid storage bottle by virtue of a pipeline, the MEMS air-liquid pump and the bi-directional valve are arranged on the pipeline, an output port of the MEMS methanol reformer clings to an anode input port of the MEMS proton exchange membrane fuel cell tightly, and the contact position is sealed by a sealing material.

Owner:HARBIN INST OF TECH

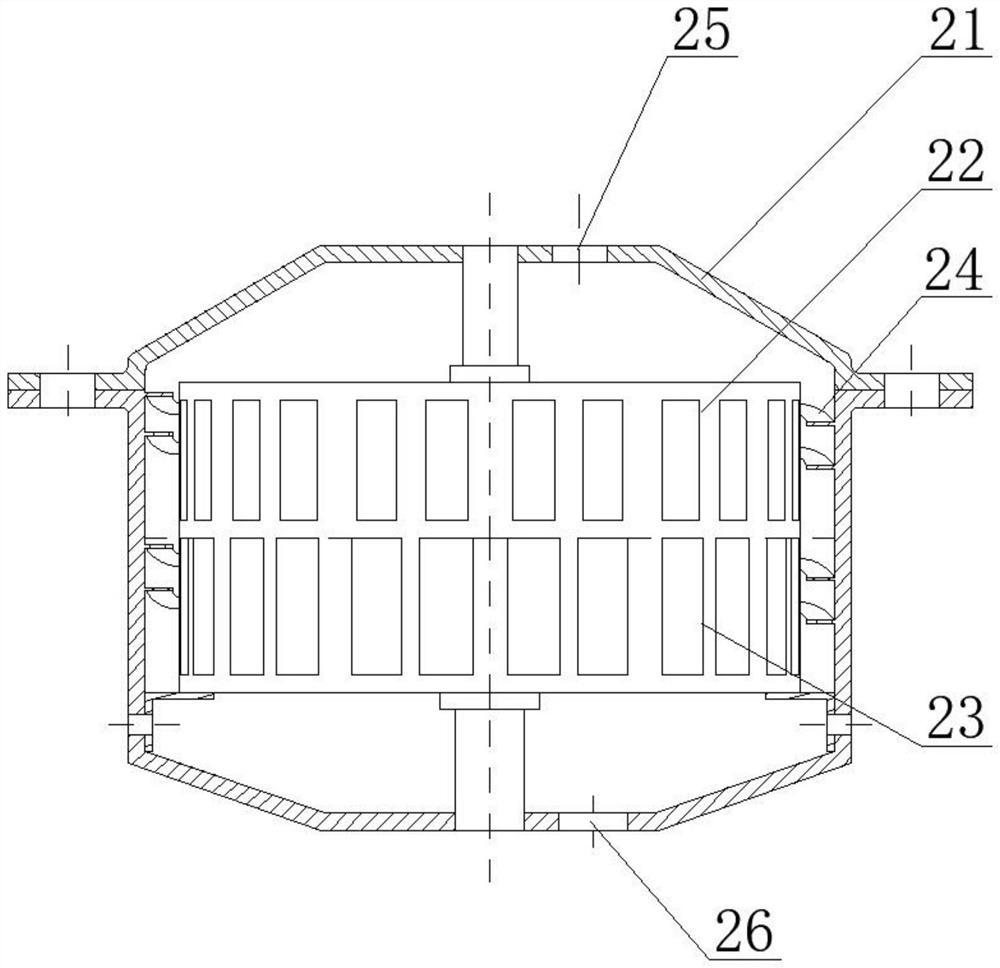

Methanol reformer

ActiveCN111717890ABreak down completelyImprove vibration resistanceHydrogenFinal product manufacturePtru catalystPhysical chemistry

The invention provides a methanol reformer. The methanol reformer comprises a flow guide mixing plate and catalyst coatings, the whole flow guide mixing plate is of a honeycomb structure, and the catalyst coatings are arranged on the inner side wall and the outer side wall of the flow guide mixing plate. The catalyst coatings are arranged on the inner side wall and the outer side wall of the flowguide mixing plate, and a fluid flows through honeycomb-shaped holes formed in the flow guide mixing plate, so that the fluid can be fully mixed and can be in better contact with the catalyst coatings, methanol is decomposed more completely, the hydrogen yield is increased, the reforming efficiency and the heat exchange efficiency are improved, and the reformer is small, exquisite, efficient and good in vibration resistance.

Owner:CHINA HYDROGEN NEW ENERGY TECH CO

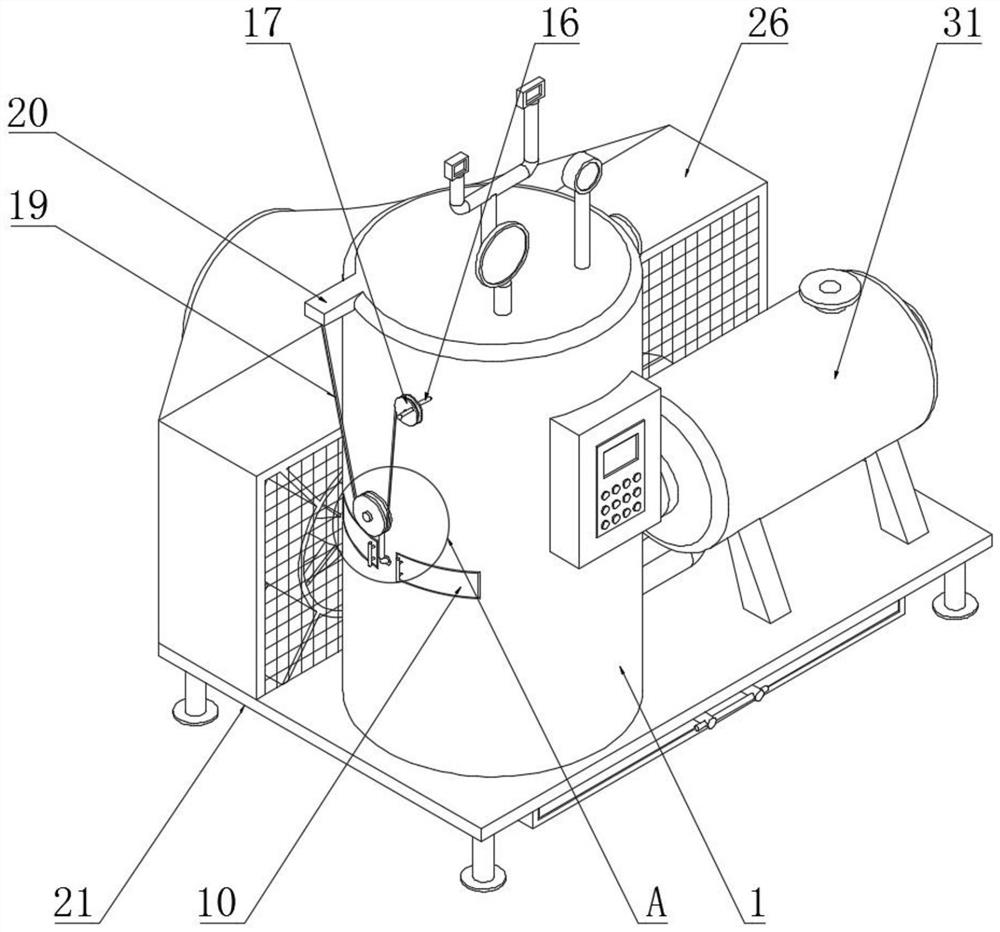

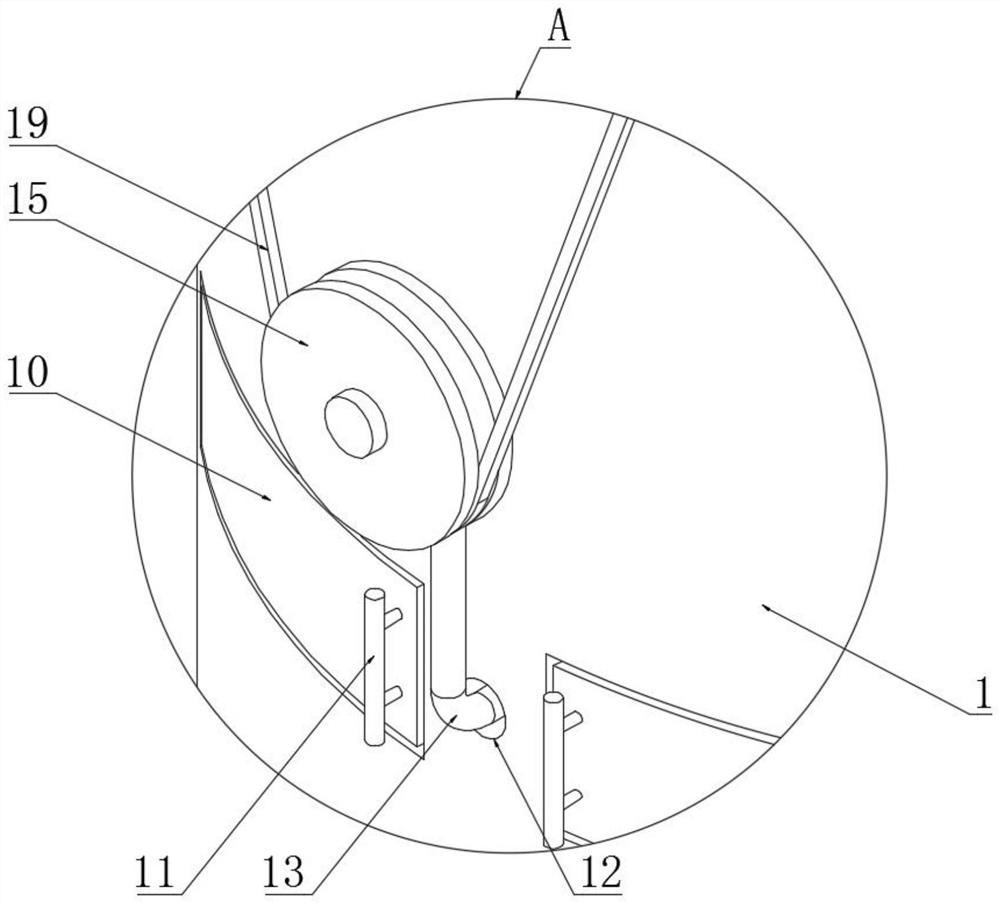

A coke oven gas-to-methanol reformer

ActiveCN108745210BReduce labor intensityLow purityOrganic compound preparationHydroxy compound preparationProcess engineeringMechanical engineering

The invention discloses a coke oven gas-to-methanol reformer, which comprises a reformer body, a tubular heat exchanger, a second installation frame, a fan, a cleaning scraper and a traction cable. Heat exchanger, a fan is installed in the middle of the second installation frame, and a traction cable is installed on one side of the middle of the cleaning scraper. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. The heat temperature is convenient for subsequent transportation and storage, and at the same time, the preheating temperature of the raw material water liquid is increased, and the energy utilization rate in the production process is improved; the fan is installed to reduce the stability around the reformer body, which is convenient for users to control the reformer body The control switch on the upper part can discharge the flammable materials in time when the material leaks, so as to avoid the occurrence of combustion and explosion in the plant; a partition plate and a ventilating installation port are set up to facilitate the uniform mixing of water vapor with oxygen and improve the reaction efficiency.

Owner:玉环市几偶孵化器有限公司

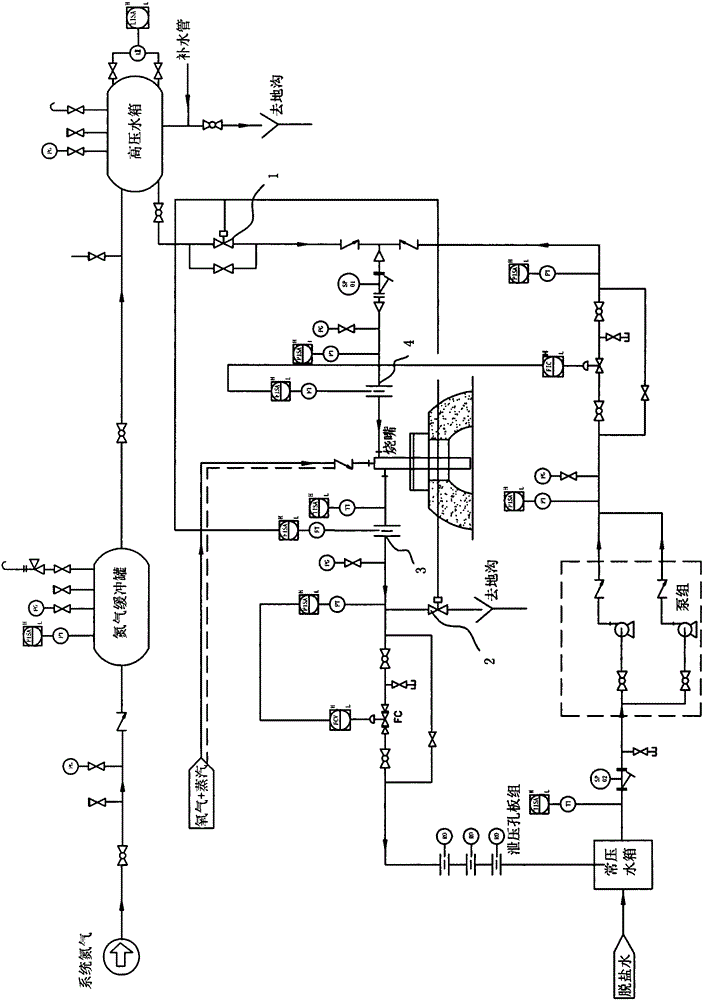

Cooling water system for reformer metal burners

ActiveCN103172020BEmergency Cooling GuaranteePrevent abnormal burningHydrogen productionBurn mouthEngineering

The invention relates to a cooling water system for the metal burner of the reformer in the synthetic ammonia or methanol industry, including a circulating water system, the circulating water system includes a normal pressure water tank, a pump group, an inlet orifice plate, a boiler Nozzle inlet pipe, burner outlet pipe, outlet orifice plate. The invention solves the technical problem that the existing metal burner easily causes burning loss of the metal burner during power failure, ensures emergency cooling of the burner, and prevents abnormal burning loss of the burner.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

Fuel Cell Hydrogen Vehicles

ActiveCN106585395BEasy to useImprove protectionUnderstructuresPropulsion by batteries/cellsPower batteryElectrical battery

The invention discloses a fuel cell hydrogen powered automobile. The objective of the invention is to solve the problems of incontinence in hydrogen feeding, hidden security hazards in use, low structural compactness and inconvenient assembly of an existing hydrogen fuel powered automobile. The fuel cell hydrogen powered automobile of the invention comprises a frame; the front end of the frame is provided with a hydrogen production by methanol reformer, a fuel cell, a DC / DC converter, a motor driving system and an automobile heat dissipation system; the rear end of the frame is provided with a methanol tank; the frame is provided with a lithium-ion power battery near the middle portion of the frame; the methanol tank is connected with the hydrogen production by methanol reformer through a pipeline; the hydrogen production by methanol reformer provides hydrogen for the fuel cell; and the fuel cell is connected in parallel with the lithium-ion battery through the DC / DC converter so as to provide power for the motor driving system. According to the fuel cell hydrogen powered automobile of the invention, the hydrogen production by methanol reformer installed on the automobile is adopted to provide hydrogen, and so that the feeding of hydrogen is not required, and a hydrogen tank can be omitted, and the automobile is more secure and reliable in a use process. The fuel cell hydrogen powered automobile has the advantages of highly compact structure, convenient assembly and reliable connection.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

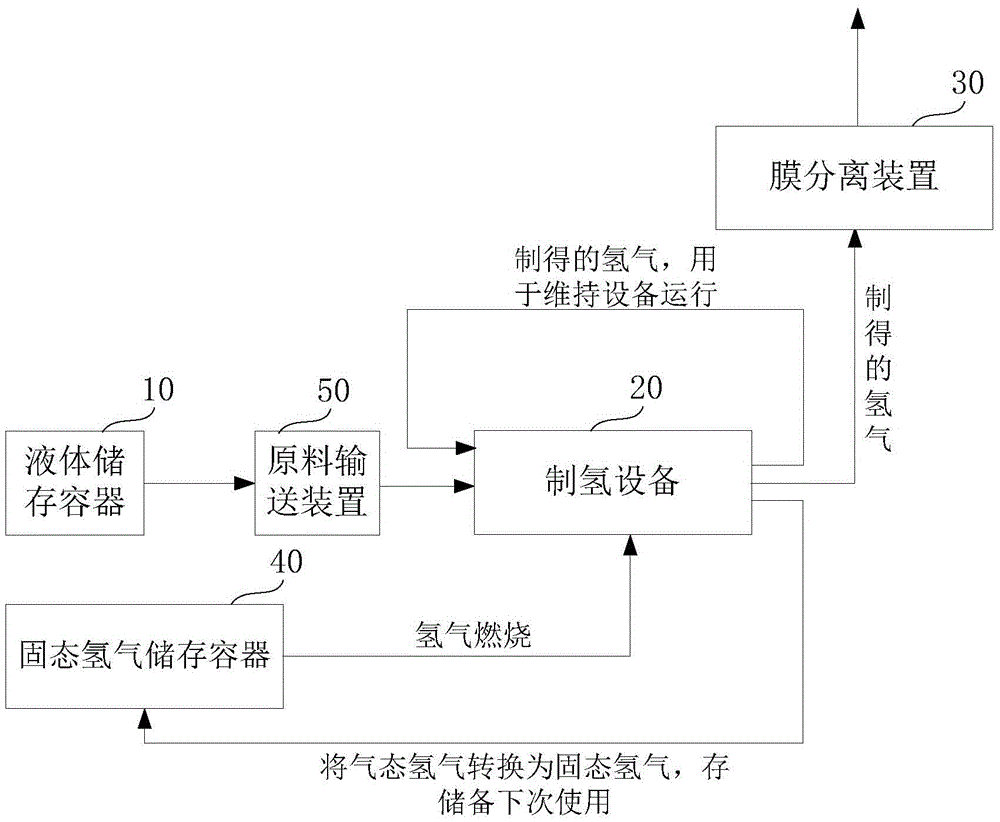

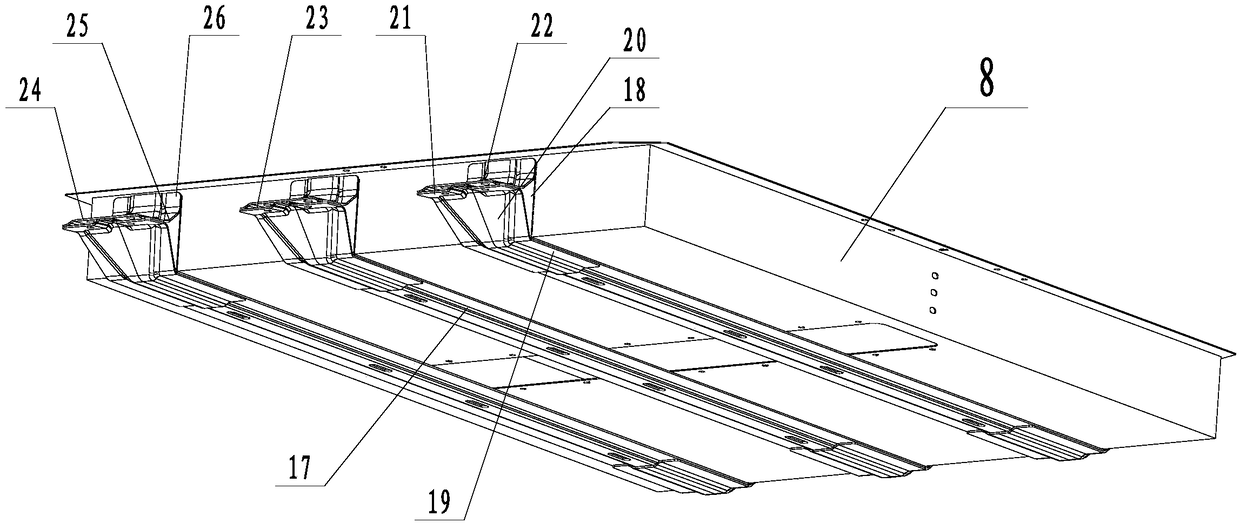

A methanol water reforming power generation refrigerator system and control method

The invention discloses a methyl alcohol reforming electricity generation refrigerator system and a control method. The refrigerator system comprises a hydrogen preparation equipment, electricity generation equipment and refrigerator equipment, the hydrogen preparation equipment prepares hydrogen through methyl alcohol reforming, the prepared hydrogen is conveyed to the electricity generation equipment for electricity generation, generated electric energy is supplied to the refrigerator equipment for operation, and the refrigerator equipment is movable refrigerator equipment. According to the methyl alcohol reforming electricity generation refrigerator system and the control method, the refrigerator system can be started without an extra power source, so that a user uses the refrigerator outdoors without a power source.

Owner:SHANGHAI HYDROGEN MOBILE REFRMER INSTR

A methanol water fuel reforming hydrogen production system

ActiveCN112290051BSimplify the way of liquid supplySimplify the liquid supply systemFuel cell heat exchangeMethanol waterThermodynamics

The invention provides a methanol water fuel reforming hydrogen production system, comprising a methanol supply device, a burner, a reformer, a fuel cell, a blower and a controller. The fuel supply pipeline of the present invention can supply methanol fuel to the burner and supply liquid to the methanol reformer at the same time, which simplifies the liquid supply mode of the reforming hydrogen production device; in addition, by setting the hydrogen recovery pipeline, the methanol water can be realized Combustion and hydrogen combustion can be switched freely, and stable control can be realized during the switching process; thus, the invention greatly simplifies the liquid supply system of the reforming hydrogen production device, and improves the utilization rate of energy.

Owner:摩氢科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com