Methanol reforming produced hydrogen-rich gas combustion heat supply device

A combustion heating and methanol technology, applied in the field of agricultural machinery, can solve the problems of heat source pollution, low degree of automation, and low energy utilization rate, and achieve the effects of high heat energy utilization rate, reasonable structural design, and easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

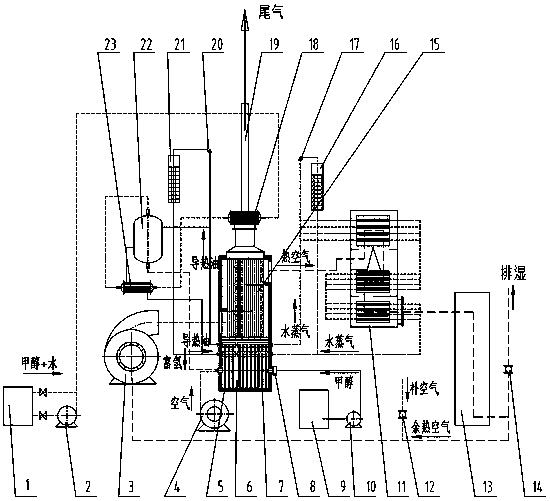

[0020] Embodiment 1: as figure 1 As shown, a hydrogen-rich combustion heating device for methanol reforming, including methanol + water tank 1, methanol + water pump 2, fan 3, small fan 4, heat transfer oil heat exchange tube 5, hydrogen-rich combustion furnace 6, steam heat exchange Pipe 7, Methanol Burner 8, Methanol Tank 9, Methanol Pump 10, Steam / Air Heat Exchanger 11, Air Supply Valve 12, Drying Box 13, Humidity Discharge Valve 14, Flue Gas Heat Exchanger 15, Steam Condenser 16 , Steam safety valve 17, flue gas / methanol+water preheater 18, chimney 19, heat transfer oil safety valve 20, heat transfer oil condenser 21, methanol reformer 22, methanol+water superheater 23.

Embodiment 2

[0021] Embodiment 2: as figure 1 As shown, a hydrogen-rich combustion heating device for methanol reforming, including methanol + water tank 1, methanol + water pump 2, fan 3, small fan 4, heat transfer oil heat exchange tube 5, hydrogen-rich combustion furnace 6, steam heat exchange Pipe 7, Methanol Burner 8, Methanol Tank 9, Methanol Pump 10, Steam / Air Heat Exchanger 11, Air Supply Valve 12, Drying Box 13, Humidity Discharge Valve 14, Flue Gas Heat Exchanger 15, Steam Condenser 16 , Steam safety valve 17, flue gas / methanol+water preheater 18, chimney 19, heat transfer oil safety valve 20, heat transfer oil condenser 21, methanol reformer 22, methanol+water superheater 23.

[0022] The steam heat exchange tube 7 and the heat transfer oil heat exchange tube 5 are arranged in parallel at the lower part of the hydrogen-rich combustion furnace 6; the flue gas heat exchanger 15 is located at the upper part of the hydrogen-rich combustion furnace 6; the flue gas / methanol+water preh...

Embodiment 3

[0023] Embodiment 3: as figure 1 As shown, a hydrogen-rich combustion heating device for methanol reforming, including methanol + water tank 1, methanol + water pump 2, fan 3, small fan 4, heat transfer oil heat exchange tube 5, hydrogen-rich combustion furnace 6, steam heat exchange Pipe 7, Methanol Burner 8, Methanol Tank 9, Methanol Pump 10, Steam / Air Heat Exchanger 11, Air Supply Valve 12, Drying Box 13, Humidity Discharge Valve 14, Flue Gas Heat Exchanger 15, Steam Condenser 16 , Steam safety valve 17, flue gas / methanol+water preheater 18, chimney 19, heat transfer oil safety valve 20, heat transfer oil condenser 21, methanol reformer 22, methanol+water superheater 23.

[0024] The steam heat exchange tube 7 and the heat transfer oil heat exchange tube 5 are arranged in parallel at the lower part of the hydrogen-rich combustion furnace 6; the flue gas heat exchanger 15 is located at the upper part of the hydrogen-rich combustion furnace 6; the flue gas / methanol+water preh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com