A coke oven gas-to-methanol reformer

A coke oven gas and reformer technology, applied in organic chemistry, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as resource waste, furnace body corrosion, and methanol purity reduction, so as to facilitate transportation and storage, avoid Waste of energy, ensure the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

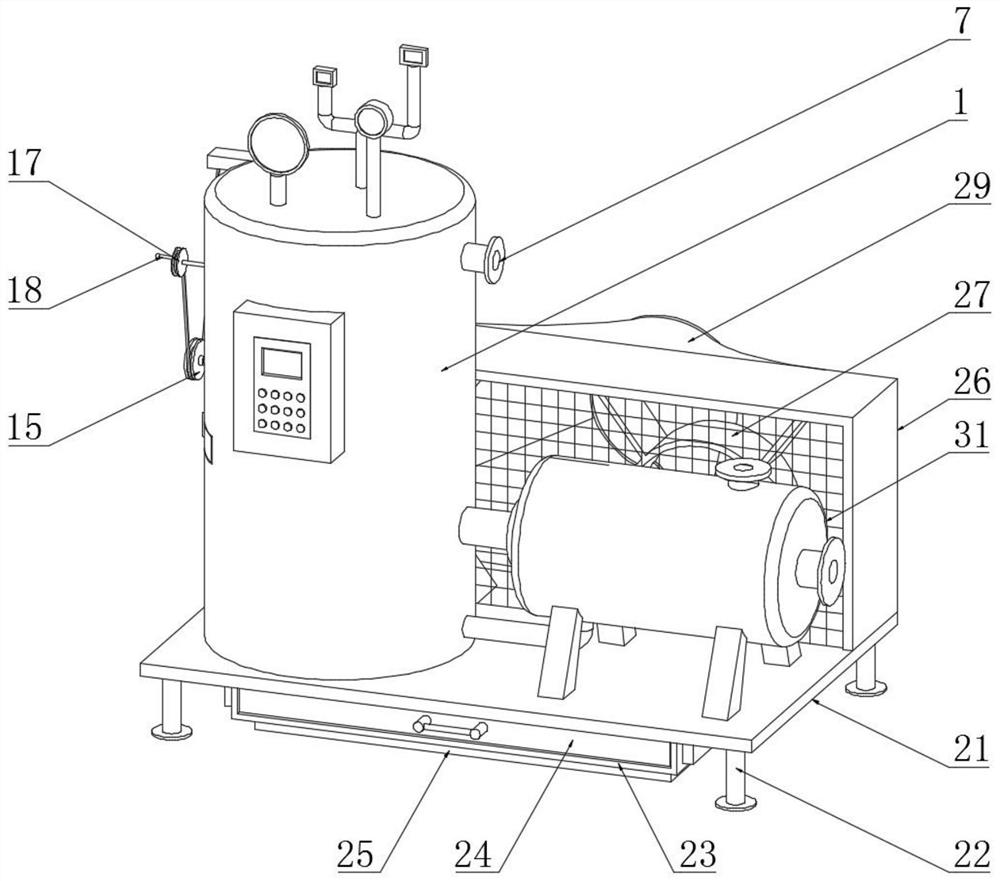

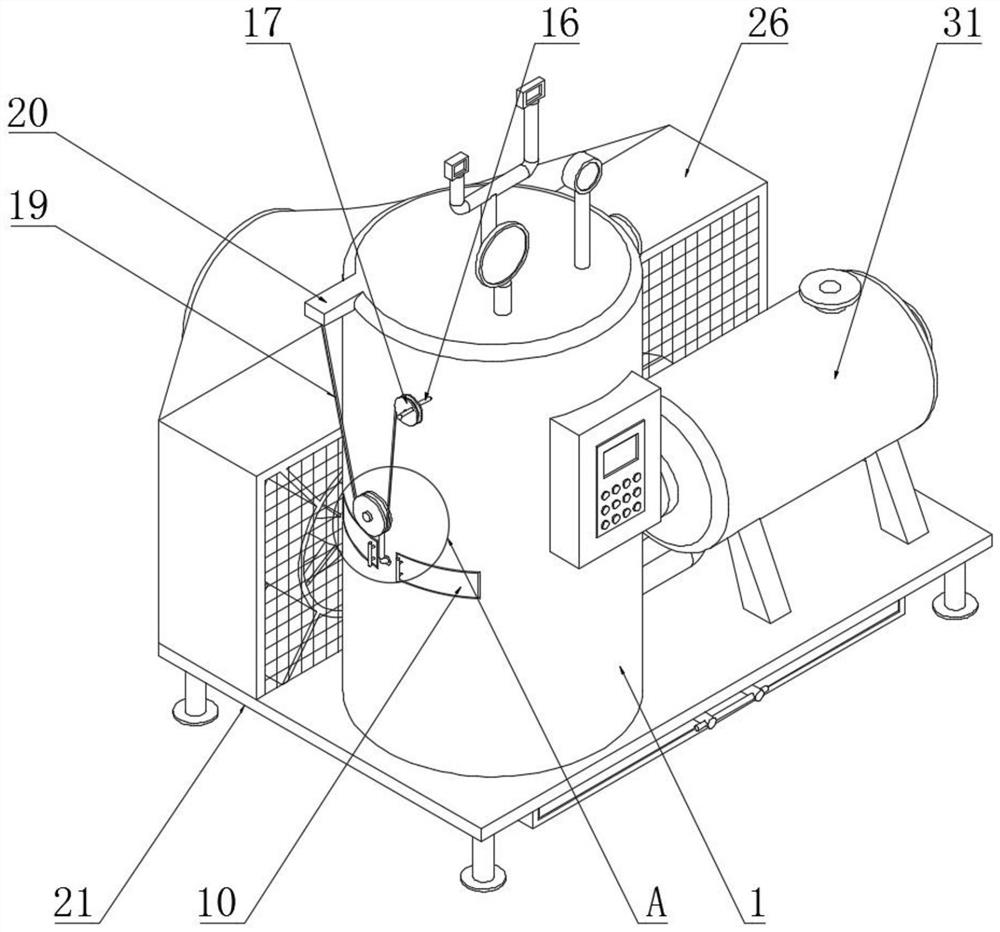

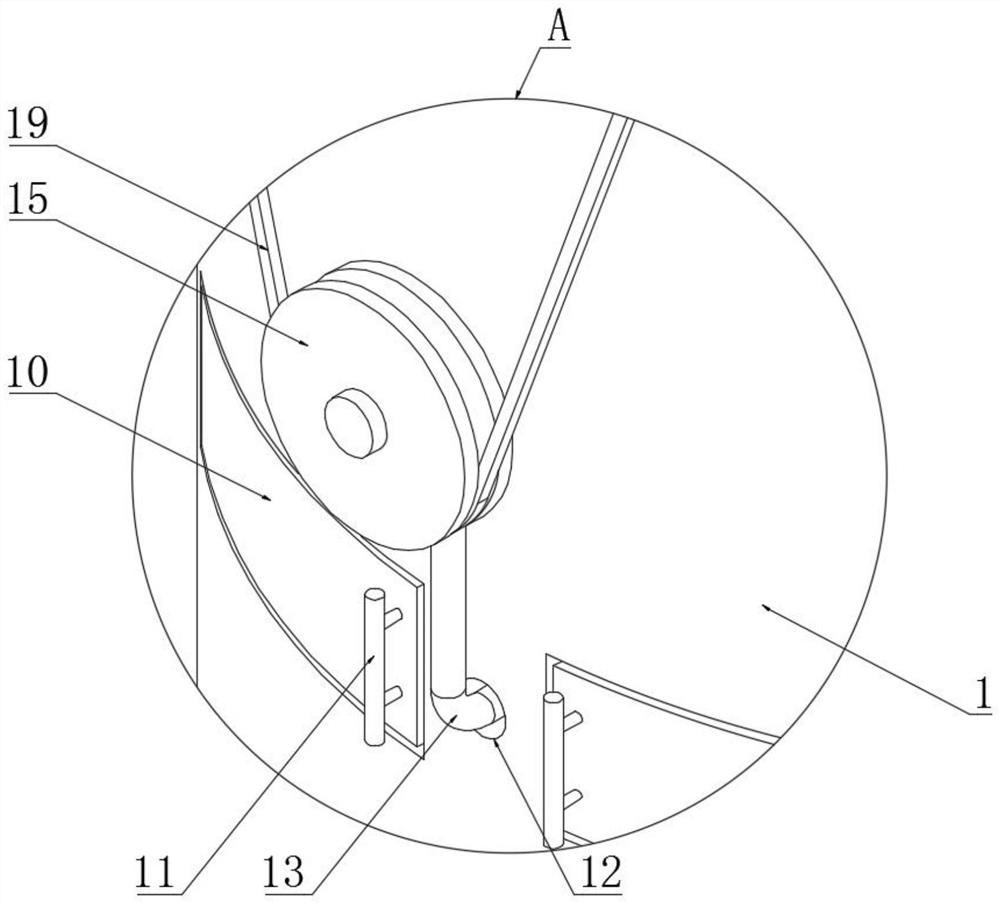

[0029] Example: such as Figure 1-6As shown, the present invention provides a technical solution, a methanol conversion furnace from coke oven gas, including a reformer body 1, a reaction chamber 2, a water storage chamber 3, a partition plate 4, a ventilating installation port 5, a one-way Valve 6, air inlet flange 7, mixed gas inlet 8, storage barbed wire 9, sealed cabinet door 10, handle 11, line notch 12, traction iron cable 13, cleaning scraper 14, movable pulley 15, fixed shaft 16, winding Turntable 17, handle 18, traction rope 19, fixed plate 20, moisture-proof bottom plate 21, support foot 22, the first installation frame 23, drawer 24, water-absorbing sponge 25, the second installation frame 26, blower fan 27, dust-proof barbed wire 28, guide Air cloth 29, ventilation pipe connector 30 and tubular heat exchanger 31, reaction chamber 2 is provided in the middle of reformer body 1, water storage chamber 3 is provided on the outside of reaction chamber 2, and water stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com