Preparation method of platinum catalyst by taking porous foaming aluminum as carrier for methyl alcohol reformer combustion chamber

A porous foam and platinum catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the negative impact of the catalyst skeleton on the catalyst and the low utilization rate of the catalyst , Insufficient contact between hydrogen and platinum, to achieve the effect that the coverage is not easy to fall off, the thickness can be adjusted, and the coverage is complete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put the porous aluminum foam in the working solution composed of 5-15g / L sodium aluminate and 0.5-2g / L sodium hypophosphite, use the foamed aluminum as the positive electrode, and the working tank as the negative electrode, and use a DC power supply at 300- 600V voltage, 10-30A / dm 2 Treat for 30-180 minutes under the condition of constant current density.

[0022] Add 15mL of chloroplatinic acid into the flask, add 1mL, 37% (mass fraction) of formaldehyde and 1mL, 20% (mass fraction) of sodium hydroxide solution, and finally put the porous aluminum foam in the flask, and raise the temperature to 80~ Stop heating after 95°C, cool, filter, and finally get a loading of 5-50mg / cm 2 platinum catalyst.

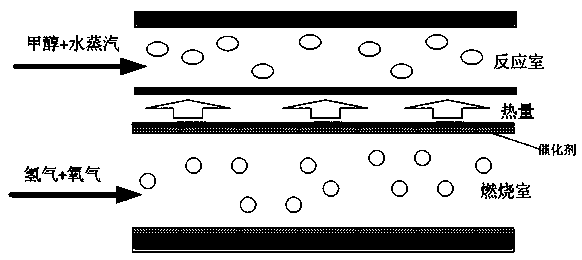

[0023] With the above-mentioned catalyst carrier, after loading the catalyst, put it in the combustion chamber (such as figure 1 ), the combustion chamber is a groove conforming to the volume of the carrier, and the front and rear respectively communicate with the inlet h...

Embodiment 2

[0025] The difference between this example and Example 1 is that the working fluid contains 10g / L of sodium aluminate and 1g / L of sodium hypophosphite. The output voltage of the DC power supply is 600V and the current density is 15A / dm. 2 , The processing time is 60 minutes.

Embodiment 3

[0027] The difference between this embodiment and Embodiment 1 is that an AC power source is used for the micro-arc oxidation power source, and the peak current density of the forward pulse is 10-30A / dm 2 , The peak current density of the negative pulse is 0-20 A / dm 2 , The working frequency is 10-3000Hz, and the processing time is 20-120min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak current density | aaaaa | aaaaa |

| Peak current density | aaaaa | aaaaa |

| Peak current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com