Composite compressed air energy storage system and method for coupling methanol reformer with internal combustion engine

A technology for compressed air energy storage and internal combustion engines, which is applied in fuel systems, combustion methods, chemical instruments and methods, etc. It can solve the problems that engine exhaust heat cannot be used in stages, so as to improve space utilization, increase contact time, and fully respond Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

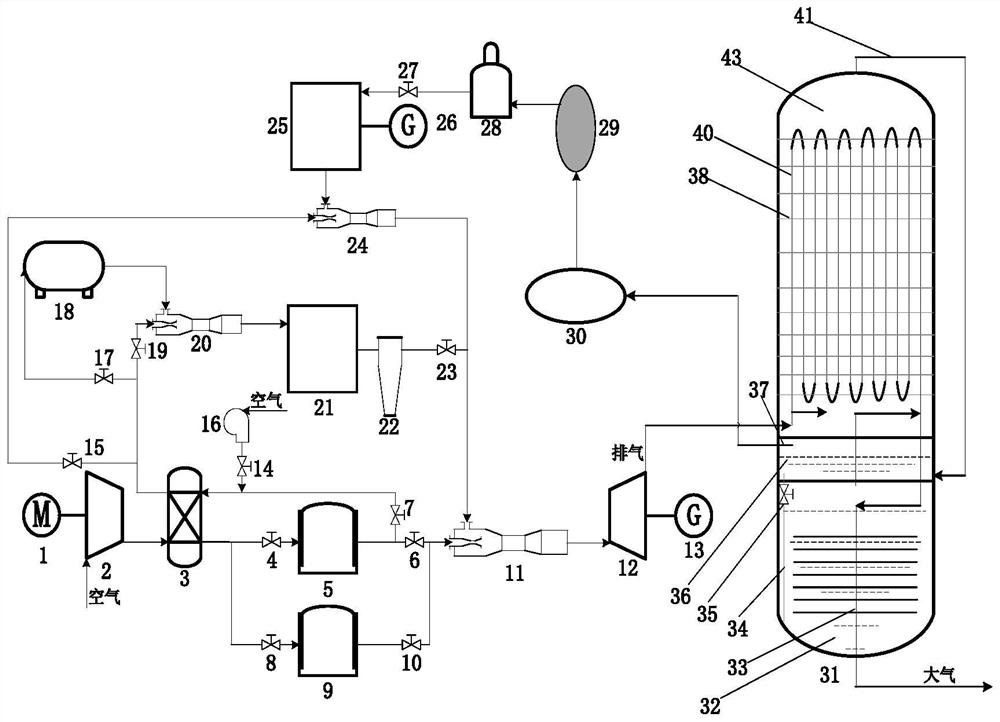

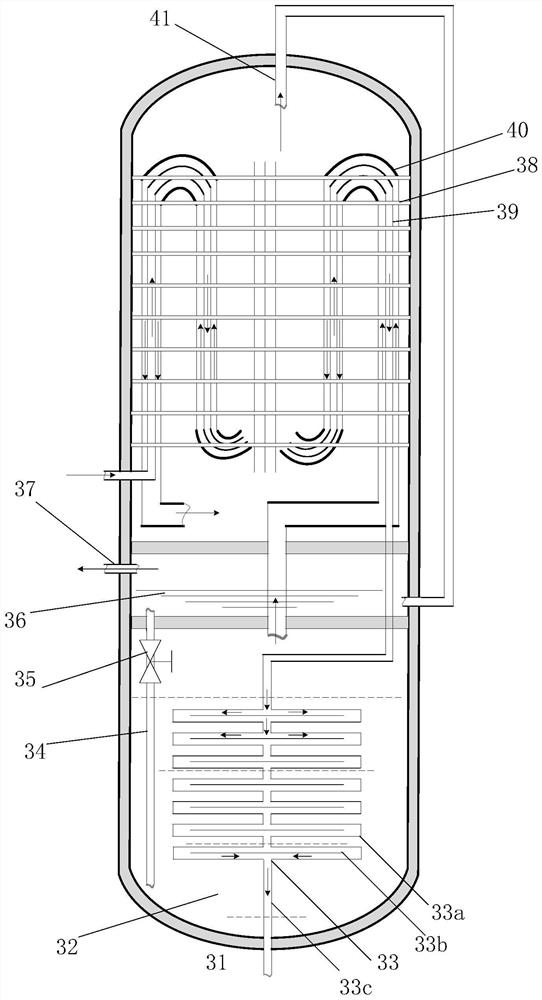

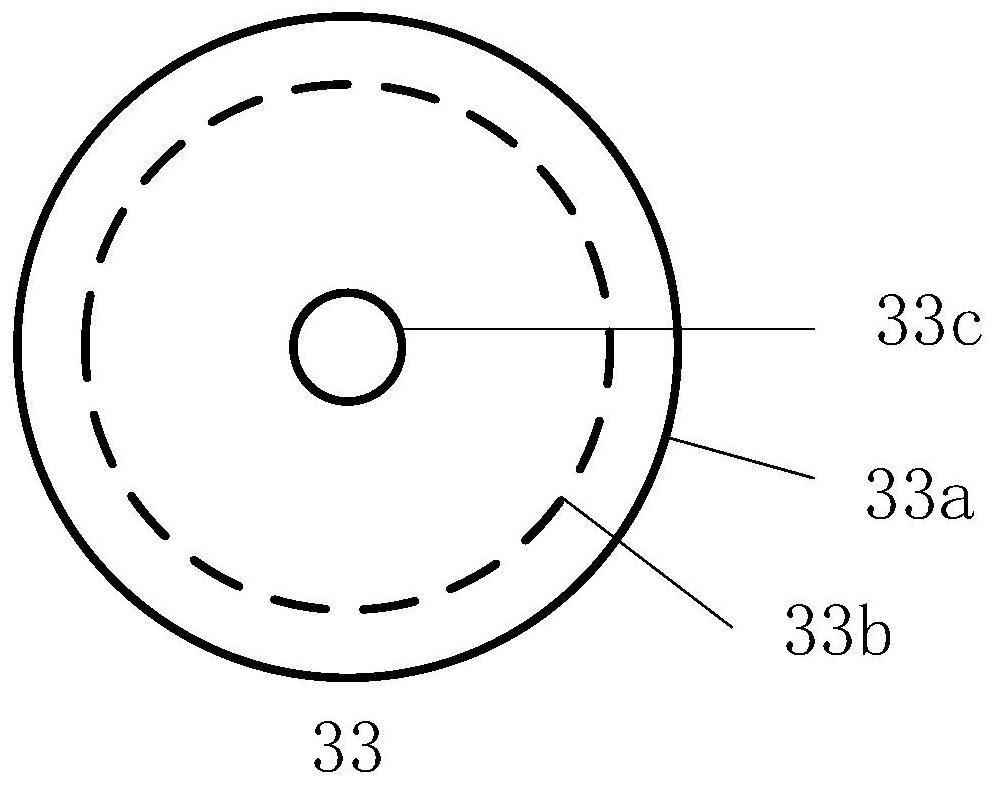

[0047] The invention provides a novel composite compressed air energy storage system and method for a methanol reformer coupled with an internal combustion engine. The new methanol reforming reactor is an integrated reactor for methanol water evaporation, reforming and methanol filtration in the mixed gas, which improves the space utilization of the system. The catalyst is prepared by cold spraying, which realizes the low cost and environmental protection of catalyst preparation. , which improves the economy of hydrogen production by steam reforming of methanol; the exhaust gas of the expander first passes through the inner tube of methanol steam reaction to provide energy for the methanol reforming reaction, and then passes through a disc-shaped heat exchanger to evaporate methanol aqueous solution to produce methanol Water vapor realizes the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com