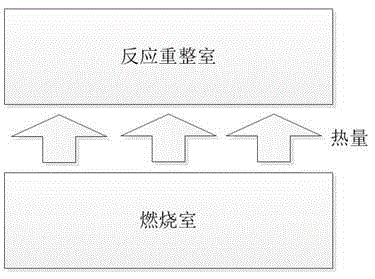

Preparation method of catalyst in combustor of micro-methanol reformer

A technology of reformer and combustion chamber, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of small contact area between reaction gas and catalyst, catalyst adhesion Focus on problems such as poor strength and low catalyst utilization rate, and achieve the effects of low cost, extended service life, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

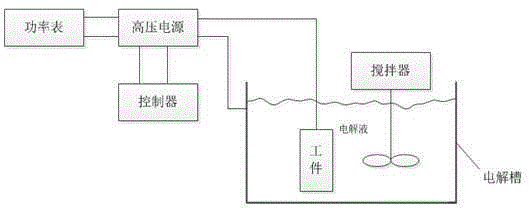

[0021] The combustion chamber of the miniature methanol reformer is made of aluminum alloy, and its composition includes an aluminum alloy body, an aluminum alloy package end plate and a flow field structure. The flow field structure is used as a gas circulation channel in the combustion chamber, located between the aluminum Between the end plates of the alloy package, on the surface of the aluminum alloy body. A layer of plexiglass is covered on the surface of the aluminum alloy body with flow channels and the flow channels are exposed, and then placed in such figure 1 In the electrolytic cell shown, the electrolytic cell is used as the cathode and the aluminum alloy body is used as the anode to perform micro-arc oxidation treatment on the flow channel. Among them: the electrolyte is a mixed solution of 5-15g / L sodium aluminate and 0.5-2.0g / L sodium hypophosphite, and the DC power supply provides an output voltage range between 400-700V, using 5-20A / dm 2 The current density ...

Embodiment 2

[0024] The difference between this example and Example 1 is that the electrolyte is a mixed solution of 10g / L sodium aluminate and 1.0g / L sodium hypophosphite, the output voltage provided by the DC power supply is 300V, and the current density is 15A / dm 2 , with a processing time of 60 minutes.

Embodiment 4

[0026] The difference between this embodiment and Embodiment 1 is that the micro-arc oxidation power supply is a bidirectional pulse power supply, and the positive pulse voltage is 400-600V, the negative pulse voltage is 0-300V, and the pulse frequency is 10-5000Hz. -120 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com