Foamed metal aluminum surface modification catalyst carrier, preparation method of the carrier, and method for preparing alcohol type reforming catalysts by utilizing carrier

A technology for catalyst support and reforming catalyst, which is applied in the direction of catalyst support, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problems of low catalyst utilization and insufficient contact, and achieve catalyst The effect of improving the utilization rate, enhancing the binding force, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

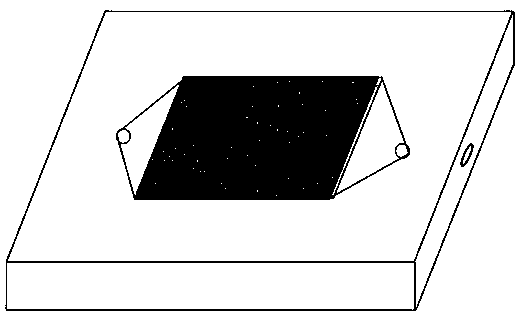

Image

Examples

Embodiment 1

[0024] Put the porous aluminum foam in the working solution composed of 5-15g / L sodium aluminate and 0.5-2g / L sodium hypophosphite, use the foamed aluminum as the positive electrode, and the working tank as the negative electrode, and use a DC power supply at 300- 600V voltage, 5-20A / dm 2 Treat for 30-120 minutes under the condition of constant current density.

[0025] The surface-modified aluminum foam is immersed in the Cu-based catalyst precursor, which is prepared from copper nitrate trihydrate, zinc nitrate hexahydrate, and aluminum nitrate nonahydrate, Cu:Zn:Al=11:4 :2 (atomic ratio) of nitrate solution in which Cu 2+ The concentration is 4.6wt%. After surface modification, there is a layer of loose and porous alumina on the surface of aluminum foam. Calcined in a nitrogen atmosphere for 2 hours, so that the nitrate is decomposed into a basic salt and then further decomposed to form an oxide. The final unit area loading is 17.9mg / cm2. 2 (25%, v%)N 2 In the atmospher...

Embodiment 2

[0027] The difference between this embodiment and embodiment 1 is that the aforementioned catalyst precursor uses 11.7wt% Na 2 CO 3 Precipitate at 65-70°C and maintain a pH of about 8.5, then age at the same temperature for 2 hours, filter and wash to obtain a precipitate, and disperse the precipitate in distilled water to obtain a 3wt% suspension to replace the catalyst precursor solution , in which the surface-modified aluminum foam is immersed.

Embodiment 3

[0029] The difference between this embodiment and Embodiment 1 is that an AC power source is used for the micro-arc oxidation power source, and the peak current density of the forward pulse is 5-30A / dm 2 , The peak current density of the negative pulse is 0-20 A / dm 2 , The working frequency is 10-3000Hz, and the processing time is 20-120min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com