Hydrogen purifying module of pure hydrogen and pure oxygen high-temperature battery system

A high-temperature battery, hydrogen technology, applied in the fields of oxygen production, hydrogen/syngas production, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of low energy utilization rate, low efficiency, not enough environmental protection, etc., and achieve cost Low, low efficiency, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

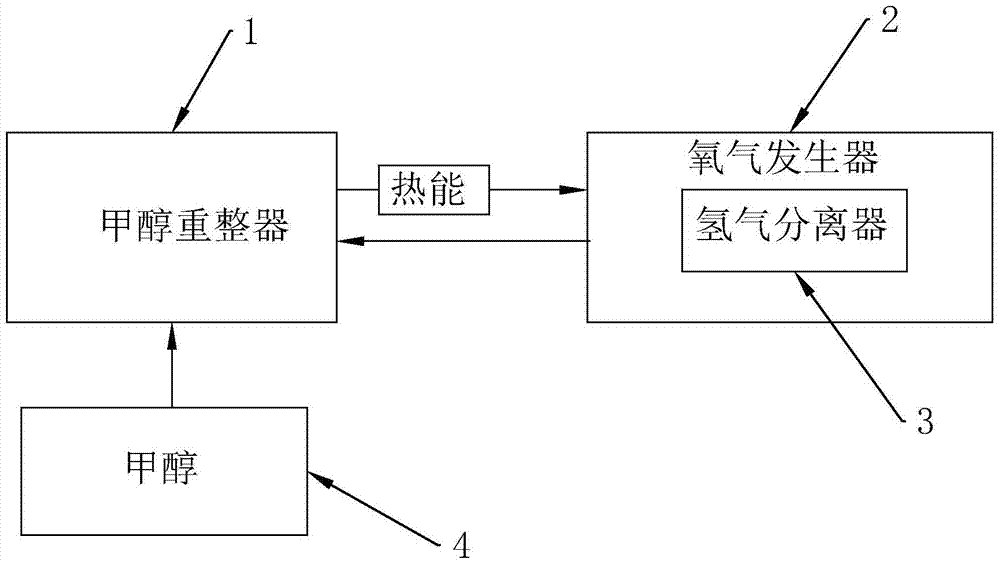

[0011] Such as figure 1 As shown, a hydrogen purification module of a pure hydrogen and pure oxygen high temperature battery system includes a methanol reformer 1, an oxygen generator 2 connected to the methanol reformer 1, and a hydrogen separator 3 arranged in the oxygen generator 2, The methanol reformer 1 utilizes the methanol raw material 4 and the oxygen generated by the oxygen generator 2 to undergo a methanol reforming reaction, and the oxygen generator 2 utilizes the heat generated by the reforming reaction of the methanol reformer 1 to carry out the conversion of hydrogen and oxygen Purify.

[0012] The working principle of the present invention is: the oxygen generator 2 includes an oxygen purification mechanism, the temperature required for oxygen purification is about 600°C, and the purification temperature of hydrogen is about 480°C. In the prior art, a heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com