Method for fuel methanol of igniting type engine

An engine and ignition-type technology, which is applied to combustion engines, internal combustion piston engines, gaseous engine fuels, etc., to achieve the effects of reducing fuel consumption rate, improving combustion efficiency, and reducing emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

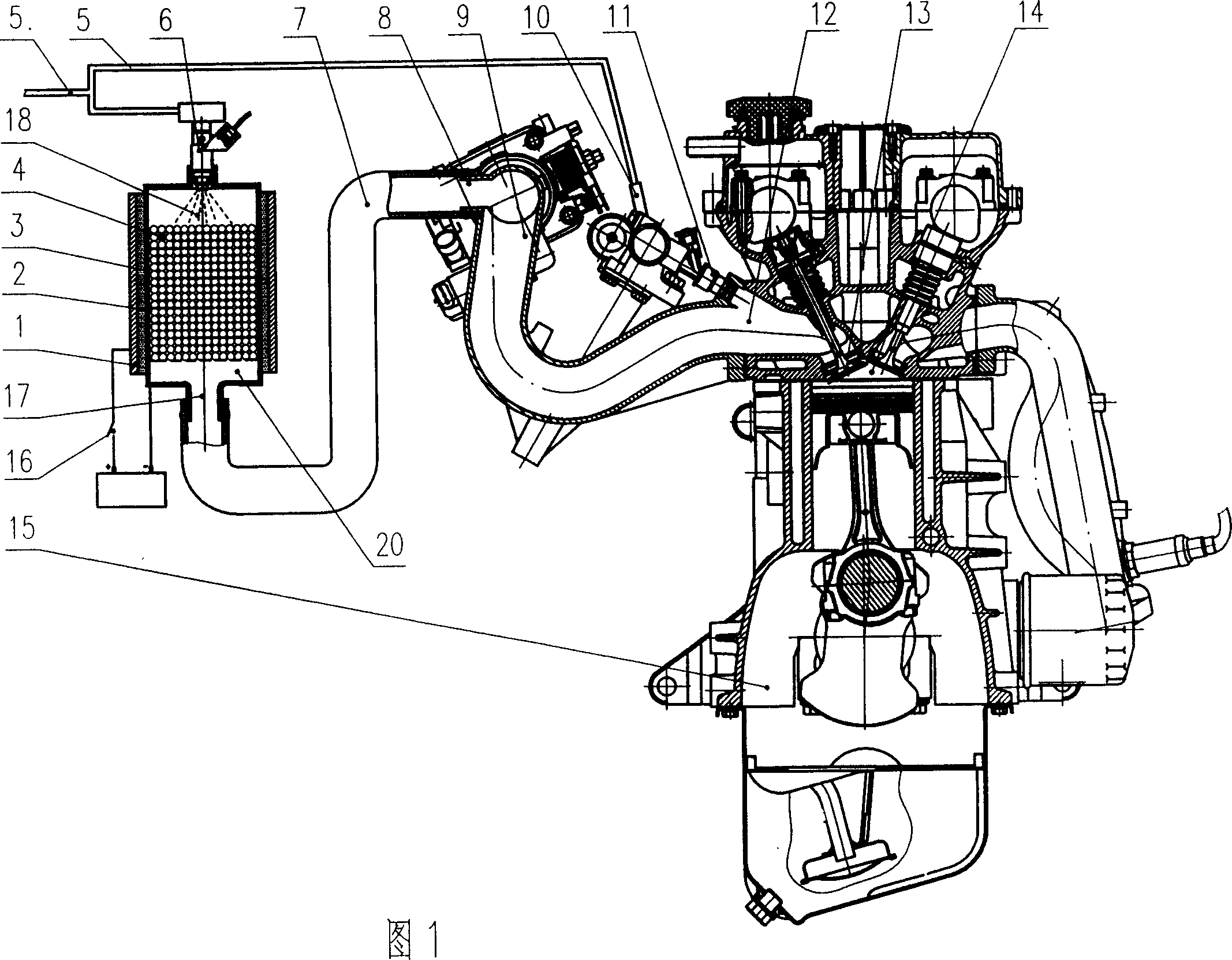

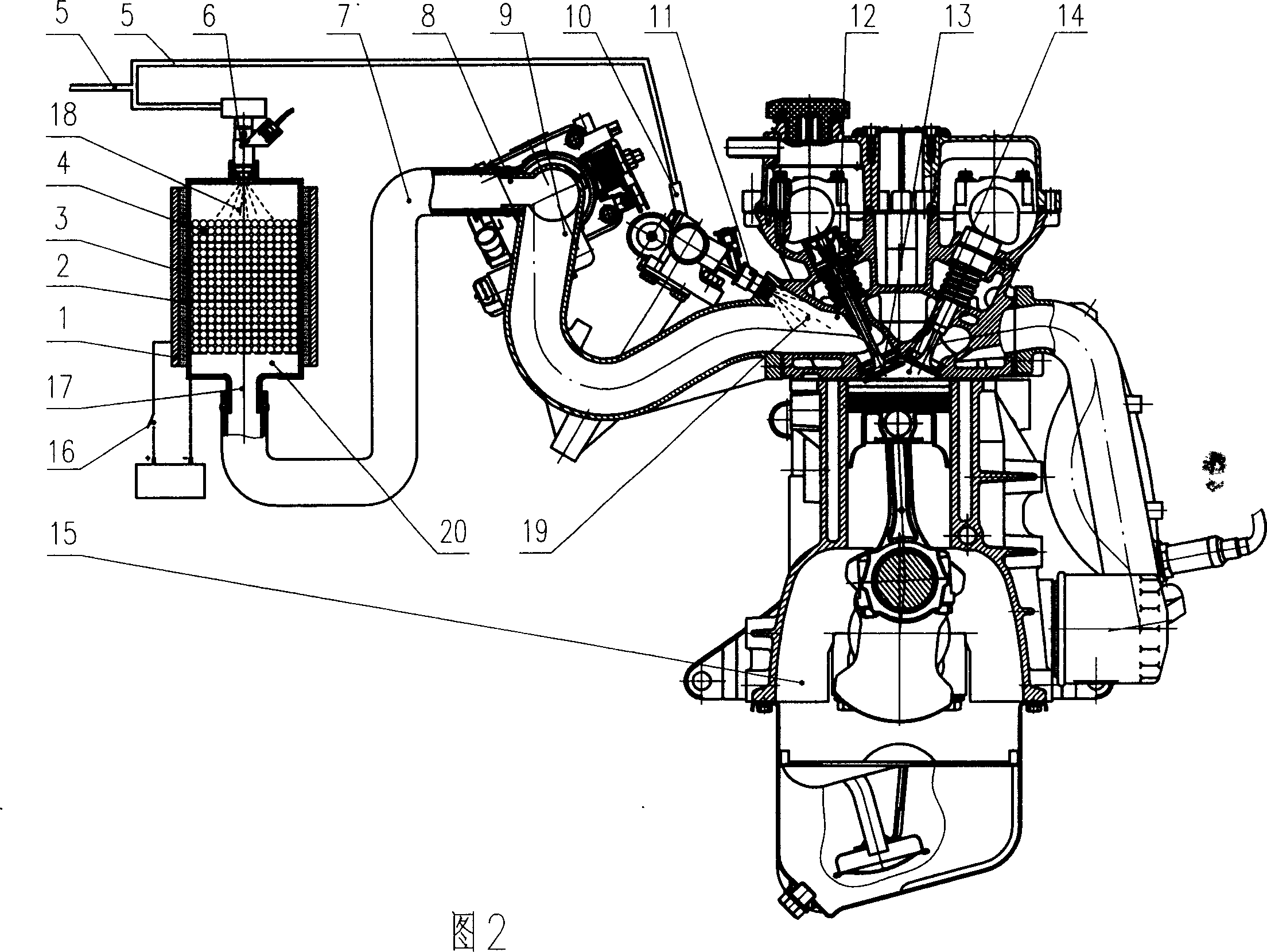

[0017] The method for ignition type engine burning methanol as shown in accompanying drawing 1, comprises the steps:

[0018] (1) Heating the methanol reforming catalyst: turn on the power switch 16, the current passes through the conductive plate 1, the PTC constant temperature heating element 2, and the reformer 3, and the PTC constant temperature heating element 2 heats the methanol reformer 3 with copper oxide (CuO) , with zinc oxide (ZnO), aluminum oxide (Al 2 o 3 ) mixed with the methanol reforming catalyst 4 and keep its temperature at 200°C to 300°C.

[0019] (2) Methanol reforming: Methanol 18 is sprayed into the methanol reformer 3 through the medium-pressure fuel pipe 5 and the electronically controlled nozzle 6, and the methanol 18 (CH3OH) contacts with the methanol reforming catalyst 4 at a temperature of 200°C to 300°C to generate reforming. The whole reaction produces hydrogen gas (H 2 ) and reformed gas 20 composed of carbon monoxide (CO);

[0020] (3) Inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com