a compressor

A technology for compressors and compressor shells, applied in the field of compressors, can solve problems such as low heat conduction efficiency, achieve gas-liquid separation, achieve stability, and improve work efficiency and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

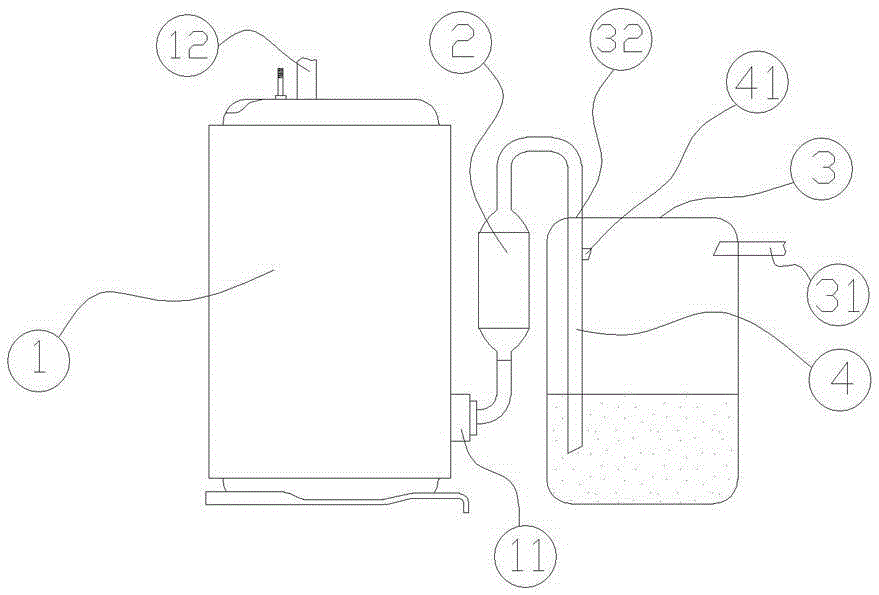

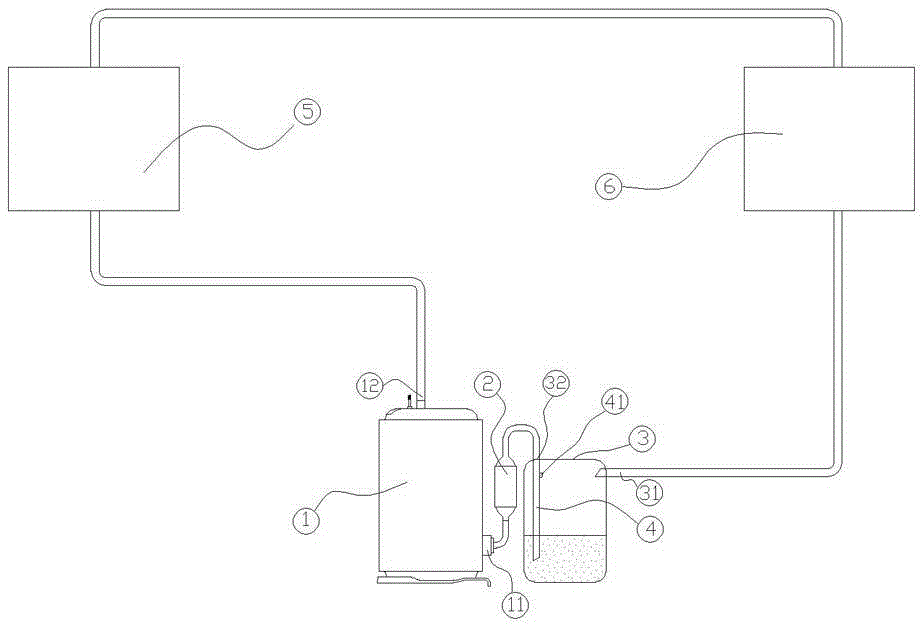

[0018] Such as figure 2 The schematic diagram of the compressor shown includes the compressor body (1), the filter (2), the liquid storage tank (3) installed on one side of the compressor body through the bracket, and the gas-liquid two in the liquid storage tank. Phase distribution pipe (4), evaporator (5), condenser (6) and connecting pipes, the compressor of the present invention is connected to the refrigerant input end of the evaporator (5) and the cooling of the condenser (6) Between the output ends of the agent, the compressor, the evaporator (5) and the condenser (6) are linked by the connecting pipes in the above order to form a two-phase flow heat pipe circulation system. The two-phase flow When the power heat pipe cycle system is working, the compressor body (1) extracts a large amount of liquid refrigerant from the liquid storage tank (3) and supplements a small amount of gaseous refrigerant that is stable throughout the cycle through the part of the return hole (41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com