A compressor gas-liquid separation structure

A gas-liquid separation and compressor technology, which is applied in the direction of refrigerators, mechanical equipment, refrigeration and liquefaction, etc., can solve the problems of cost increase, increase in external size, unfavorable internal structure optimization, etc., achieve strong applicability, improve gas-liquid Effect of Separation Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

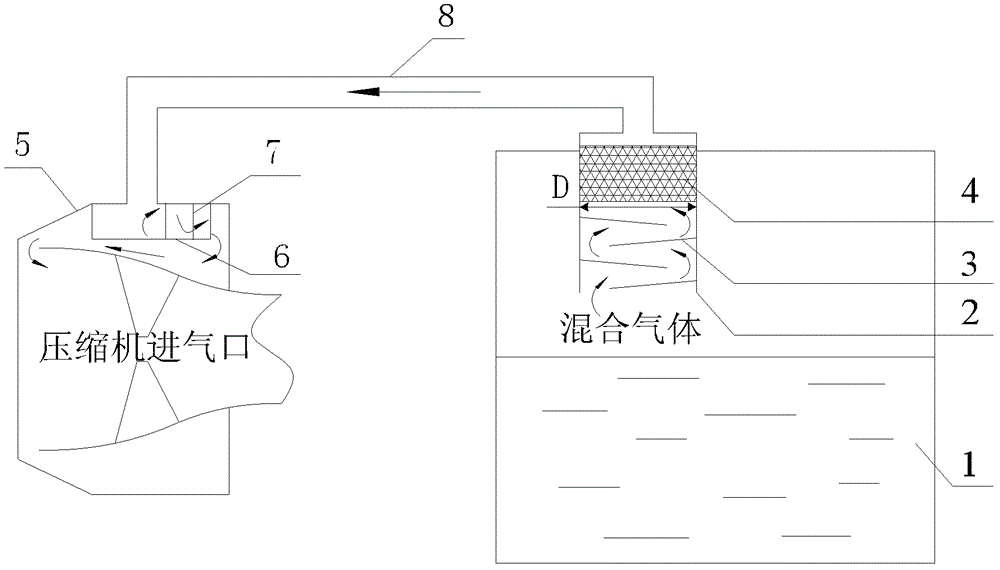

[0019] The embodiment of the present invention provides a compressor gas-liquid separation structure, which is used to achieve gas-liquid separation by utilizing the property that the liquid droplets are easy to attach to barriers due to the existence of viscosity when the flow velocity of the gas-liquid mixture decreases and the flow direction changes. The purpose is to obtain higher separation precision through multiple baffles and improve the separation effect of the gas-liquid mixture formed by refrigerant and lubricating oil in the compressor system.

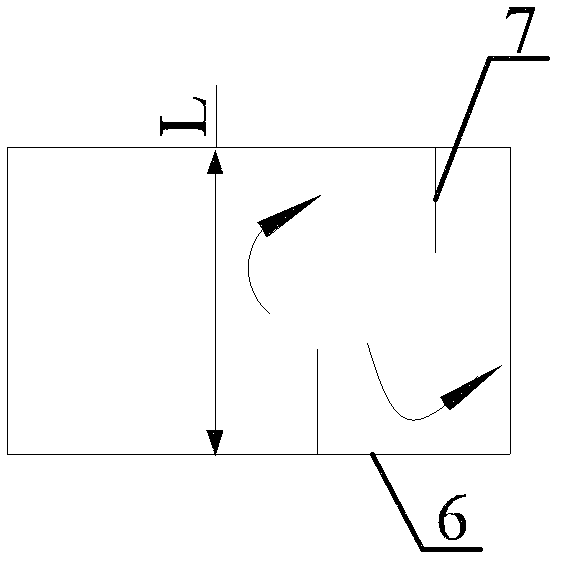

[0020] refer to figure 1 , shows a gas-liquid separation structure of a compressor according to an embodiment of the present invention, which includes a primary baffle set 3, a gas-liquid filter 4, and is further provided with a baffle 6 and a secondary baffle set 7, Among them, the primary baffle group 3 and the gas-liquid filter screen 4 are arranged in the same cylinder 2 on the top of the compressor oil tank 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com