A wet steam vapor-liquid two-phase separation device

A separation device, wet steam technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

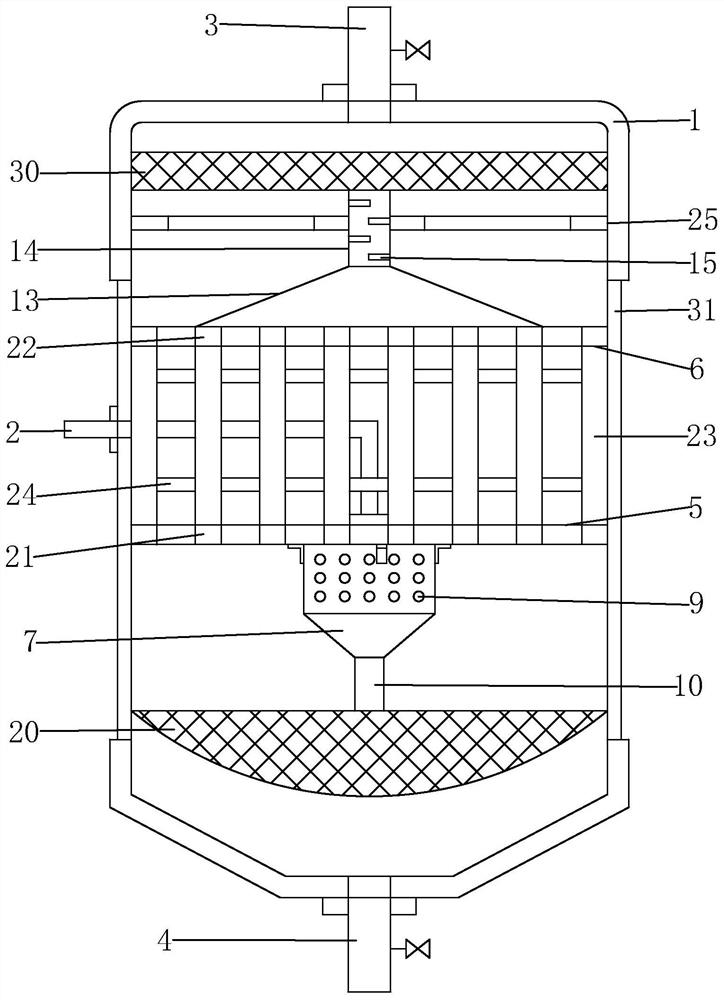

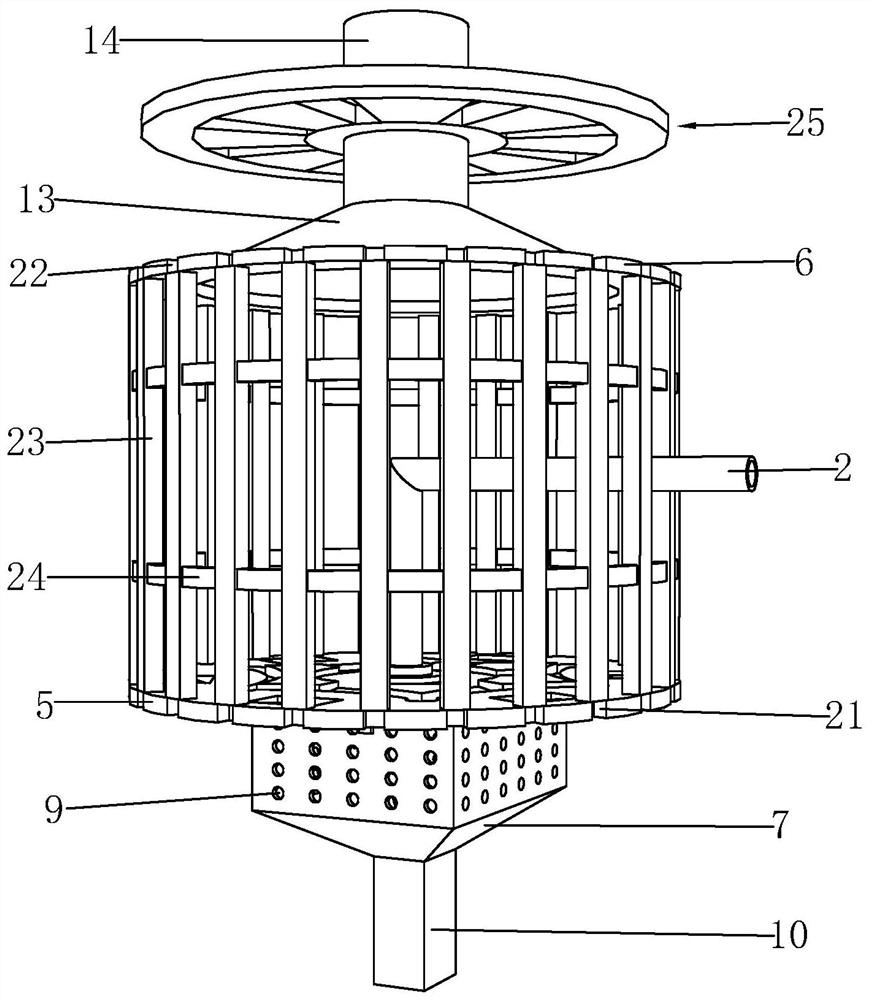

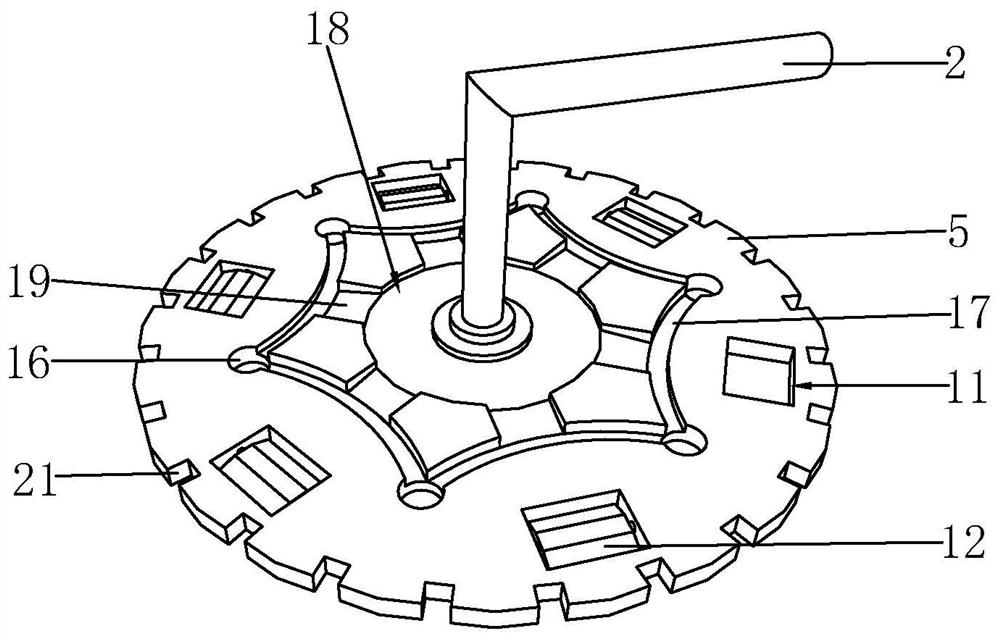

[0025] Such as Figure 1 to Figure 5 As shown, it is a wet steam vapor-liquid two-phase separation device according to the present invention, which includes a cylinder body 1, and an air inlet pipe 2 is arranged on the cylinder body 1, and the wet steam enters the cylinder body 1 from the air inlet pipe 2, and the top of the cylinder body 1 There is an exhaust pipe 3, and the separated gas is discharged from the exhaust pipe 3. The bottom of the cylinder 1 is provided with a liquid discharge pipe 4, and the separated liquid is discharged from the liquid discharge pipe 4. The cylinder 1 is respectively equipped with a support plate 5 and the liquid baffle 6, the liquid baffle 6 is located above the support plate 5, the bottom surface of the support plate 5 is provided with a separation bucket 7, and an L-shaped reinforcement piece 8 is provided between the support plate 5 and the separation bucket 7, which improves the installation The firmness on the support plate 5 is not eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com