Air cushion furnace gas-liquid quenching spray nozzle structure and gas-liquid cooperative quenching system

A technology of air cushion furnace and gas nozzle, which is applied in the direction of quenching device, furnace, furnace type, etc., and can solve the problems of water accumulation in the air duct, accelerated structural corrosion, and threats to the safe operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

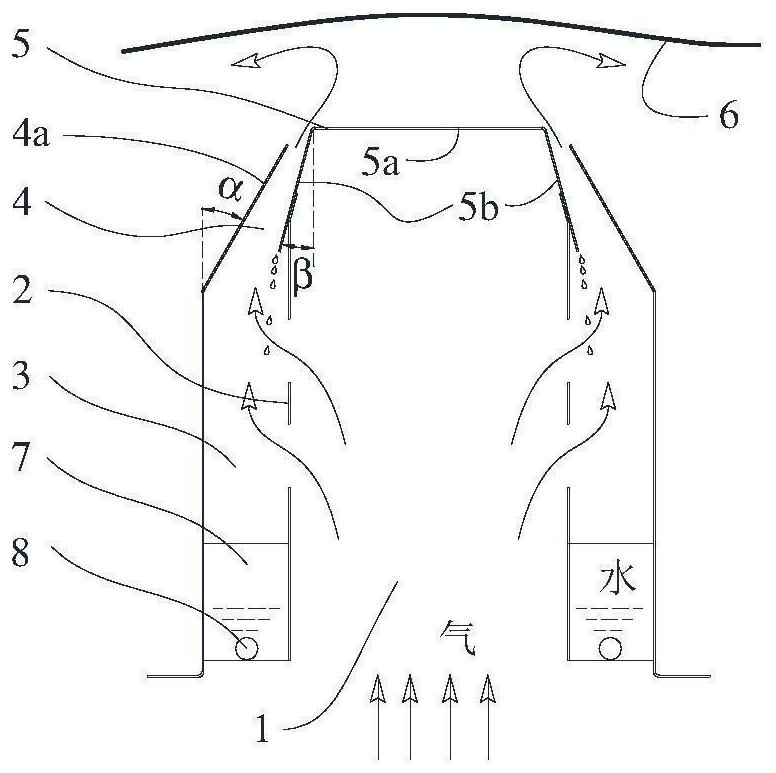

[0028] Such as figure 1 As shown, a gas-liquid quenching nozzle structure of a hovering furnace includes an air inlet chamber 1, a nozzle 4, a waterproof cover 5, a gas-liquid separation chamber 3, and a drainage groove 7 arranged at the bottom of the gas-liquid separation chamber. The air inlet chamber 1 and the gas-liquid separation chamber 3 are separated by a circular orifice plate 2, and the holes of the orifice plate are as follows: image 3 shown. The top of the orifice plate 2 is connected and fixed to the inner side of the waterproof cover water eaves 5b, and the lower end of the waterproof cover water eaves 5b protrudes a certain distance to facilitate the drop of liquid droplets into the gas-liquid separation chamber 3. The air first enters the air intake chamber 1, and flows into the nozzle 4 through the orifice plate 2 in turn. The design size of the nozzle 4 is relatively narrow, and the design flow velocity is about 40m / s. The gas forms an air cushion layer be...

Embodiment 2

[0033] Embodiment two is similar to embodiment one, the difference is:

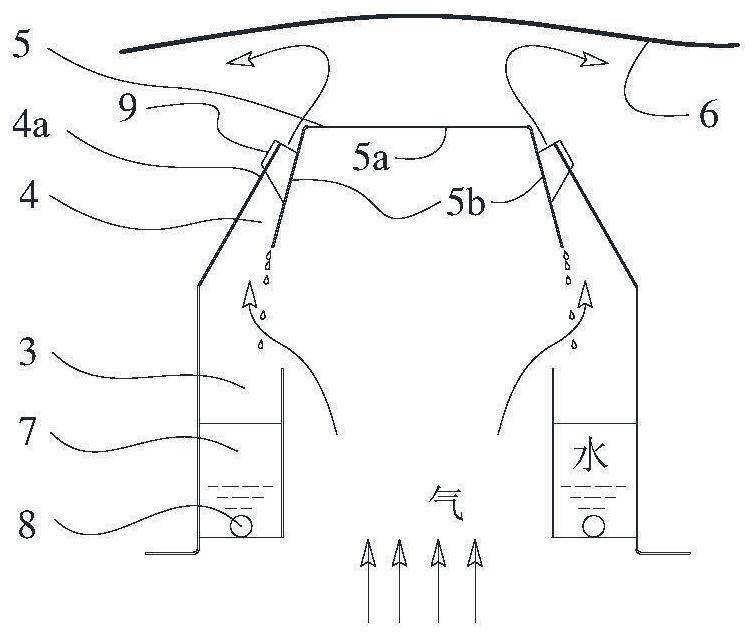

[0034] Such as figure 2 As shown, there is no obvious separation boundary between the air inlet chamber 1 and the gas-liquid separation chamber 3, and the orifice plate is cancelled. The outer side of the water eaves 5b of the waterproof cover is fixed on the spout bending plate 4a through the rib plate 9. Its advantage is that it can reduce part of the loss of air circulation resistance and reduce the height of the nozzle.

Embodiment 3

[0036] Embodiment three is similar to embodiment one, the difference is:

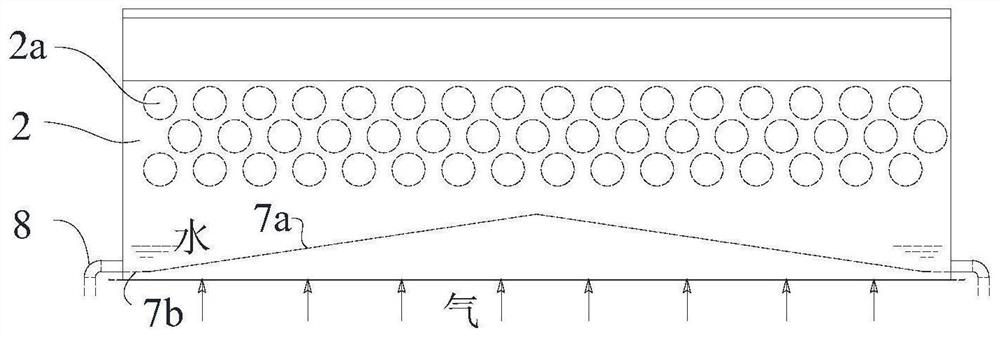

[0037] Such as Figure 4 As shown, the drainage groove 7 is a one-sided diversion method, and the bottom plate is in the form of a flat plate composed of an inclined section bottom plate 7a and a horizontal section bottom plate 7b, and the slope of the inclined section bottom plate 7a is 0.04.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com