Gas-liquid multistage separation device for gas bearing experiment for incoming flow of pump

A multi-stage separation and gas-liquid separation plate technology, applied in the field of pump experiments, can solve the problems of unfavorable floor space, single separator, bulky volume, etc., and achieve the effect of compact structure, high separation efficiency and sufficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

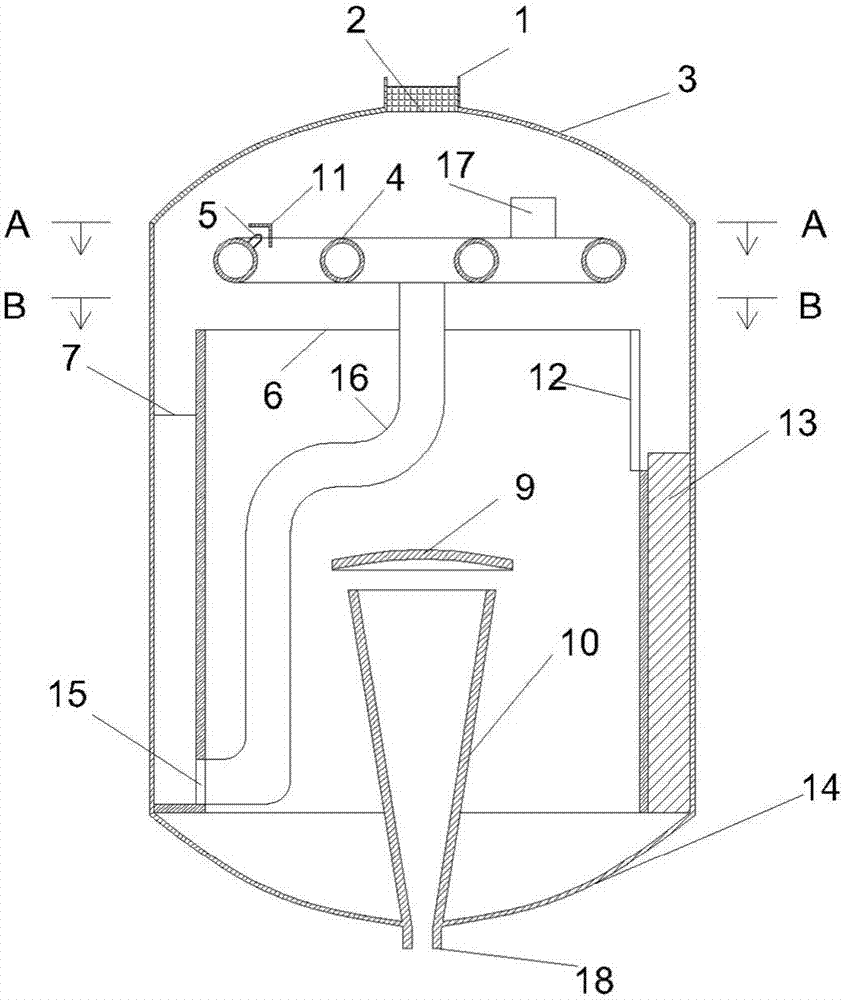

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as figure 1 As shown, the specific implementation of the present invention includes a tank body 14 and a first-level separation part placed in the tank body 14, a second-level separation part and a third-level separation part, and the first-level separation part is placed in the inner cavity of the tank body 14 In the upper space, the second-level separation part is placed on the inner wall of the tank body 14, the first-level separation part and the second-level separation part are connected by a water pipe 16, the third-level separation part is placed at the bottom of the tank body 14, and the tank body 14 The tank cover 3 has a top air outlet 1, and a wire mesh filter 2 is installed at the top air outlet 1.

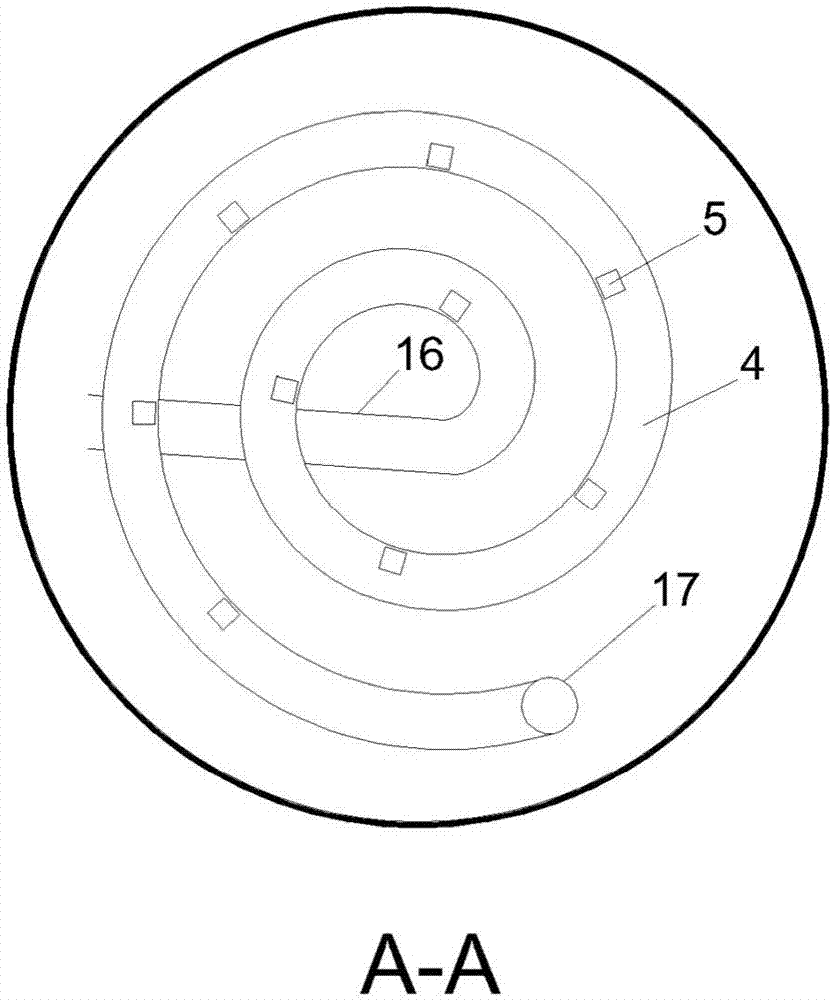

[0032] Such as figure 2 As shown, the first-stage separation part is mainly composed of a spiral tube 4, a nozzle 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com