Gas-liquid separation device and method, crude oil extraction system and crude oil detection system

A gas-liquid separation device, crude oil technology, applied in the direction of measuring devices, material separation, analysis of materials, etc., can solve the problems of liquid light hydrocarbon retention, poor separation effect, measurement error, etc., to achieve the effect of gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

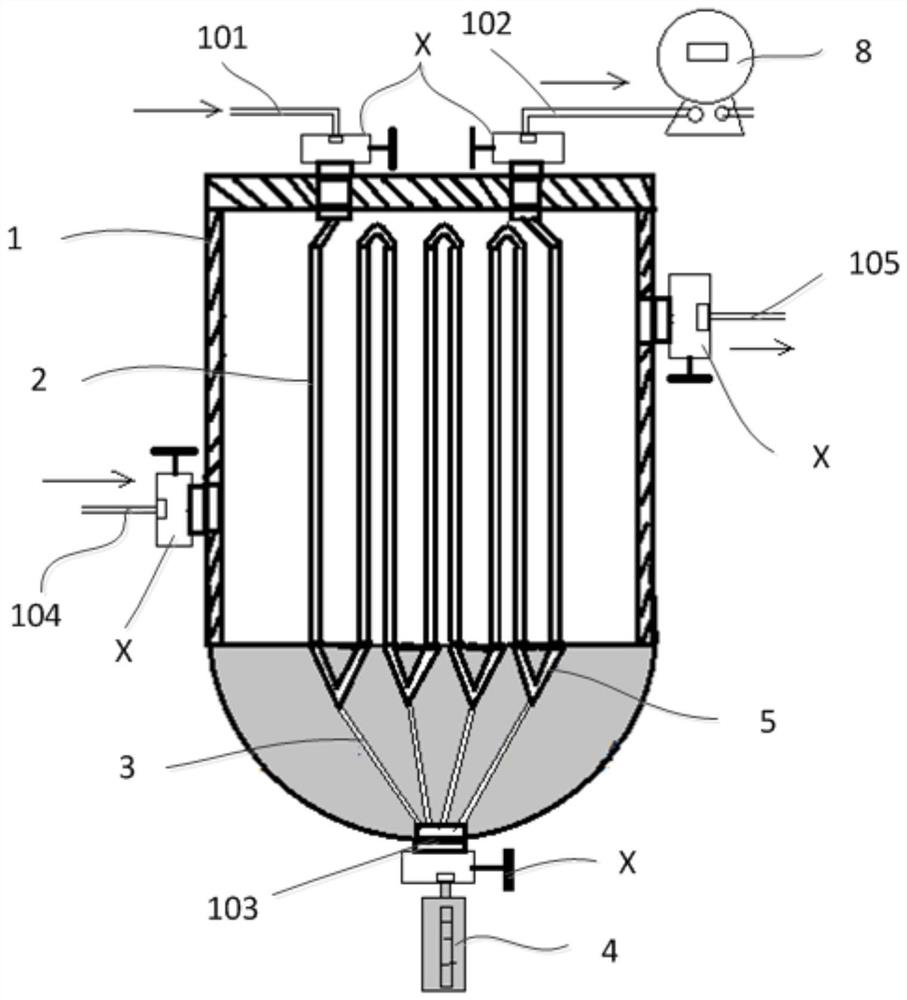

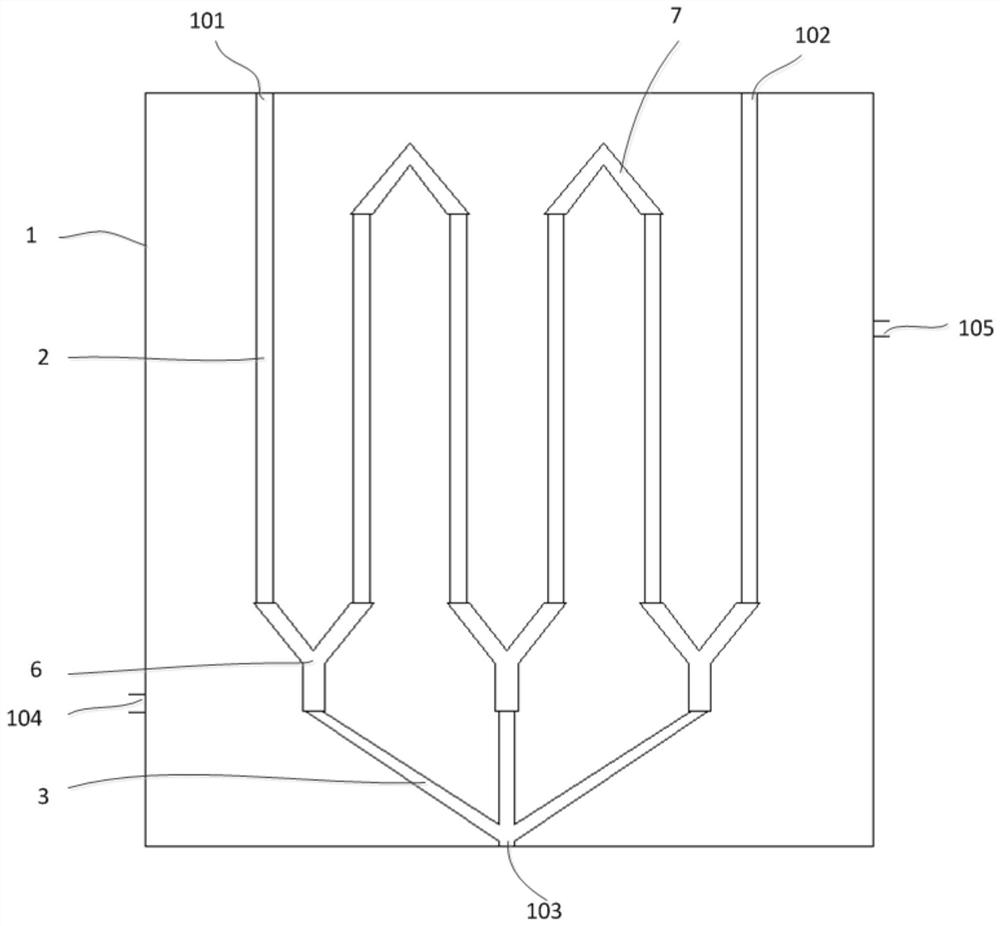

[0068] This embodiment provides a gas-liquid separation device for fluid obtained by extracting light hydrocarbons from crude oil with high-pressure gas. See figure 2 , the gas-liquid separation device comprises: a housing 1, 8 fluid inlet pipelines 2, 4 liquid drainage pipelines 3, and a liquid collector 4; the housing 1 has a fluid inlet 101, a gas outlet 102, a liquid outlet 103, a condensation The medium inlet 104, the condensing medium outlet 105, and the base 106; the fluid inlet 101, the gas outlet 102, the liquid outlet 103, the condensing medium inlet 104, and the condensing medium outlet 105 are all provided with a valve X; the base 106 is a hemispherical solid structure, and the base 106 is provided with 4 V-shaped grooves 5, each V-shaped groove has two through holes, and 8 through holes are located on the upper surface of the base 106; each fluid inlet line is connected to one of the through holes , and the two through-holes of each V-groove are respectively in ...

Embodiment 2

[0070] This embodiment provides a crude oil extraction system. The crude oil extraction system includes: a crude oil extraction device and the above-mentioned gas-liquid separation device; the crude oil extraction device communicates with the fluid inlet of the gas-liquid separation device.

Embodiment 3

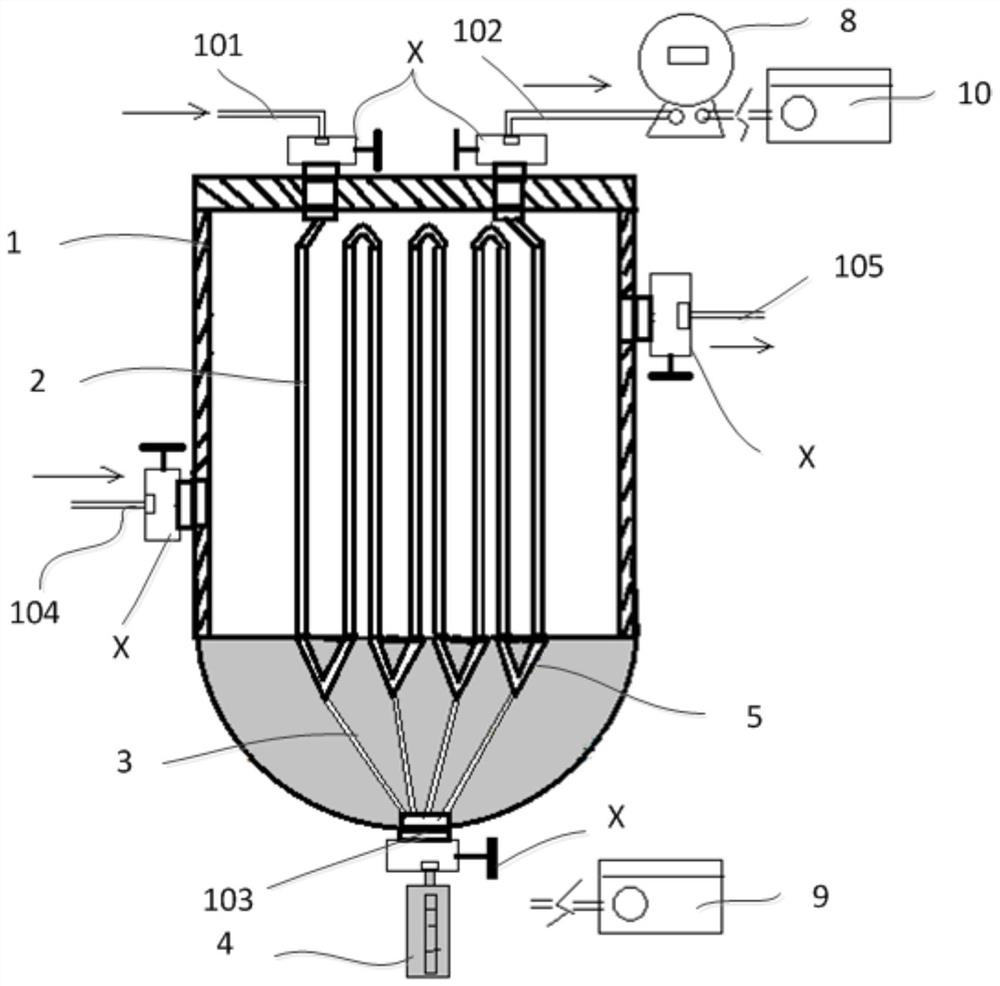

[0072] This embodiment provides a crude oil detection system. See image 3 , the crude oil detection system comprises: the above-mentioned gas-liquid separation device, a liquid chromatography system 9, and a gas chromatography system 10, the liquid chromatography system 9 is used to detect the liquid in the liquid collector 4, the gas chromatography system 10 and the gas meter 8 connected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com