Treatment method of waste gas containing organic pollutants

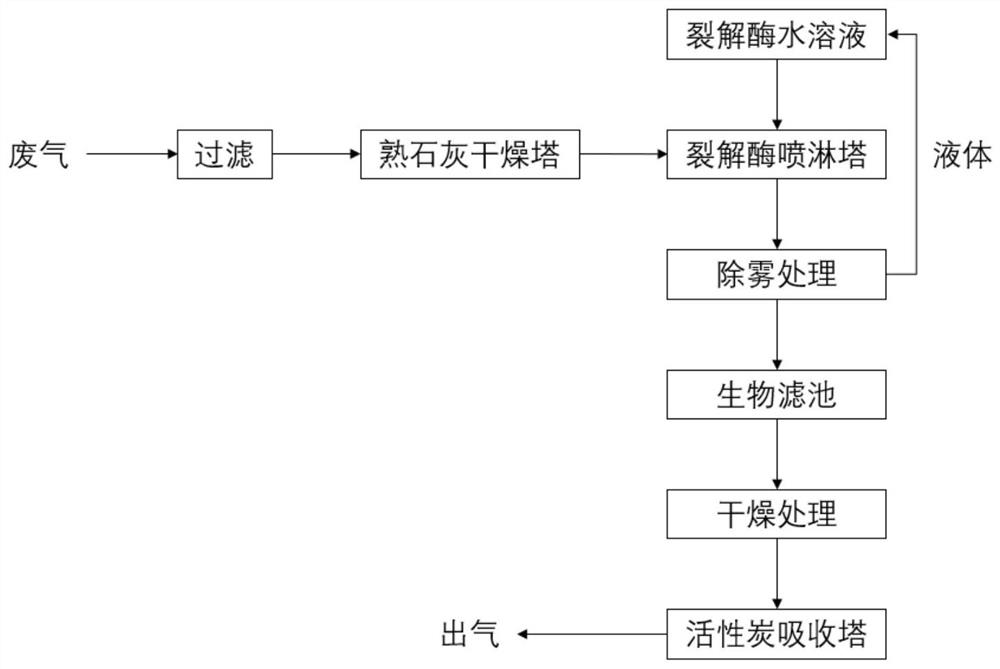

A technology of organic pollutants and treatment methods, which is applied in the field of waste gas treatment, can solve the problems of difficult long-term stable operation of biological filters and poor pollutant removal effect, and achieves the effect of increasing the contact probability and improving the removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

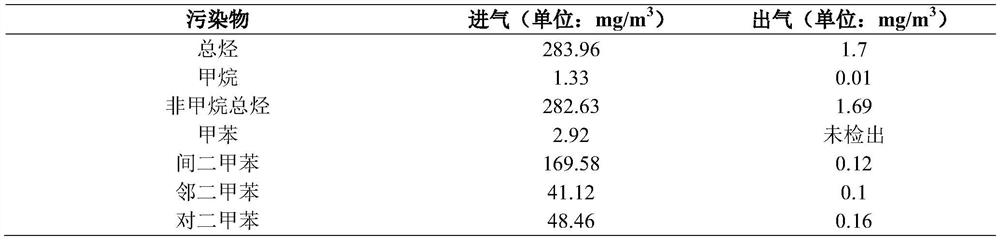

[0042] For waste gas containing pollutants such as hydrogen sulfide, sulfur dioxide, methane, toluene, xylene, etc., the content of each pollutant in the intake air is shown in Table 1. This embodiment provides a treatment method for waste gas containing organic pollutants, including:

[0043] In the pretreatment step, the exhaust gas enters the belt dust collector under the action of the induced draft fan for dust removal, and the purified exhaust gas is subjected to the following steps:

[0044] 1) Pass the dedusted waste gas into the absorption tower equipped with slaked lime to remove acid pollutants such as hydrogen sulfide and sulfur dioxide contained in the waste gas;

[0045] 2) Laccase spray treatment:

[0046] The activity unit of the laccase used in this embodiment is about 100,000 u / g, and the addition amount in water is 5ppm. A sprayer is installed in the spray tower to spray the aqueous solution containing laccase from top to bottom in the form of water mist. Th...

Embodiment 2

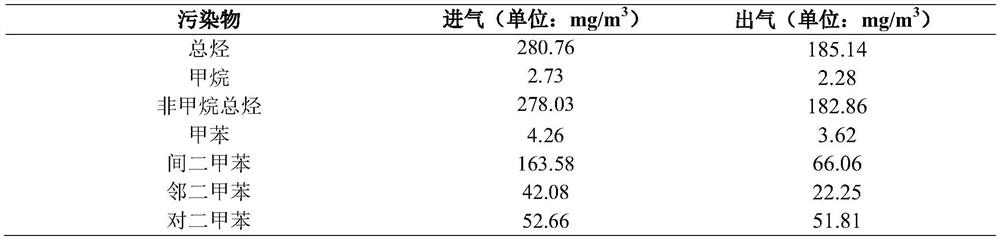

[0062] For waste gas containing pollutants such as hydrogen sulfide, methane, toluene, xylene, etc., the content of each pollutant in the intake air is shown in Table 3. This embodiment provides a treatment method for waste gas containing organic pollutants, including:

[0063] In the pretreatment step, the exhaust gas enters the belt dust collector under the action of the induced draft fan for dust removal, and the purified exhaust gas is subjected to the following steps:

[0064] 1) Pass the dedusted exhaust gas into the absorption tower equipped with slaked lime to remove acidic and odorous pollutants such as hydrogen sulfide contained in the exhaust gas;

[0065] 2) Laccase spray treatment:

[0066] The activity unit of the laccase used in this example is about 100,000 u / g, and the addition amount in water is 10ppm. A sprayer is installed in the spray tower to spray the aqueous solution containing laccase from top to bottom in the form of water mist. The exhaust gas is pa...

Embodiment 3

[0076] The treatment method in this example is basically the same as that in Example 2, except that the organic pollutants contained in the waste gas include hydrogen sulfide, methane, toluene, xylene, etc., and the contents are shown in Table 4.

[0077] Pollutant content in the inlet and outlet gas in the embodiment 3 of table 4

[0078]

[0079] The biofilter in this embodiment has been in stable operation for 180 days for a long time, and can still reach the concentration of total hydrocarbons at 15mg / m3. 3 the following.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com