Two-phase flow liquid storage flow stabilizer

A two-phase flow liquid storage and flow stabilizer technology, which is applied in the direction of refrigeration and liquefaction, refrigeration components, refrigerators, etc., can solve the problems of single performance and simple structure, and achieve single performance, simple structure, and realize gas-liquid separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

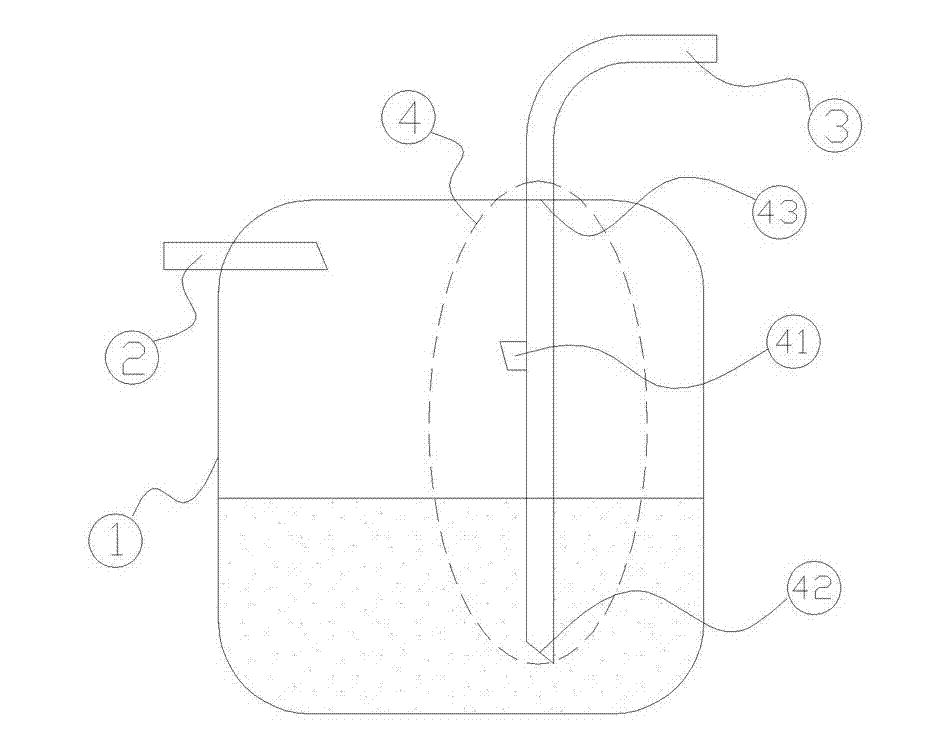

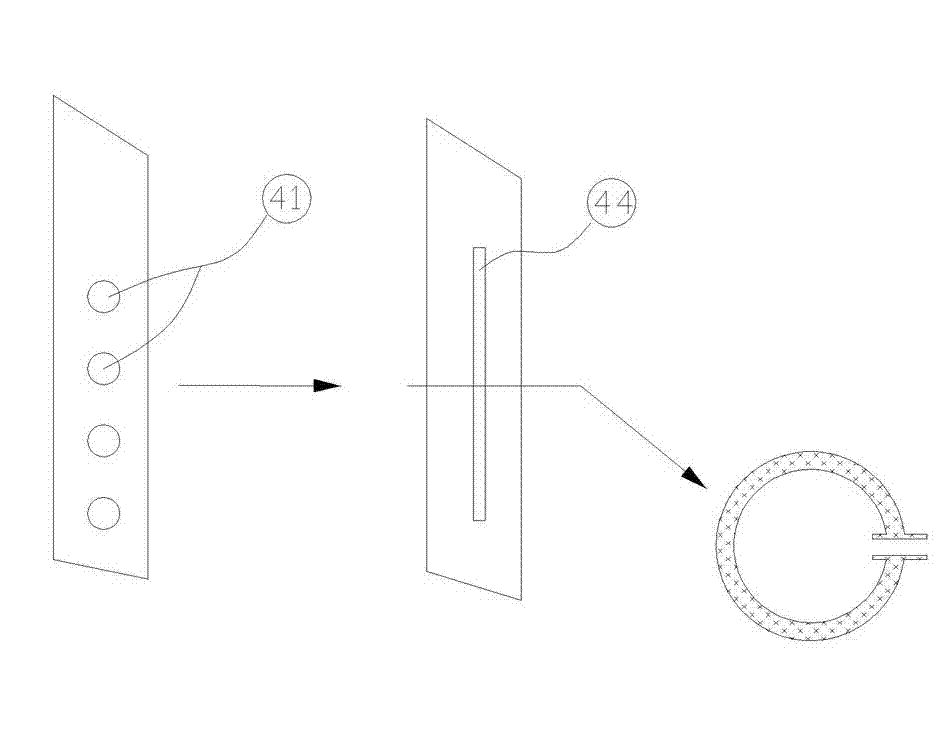

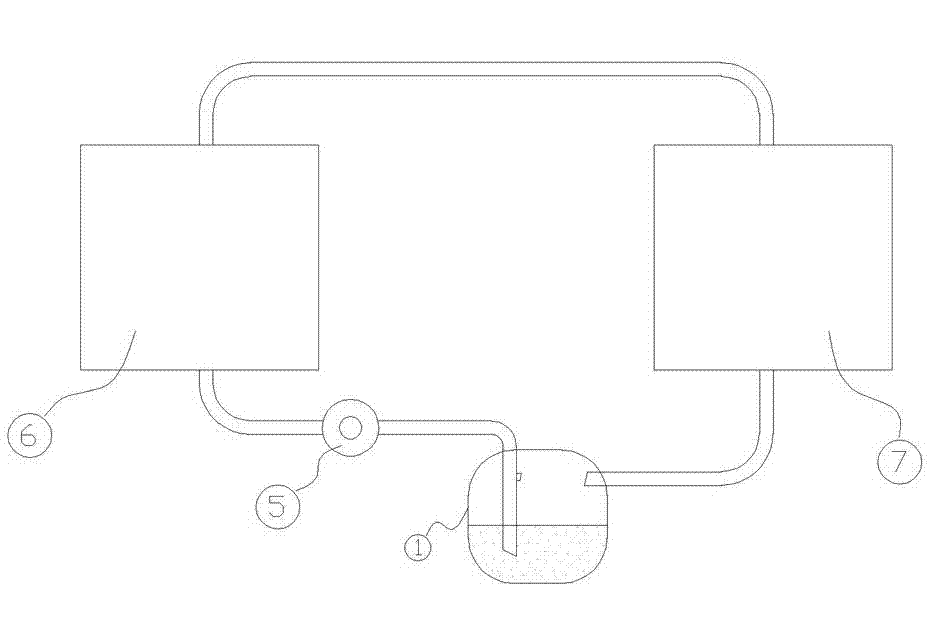

[0019] like image 3 The schematic diagram of the shown two-phase flow liquid storage stabilizer, including circulation pump (5), evaporator (6), condenser (7), two-phase flow liquid storage stabilizer and connecting pipelines, the circulation The pump (5), the evaporator (6), the condenser (7) and the two-phase flow liquid storage stabilizer are connected in the above order through the connecting pipes to form a two-phase flow power heat pipe circulation system, the When the two-phase flow power heat pipe circulation system is working, the circulation pump (5) draws a large amount of liquid refrigerant from the liquid storage tank (1) of the two-phase flow liquid storage stabilizer and replenishes the entire cycle through the part passing through the return hole (41) A small amount of stable gaseous refrigerant enters the evaporator (6) through the evaporator liquid guide tube, and the evaporator (6) is in contact with a high-temperature heat source, and the liquid working me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com