Novel all-welding plate shell type heat exchanger

An all-welded, plate-and-shell technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of increasing unilateral fluid disturbance, increasing heat exchange efficiency, complex impermeability, etc., to achieve High energy recovery utilization rate, increased heat exchange area, and flexible and changeable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

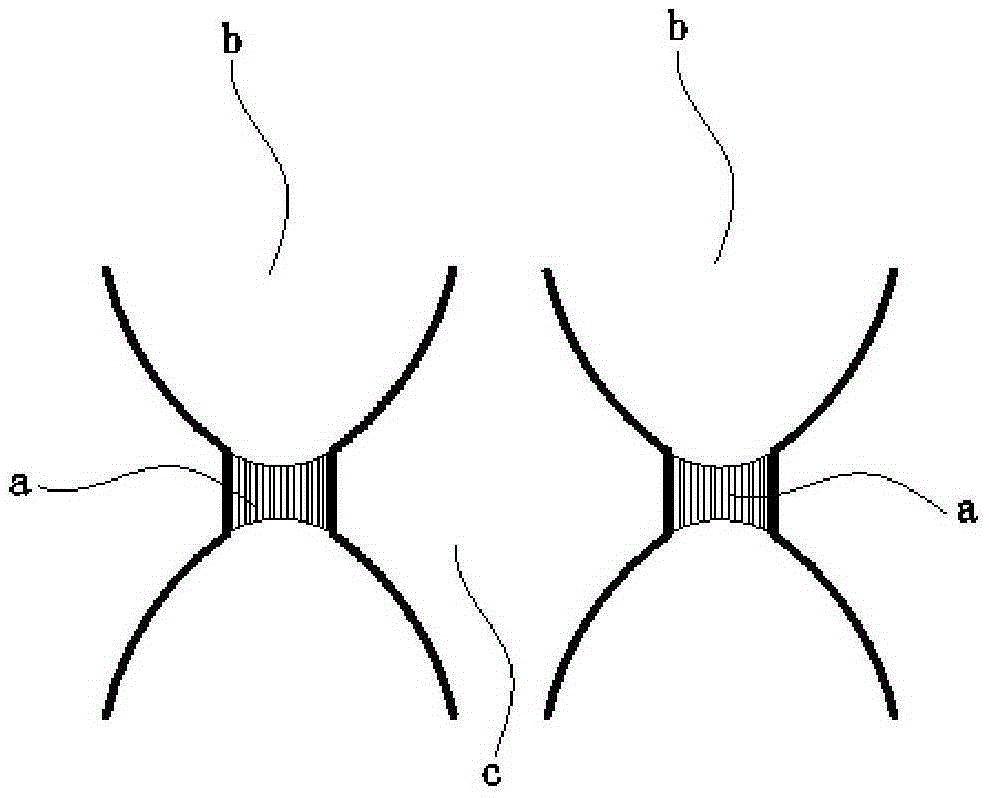

[0047] Such as Figure 4 As shown, a new type of fully welded plate and shell heat exchanger includes a shell 1, a heat exchange plate pair body 7, and a plate-side heat exchange fluid inlet N1, a plate-side heat exchange fluid outlet N2, Shell side heat exchange fluid inlet N3, shell side heat exchange fluid gas phase outlet N4 and shell side heat exchange fluid liquid phase outlet N5. The heat exchange plate pair main body 7 is installed in the housing 1, and is composed of the heat exchange plate pair 3, such as figure 1 As shown, the heat exchange plate pair 3 is composed of two metal plates by welding a plurality of contacts to form a plate side cavity b for the circulation of the plate side heat exchange fluid. Between each heat exchange plate pair 3 and the housing 1 forms a shell-side cavity c for the circulation of the shell-side heat exchange fluid. In the heat exchange plate pair 3, the contact welding method is that the welding contact welding method is spot weld...

Embodiment 2

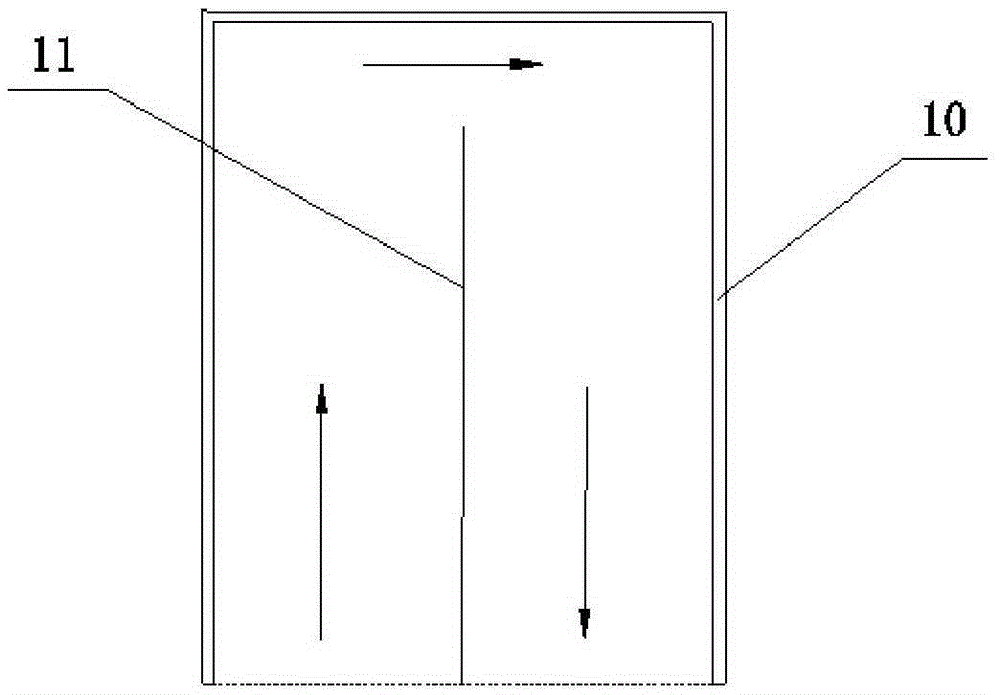

[0058] Such as Figure 8 As shown, in this embodiment, the heat exchange plate pair main body 7 of the new all-welded plate and shell heat exchanger is a cuboid structure, and the cuboid structure is formed by parallel arrangement of multiple pairs of square heat exchange plate pairs 3 of the same size. , the heat exchange plate pairs forming the plate bundle have the same size, the heat exchange fluid in the plate side enters the plate side cavity b through the heat exchange fluid connection pipe 12 in the plate side, and the heat exchange fluid in the shell side can be selected from Entering the shell-side cavity c in any direction can realize counter-current, forward-current and cross-flow heat exchange.

[0059] All the other are identical with embodiment 1.

Embodiment 3

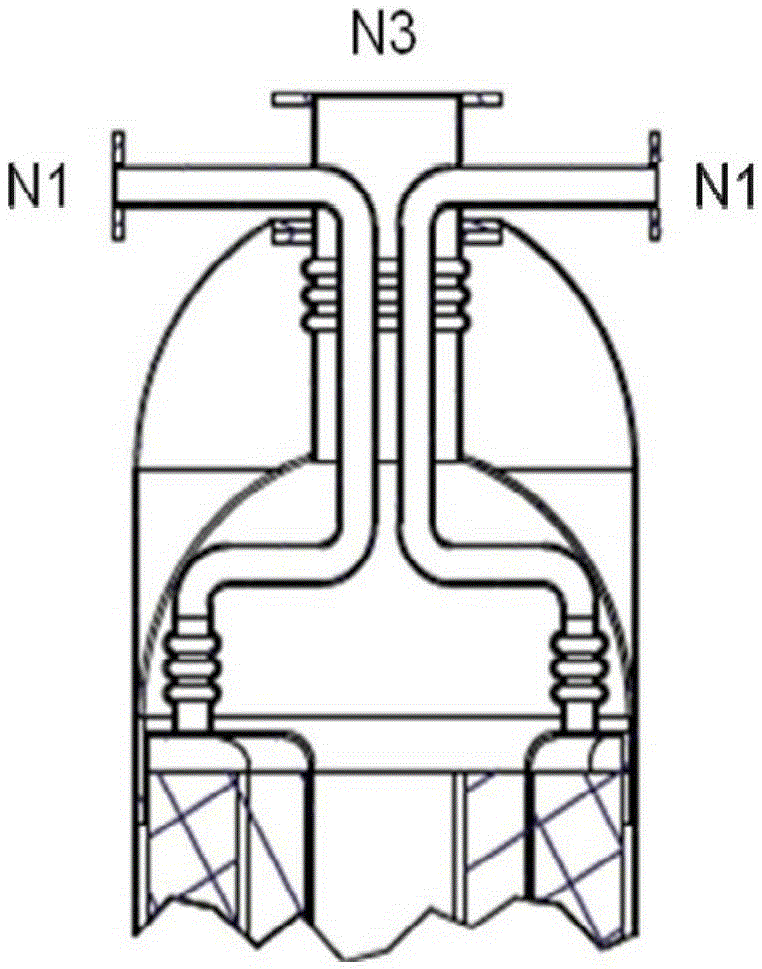

[0061] Such as Figure 6 , Figure 7 As shown, in this embodiment, the main body 7 of the heat exchange plate pair is a spiral cylindrical structure, and the said spiral cylindrical structure is a pair of coiled plate heat exchange plate pairs 3 with a spiral cross-section, which are cylindrical as a whole. In the spiral cylinder structure, the outer edges of the two ends of the pair of heat exchange plates 3 are provided with tongues, and the pair of heat exchange plates 3 is fixed on the shell 1 through the positioning holes on the tongues. The plate-side heat exchange fluid enters from the plate-side heat-exchange fluid inlet N1, flows through the plate-side chamber b of the entire heat exchange plate pair 3, and exits from the plate-side heat-exchange fluid outlet N2. The shell-side heat exchange fluid enters axially from the shell-side heat exchange fluid inlet N3, and flows axially through the entire shell-side space; or enters from the center, flows out from the edge, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com