Gas-liquid separation device for single-well booster set

A technology of a gas-liquid separation device and a booster unit, which is applied in the field of filters, can solve the problems of water inflow and deactivation of the booster unit, and achieve the effects of reducing the processing load, increasing the separation processing capacity, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

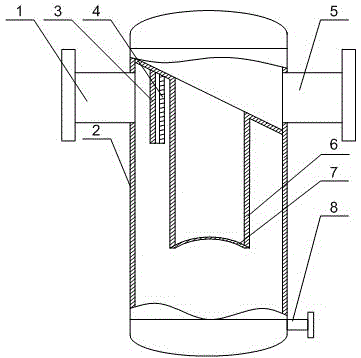

[0016] Such as figure 1 As shown, this embodiment includes a tank body 2, an air inlet 1 and an air outlet 5 are arranged on both sides of the tank body 2, a filter cartridge 6 is arranged in the tank body 2, and the air inlet 1 faces the filter cartridge 6 The side wall, the top of the filter cartridge 6 is inclined and facing the air outlet 5, and the bottom end of the filter cartridge 6 is provided with a separation filter screen 7 bent along the direction from the bottom end of the filter cartridge 6 to its top. The filter aperture of the filter screen 7 is smaller than the filter aperture of the filter cartridge 6; it also includes a baffle plate 3 and a water-absorbing plate 4 fixed on the filter cartridge 6 and parallel to each other, and the baffle plate 3 is provided with A plurality of small holes and the small holes are facing the air inlet 1, and there is a gap between the baffle plate 3 and the water-absorbing plate 4.

[0017] When working, the extracted gas-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com