Patents

Literature

45results about How to "Improve separation capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

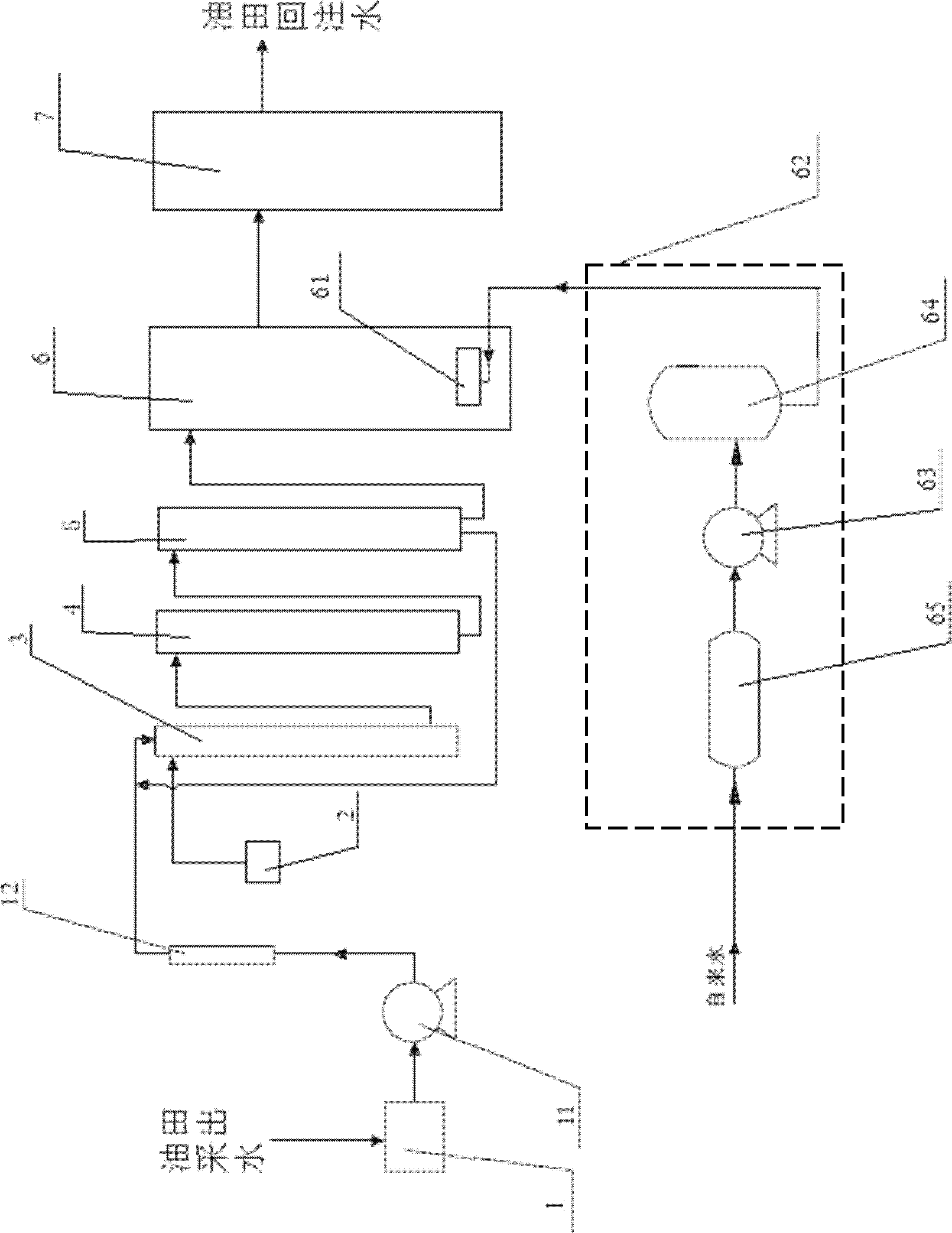

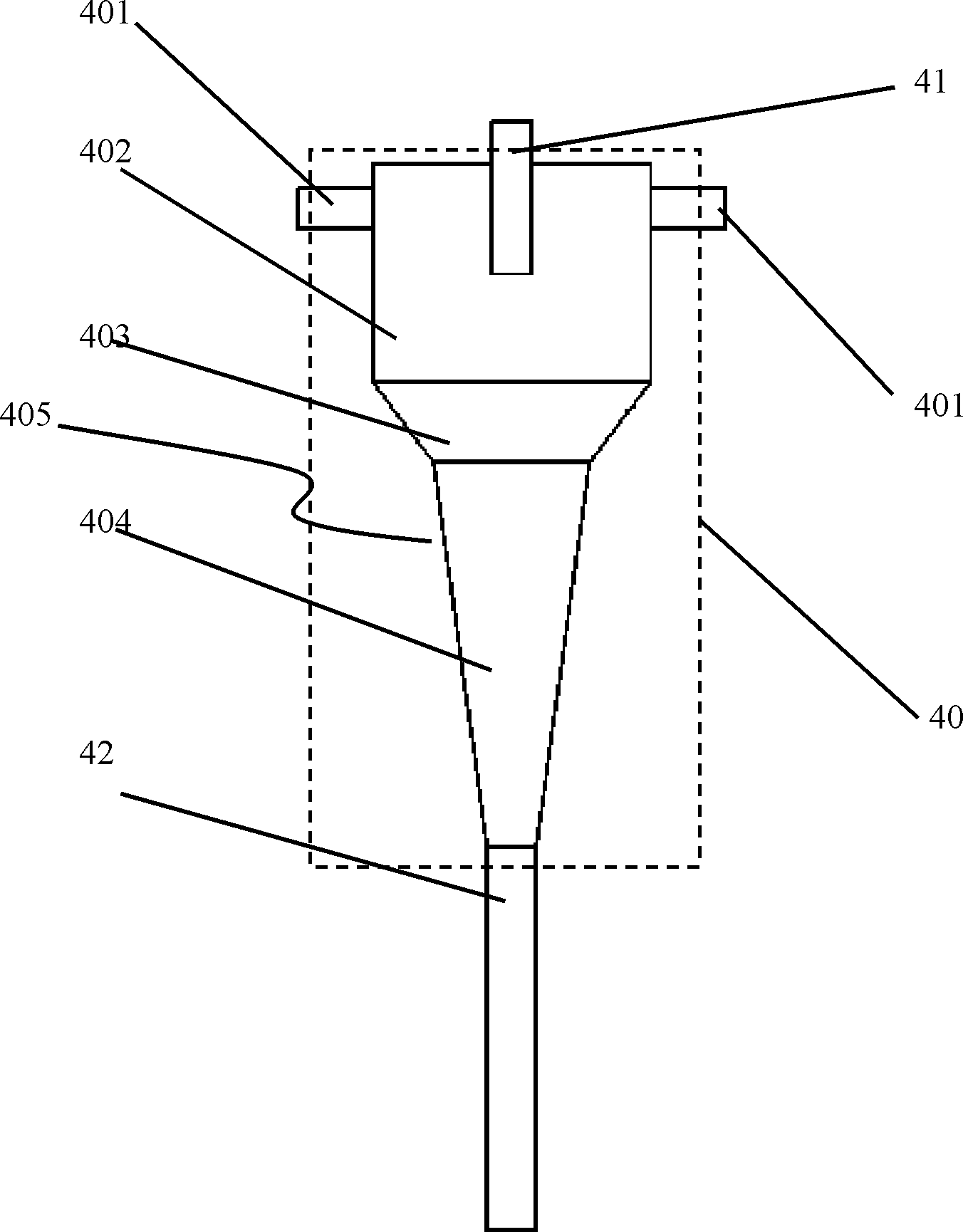

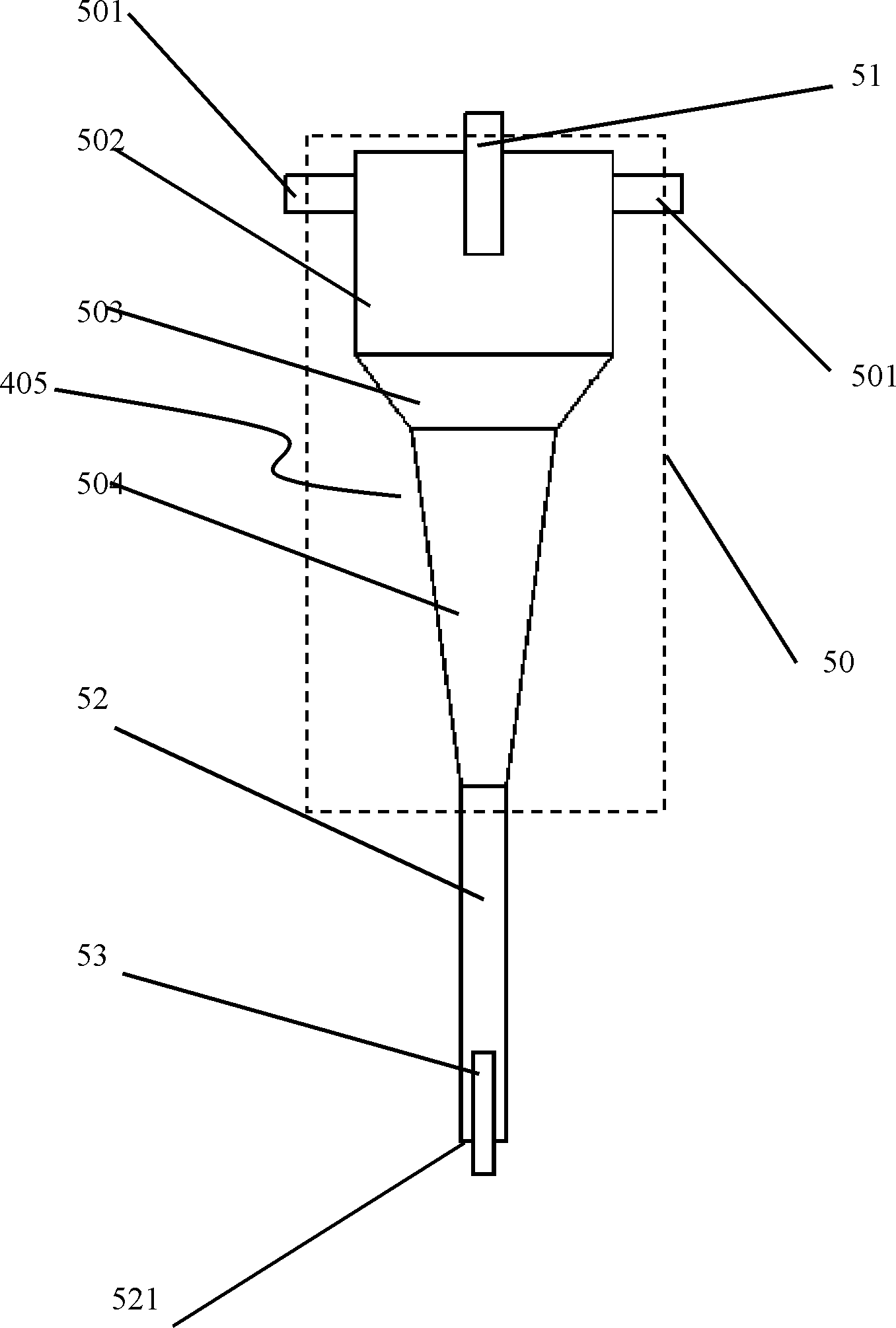

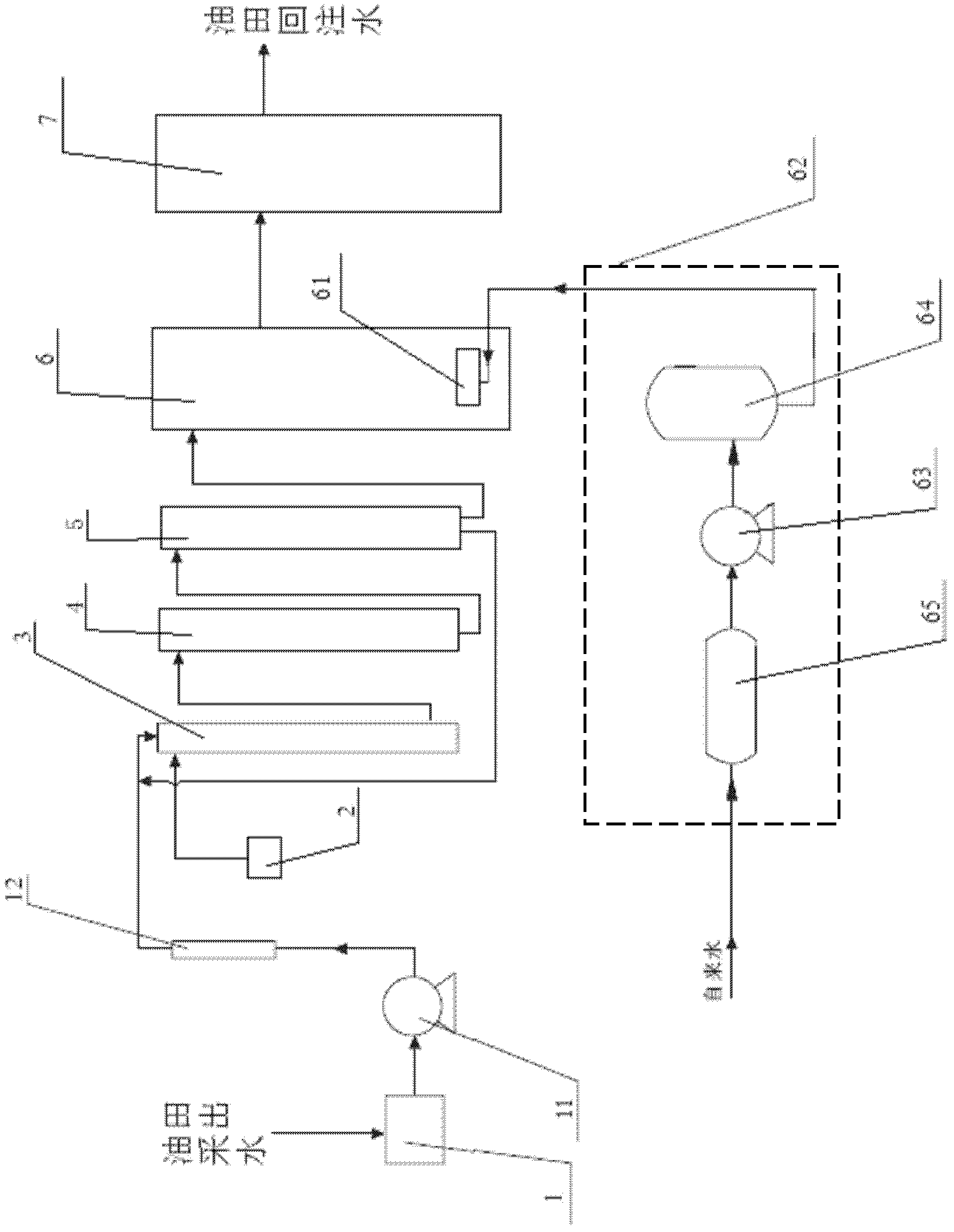

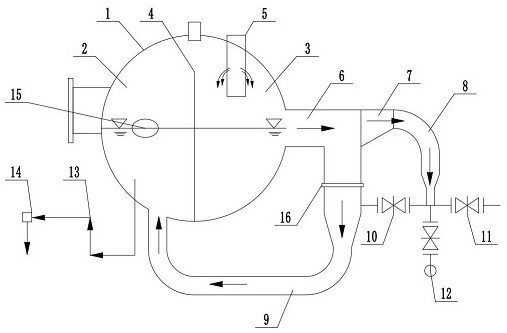

Treatment method and equipment for oilfield produced water

The invention relates to a treatment process of oilfield produced water. The treatment process using two-stage oil-water hydrocyclone separation with backflow as a main part is adopted. The treatment process comprises the steps as follows: firstly, adding a demulsifier to perform demulsification pretreatment; next, carrying out two-stage oil-water hydrocyclone separation; and finally carrying out a deep treatment by combination of air floatation and fiber filtration. After the treatment process provided by the invention is carried out, oil in the oilfield produced water can be recycled, and the produced water meets the Recommended Standard of Water Quality of Hidden Water Injection of Clastic Rocks (SY / T5329-1994) and can be used for water injection in oilfields. The treatment process provided by the invention not only reduces the influence of the oilfield produced water on environment, but also recycles resources.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

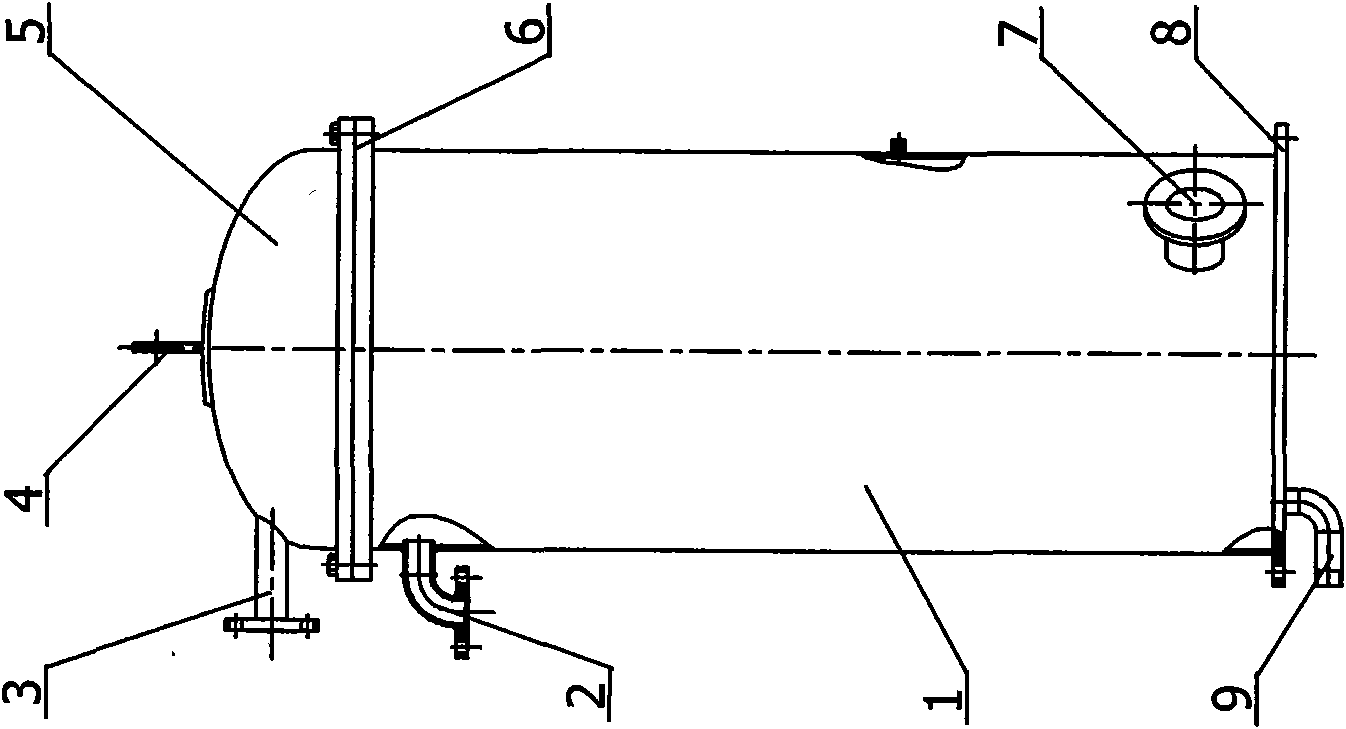

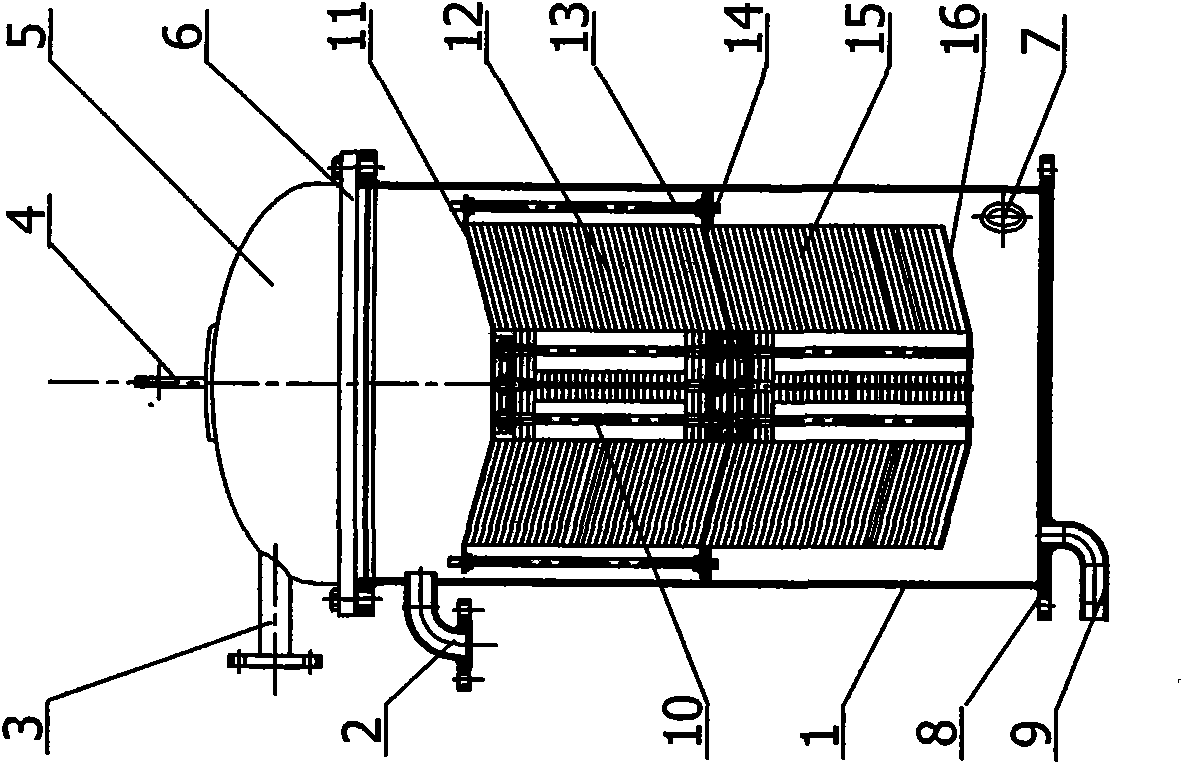

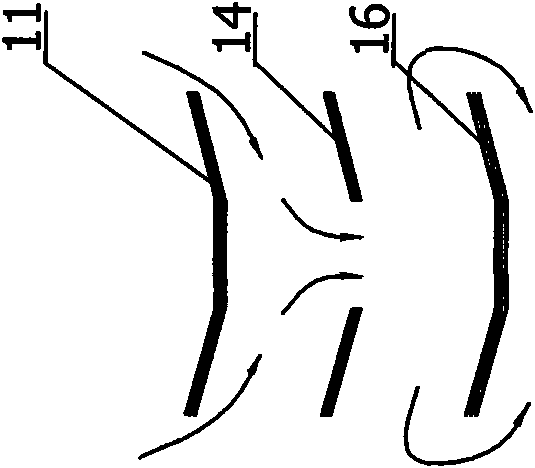

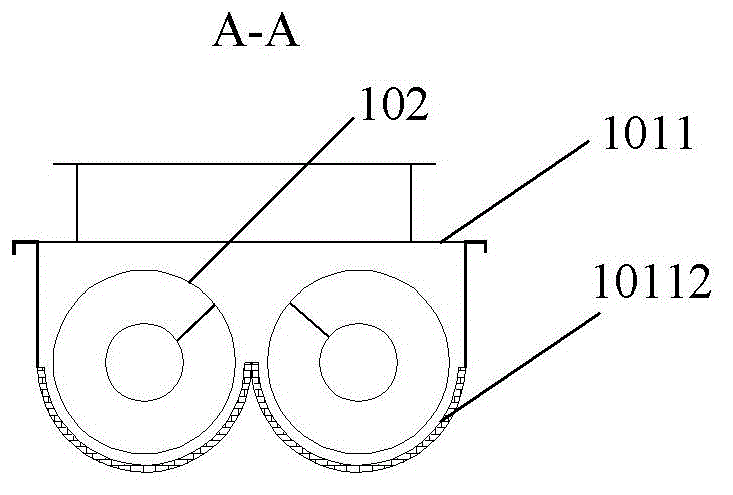

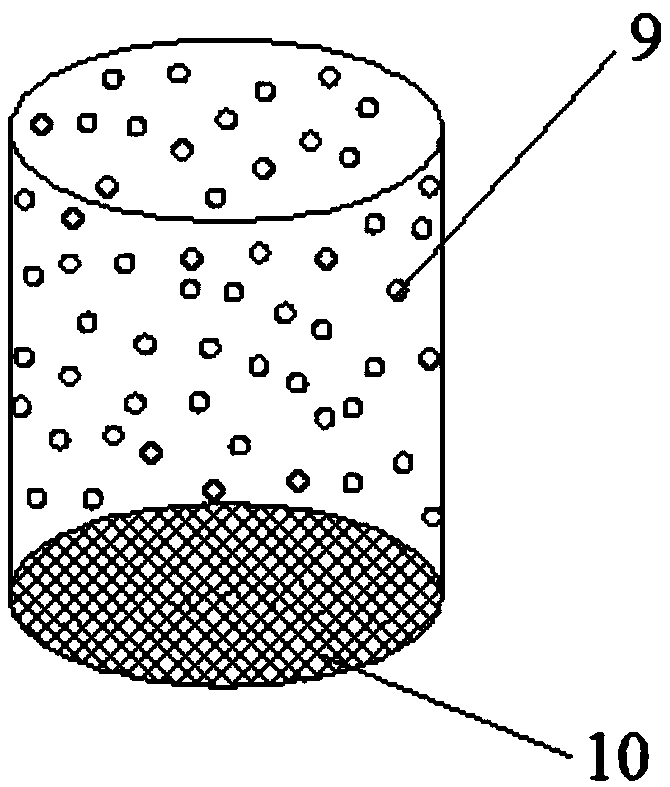

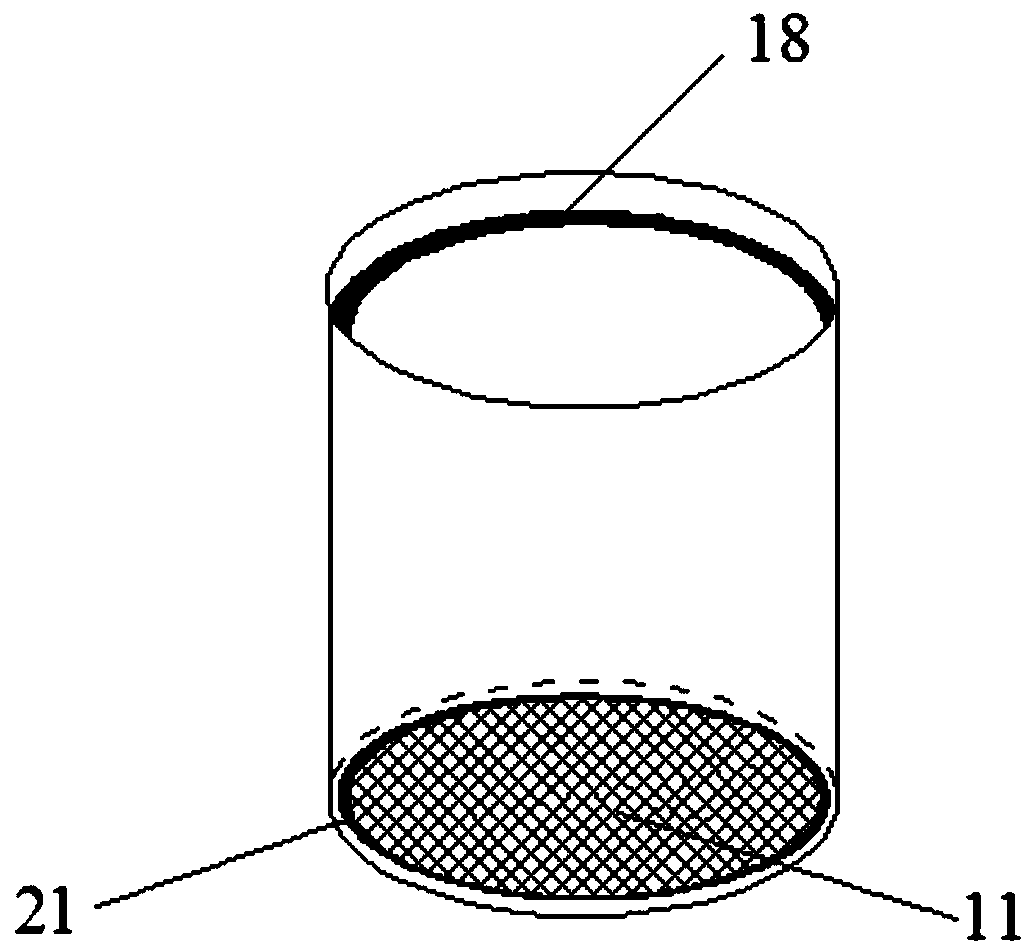

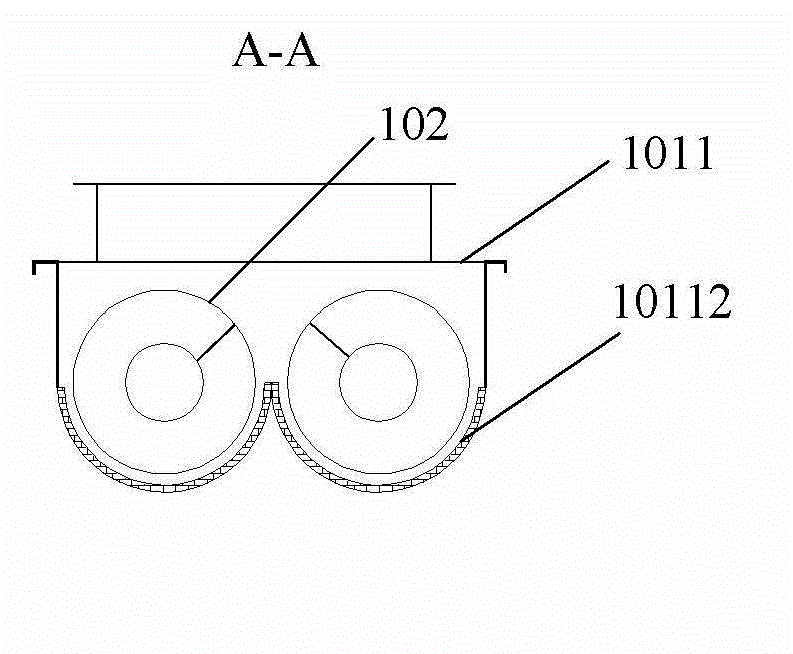

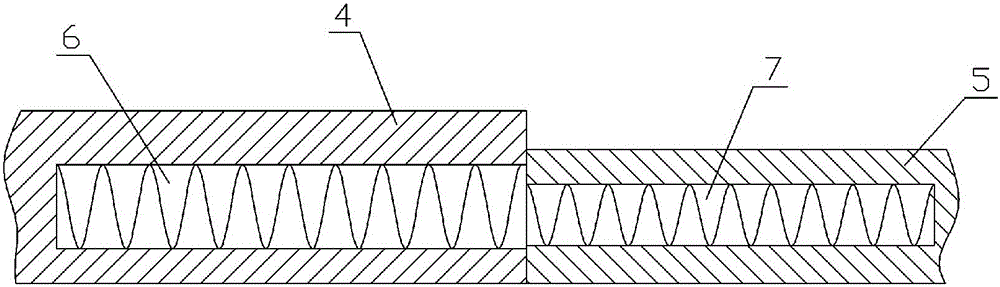

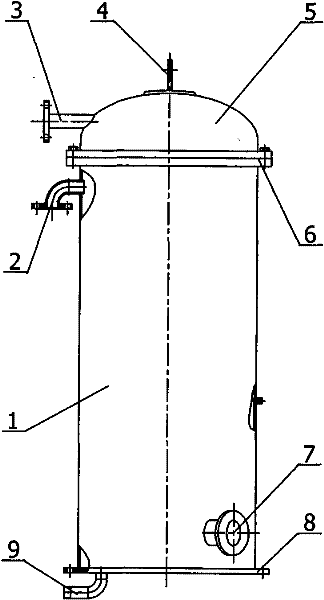

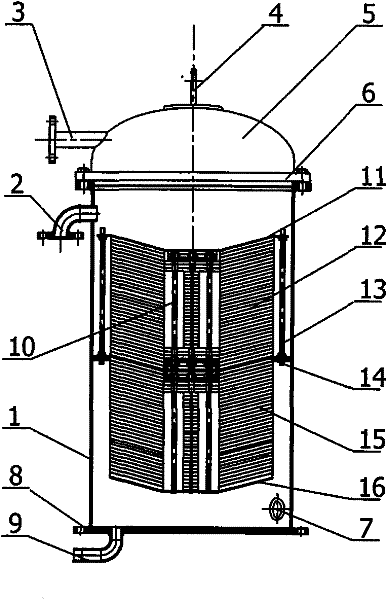

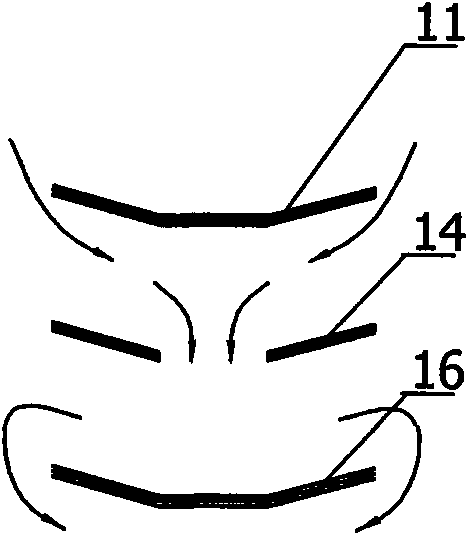

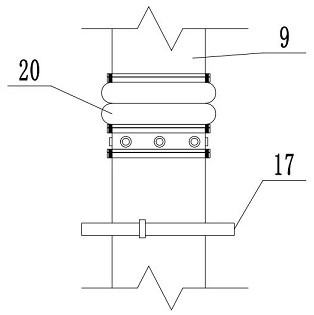

Marine oily water disk aggregation and separation device

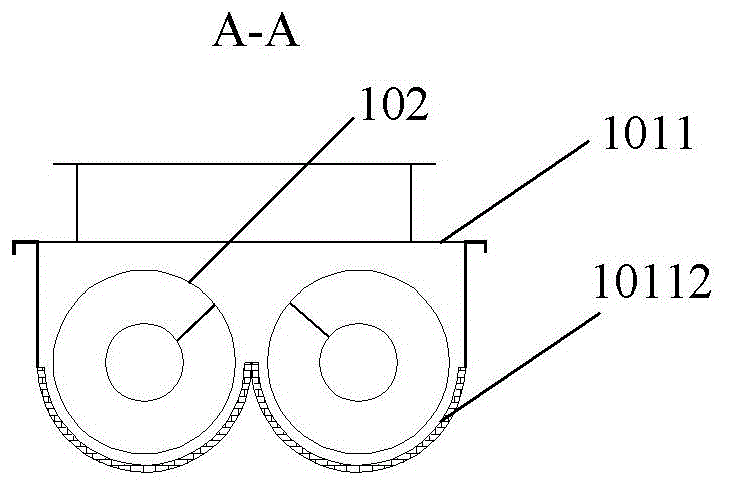

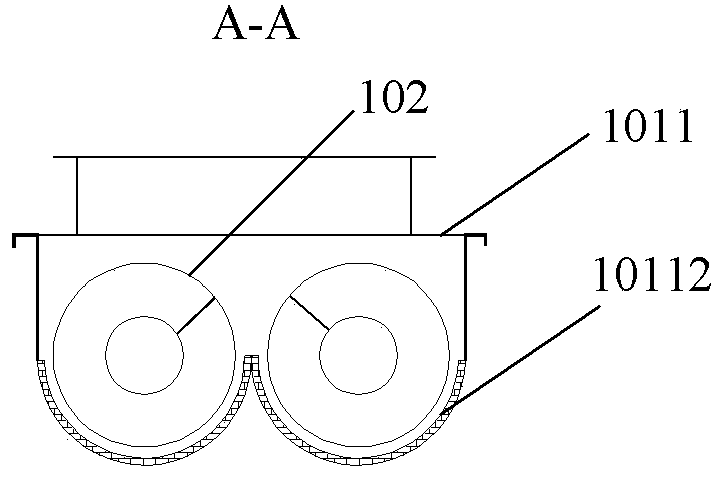

InactiveCN101654149AImprove separation capacityIncrease multipleAuxillariesWater treatment installationsSewageEngineering

The invention discloses a marine oily water disk aggregation and separation device, comprising a barrel body, wherein at least a first aggregation separator and a second aggregation separator are arranged in the barrel body; the first aggregation separator and the second aggregation separator are respectively positioned on the upper side and the lower side of a fluid guide hole plate; the periphery of the fluid guide hole plate are fixedly installed on the inner wall of the barrel body in a sealing manner; the middle position of the fluid guide hole plate is provided with a fluid guide throughhole; the top end of the first aggregation separator is provided with a top part cover plate, and a gap is left between the periphery of the top part cover plate and the inner wall of the barrel body; the bottom part of the second aggregation separator is provided with a fluid guide blind plate, and a gap is left between the periphery of the fluid guide blind plate and the inner wall of the barrel body; and the first aggregation separator and / or the second aggregation separator comprise / comprises a plurality of mutually superposed ripple separating discs. The separation device has the advantages of simple structure, convenient maintenance and manufacturing, and ideal oil-water separation effect, and is particularly applicable to marine oily water separation.

Owner:DONGTAI CITY DONGFANG MARINE FITTING

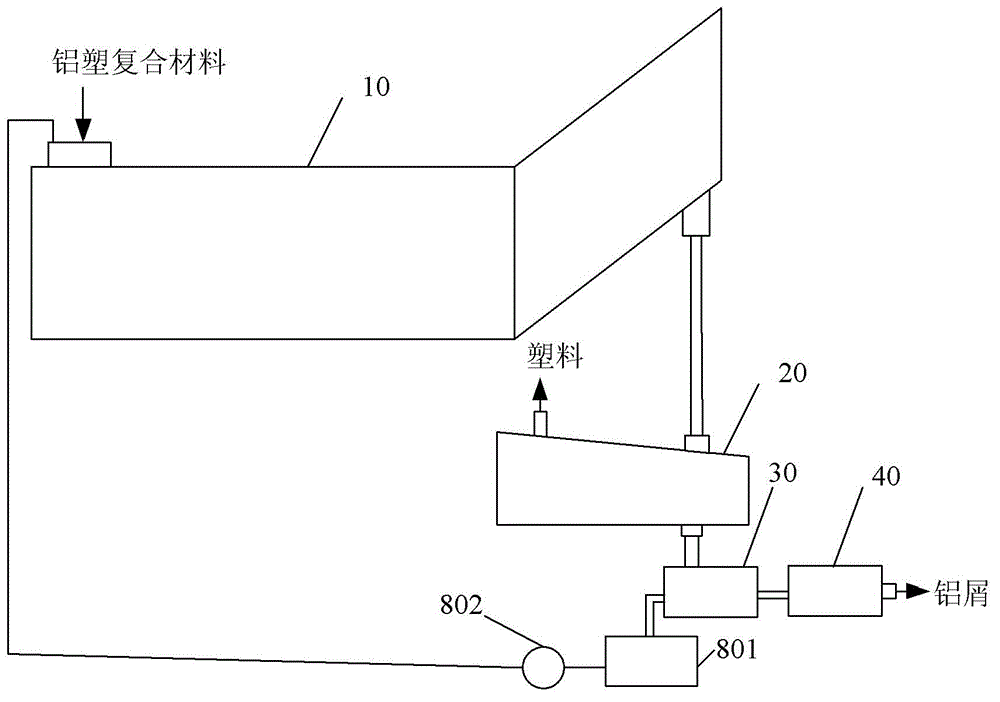

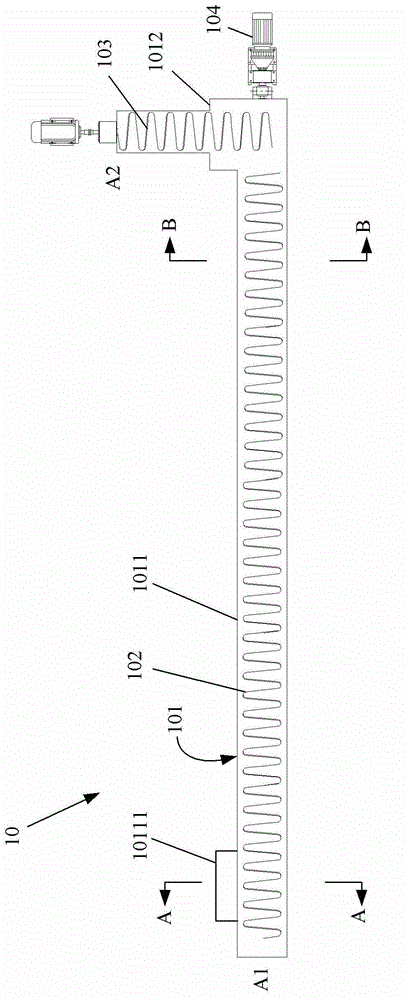

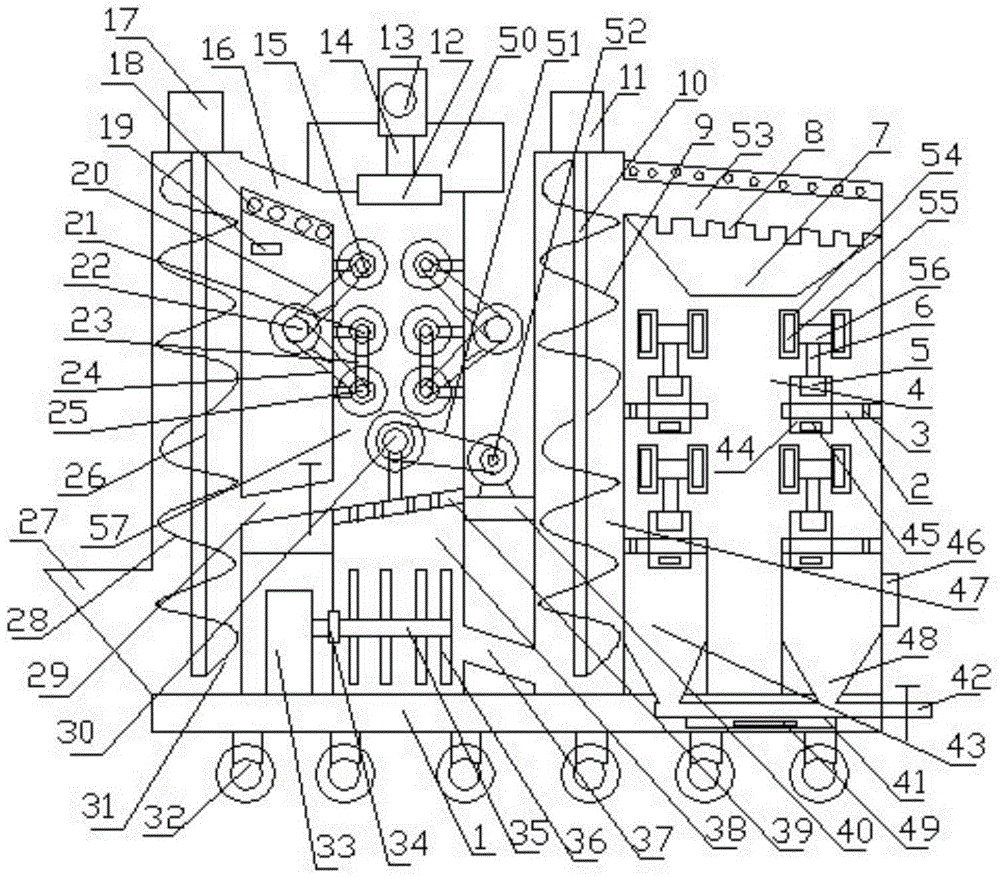

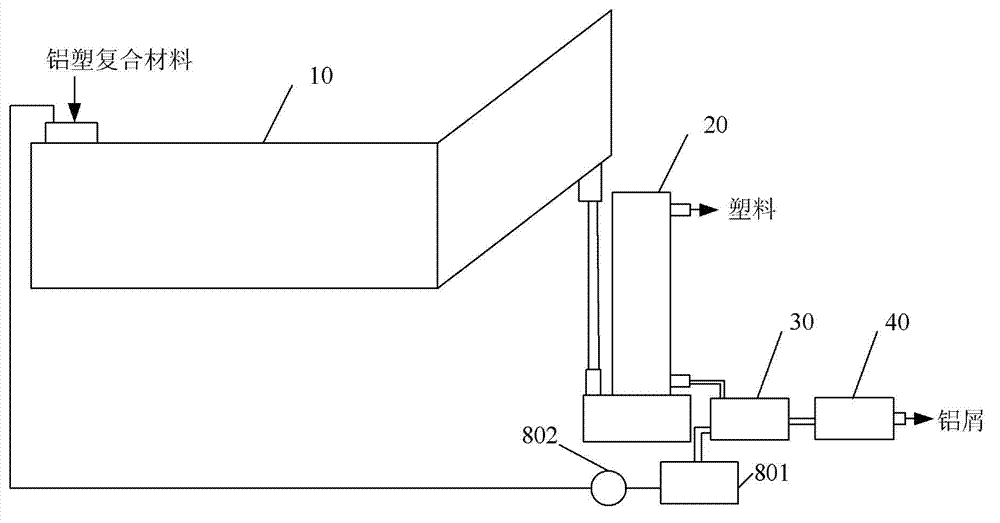

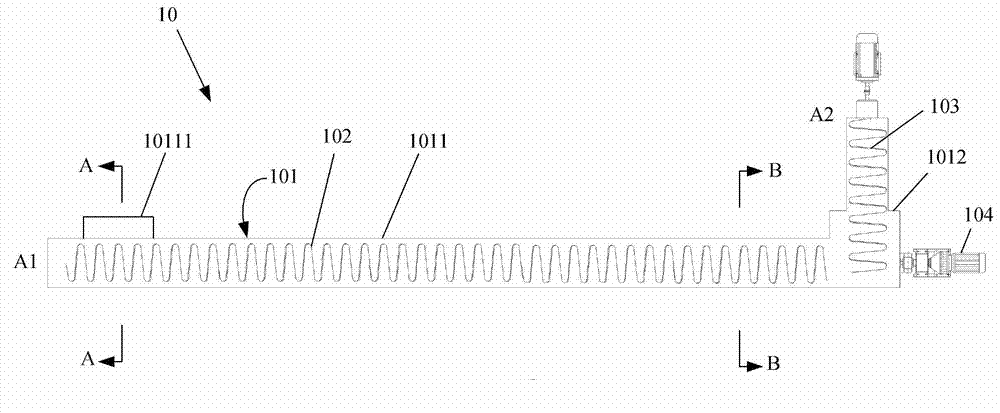

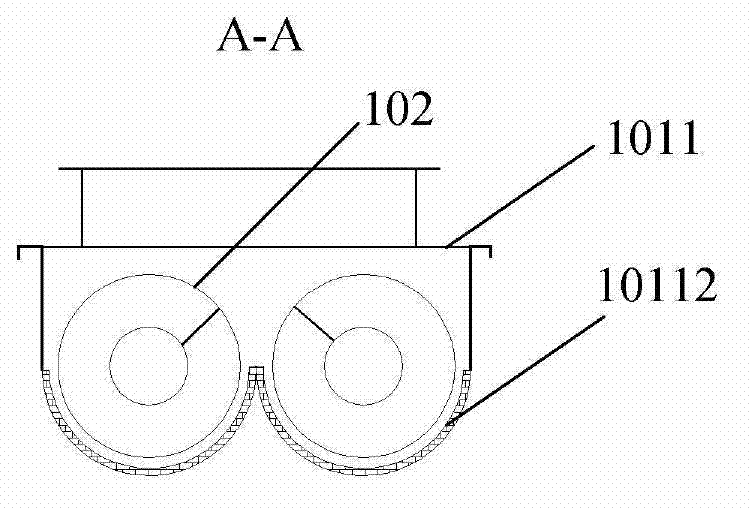

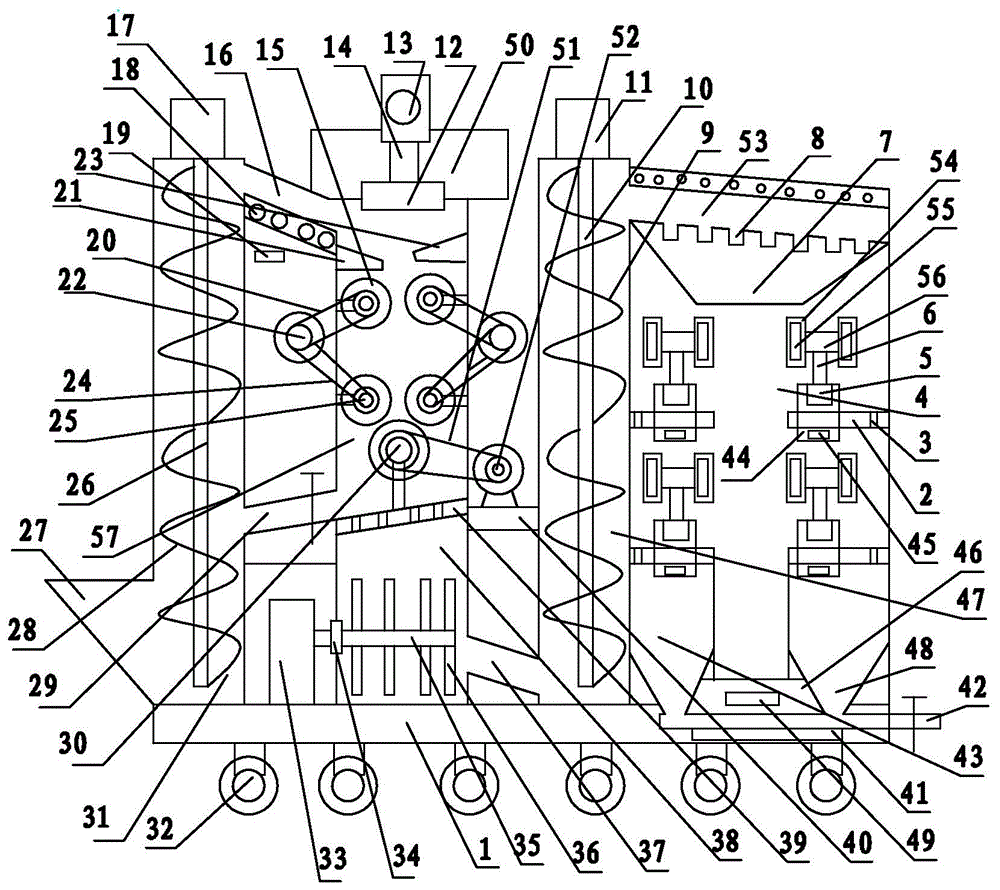

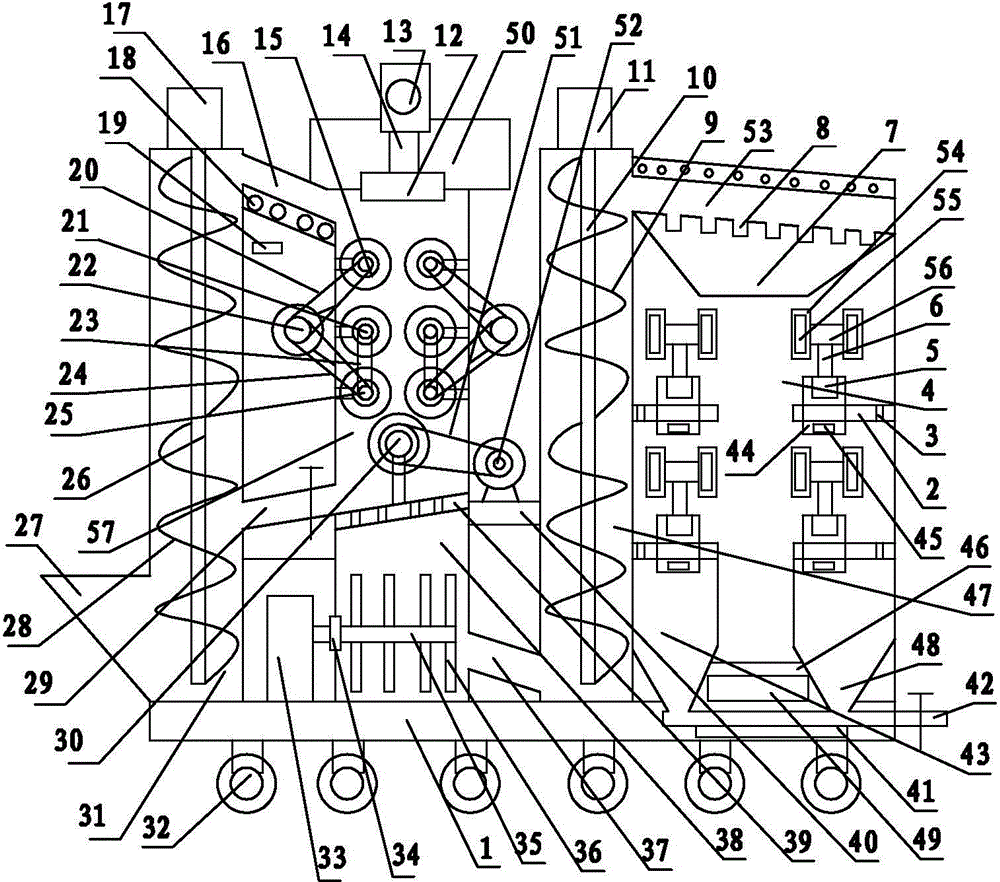

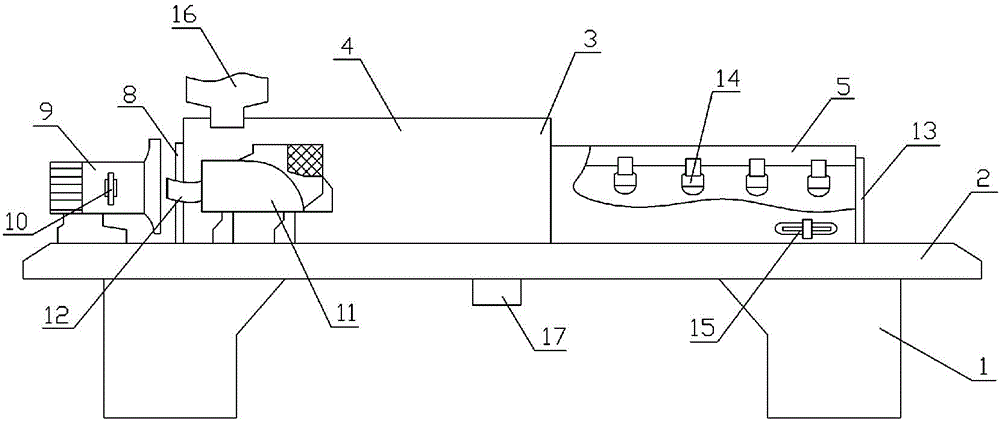

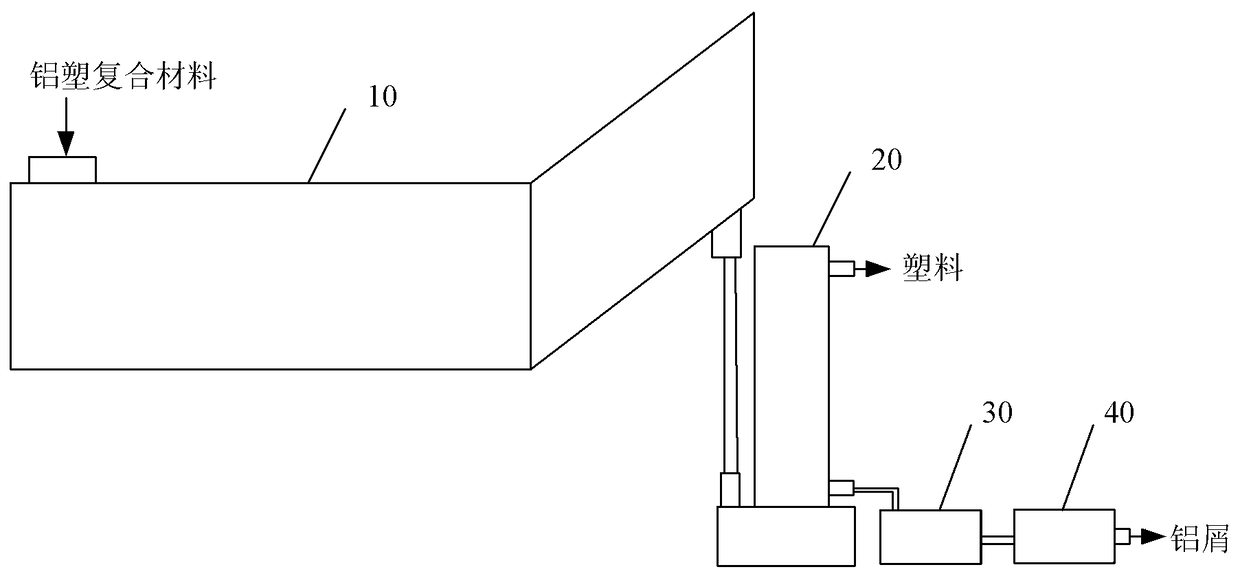

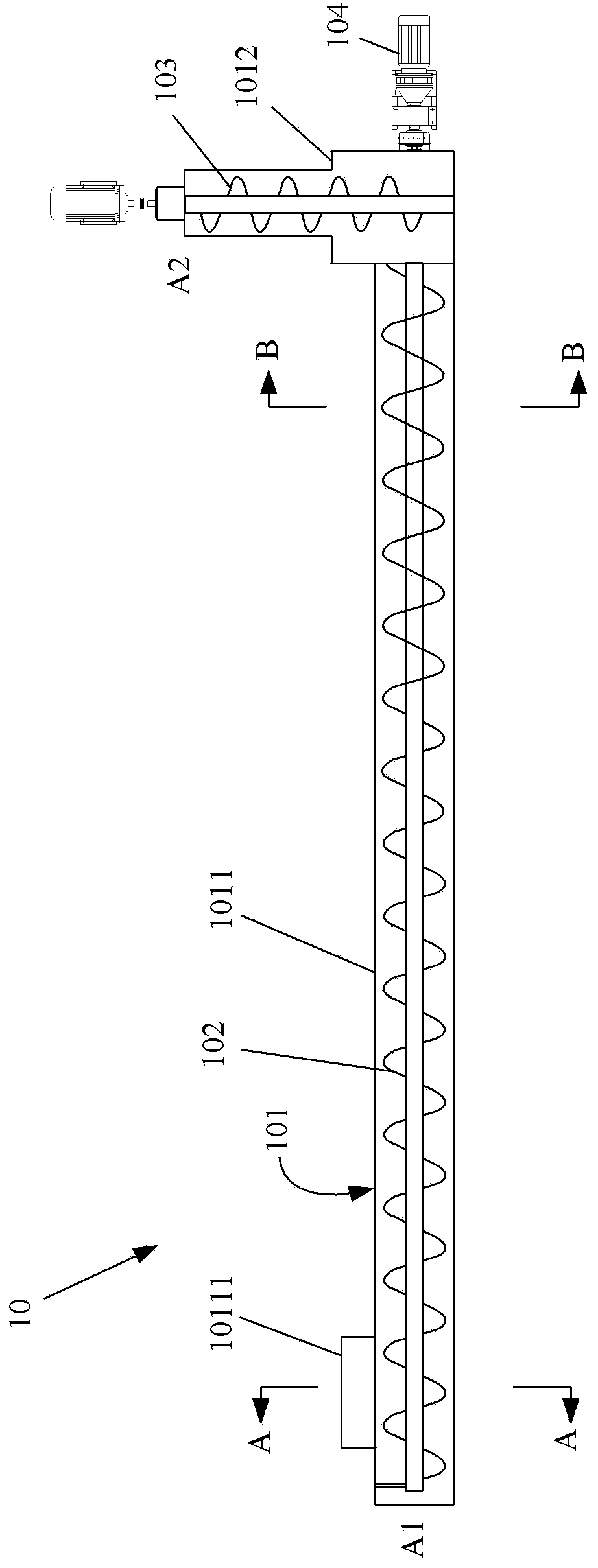

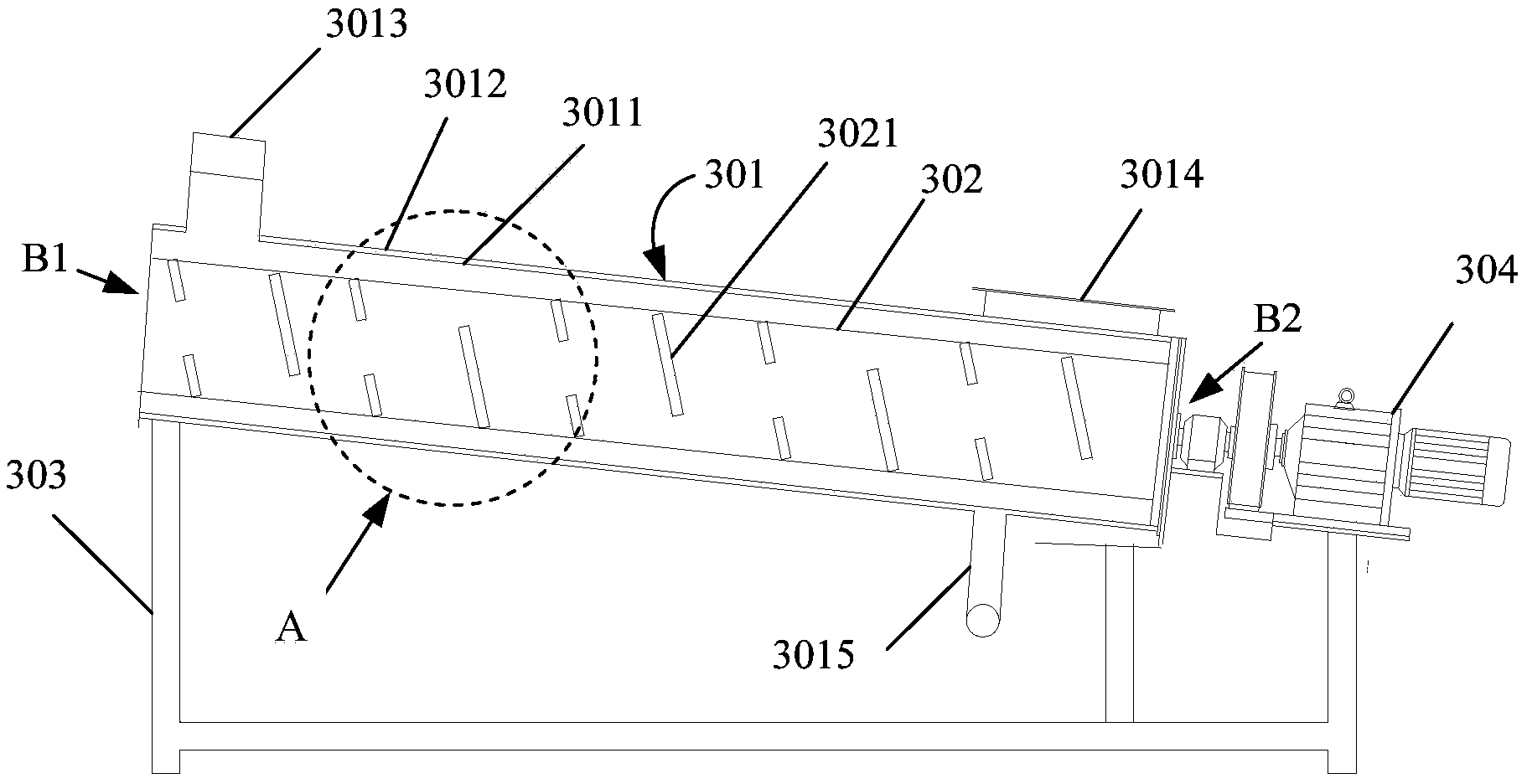

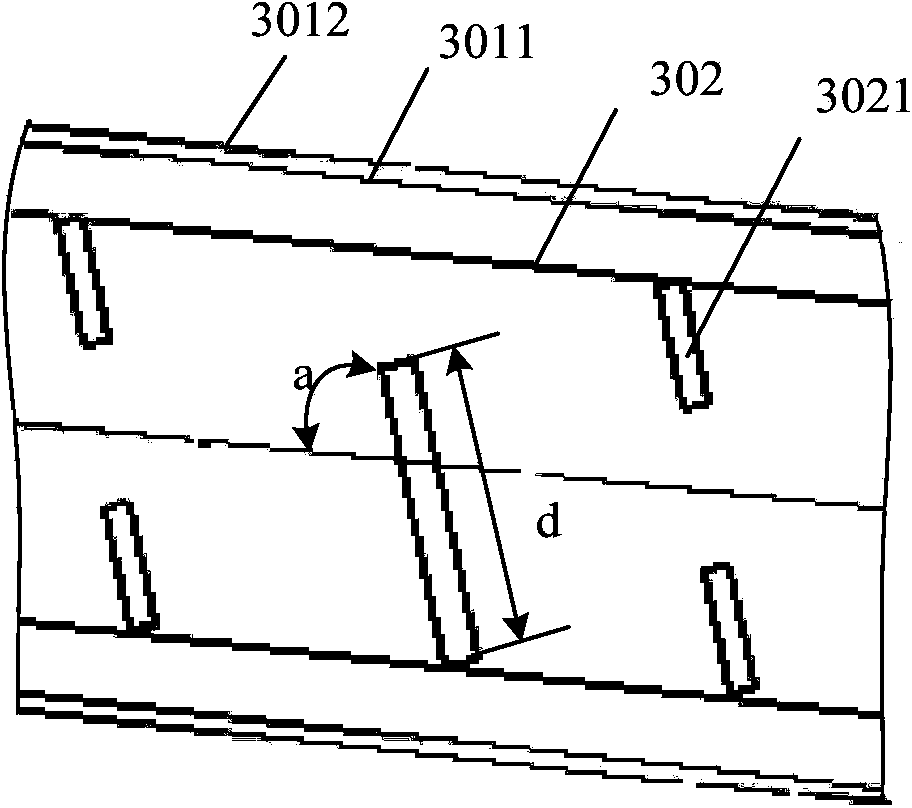

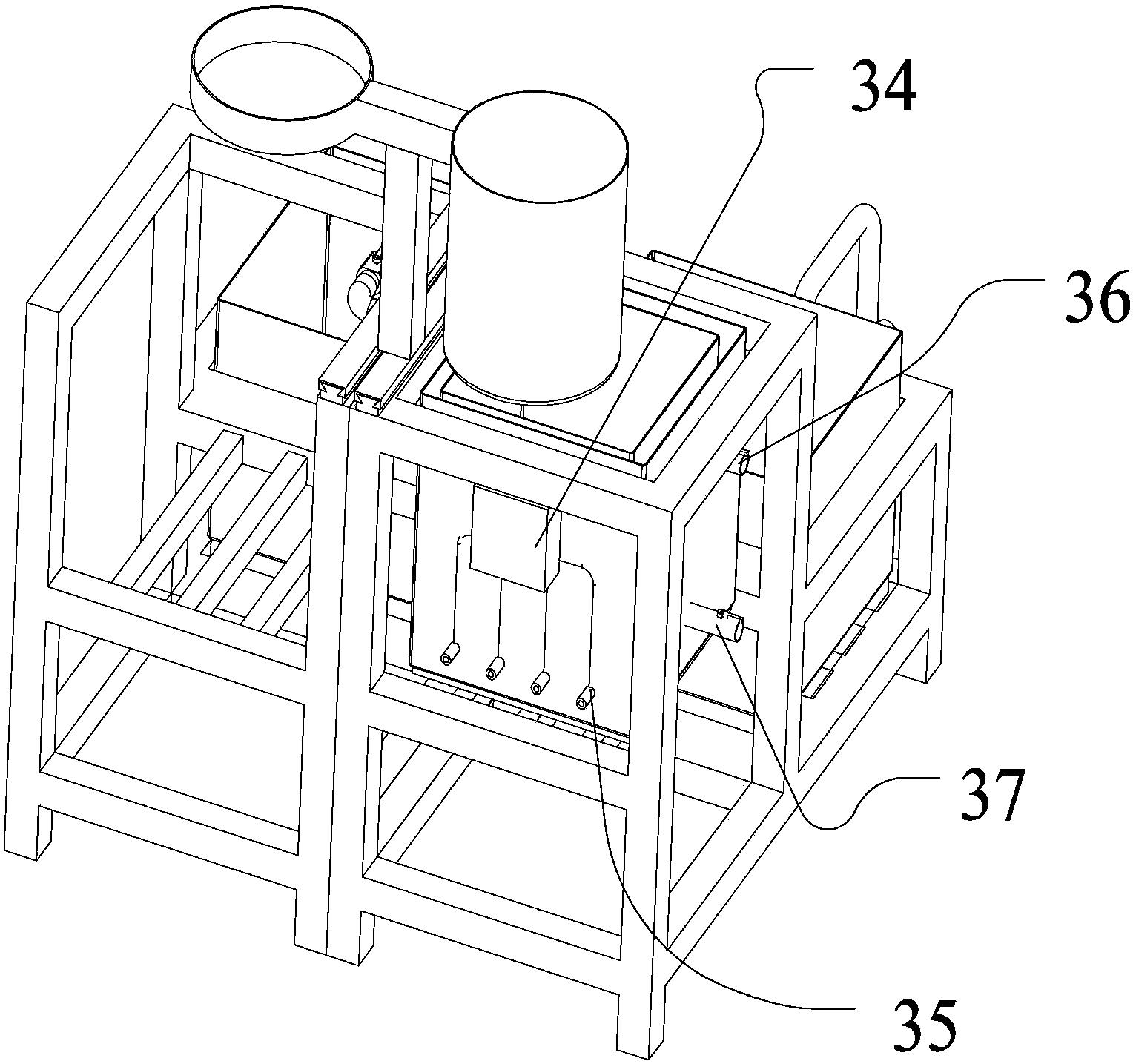

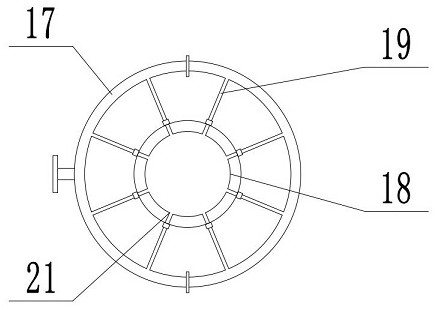

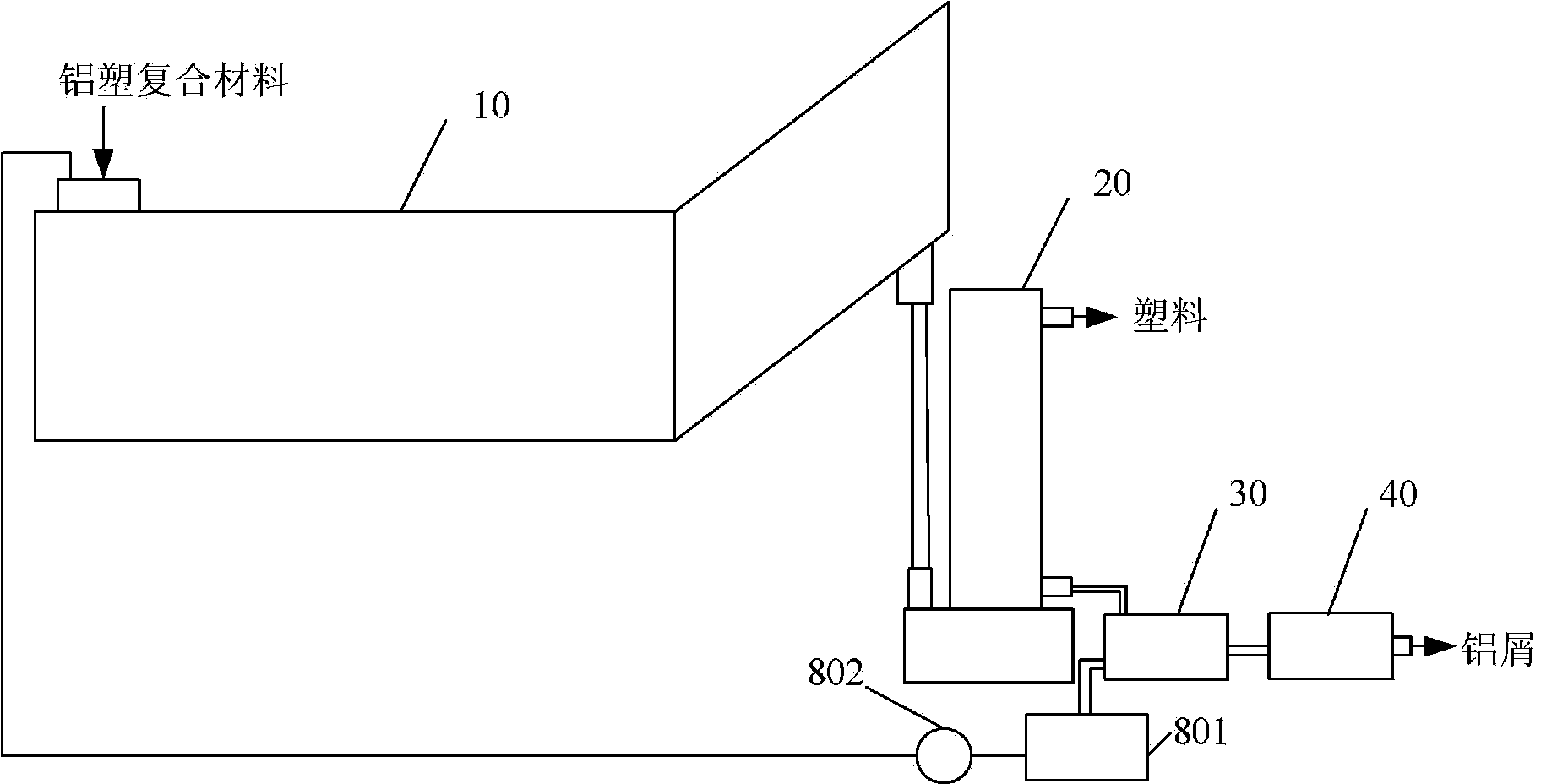

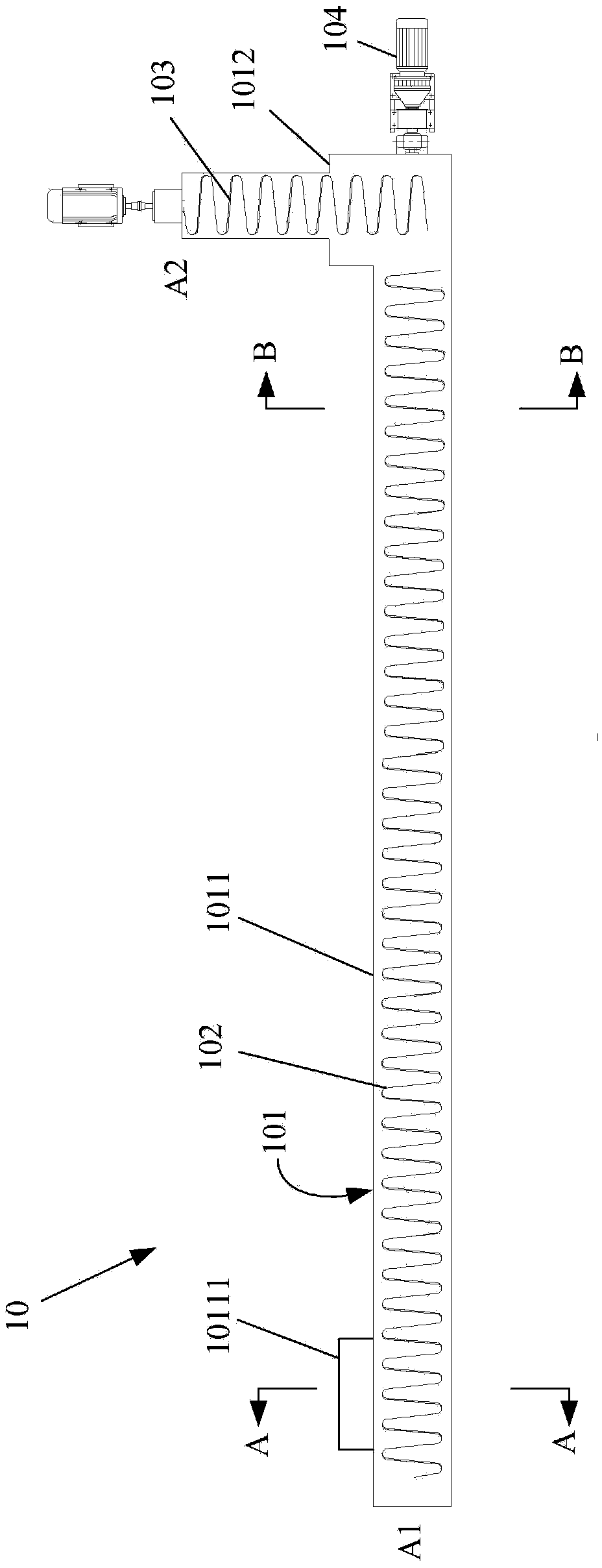

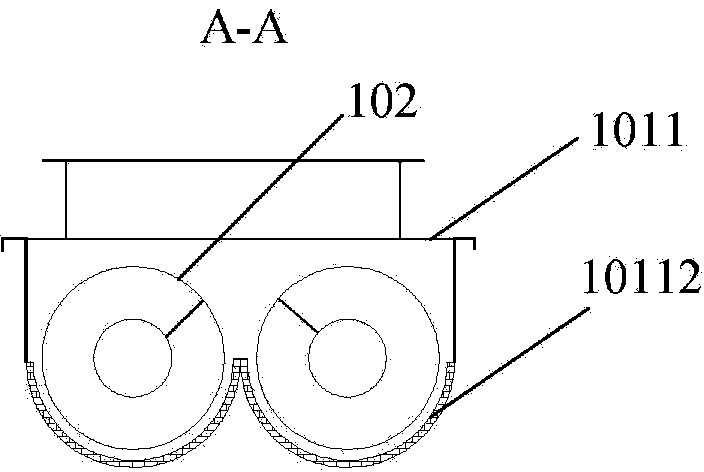

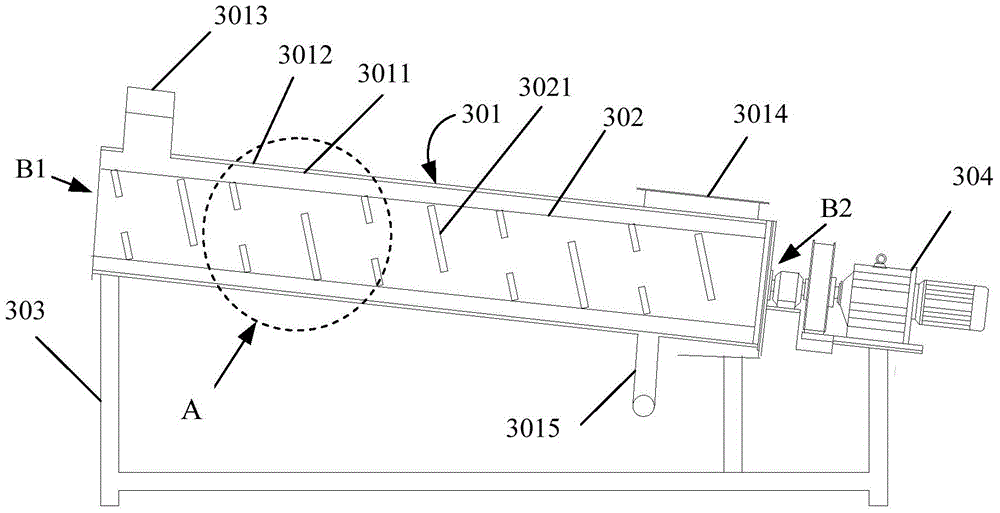

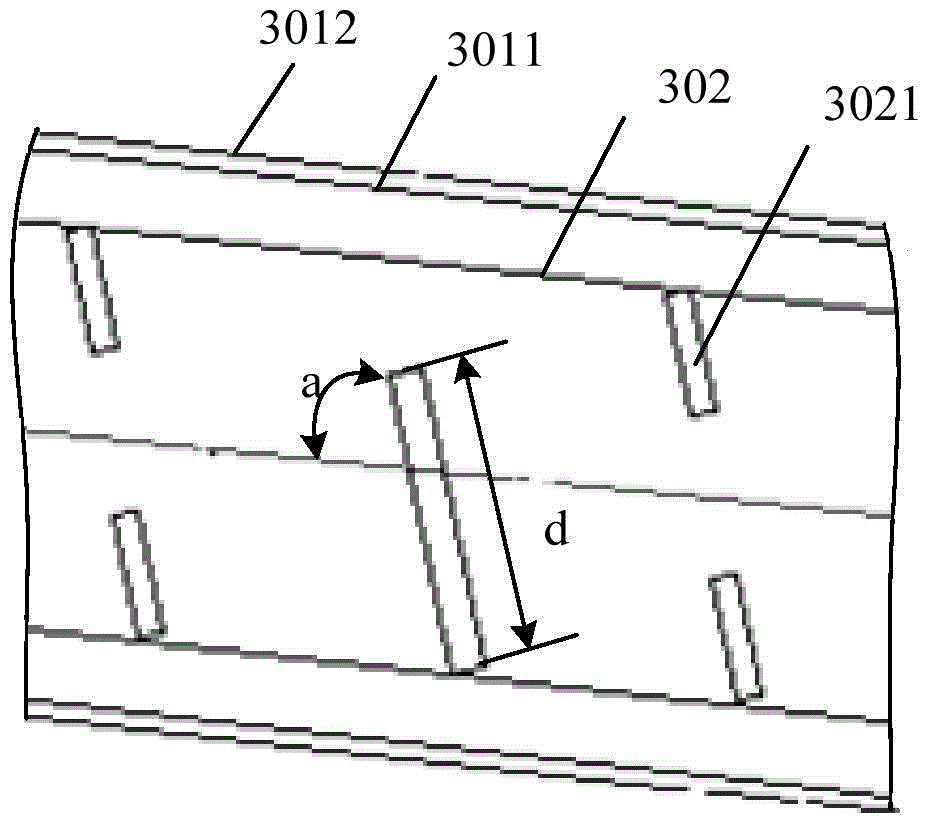

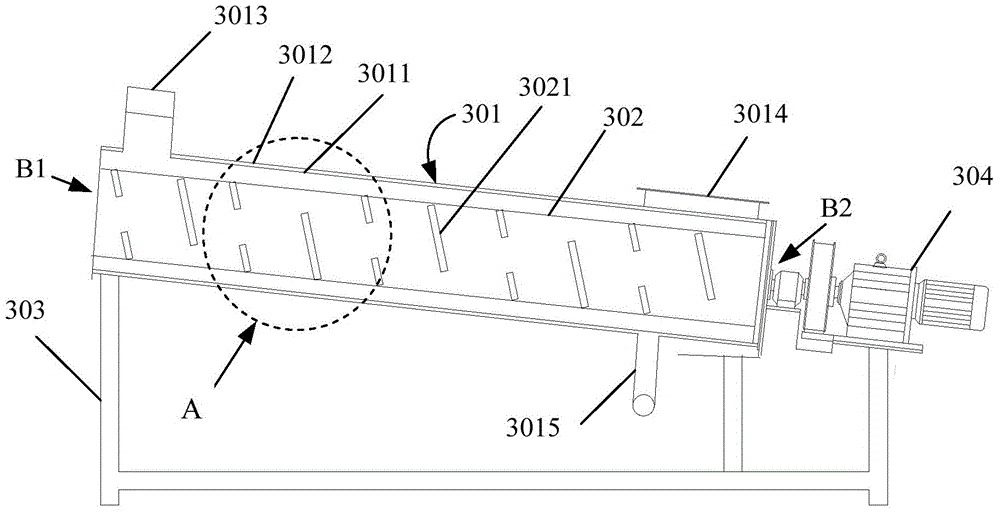

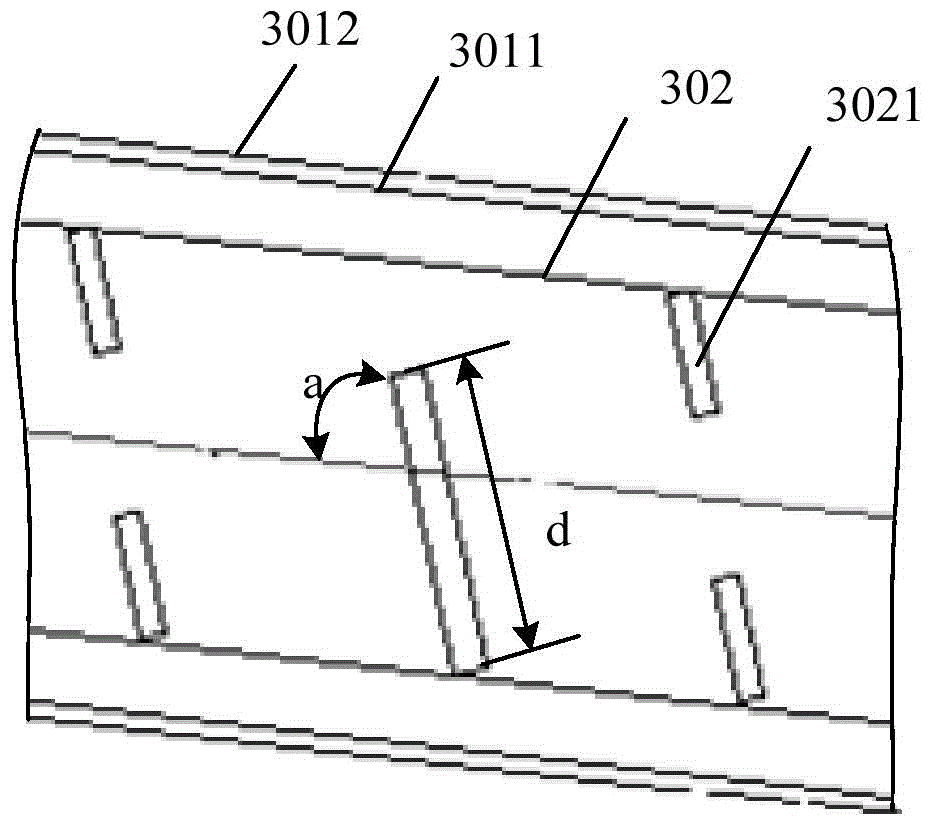

Separating agent recovery horizontal-type continuous separation system of aluminum-plastic compound package material

ActiveCN102744246AReduce consumptionEasy to handleSievingSolid waste disposalPhysical separationChemical separation

The invention provides a separating agent recovery horizontal-type continuous separation system of an aluminum-plastic compound package material. The separating agent recovery horizontal-type continuous separation system of the aluminum-plastic compound package material comprises a separation reaction device and a horizontal-type separation spin-drying device, wherein the separation reaction device carries out chemical separation treatment on the aluminum-plastic compound package material; the horizontal-type separation spin-drying device carries out physical separation treatment on the chemically separated aluminum-plastic compound package material; a reaction spiral and a discharge spiral arranged in the separation reaction device are both in shaftless spiral structures; an inner cylinder body of the horizontal-type separation spin-drying device is internally provided with a rotating shaft, and the rotating shaft is provided with a plurality of sickle-shaped blades at intervals; the horizontal-type separation spin-drying device is connected with a sedimentation centrifuge, and the sedimentation centrifuge is connected with a separating agent buffer pool. The separating agent recovery horizontal-type continuous separation system of the aluminum-plastic compound package material can effectively realize the continuous separation treatment of the aluminum-plastic compound package material, is higher in aluminum-plastic separation treatment capability and can recycle the separating agent.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

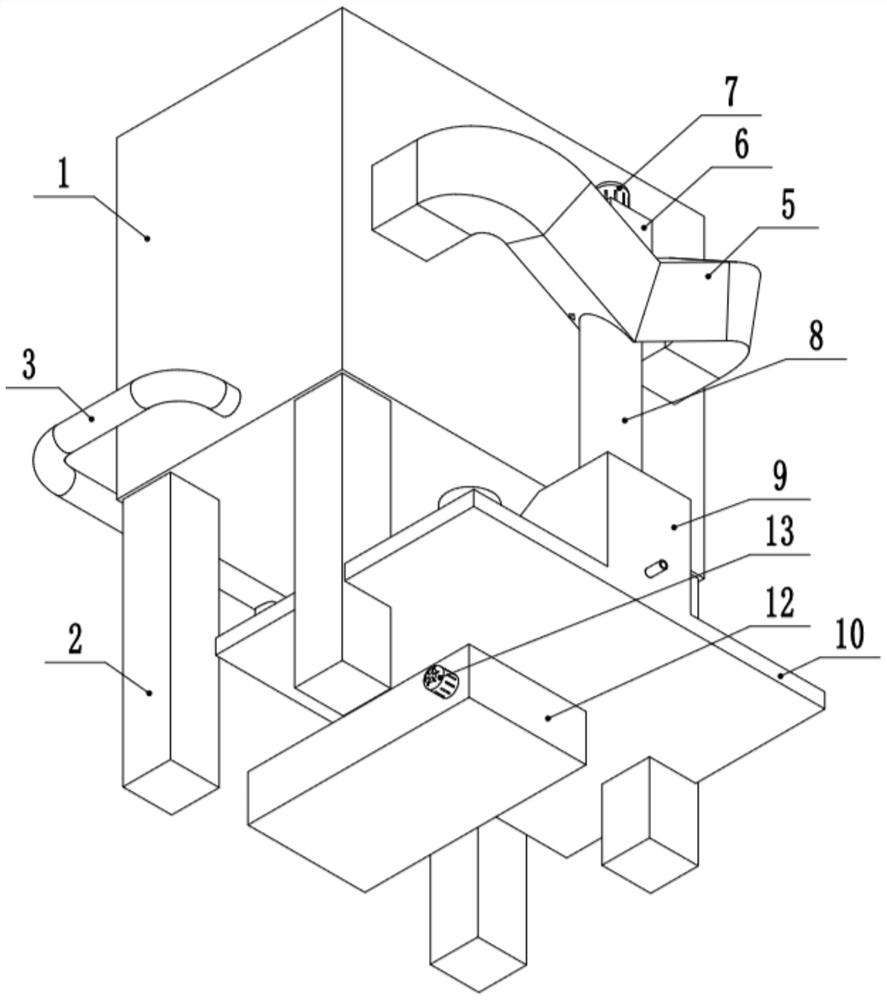

Material crushing magnetic separator

InactiveCN104907126AImprove the crushing effectEasy to separateSievingScreeningMagnetic separatorTherapeutic effect

The invention relates to a material crushing magnetic separator. The material crushing magnetic separator comprises a bottom seat, wherein a feeding cavity is formed in the left side of the upper portion of the bottom seat, a left lifting cavity is connected with the right side of the feeding cavity, a feeding pipe is connected with the upper portion of the right side of the left lifting cavity, a crushing cavity is connected with the right side of the feeding cavity, a return pipe is connected with the lower portion of the left side of the crushing cavity, a filter plate is arranged on the lower portion of the crushing cavity, a stirring cavity is formed in the lower portion of the filter plate, a blanking pipe is connected with the right side of the stirring cavity, a right lifting cavity is connected with the right side of the blanking pipe, a discharging cavity is connected with the upper portion of the right side of the right lifting cavity, a plurality of discharging holes are formed in the lower portion of the discharging cavity, a feeding cavity is located on the lower portion of each discharging hole, and separation cavities are arranged on the lower portions of the feeding cavities. The material crushing magnetic separator can effectively perform crushing treatment on materials, facilities lifting treatment after the materials are crushed, improves crushing treatment effects of the materials, facilitates drying treatment, performs magnetic separation after the materials are crushed more than once, conveniently separates out impurities, facilitates counting of the quantity of the impurities, improves separation treatment effects of the impurities, and is convenient to use.

Owner:陈守树

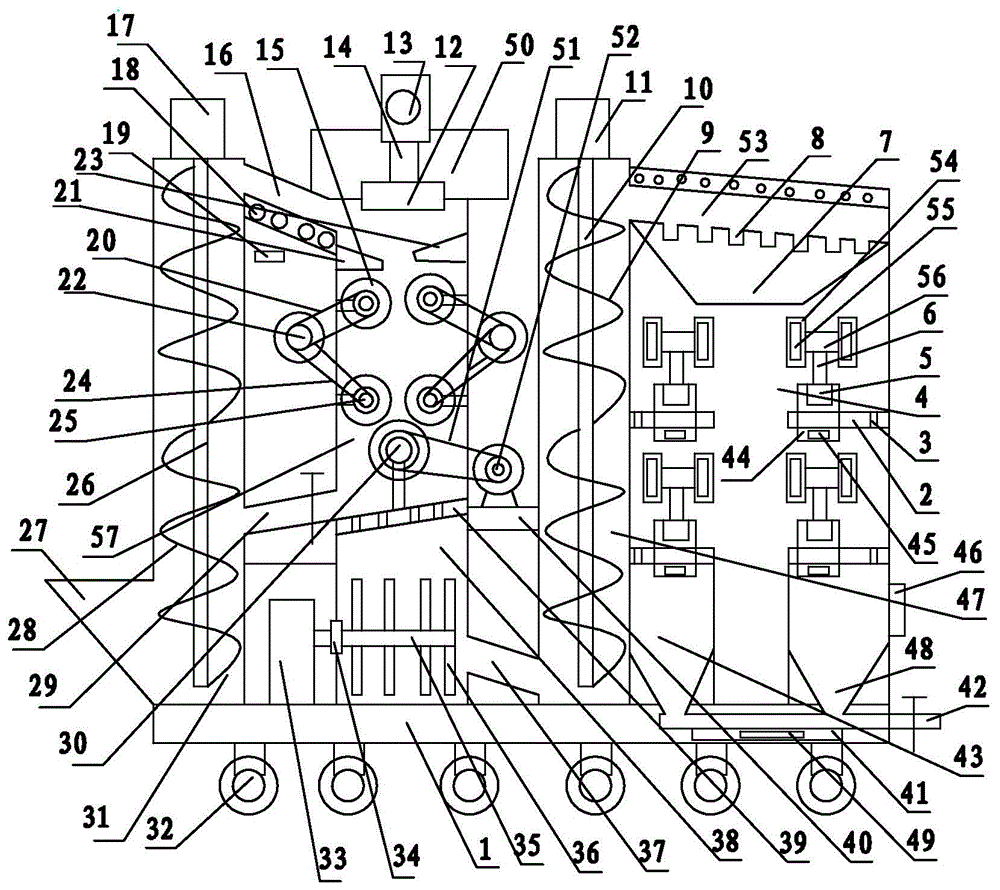

Internal circulating garbage separation system

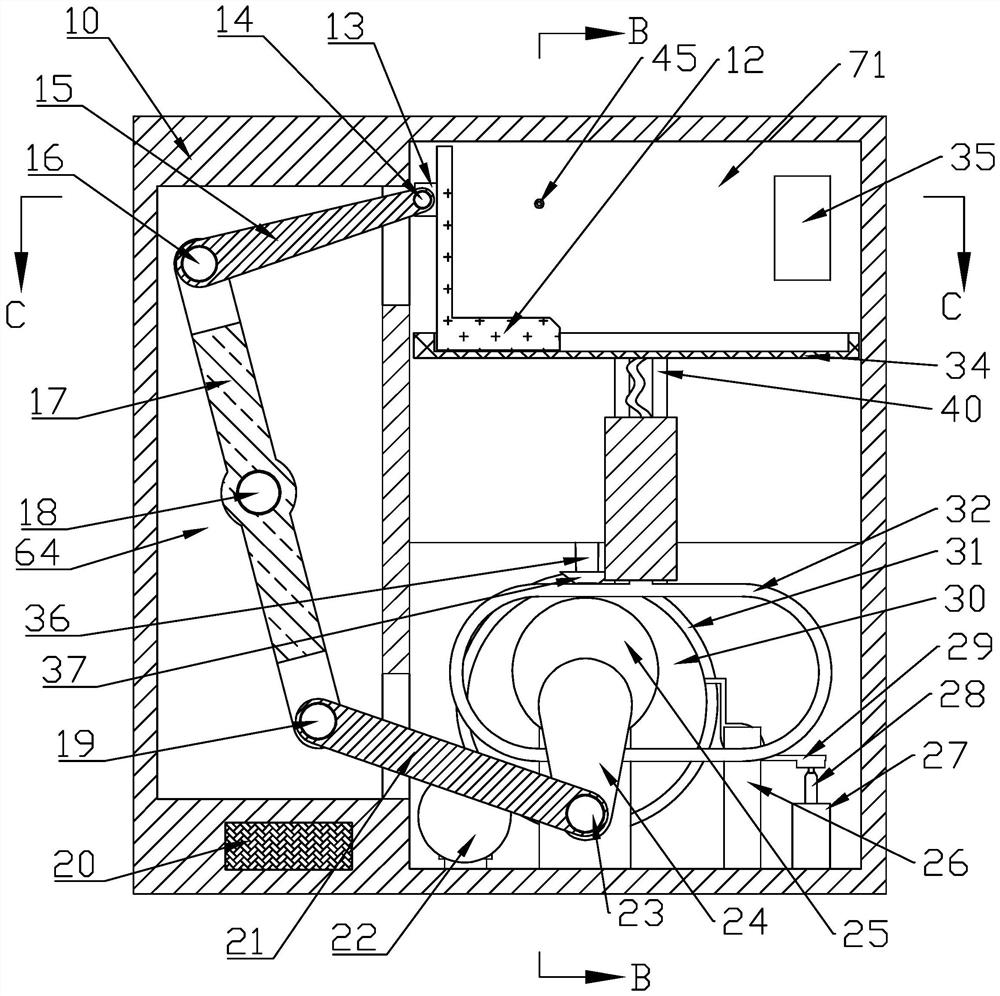

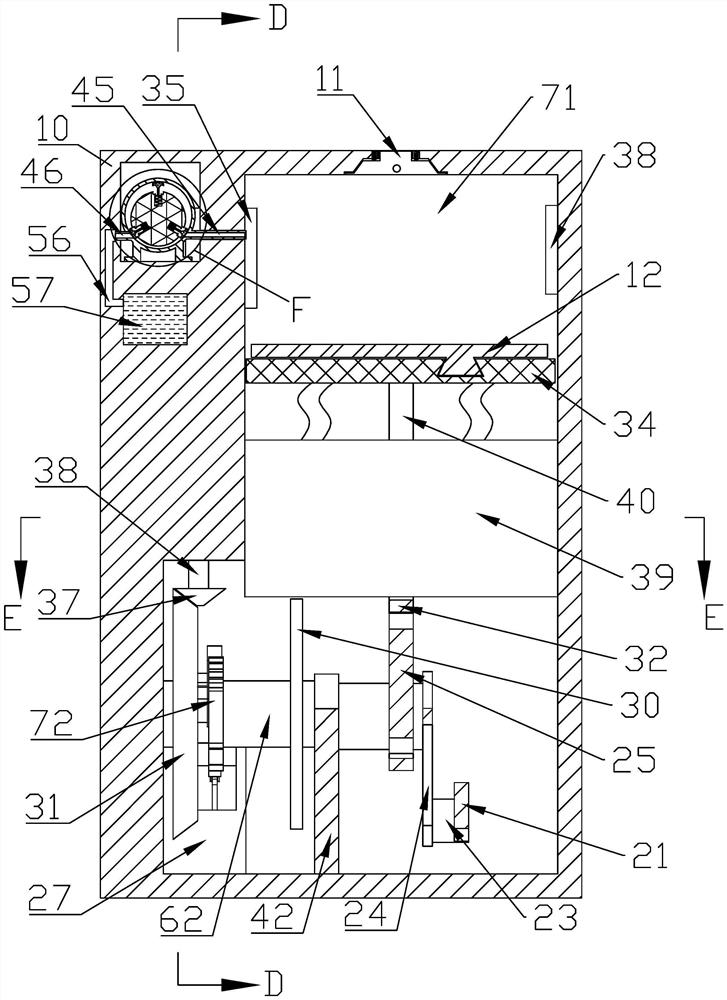

PendingCN108889438AEasy to recyclePrevent overflowSolid waste disposalGrain treatmentsCrusherMaterial supply

The invention relates to the technical field of garbage landfill treatment, in particular to an internal circulating garbage separation system. A feeder is used for conveying buried garbage, a crusheris used for conveying the garbage to a material supply tank after crushing the excavated buried garbage, soil and other heavy objects in the buried garbage fall on a deslagging belt conveyor and thenare transported out, recyclable garbage (plastic and the like) in the buried garbage is blown into a material conveying tank by wind from the air outlet end of the material supply tank, a spiral receiving machine conveys recyclable garbage to a wrapping machine for wrapping and discharge, wind from a circulating fan enters a circulating pipeline through an air inlet end of the top of the materialconveying tank, internal circulating is conducted under driving of the circulating fan, exhaust gas generated during the separation of garbage is effectively prevented from spilling in the air, energy conservation and environment protection are achieved, the system conforms to the concept of sustainable development, meanwhile one part of the recyclable garbage separated out by the separation system is high in recycling rate and good in separation effect, and the buried garbage can be effectively disposed centralizedly and recycled and become harmless.

Owner:SUZHOU JINYANG ENVIRONMENTAL PROTECTION TECH CO LTD

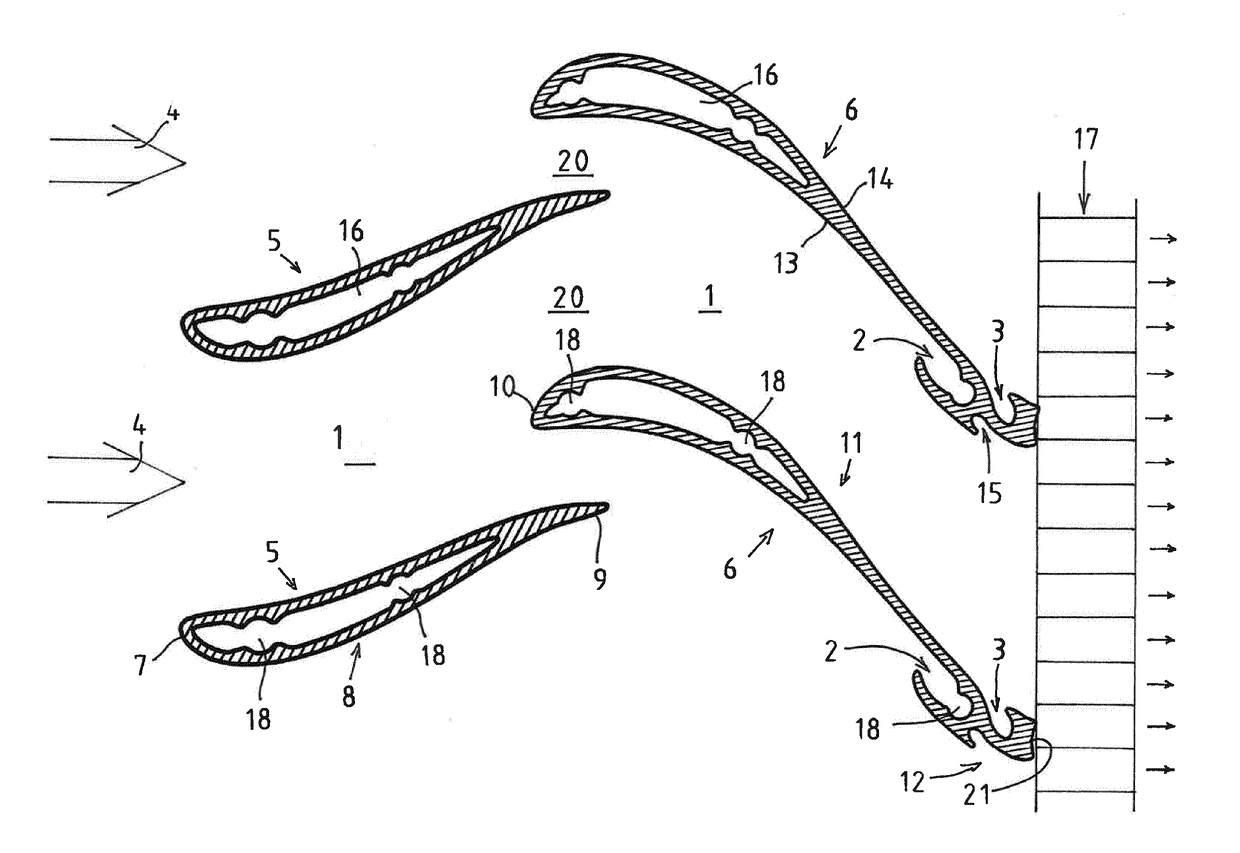

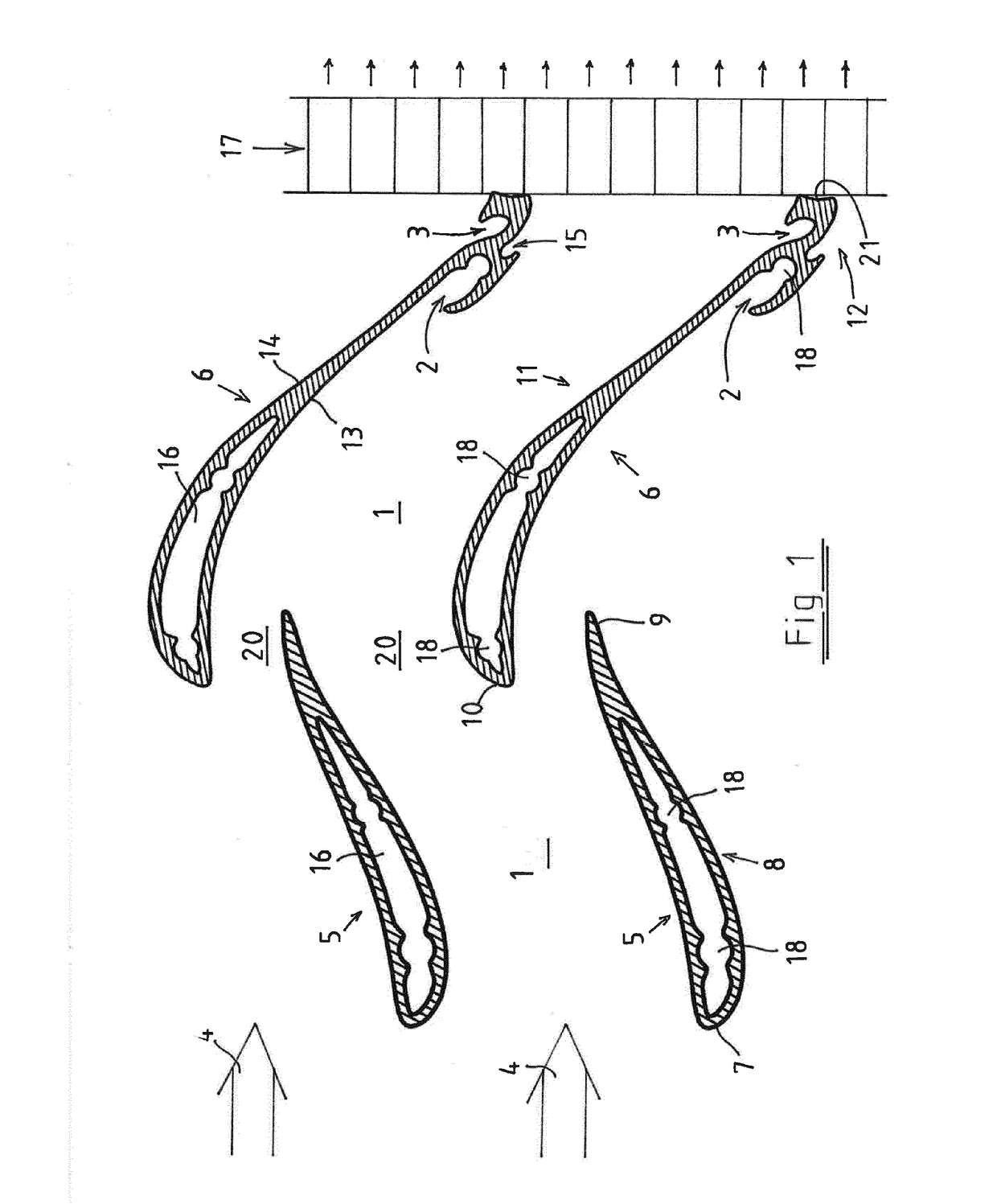

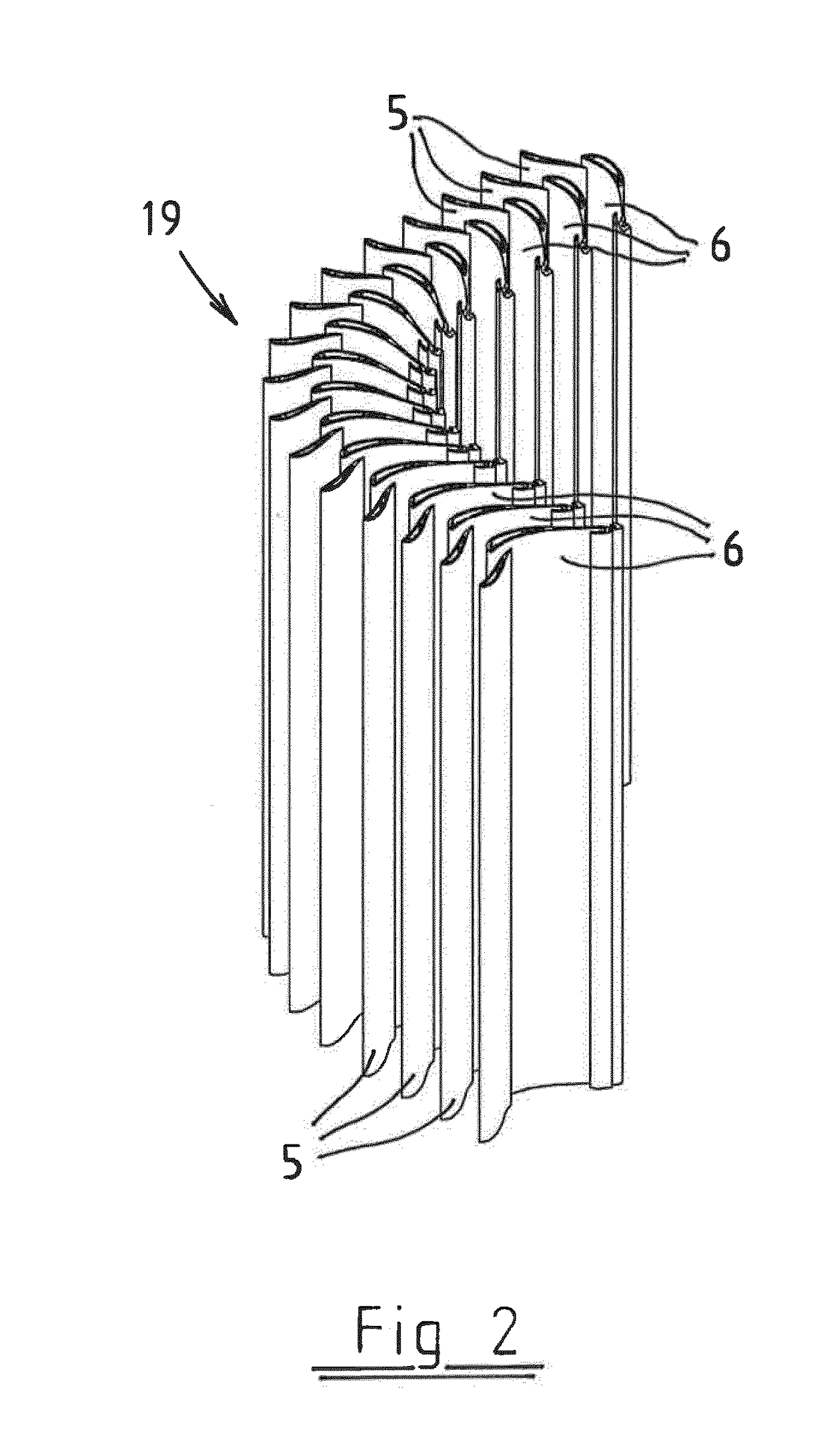

Louvered separator

ActiveUS20170157545A1Low pressure lossReduce total powerLighting and heating apparatusVentilation arrangementLeading edgeTrailing edge

The invention relates to a louvered separator for separating water from an air flow. The louvered separator comprises a number of vertical slat structures having a constant profile, horizontally spaced from each other so as to form horizontally tortuous separating channels (1) in the spaces between the slats. The slat structures are provided with water-collecting troughs (2,3). The slat structure comprises two separate slats having differing constant profiles; in the air flow direction (4) a foremost front slat (5) and a following back slat (6). The front slat comprises, in the flow direction, a leading edge (7), a middle area (8) and a trailing edge (9), and the back slat comprises, in the flow direction, a leading edge (10), a middle area (11) and a trailing edge (12). According to the invention, the water-collecting trough (2,3) is limited to the area of the trailing edge (12) of the back slat (6), so that the front slat (5) entirely, and the back slat (6) for more than a half of its length from the leading edge (10) towards the trailing edge (12), form only even surfaces to guide the flow.

Owner:ALUPRO

Automatic material smashing and magnetic separation separator

InactiveCN104923338AImprove the crushing effectEasy to separateMagnetic separationGrain treatmentsEngineeringMaterial supply

The invention relates to an automatic material smashing and magnetic separation separator comprising a base. A feeding cavity is formed in the left side of the upper portion of the base. The right side of the feeding cavity is connected with a left lifting cavity. The upper portion of the right side of the left lifting cavity is connected with a feeding pipe. The right side of the feeding pipe is connected with a smashing cavity. The lower portion of the left side of the smashing cavity is connected with a material return pipe. The lower portion of the smashing cavity is provided with a filtering plate. The lower portion of the filtering plate is provided with a stirring cavity. The right side of the stirring cavity is connected with a discharging pipe. The right side of the discharging pipe is connected with a right lifting cavity. The upper portion of the right side of the right lifting cavity is connected with a discharging cavity. The lower portion of the discharging cavity is provided with multiple discharging holes. A material supplying cavity is formed below the discharging holes. A separation cavity is arranged below the material supplying cavity. The automatic material smashing and magnetic separation separator can effectively smash materials, conveniently lift smashed materials, improves the material smashing effect and facilitates drying, magnetic separation is conducted after repeated smashing, impurities can be conveniently separated from the materials, statistics of the weight of the impurities can be conveniently conducted, the impurity separation effect is improved, and the automatic material smashing and magnetic separation separator is convenient to use.

Owner:郑小燕

Novel anti-infection isolation device for paediatrics clinical medicine

PendingCN108726043AReduce bacteria contentAvoid fermentation reactionsRefuse receptaclesRefuse cleaningAirflowEngineering

The invention discloses a novel anti-infection isolation device for paediatrics clinical medicine. The device comprises a liquid collecting box; a liquid inlet pipe, a first mounting groove and a gastreatment device are arranged on a top plate of the liquid collecting box; a first liquid passing hole is formed in a base plate of the first mounting groove; a garbage can is arranged in the first mounting groove; the garbage can comprises an outer can and an inner can; a ventilation hole is formed in the side wall of the inner can; a second liquid passing hole is formed in the base plate; a third liquid passing hole is formed in the overlapped place of the base plate of the outer can and the base plate of the inner can; a gap is filled with a sterilization layer; a first annular ultravioletlamp tube, a photocatalytic net plate and a second annular ultraviolet lamp tube are arranged in the gas treatment device in an airflow direction in sequence; a second exhaust hole is formed in an exhaust end of the gas treatment device, and is provided with a second pipe; and an exhaust end of the second pipe communicates with an intake hole. The device is simple in structure and convenient to use, and prevents intentional or unintentional contact of medical garbage with people crowds in the collection, transportation and treatment process to effectively prevents the virus infection risk.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Medical waste liquid removing and separating device

InactiveCN111672878AImprove separation capacityEasy dischargeSolid waste disposalTransportation and packagingWater filterMedical waste

The invention discloses a medical waste liquid removing and separating device and relates to the field of medical waste treatment. The medical waste liquid removing and separating device comprises a treatment box; a smashing mechanism, an extruding mechanism and a water filtering mechanism are arranged in the treatment box; a motor base is fixedly connected with the top end of a deslagging pipe; an extruding water removing mechanism is arranged in a bottom cover; the bottom end of an extruding conveying pipe is fixedly connected with the top end of the bottom cover; and a conveying mechanism is fixedly arranged at the bottom end of a bottom plate. According to the medical waste liquid removing and separating device, the smashing mechanism is arranged to smash the medical waste so as to crack the medical waste, so that liquid contained in the medical waste can be drained; the extruding mechanism is arranged to further extrude the cracked medical waste to drain the liquid; the water filtering mechanism is arranged to discharge liquid and solid waste in a separated manner; a screw conveying plate is arranged in the extruding conveying pipe and is cooperated with the extruding water removing mechanism to carry out further extrusion water removing operation on the separated solid medical waste to realize an excellent separating treatment effect on the medical waste.

Owner:刘浩

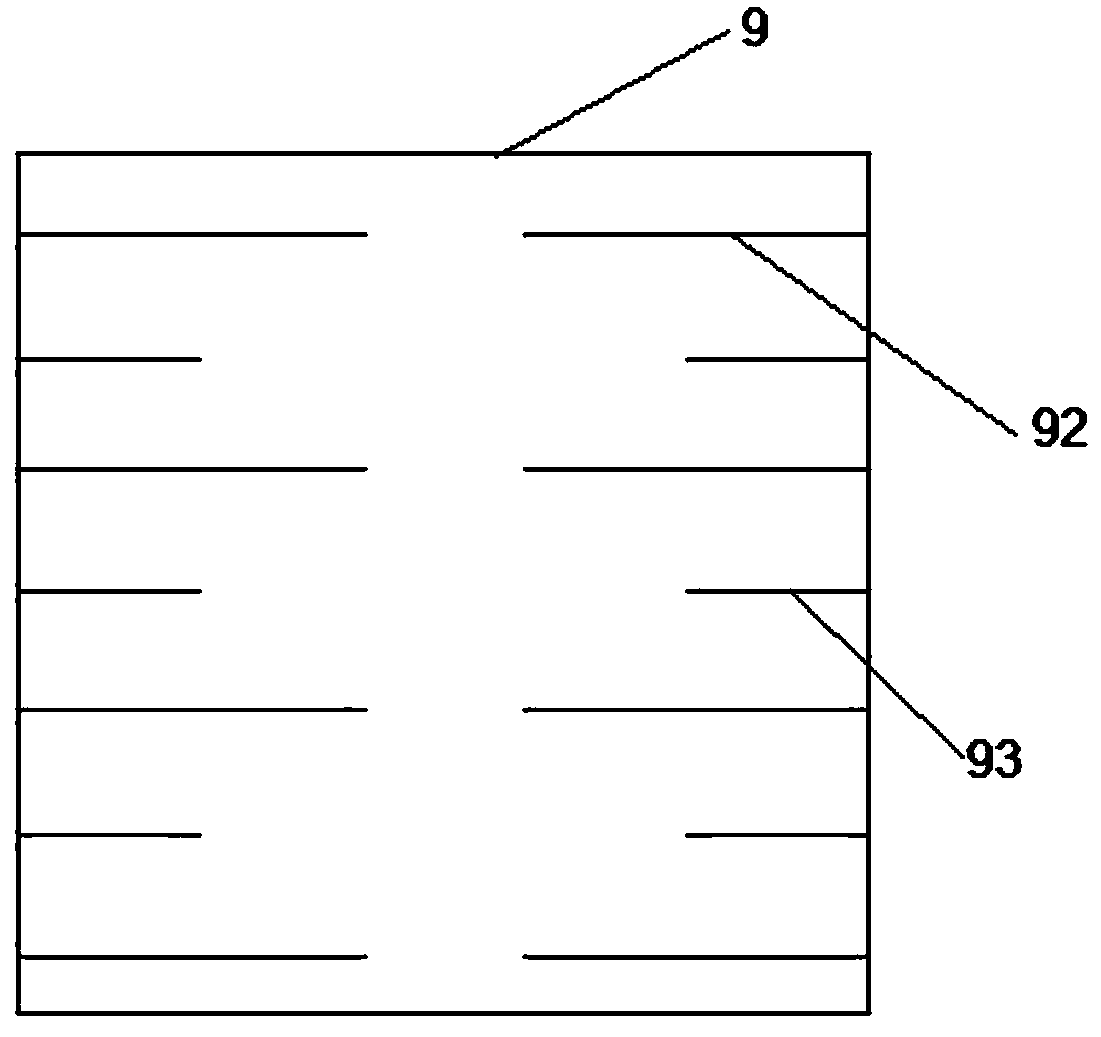

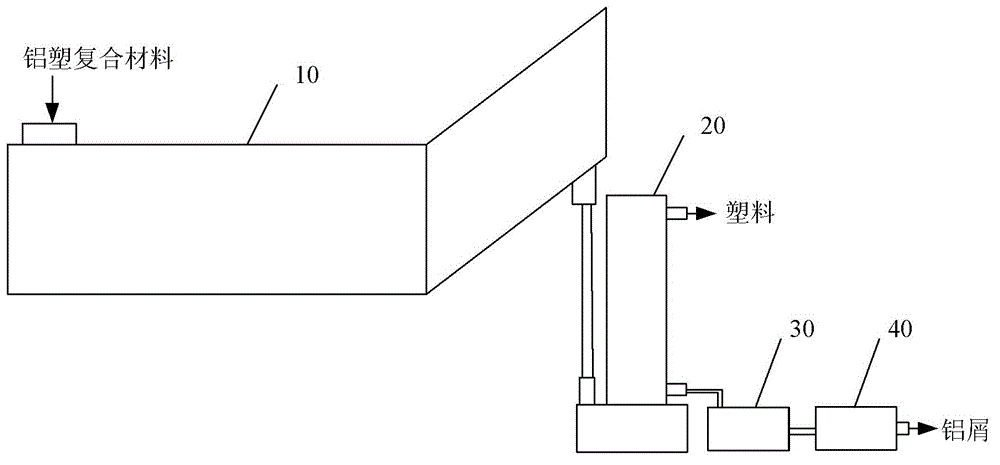

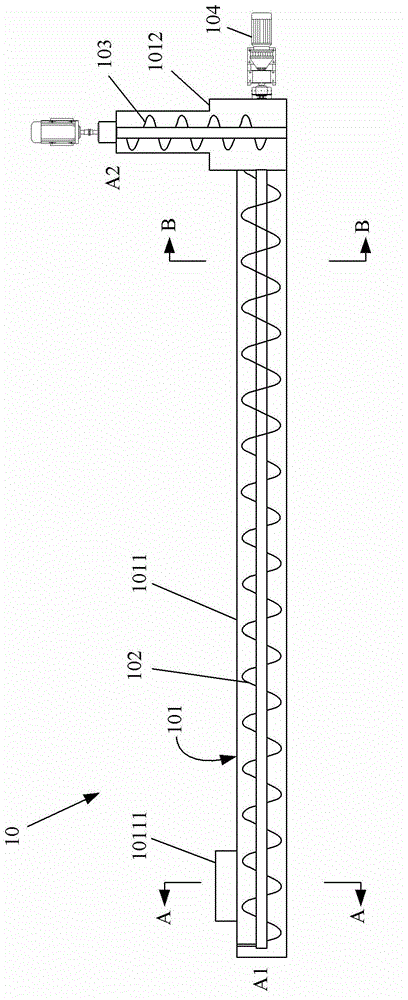

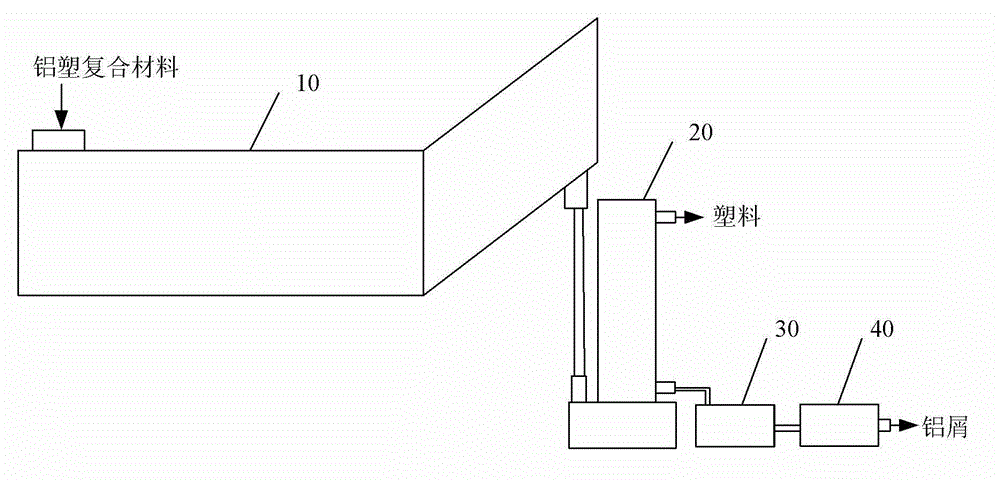

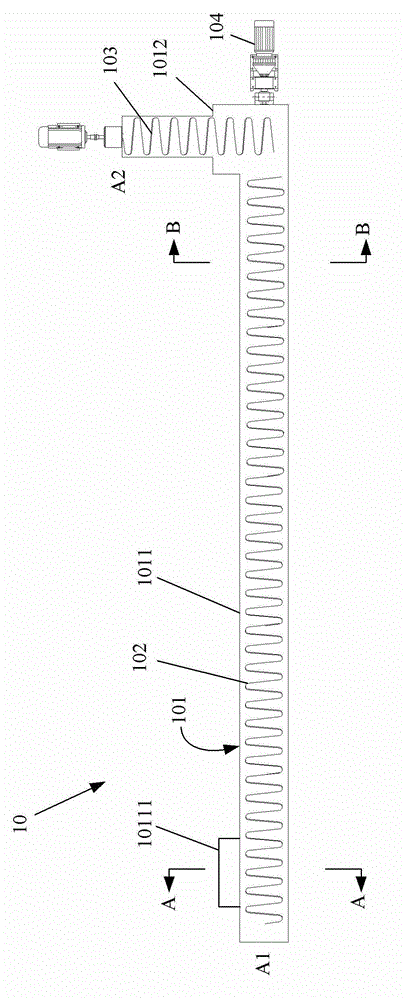

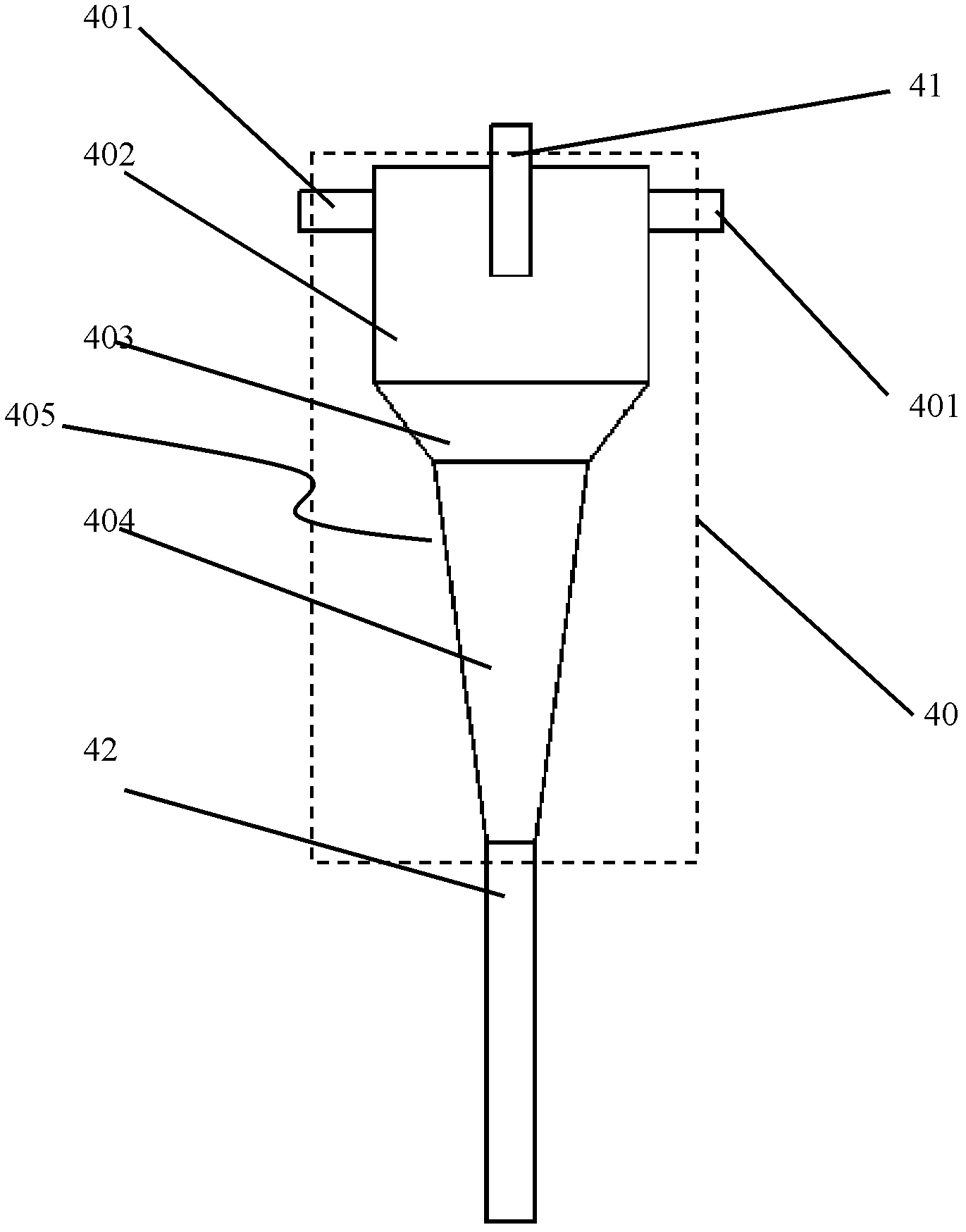

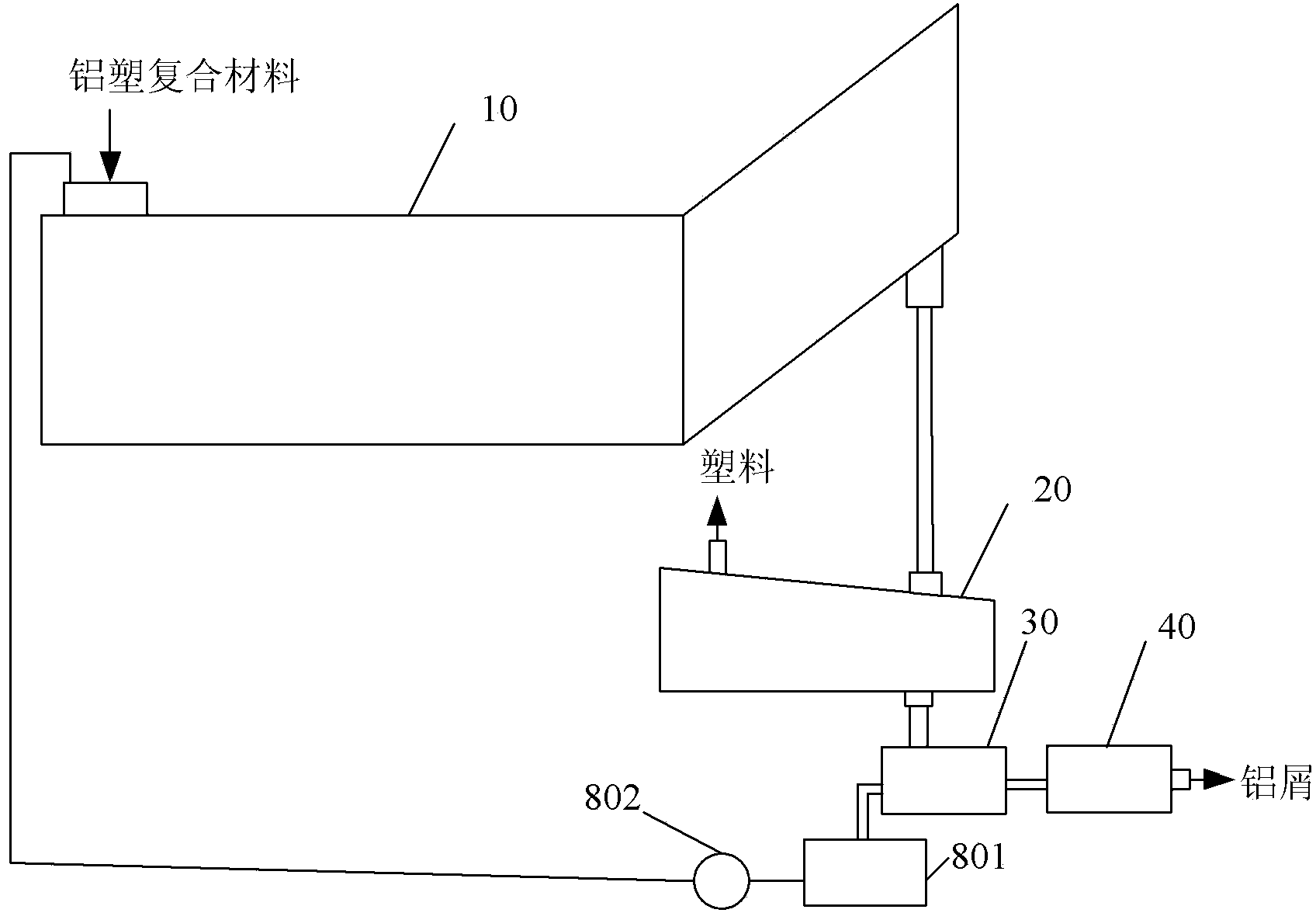

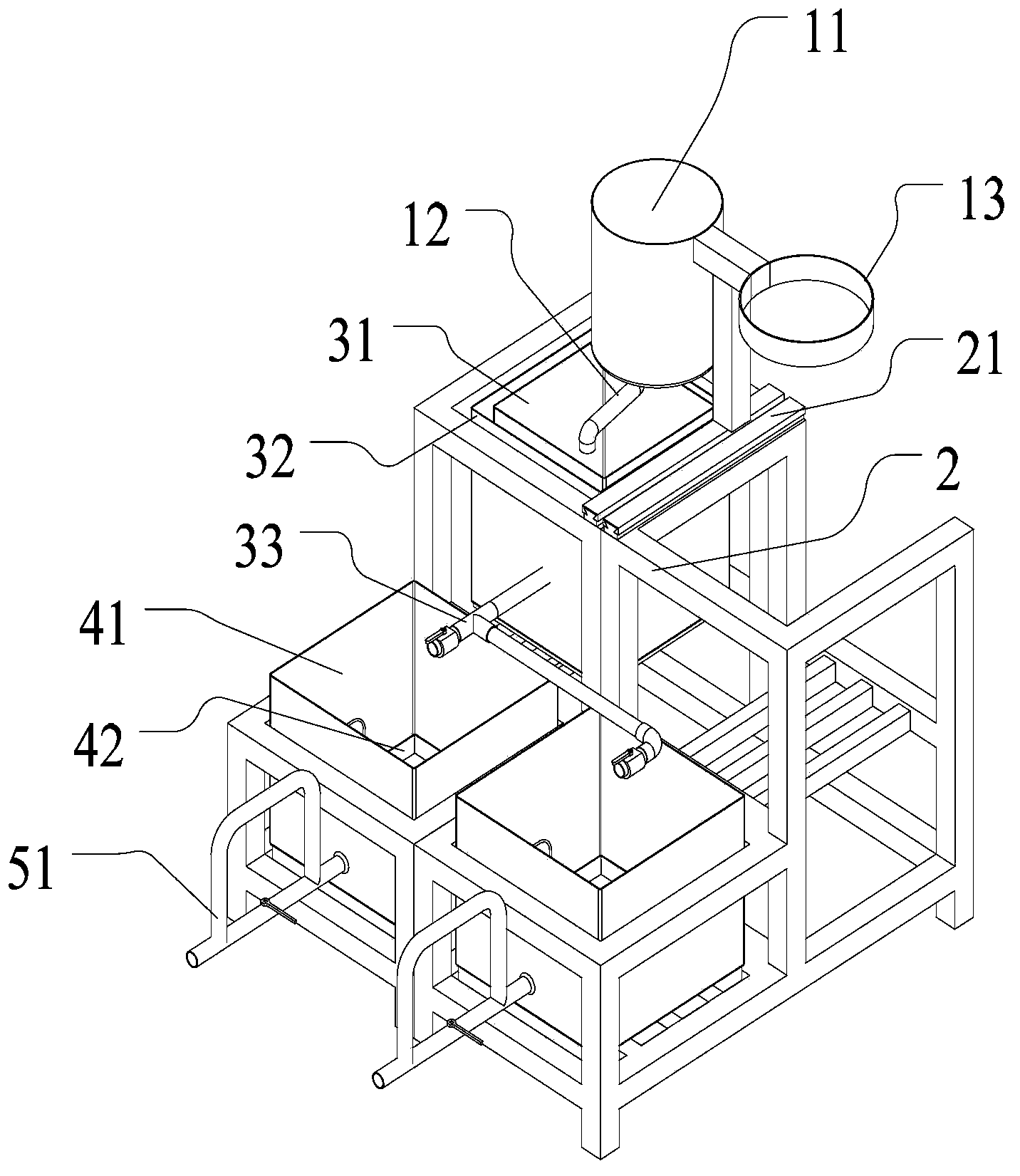

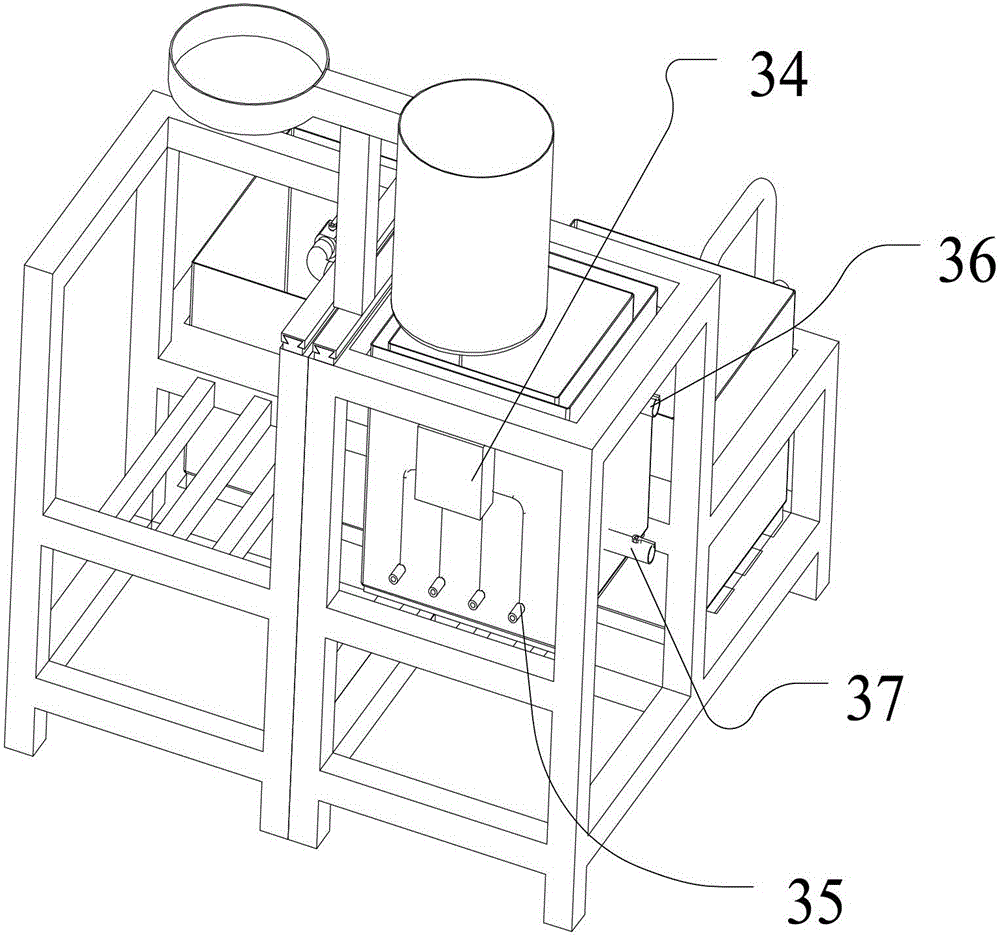

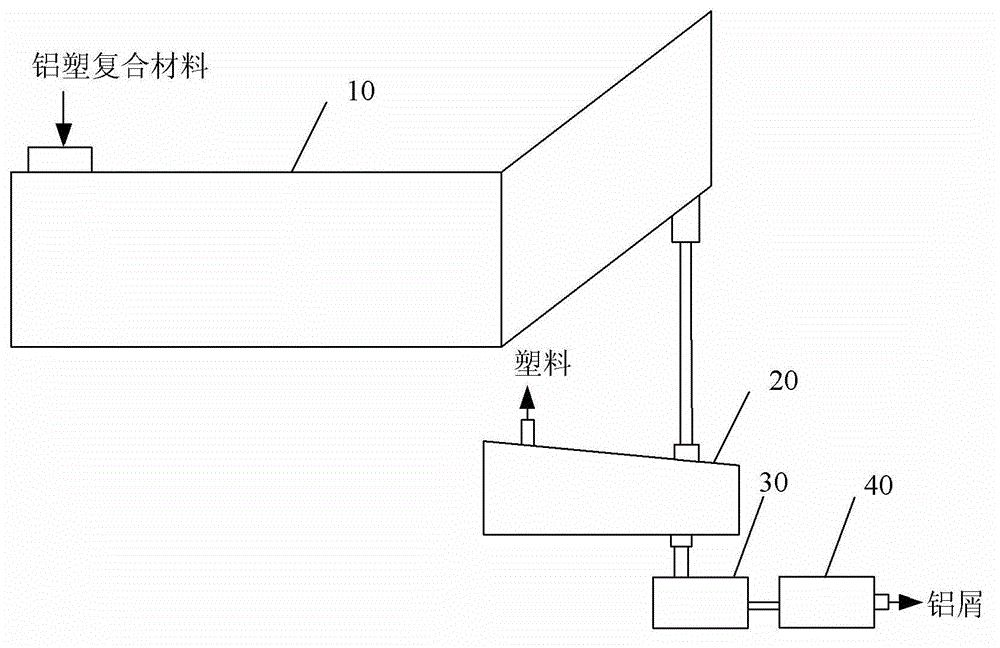

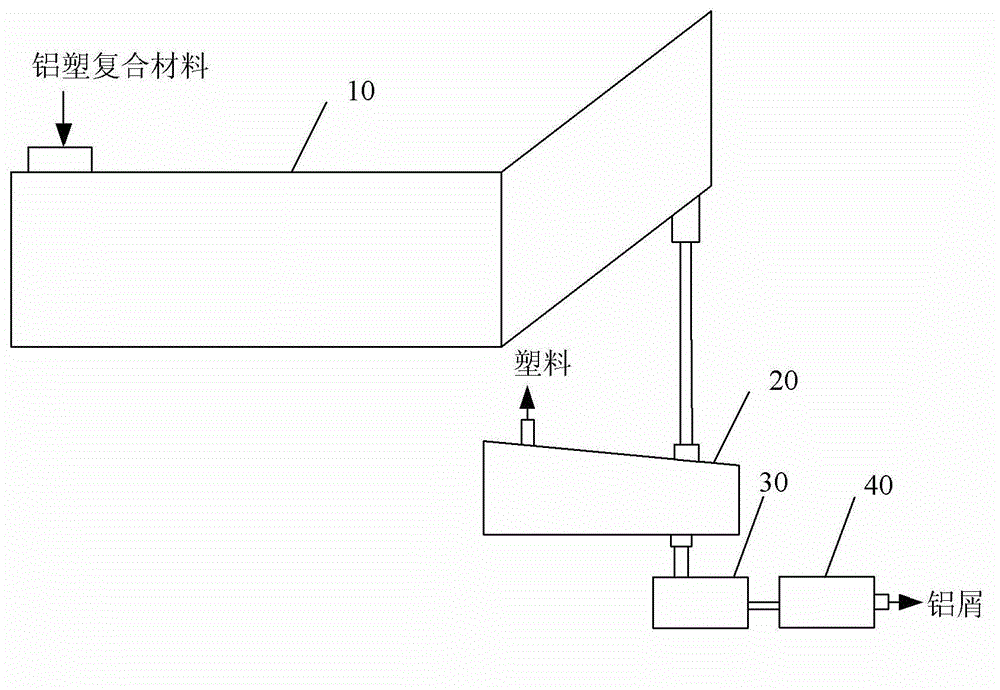

Vertical-type continuous separation spin-drying separation treatment system of aluminum-plastic compound package material

ActiveCN102744244AImprove separation capacityLow costSievingScreeningChemical separationPhysical separation

The invention provides a vertical-type continuous separation spin-drying separation treatment system of an aluminum-plastic compound package material. The vertical-type continuous separation spin-drying separation treatment system of the aluminum-plastic compound package material comprises a separation reaction device and a vertical-type separation spin-drying device, wherein the separation reaction device carries out chemical separation treatment on the aluminum-plastic compound package material; the vertical-type separation spin-drying device carries out physical separation treatment on the chemically separated aluminum-plastic compound package material; an inner cylinder body of the vertical-type separation spin-drying device is internally provided with a rotating shaft, and the rotating shaft is provided with a plurality of sickle-shaped blades at intervals. The vertical-type continuous separation spin-drying separation treatment system can effectively realize the continuous separation treatment of the aluminum-plastic compound package material and is higher in aluminum-plastic separation treatment capability.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

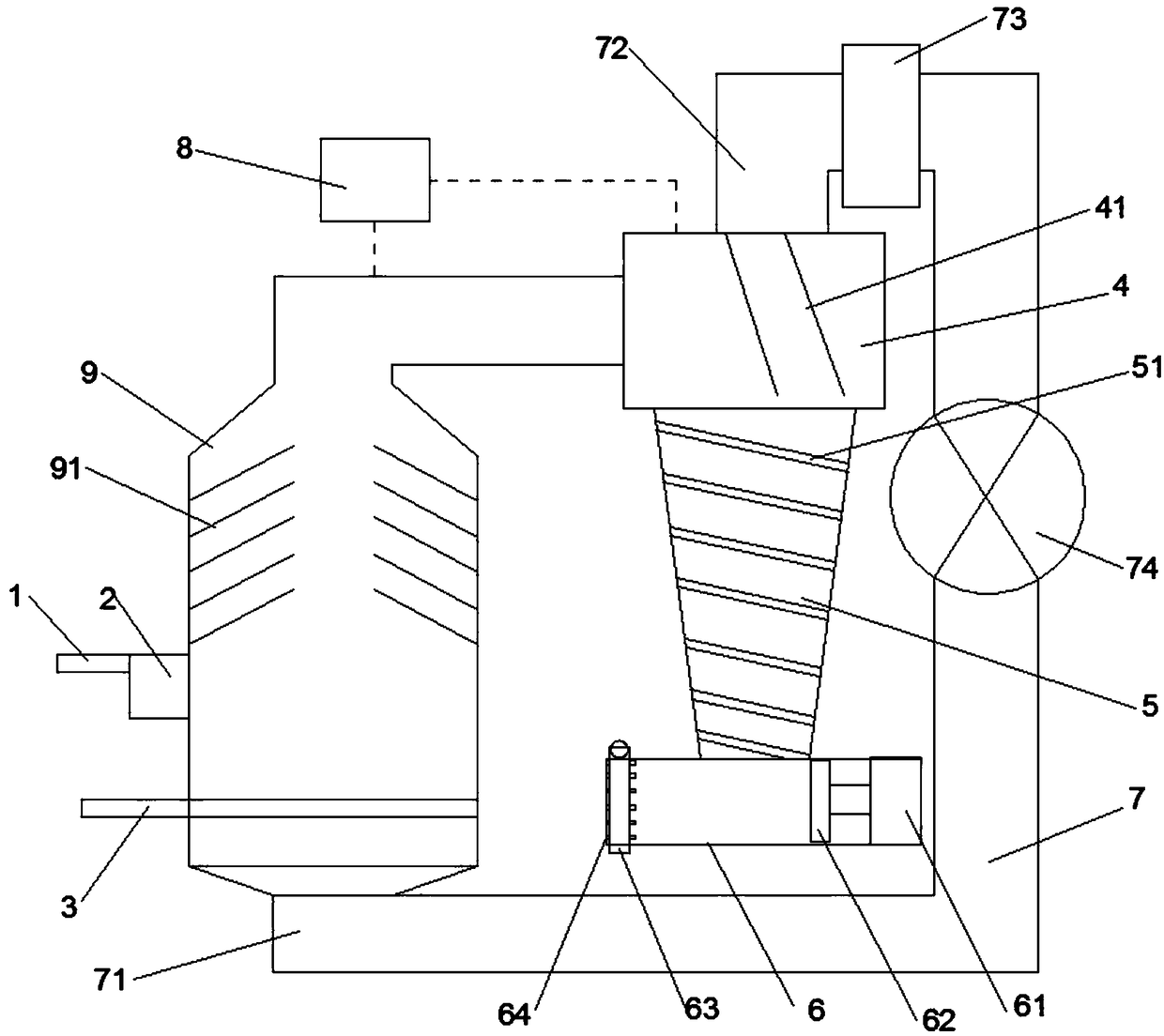

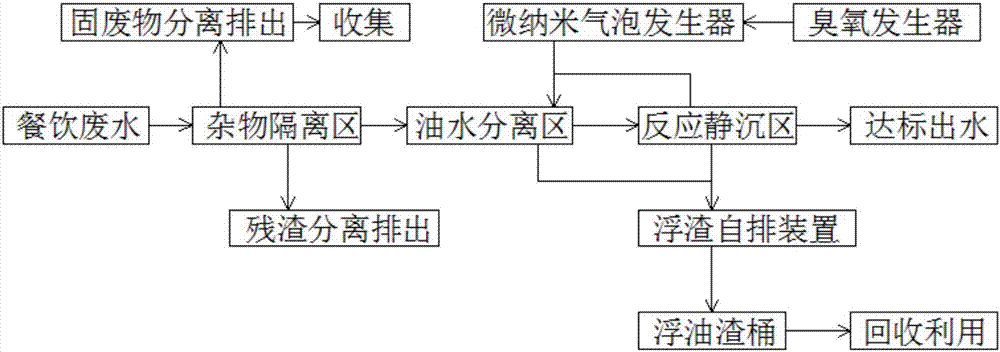

Micro-nano catering waste water pretreatment process

InactiveCN108002588AMaintain dissolved oxygen concentrationImprove separation capacityWater treatment parameter controlMultistage water/sewage treatmentParticulatesMicro nano

The invention discloses a micro-nano catering waste water pretreatment process. The micro-nano catering waste water pretreatment process comprises the following steps: gathering kitchen catering wastewater to automatically flow into an impurity separation area by virtue of gravity, and separating and removing large-particle impurities in the waste water; settling small particles in the waste water along a 30-DEG conical hopper; when the waste water flows by the front end of an oil-water separation area, transporting ozone generated by an ozone generator to a micro-nano bubble generator, mixing the catering waste water and the ozone sufficiently under the effect of the micro-nano bubble generator, then circularly cutting, and generating micro-nano bubbles; absorbing, by the micro-nano bubbles in the waste water, suspended solids, forming the suspended solid cluster, and then enabling the suspended solid cluster to float on the surface of the water to form floating slag; and enabling the waste water to flow from the tail end of the oil-water separation area to a reaction static settling area, standing for 2 to 3 min, arranging a sampling valve on a water outlet end, monitoring, by the sampling valve, the water quality, and discharging the water after the water quality reaches the standard. The micro-nano catering waste water pretreatment process has the advantages of good treatment effect, up-to-standard water quality and the like.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

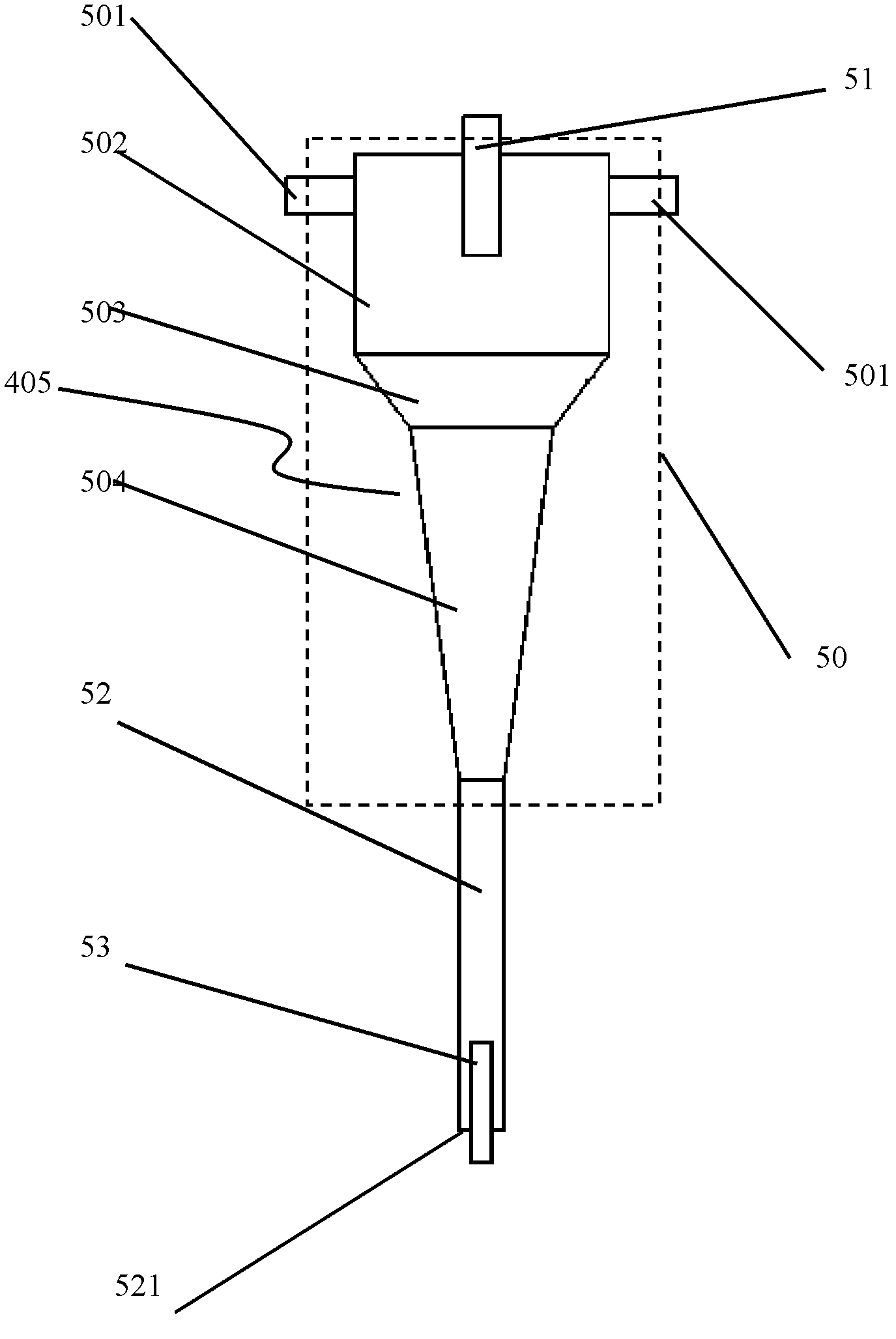

Vertical continuous aluminum-plastic composite packaging material separating system capable of recovering separating agent

ActiveCN102764753AReduce consumptionEasy to handleSievingScreeningChemical separationProcess engineering

The invention provides a vertical continuous aluminum-plastic composite packaging material separating system capable of recovering a separating agent. The system comprises a separating reaction device for performing chemical separating treatment to the aluminum-plastic composite packaging materials, and a vertical separating and spin drying device for performing physical separating treatment to the chemically separated aluminum-plastic composite packaging materials, wherein a reaction screw and a discharge screw arranged in the separating reaction device both are shaft-less screw structures; an inner cylinder of the vertical separating and spin drying device is provided with a rotating shaft, and the rotating shaft is discontinuously provided with a plurality of sickle blades; and the vertical separating and spin drying device is connected with a sedimenting centrifuge which is connected with a separating agent buffer pool. With the adoption of the aluminum-plastic composite packaging material vertical continuous separating system capable of recovering separating agent, the continuous separating treatment of aluminum-plastic composite packaging materials is realized effectively, and the system has high aluminum-plastic separating property.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Automatic magnetic separator for materials

InactiveCN104959206AImprove the crushing effectEasy to separateMagnetic separationGrain treatmentsMagnetic separatorTherapeutic effect

The invention relates to an automatic magnetic separator for materials. The automatic magnetic separator comprises a base, wherein a feeding cavity is formed in the left side of the upper part of the base; a left lifting cavity is connected to the right side of the feeding cavity; a material supplying pipe is connected to the upper part of the right side of the left lifting cavity; a crushing cavity is connected to the right side of the material supplying pipe; a material returning pipe is connected to the lower part of the left side of the crushing cavity; a filtering plate is arranged at the lower part of the crushing cavity; a stirring cavity is formed at the lower part of the filtering plate; a discharging pipe is connected to the right side of the stirring cavity; a right lifting cavity is connected to the right side of the discharging pipe; a discharging cavity is connected to the upper part of the right side of the right lifting cavity; a plurality of discharging holes are formed in the lower part of the discharging cavity; a material supplying cavity is formed below the discharging holes; a separating cavity is formed below the material supplying cavity. The automatic magnetic separator disclosed by the invention can be used for crushing materials and favorably lifting the crushed materials, so that the crushing treatment effect of the materials is improved; in addition, the drying treatment is facilitated, magnetic separation is carried out after crushing for multiple times, and impurities are conveniently separated; besides, the mass of the impurities is conveniently counted, the separating treatment effect of the impurities is improved, and the convenience in use is realized.

Owner:陈少军

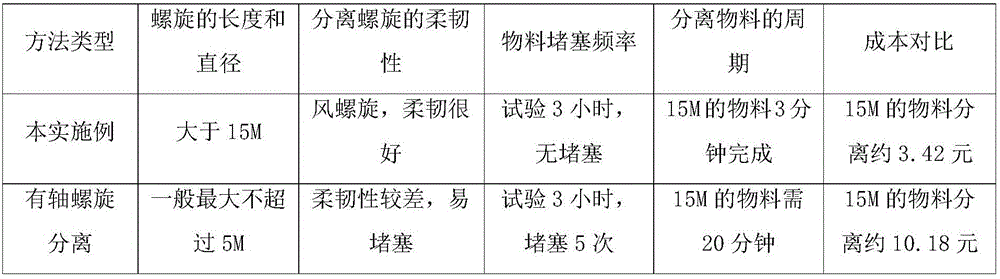

Shaftless spiral vertical-type continuous separation treatment system of aluminum-plastic compound package material

ActiveCN102744241AImprove separation capacityAvoid cloggingSolid waste disposalPlastic recyclingPhysical chemistryChemical separation

The invention provides a shaftless spiral vertical-type continuous separation treatment system of an aluminum-plastic compound package material. The shaftless spiral vertical-type continuous separation treatment system of the aluminum-plastic compound package material comprises a separation reaction device and a vertical-type separation spin-drying device, wherein the separation reaction device carries out chemical separation treatment on the aluminum-plastic compound package material; the vertical-type separation spin-drying device carries out physical separation treatment on the chemically separated aluminum-plastic compound package material; a reaction spiral and a discharge spiral arranged in the separation reaction device are both in shaftless spiral structures; an inner cylinder body of the vertical-type separation spin-drying device is internally provided with a rotating shaft, and the rotating shaft is provided with a plurality of sickle-shaped blades at intervals. The shaftless spiral vertical-type continuous separation treatment system of the aluminum-plastic compound package material can effectively realize the continuous separation treatment of the aluminum-plastic compound package material and is higher in aluminum-plastic separation treatment capability.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Material magnetic separating machine

ActiveCN104941799AImprove the crushing effectEasy to separateMagnetic separationGrain treatmentsTherapeutic effectEngineering

The invention relates to a material magnetic separating machine which comprises a base, wherein a feeding cavity is formed on the left side of the upper part of the base; the right side of the feeding cavity is connected with a left lifting cavity; the upper part of the right side of the left lifting cavity is connected with a material supply pipe; the right side of the material supply pipe is connected with a crushing cavity; the lower part of the left side of the crushing cavity is connected with a material return pipe; a filter plate is arranged at the lower part of the crushing cavity; a mixing cavity is formed at the lower part of the filter plate; the right side of the mixing cavity is connected with a material unloading pipe; the right side of the material unloading pipe is connected with a right lifting cavity; the upper part of the right side of the right lifting cavity is connected with a discharge cavity; a plurality of discharge holes are formed at the lower part of the discharge cavity; a material supply cavity is formed at the lower parts of the discharge holes; and a separating cavity is formed at the lower part of the material supply cavity. The material magnetic separating machine can effectively performs crushing treatment on a material specifically, facilitates lifting treatment on the material after crushing, improves the crushing treatment effect of the material, and facilitates drying treatment; magnetic separation is performed after crushing for multiple times, so that the separation of impurity matters can be separated out conveniently; the quantity of the impurity matters can be counted conveniently; the impurity separation treatment effect is improved; and the material magnetic separating machine is convenient to use.

Owner:重庆先隆电力设备制造有限公司

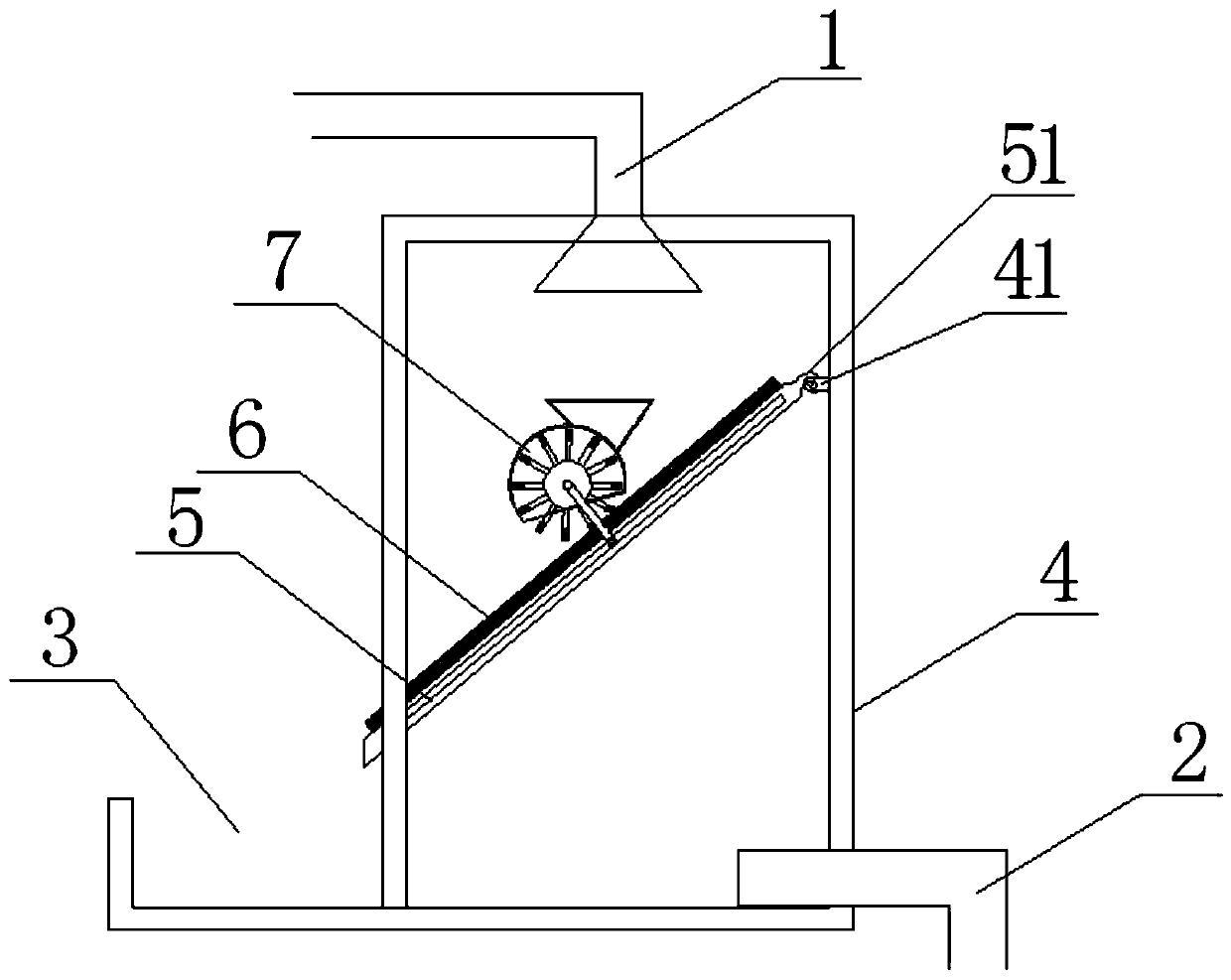

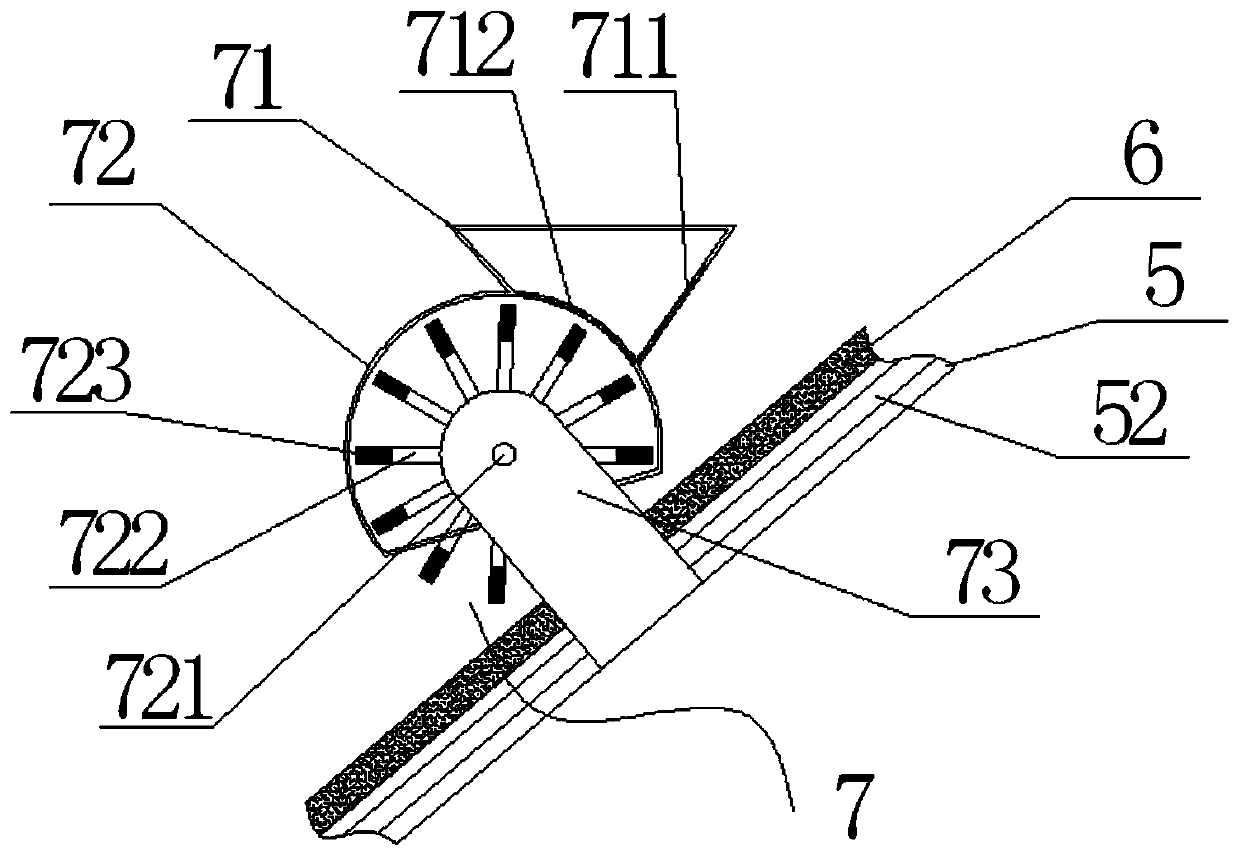

A sewage treatment grille device

ActiveCN107982972BReduce resistanceImprove separation capacityTreatment involving filtrationStationary filtering element filtersSewage treatmentFan blade

The invention relates to sewage treatment equipment, and in particular relates to a sewage treatment grating device. The sewage treatment grating device comprises a water inlet pipe, a water outlet pipe, a garbage collection tank and a sewage treatment tank, wherein a grating bed which is arranged in an inclined way is arranged in the sewage treatment tank, a screen is arranged on the grating bed,and sliding grooves are formed in the two sides of the grating bed; a rolling brush component is arranged on the screen, the rolling brush component is composed of a water inlet bin, a roller and a supporting plate, the water inlet bin is arranged at the upper end of the roller and is close to one side of the upper end of the grating bed, the upper end of the supporting plate is fixed on the roller, a walking wheel is arranged at the lower end of the supporting plate, and the walking wheel is arranged in the sliding grooves of the grating bed; and a rotating shaft and fan blades are arrangedin the roller, the fan blades are symmetrically arranged on the rotating shaft, and bristles are arranged at the front end of the fan blades. The sewage treatment grating device provided by the invention is simple in structure, safe, reliable, small in size, high in sewage treatment efficiency, good in separation effect, easy to use and extremely low in energy consumption.

Owner:ANHUI XINRUI ENVIRONMENTAL PROTECTION EQUIP

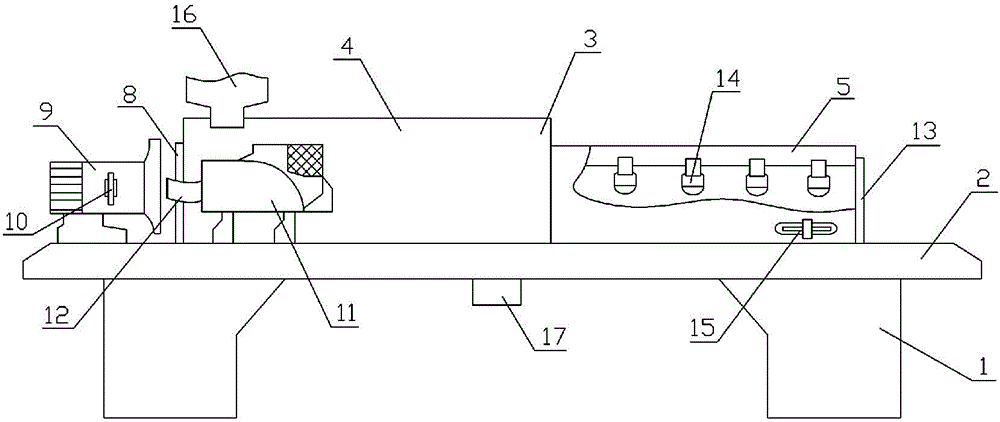

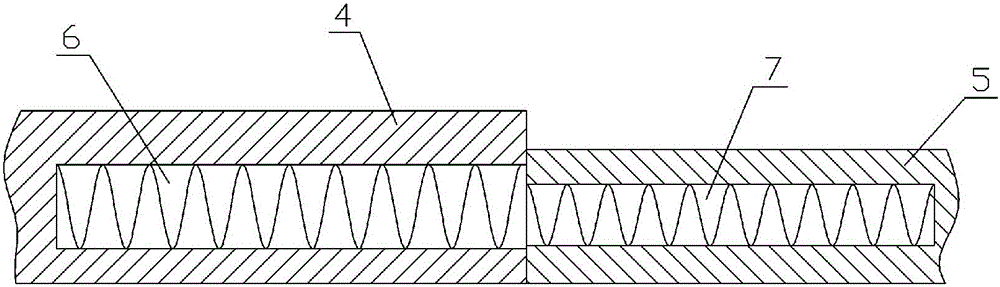

Separation device for food aluminum plastic bagged material

ActiveCN105817468ARealize continuous separation processingEasy to handleSolid waste disposalPlastic recyclingDisinfectantEngineering

The invention discloses a separation device for a food aluminum plastic bagged material. The separation device comprises a rack and a workbench arranged on the rack; a separation pipeline comprises a first pipe section and a second pipe section which form a stepped separation pipeline body; the diameter of the first pipe section is greater than that of the second pipe section; a first spiral cavity is formed inside the first pipe section; a second spiral cavity is formed in the second pipe section; the other end of the first pipe section communicates with the second pipe section; a blower is arranged at a feeding inlet; a gasification machine with disinfectant is installed at the feeding inlet; a water inlet pipe with separation agents is arranged in the position, close to the feeding inlet, of the top of the first pipe section; and a drain pipe is arranged in the position, close to the position communicating with the second pipe section, of the bottom of the first pipe section. The problems that by the adoption of an existing soaking separator for the aluminum plastic composite bagged material, the material separation processing efficiency is poor, a material blockage fault occurs easily and the production cycle is long as the material is repeatedly transferred are solved.

Owner:DINGSHENG CORP

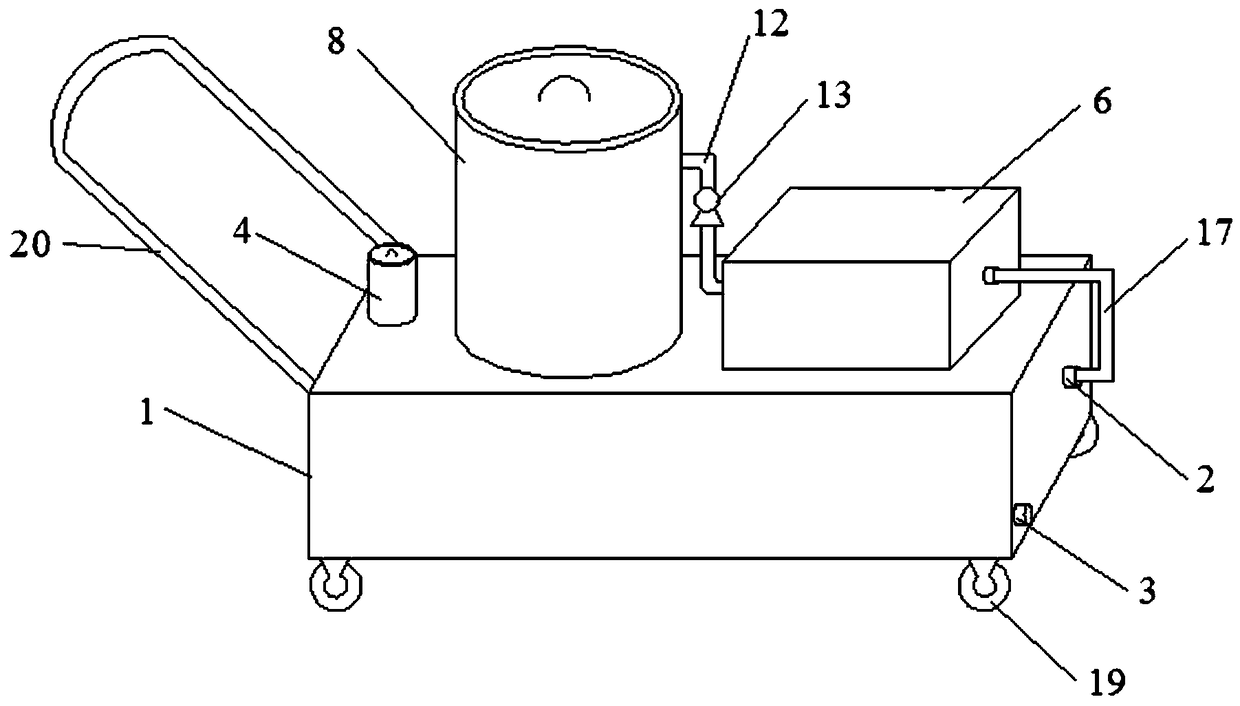

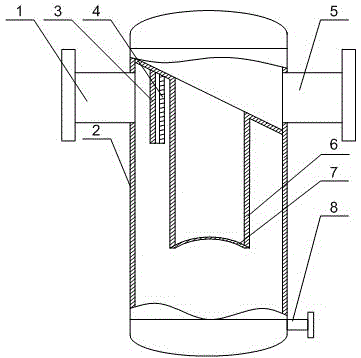

Gas-liquid separation device for single-well booster set

InactiveCN105080272ARealize gas-liquid separationAvoid deactivationCombination devicesEngineeringKinetic energy

The invention discloses a gas-liquid separation device for a single-well booster set. The gas-liquid separation device comprises a tank body, wherein a gas inlet and a gas outlet are formed in two sides of the tank body; a filtering core barrel is arranged in the tank body; the gas inlet is opposite to the side wall of the filtering core barrel; the top end of the filtering core barrel is inclined and is opposite to the gas outlet; a separation filtering net which is bent in the direction of pointing to the top end along the bottom end of the filtering core barrel is arranged at the bottom end of the filtering core barrel. The gas-liquid separation device also comprises a flow blocking plate and a water absorbing plate, wherein the flow blocking plate is opposite to the gas inlet; a gap is formed between the flow blocking plate and the water absorbing plate; liquid moves upwards after direction changing, so that the distance, entering the interior of the filtering core barrel, of the liquid is increased, namely kinetic energy of rest liquid cannot move upwards continuously after the consumption that the kinetic energy is converted into potential energy after direction changing or upward moving, and falls down to the bottom of the tank body directly, so that the gas-liquid separation of mixtures is finally realized, a condition that the residual liquid enters the booster set to cause the halt of the booster set when the residual liquid is conveyed from the gas outlet is avoided, and simultaneously the separation treatment capacity of the booster set is improved.

Owner:CHENGDU ZHENGSHENG ENERGY TECH DEV CO LTD

Treatment method and equipment for oilfield produced water

The invention relates to a treatment process of oilfield produced water. The treatment process using two-stage oil-water hydrocyclone separation with backflow as a main part is adopted. The treatment process comprises the steps as follows: firstly, adding a demulsifier to perform demulsification pretreatment; next, carrying out two-stage oil-water hydrocyclone separation; and finally carrying out a deep treatment by combination of air floatation and fiber filtration. After the treatment process provided by the invention is carried out, oil in the oilfield produced water can be recycled, and the produced water meets the Recommended Standard of Water Quality of Hidden Water Injection of Clastic Rocks (SY / T5329-1994) and can be used for water injection in oilfields. The treatment process provided by the invention not only reduces the influence of the oilfield produced water on environment, but also recycles resources.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Standing continuous separation spin-drying treatment system for aluminum plastic composite material

InactiveCN108214991AImprove separation capacityImprove processing efficiencySolid waste disposalPlastic recyclingPhysical separationChemical separation

The invention provides a standing continuous separation spin-drying treatment system for an aluminum plastic composite material. The standing continuous separation spin-drying treatment system comprises a separation reaction device for conducting chemical separation treatment on the aluminum plastic composite packing material, and a standing separation spin-drying device for conducting physical separation treatment on aluminum plastic composite packing material subjected to chemical separation, wherein an inner cylindrical body of the standing separation spin-drying device is internally provided with a rotary shaft, and the rotary shaft is discontinuously provide with a plurality of crescent blades. The standing continuous separation spin-drying treatment system for the aluminum plastic composite material can effectively conduct continuous separation treatment on the aluminum plastic composite packing material, and has high aluminum plastic separation processing capacity.

Owner:胡雨思

Separating system and method for aluminum-plastic prebagged materials

ActiveCN106393485AEasy to handleAvoid cloggingPlastic recyclingChemicalsDisinfectantProcess engineering

The invention discloses a separating system and method for aluminum-plastic prebagged materials. The separating system comprises a machine frame and a workbench arranged on the machine frame and is characterized in that a separating pipeline comprises a first pipe section and a second pipe section, the first pipe section and the second pipe section form a separating pipeline body in a step shape, a spiral first cavity is formed in the first pipe section, a spiral second cavity is formed in the second pipe section, one end of the first pipe section is provided with a feed inlet, a gasification machine with disinfectant is installed at the position of the feed inlet, the second pipe section is provided with a discharge outlet, a water inlet pipe for a separating agent is formed in the position, close to the feed inlet, of the top of the first pipe section, and a drainage pipe is arranged at the position, close to the communicated position between the first pipe section and the second pipe section, of the first pipe section. The separating method comprises four steps of material placement and the like. The separating system and method aim to solve the problems that when an existing soaking separator for aluminum-plastic composite prebagged materials is adopted, the material separation processing efficiency is poor, a material blockage fault is likely to be produced and the production period is long due to repeated material transfer.

Owner:DINGSHENG CORP

Separating agent recovery horizontal-type continuous separation system of aluminum-plastic compound package material

The invention provides a separating agent recovery horizontal-type continuous separation system of an aluminum-plastic compound package material. The separating agent recovery horizontal-type continuous separation system of the aluminum-plastic compound package material comprises a separation reaction device and a horizontal-type separation spin-drying device, wherein the separation reaction device carries out chemical separation treatment on the aluminum-plastic compound package material; the horizontal-type separation spin-drying device carries out physical separation treatment on the chemically separated aluminum-plastic compound package material; a reaction spiral and a discharge spiral arranged in the separation reaction device are both in shaftless spiral structures; an inner cylinder body of the horizontal-type separation spin-drying device is internally provided with a rotating shaft, and the rotating shaft is provided with a plurality of sickle-shaped blades at intervals; the horizontal-type separation spin-drying device is connected with a sedimentation centrifuge, and the sedimentation centrifuge is connected with a separating agent buffer pool. The separating agent recovery horizontal-type continuous separation system of the aluminum-plastic compound package material can effectively realize the continuous separation treatment of the aluminum-plastic compound package material, is higher in aluminum-plastic separation treatment capability and can recycle the separating agent.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

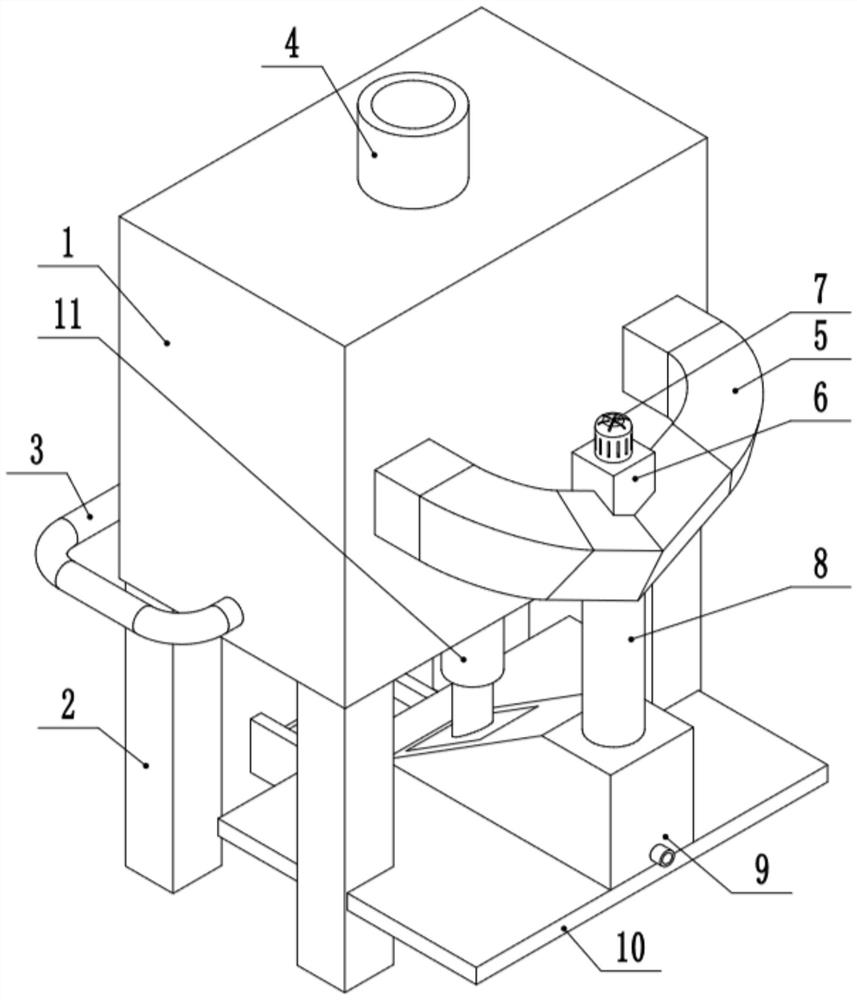

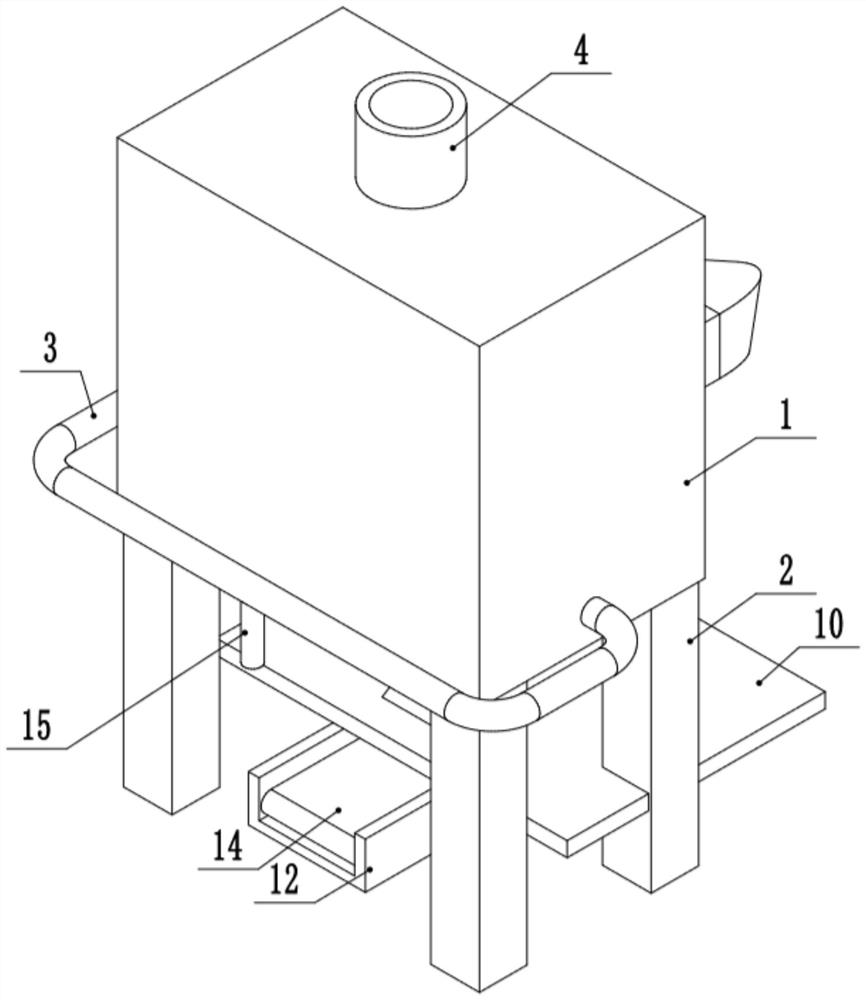

Treatment device for separating polyurethane waste material

InactiveCN104338373AEasy to operateImprove separation capacityFiltration circuitsWaste collectionTherapeutic effect

The invention provides a treatment device for separating a polyurethane waste material. The device comprises a support frame, as well as a waste collection device and at least one heating and separation device which are fixed on the support frame. A filtering device is arranged in the waste collection device. The waste collection device is communicated with the heating and separation device by at least one first pipeline. The treatment device for separating the polyurethane waste material is convenient to operate, good in separation treatment effect and environmental-friendly.

Owner:SHANGHAI YONGHONG AUTO PARTS

Marine oily water disk aggregation and separation device

InactiveCN101654149BImprove separation capacityIncrease multipleAuxillariesWater treatment installationsSewageEngineering

The invention discloses a marine oily water disk aggregation and separation device, comprising a barrel body, wherein at least a first aggregation separator and a second aggregation separator are arranged in the barrel body; the first aggregation separator and the second aggregation separator are respectively positioned on the upper side and the lower side of a fluid guide hole plate; the periphery of the fluid guide hole plate are fixedly installed on the inner wall of the barrel body in a sealing manner; the middle position of the fluid guide hole plate is provided with a fluid guide through hole; the top end of the first aggregation separator is provided with a top part cover plate, and a gap is left between the periphery of the top part cover plate and the inner wall of the barrel body; the bottom part of the second aggregation separator is provided with a fluid guide blind plate, and a gap is left between the periphery of the fluid guide blind plate and the inner wall of the barrel body; and the first aggregation separator and / or the second aggregation separator comprise / comprises a plurality of mutually superposed ripple separating discs. The separation device has the advantages of simple structure, convenient maintenance and manufacturing, and ideal oil-water separation effect, and is particularly applicable to marine oily water separation.

Owner:DONGTAI CITY DONGFANG MARINE FITTING

Oily free water oil slick collector

ActiveCN112374574BImprove separation capacityAvoid enteringFatty/oily/floating substances removal devicesNature of treatment waterOil waterFree water

The invention discloses an oil-containing free water floating oil collector and relates to the field of oil-water separation equipment. It specifically includes a cavity; a partition is provided in the cavity, and the cavity is divided into a water collection chamber and an oily water purification chamber; an opening is provided above the partition to communicate with the upper part of the water collection chamber and the oily water purification chamber; One side of the oil-containing water purification chamber is provided with an oil outlet pipeline; one side of the oil outlet pipeline is provided with an oil outlet different diameter pipe, and a circulation pipeline is provided under the oil outlet pipeline; the circulation pipeline is connected with the collected water The lower part of the chamber is connected; the oil outlet reducing pipe is connected with an oil outlet pipe; the upper part of the oil-containing water purification chamber is provided with an inlet. Compared with the prior art, the invention has the advantages of simple structure and convenient control, and the oil slick on the upper layer can be collected and processed by itself through the fluctuation of the liquid level generated by the falling of the oil and gas liquid, so as to improve the oil slick collection effect.

Owner:SENUO TECH CO LTD +1

Treatment unit for separation of polyurethane waste

InactiveCN104338373BEasy to operateImprove separation capacityFiltration circuitsWaste collectionTherapeutic effect

The invention provides a treatment device for separating a polyurethane waste material. The device comprises a support frame, as well as a waste collection device and at least one heating and separation device which are fixed on the support frame. A filtering device is arranged in the waste collection device. The waste collection device is communicated with the heating and separation device by at least one first pipeline. The treatment device for separating the polyurethane waste material is convenient to operate, good in separation treatment effect and environmental-friendly.

Owner:SHANGHAI YONGHONG AUTO PARTS

Vertical continuous aluminum-plastic composite packaging material separating system capable of recovering separating agent

ActiveCN102764753BReduce consumptionEasy to handleSievingSolid waste disposalChemical separationProcess engineering

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Shaftless spiral horizontal-type continuous separation treatment system of aluminum-plastic compound package material

ActiveCN102744239BImprove separation capacityAvoid cloggingSolid waste disposalPlastic recyclingPhysical chemistryChemical separation

The invention provides a shaftless spiral horizontal-type continuous separation treatment system of an aluminum-plastic compound package material. The shaftless spiral horizontal-type continuous separation treatment system of the aluminum-plastic compound package material comprises a separation reaction device and a horizontal-type separation spin-drying device, wherein the separation reaction device carries out chemical separation treatment on the aluminum-plastic compound package material; the horizontal-type separation spin-drying device carries out physical separation treatment on the chemically separated aluminum-plastic compound package material; a reaction spiral and a discharge spiral arranged in the separation reaction device are both in shaftless spiral structures; an inner cylinder body of the horizontal-type separation spin-drying device is internally provided with a rotating shaft, and the rotating shaft is provided with a plurality of sickle-shaped blades at intervals. The shaftless spiral horizontal-type continuous separation treatment system of the aluminum-plastic compound package material can effectively realize the continuous separation treatment of the aluminum-plastic compound package material and is higher in aluminum-plastic separation treatment capability.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Separating and cleaning system for oil mist purifier

PendingCN114011577AImprove separation capacityQuick responseElectrode constructionsElectrodes cleaningEnvironmental engineeringCleansing Agents

The invention belongs to the field of oil mist purification, and relates to a separating and cleaning system for an oil mist purifier. The separating and cleaning system comprises a shell, and is characterized in that a left side cavity is formed in the shell, a fixing rod is fixedly arranged in the left side cavity, a circular groove is formed in the left side of the shell, an electric box is arranged at the lower left part of the shell, an air inlet and outlet valve is arranged on the upper side wall of the shell, a cleaning agent box is arranged on the upper left portion of the shell, a U-shaped pipe is arranged on the left side of the shell, and the U-shaped pipe is connected with the cleaning agent box. When oil mist in air generated in the industry is treated, the oil mist is sucked and discharged by moving the oil mist to enable the air pressure in the cavity to change, oil and water are separated in an electrode deposition mode, and when more oil stains are deposited, cleaning liquid is sprayed at regular time to clean the oil stains on an oil side electrode, and finally the oil stains are discharged.

Owner:喻梅

Aluminum-plastic composite packing material separation processing system adopting horizontal type continuous separation drying

ActiveCN102744245BImprove separation capacityLow costSievingScreeningChemical physicsChemical separation

The invention provides an aluminum-plastic composite packing material separation processing system adopting horizontal type continuous separation drying. The system comprises a separation reaction device for performing chemical separation process on an aluminum-plastic composite packing material, and a horizontal type separation drying device for performing physical separation process on the aluminum-plastic composite packing material subjected to the chemical separation process, wherein an internal cylinder of the horizontal type separation drying device is internally provided with a rotating shaft which is equipped with a plurality of sickle-shaped blades spaced to each other. The aluminum-plastic composite packing material separation processing system is used for realizing the continuous separation processes for the aluminum-plastic composite packing material effectively and has high aluminum-plastic separation process ability.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com