Medical waste liquid removing and separating device

A medical waste and liquid separation technology, which is applied in the field of medical waste liquid removal and separation devices, can solve the problems of epidemic epidemics, environmental pollution, and troublesome treatment of medical solid-liquid mixed waste, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

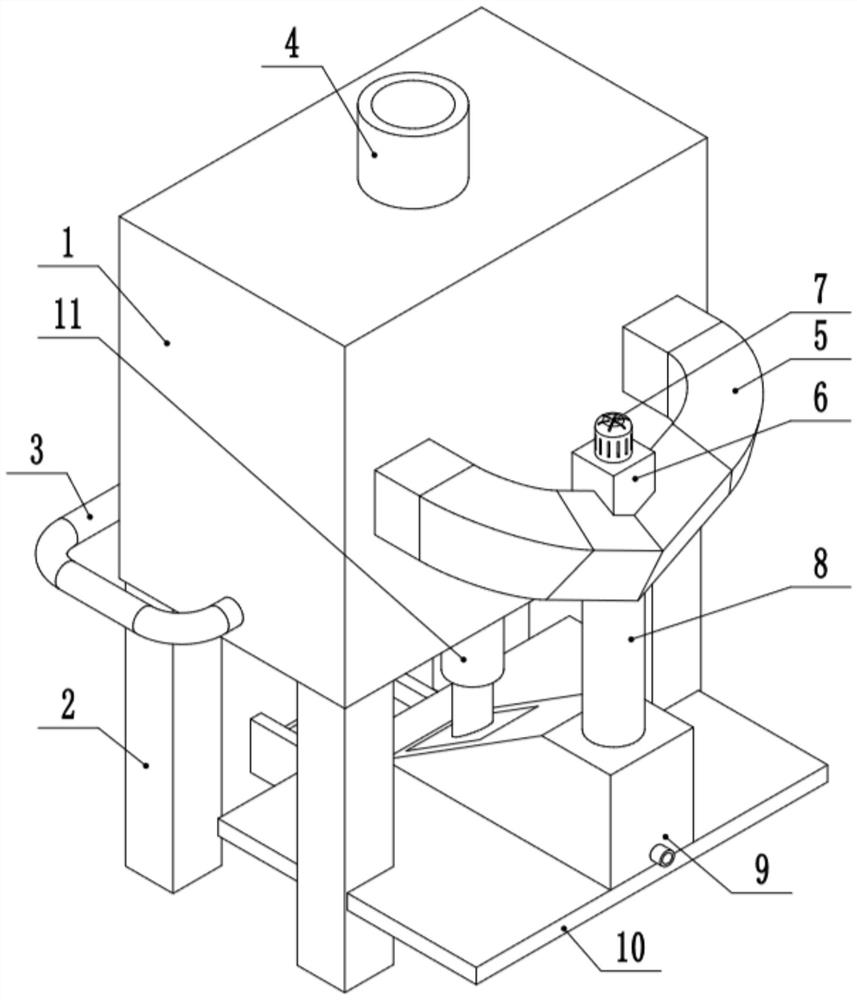

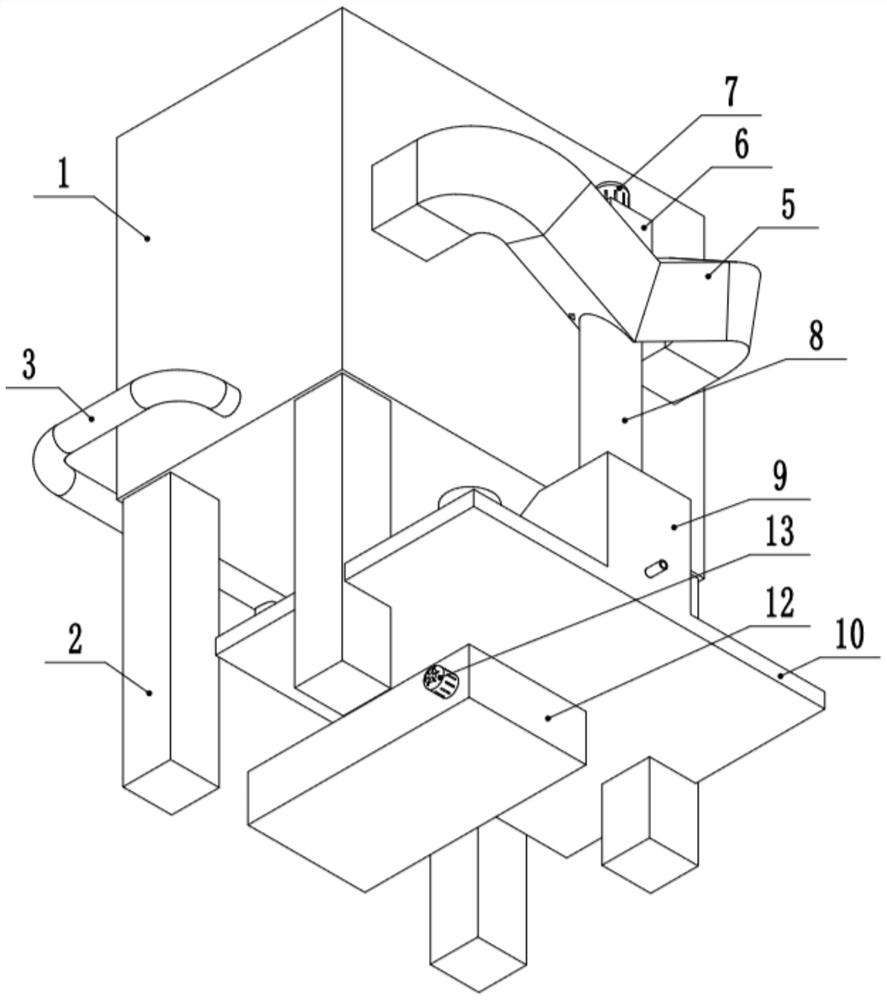

[0026] see Figure 1-6 , a device for liquid removal and separation of medical waste, comprising a treatment box 1, the four corners of the bottom of the treatment box 1 are fixedly connected to the support legs 2, the top of the treatment box 1 is fixedly connected to the feed port 4, and the treatment box 1 is provided with a crushing mechanism , an extrusion mechanism and a water filter mechanism, one side of the treatment box 1 is fixedly connected to the slag discharge pipe 5, the top of the slag discharge pipe 5 is fixedly connected to the motor seat 6, the top of the motor seat 6 is fixedly connected to the first drive motor 7, and the slag discharge pipe The bottom end of 5 is fixedly connected to the extruded delivery pipe 8, the support leg 2 is fixedly connected to the base plate 10, and the top of the base plate 10 is fixedly connected to the bottom cover 9, and the bottom cover 9 is provided with an extrusion dewatering mechanism, and the bottom end of the extruded...

Embodiment 2

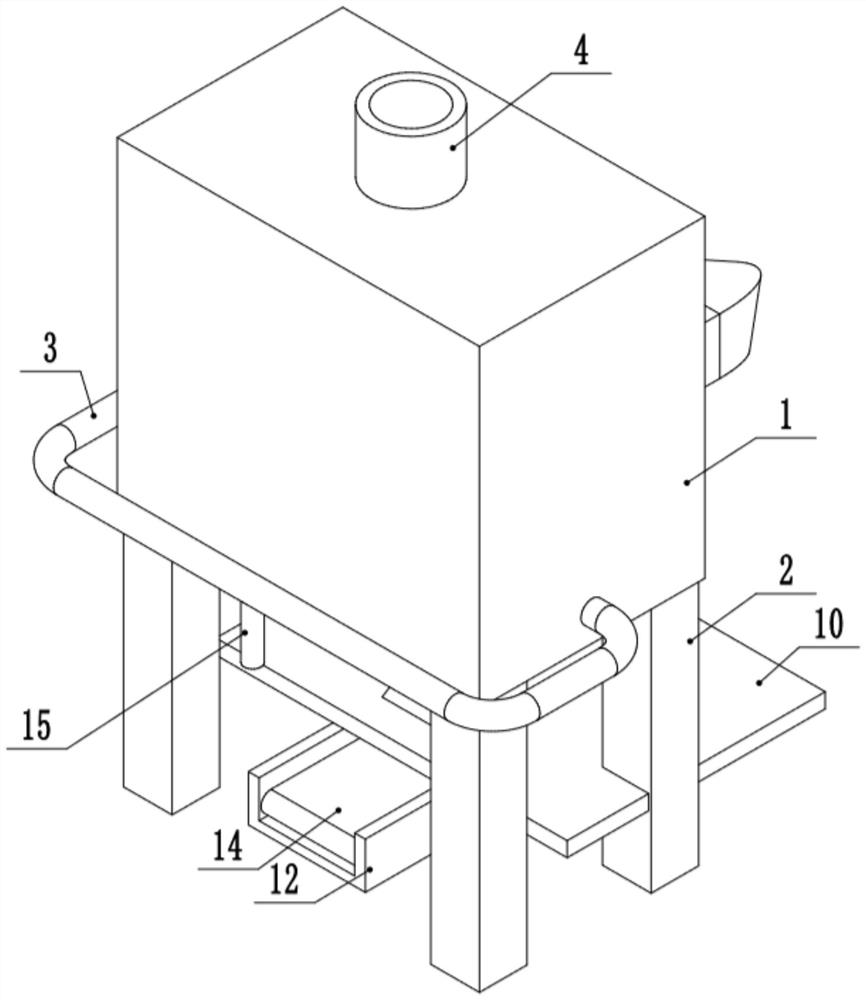

[0034] see Figure 1-6 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the extrusion dewatering mechanism includes a temporary storage cavity 17 located in the bottom cover 9, and a drain is provided on the bottom cover 9 at one end of the temporary storage cavity 17. The second filter screen 19 is fixedly connected to the drain port, the outside of the bottom cover 9 is fixedly connected to the third drain pipe 20 at the drain port, the bottom end of the treatment box 1 is fixedly connected to the hydraulic cylinder 11, and the telescopic end of the hydraulic cylinder 11 The blocking block 16 is fixedly connected, the blocking block 16 runs through the top of the bottom cover 9 , and the bottom cover 9 below the blocking block 16 is provided with a corresponding discharge port 18 . The conveying mechanism includes an output bottom cover 12 fixedly connected to the bottom of the bottom plate 10 , a conveyor belt 14 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com