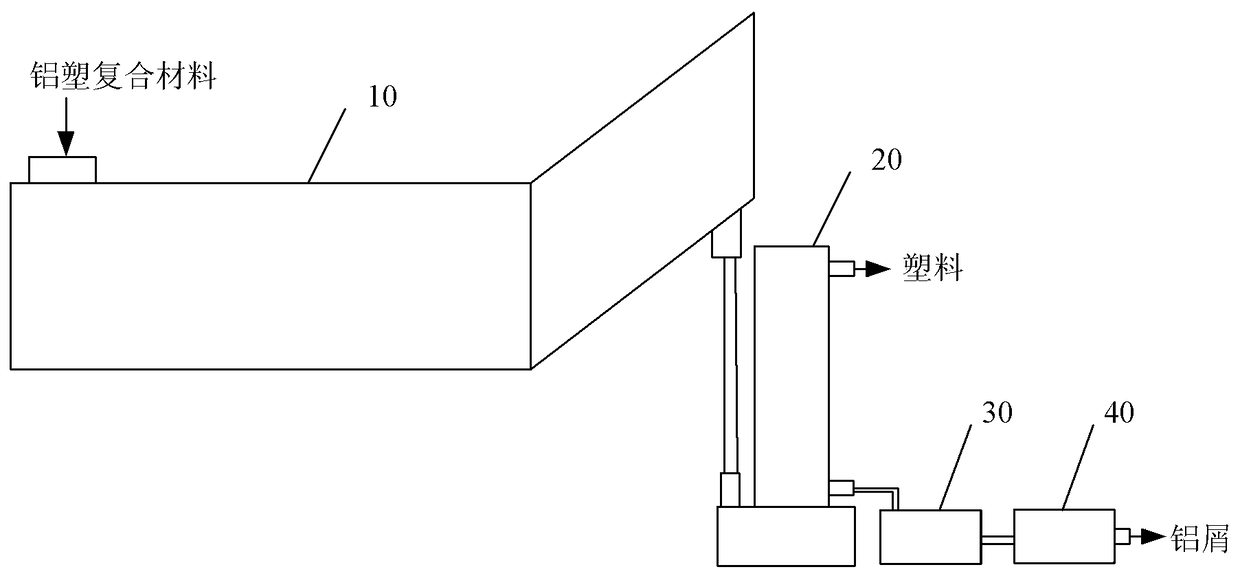

Standing continuous separation spin-drying treatment system for aluminum plastic composite material

A composite material and treatment system technology, which is applied in the field of standing continuous isolation drying treatment system, can solve the problems of high waste water treatment cost, poor treatment capacity, and easy clogging of materials, so as to save costs, reduce production volume, and avoid material clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

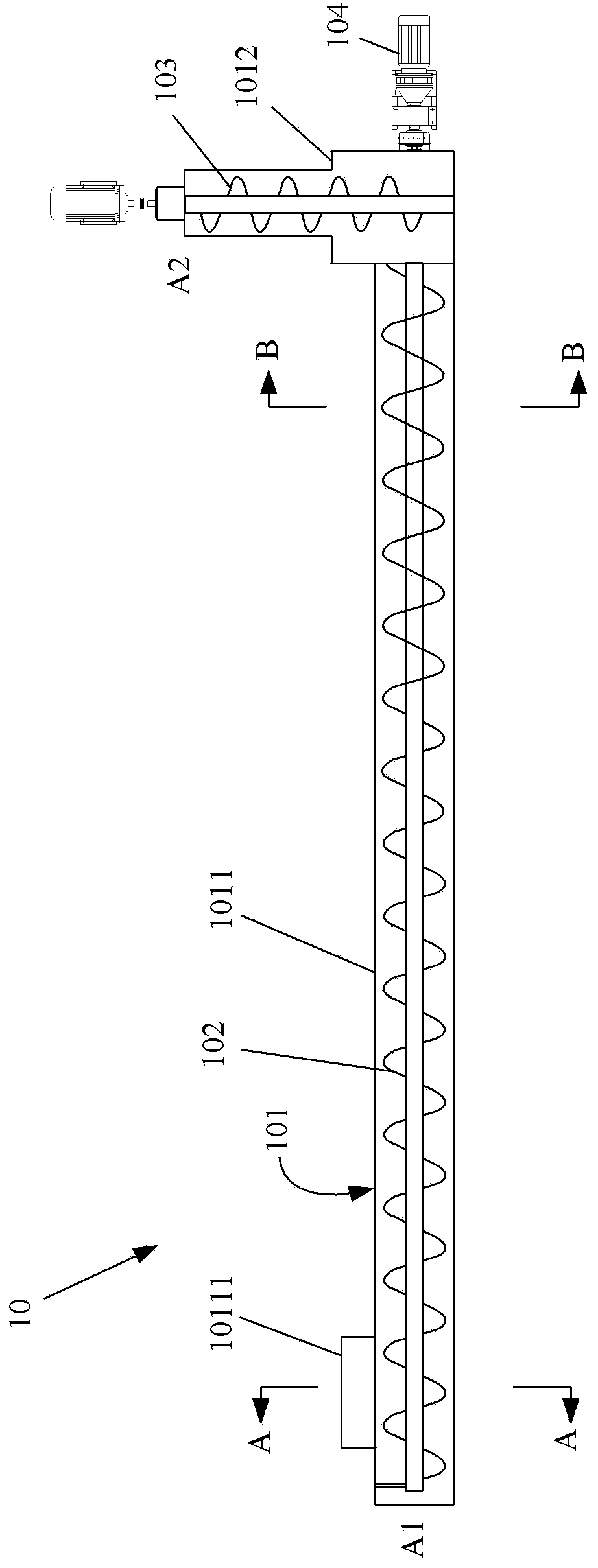

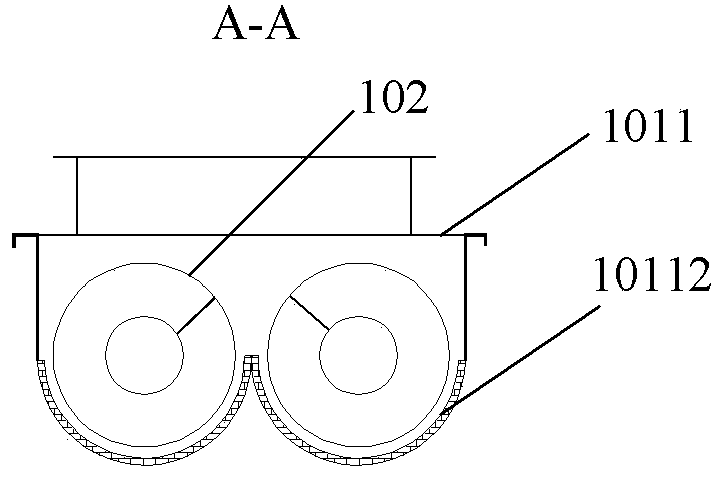

[0024] In view of the problems existing in the physical separation treatment in the separation system of the prior art, the present invention provides a standing continuous isolation and drying treatment system using aluminum-plastic composite materials, which can simultaneously treat the aluminum-plastic composite packaging materials after chemical separation The standing separation and drying device for drying and separation can effectively reduce the number of equipment used in the separation system, and only one device is needed to realize the physical separation of materials, which can effectively reduce the cost of the separation system; the separation system provided by the invention The treatment system can continuously process aluminum-plastic composite packaging materials, which can meet industrial applications. At the same time, it can reduce the loss of separating agent and aluminum chips, reduce the amount of waste water, and improve the separation and treatment cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com