Separation device for food aluminum plastic bagged material

A separation device, aluminum-plastic technology, used in plastic recycling, solid waste removal, recycling technology, etc., can solve the problems of material blockage, production cycle, poor material separation and treatment efficiency, etc. ability, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

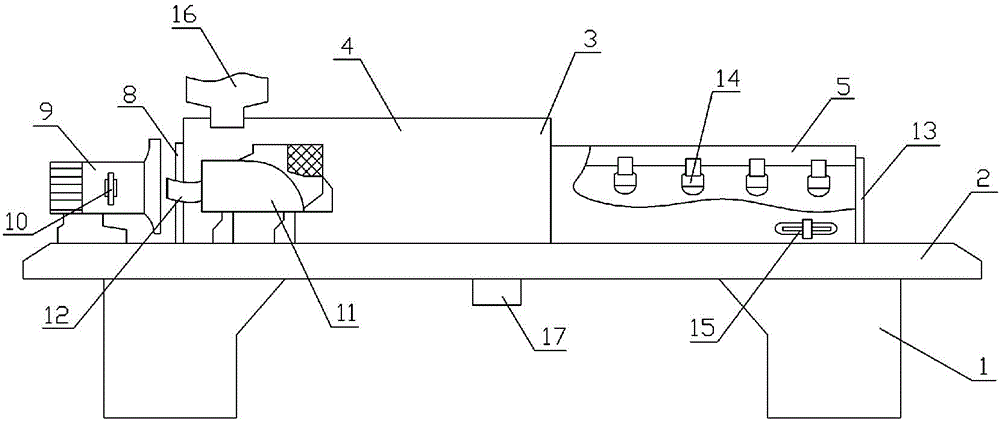

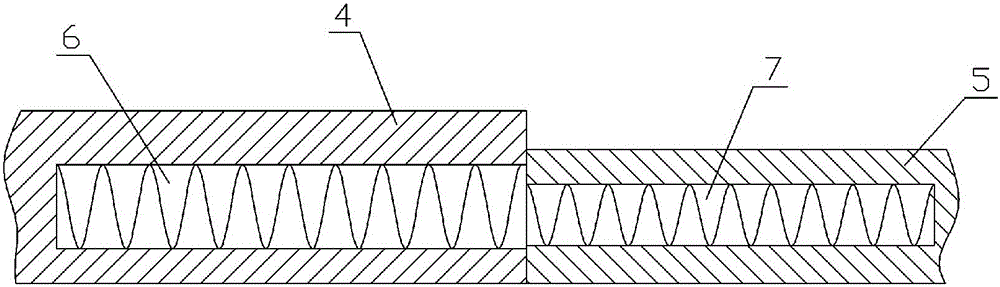

[0016] The reference signs in the drawings of the description include: frame 1, workbench 2, separation pipe 3, first pipe section 4, second pipe section 5, first cavity 6, second cavity 7, feed port 8, blower 9. Screw switch 10, gasifier 11, gas pipeline 12, discharge port 13, drying lamp 14, control switch 15, water inlet pipe 16, drain pipe 17.

[0017] The embodiment is basically as attached figure 1 , figure 2 Shown: The separation device for food aluminum-plastic bagged materials includes a frame 1 and a workbench 2 arranged on the frame 1. The workbench 2 is provided with a separation pipe 3, and the separation pipe 3 includes a first pipe section 4 and a second pipe section 4. The pipe section 5, the first pipe section 4 and the second pipe section 5 form a stepped separated pipe body, and the diameter of the first pipe section 4 is larger than the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com