Separating system and method for aluminum-plastic prebagged materials

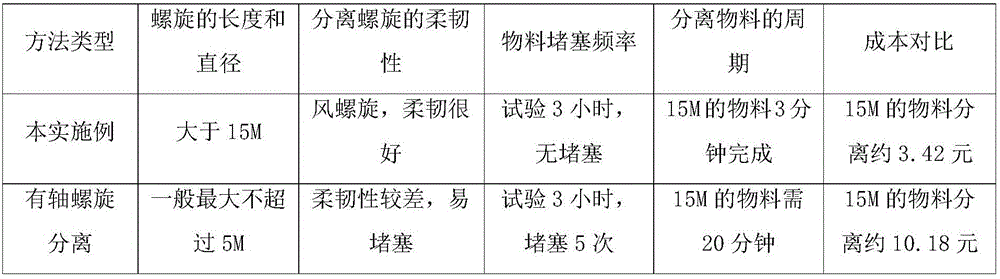

A separation system and aluminum-plastic technology, applied in the field of separation system of aluminum-plastic bagged materials, can solve the problems of poor material separation processing efficiency, material blockage failure production cycle, etc., to improve processing capacity, improve separation processing capacity, and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

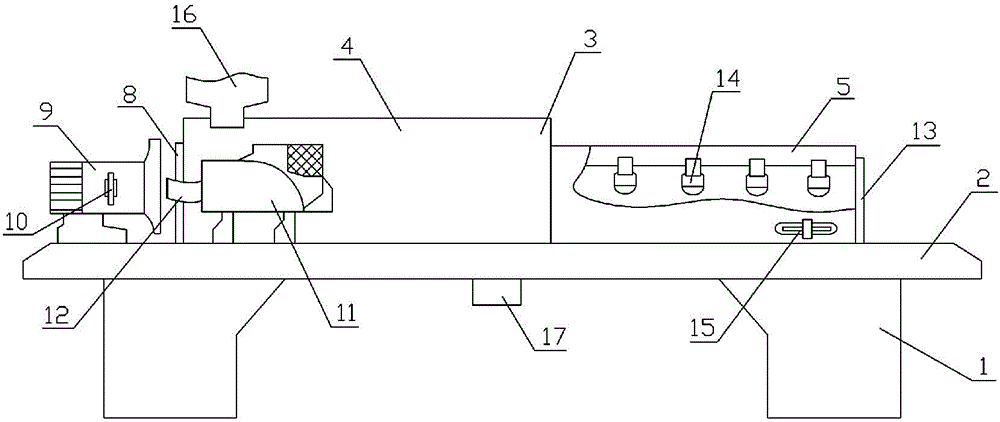

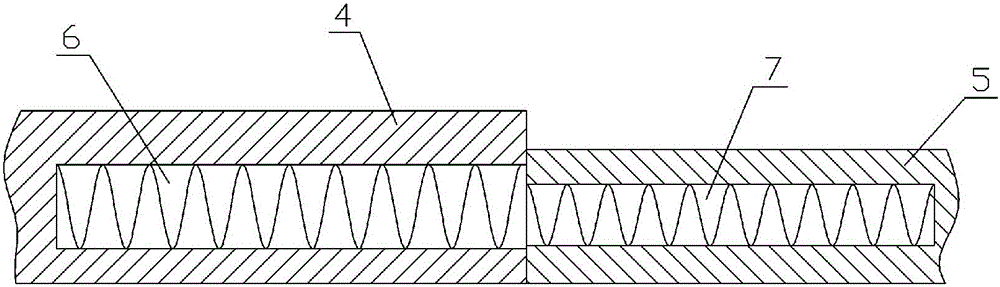

[0022] The reference signs in the drawings of the description include: frame 1, workbench 2, separation pipe 3, first pipe section 4, second pipe section 5, first cavity 6, second cavity 7, feed port 8, blower 9. Screw switch 10, gasifier 11, gas pipeline 12, discharge port 13, drying lamp 14, control switch 15, water inlet pipe 16, drain pipe 17.

[0023] The embodiment is basically as attached figure 1 , figure 2 Shown: the separation system of aluminum-plastic bagged materials, including a frame 1 and a workbench 2 arranged on the frame 1, a separation pipe 3 is arranged on the workbench 2, and the separation pipe 3 includes a first pipe section 4 and a second pipe section 5. The first pipe section 4 and the second pipe section 5 form a stepped separated pipe body, and the diameter of the first pipe section 4 is larger than the diameter of the second pipe section 5, and the first pipe section 4 is provided with a spiral first cavity 6 , the second pipe section 5 is provi...

Embodiment 2

[0027] This embodiment provides a method for separating aluminum-plastic bagged materials, comprising the following steps:

[0028] Step 1: Place the food aluminum-plastic bag material to be separated on the workbench on the frame, and put the material into the first pipe section through the feed port on the first pipe section;

[0029] Step 2: Turn on the blower at the feed inlet, the power of the blower is 0.65-0.75HP, the voltage and current is 220V / 5A, and at the same time, start the gasifier with disinfectant, and the flow rate of the gasifier is 2.3-3.0Nm 3 / min, pressure ≥ 15kPa, the output end of the gasifier is located on one side of the blower, so that the gasification gas can mix with the airflow generated by the blower and enter the first spiral cavity in the first pipe section;

[0030] Step 3: Continuously add the separating agent in the water inlet pipe near the feed inlet, the flow rate of the separating agent is controlled at 1.5-3.0m / s, the separating agent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com