Separation device of aluminum plastic composite packing materials

A packaging material and separation device technology, which is applied in the field of shaftless double-spiral aluminum-plastic composite packaging material separation device, can solve the problems of easy blockage of materials and poor separation processing capacity, and achieves avoiding blockage, improving processing capacity, and improving separation processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

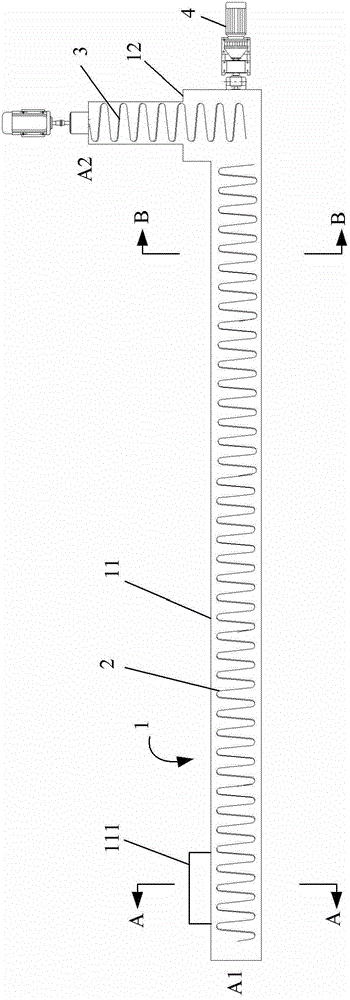

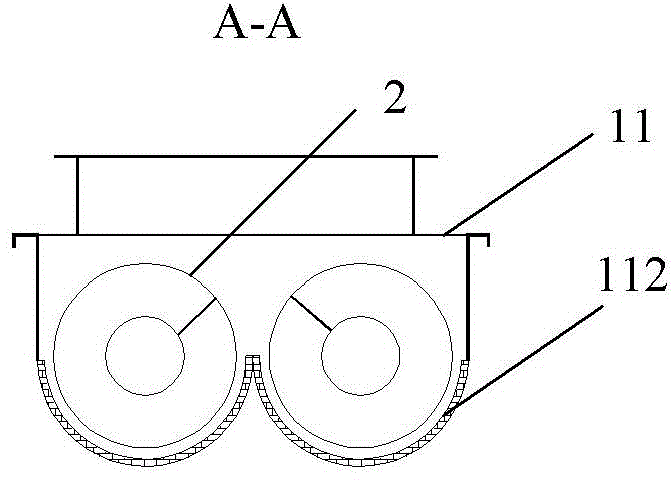

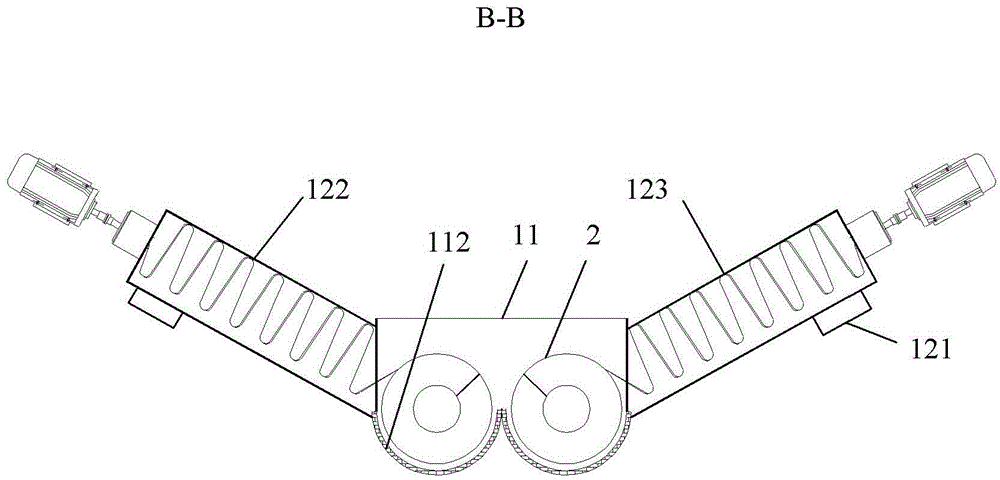

[0026] figure 1 Schematic diagram of the structure of the separation device for aluminum-plastic composite packaging materials provided by the embodiment of the present invention; figure 2 for figure 1 The sectional view of A-A in the center; image 3 for figure 1 The cross-sectional view of B-B in the middle. Such as Figure 1-Figure 3 As shown, the device of this embodiment includes a separator 1, a reaction screw 2 and a discharge screw 3, wherein the separator 1 has a hollow cavity, and the separator 1 includes a reaction section 11 and a discharge section 12, and the reaction section A feed port 111 is provided on the feed end A1 away from the discharge section 12 on the feed section 11, and a discharge port 121 is provided on the feed end A2 of the discharge section 12 away from the reaction section 11. The height of the discharge end A2 is high At the height of the feed end A1; the reaction screw 2 is arranged in the cavity of the reaction section 11, the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com