Treatment method and equipment for oilfield produced water

A technology of treatment equipment and treatment methods, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution, high labor intensity, poor safety, etc. Reduce the impact on the environment, the equipment occupies a small area, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

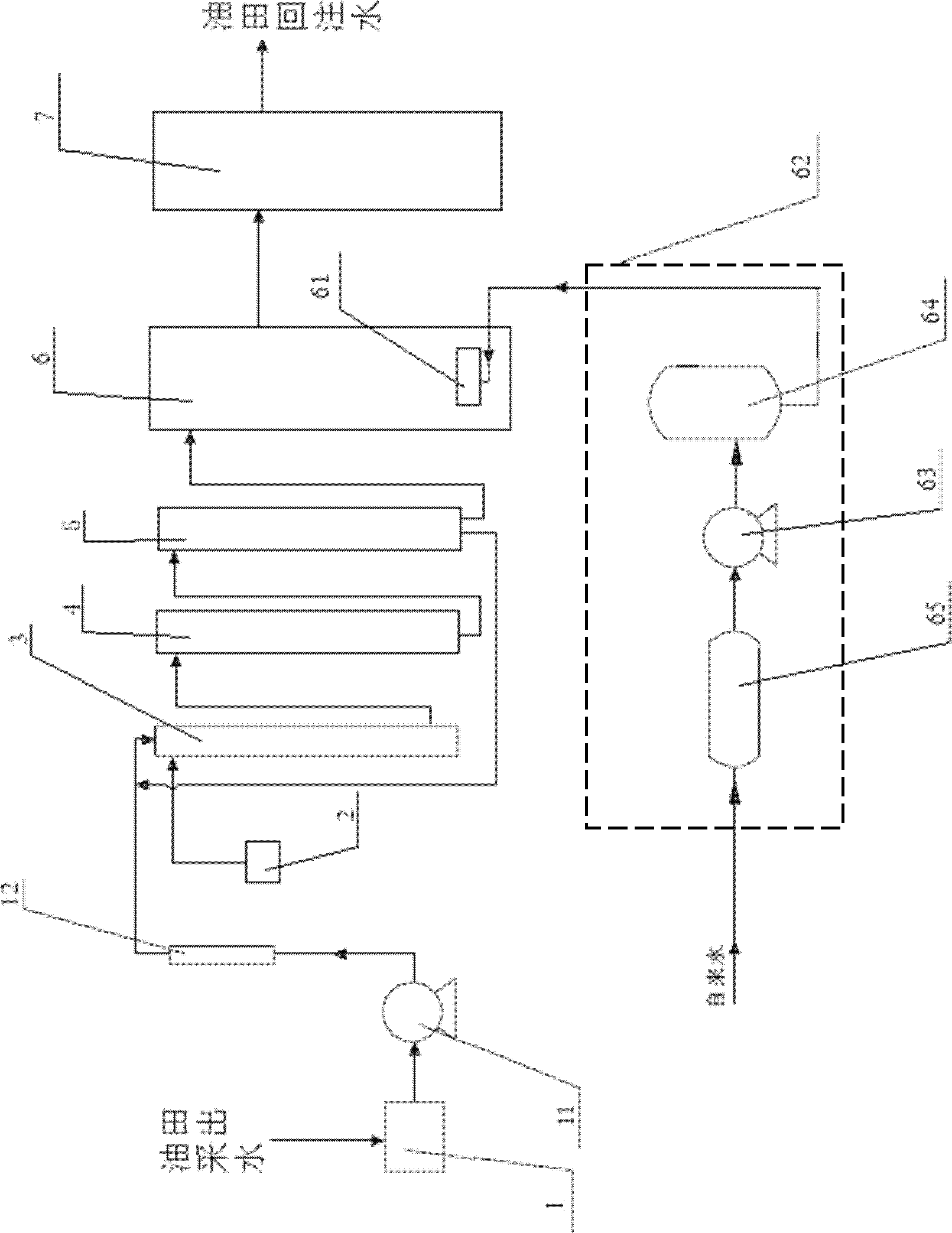

[0111] as per figure 1 The process shown is for the treatment of the produced water in the oil field. The oil content of the oilfield produced water is 2300mg / L.

[0112] 1) Demulsification treatment

[0113] The produced water from the oil field is input into the raw sewage regulating tank 1, and the produced water is left standing in the regulating tank 1 to initially remove the sediment and part of the oil slick in the sewage, and then the effluent from the regulating tank is input into the demulsification reaction tank 3 through the flow meter 12;

[0114] The demulsifier polyaluminum chloride flows out from the demulsifier tank 2, and is sent into the demulsification reaction tank 3 through the flow meter 12, and is mixed with the produced water of the oil field to perform demulsification reaction, and the emulsified oil in the sewage is demulsified to make the demulsification in the produced water The oil phase and the water phase are separated from each other to obtai...

Embodiment 2

[0128] During the demulsification process, the demulsification agent polyaluminum chloride was used in an amount of 50 mg / L oilfield produced water, and the demulsification reaction time was 30 minutes, and the rest was the same as that of Example 1.

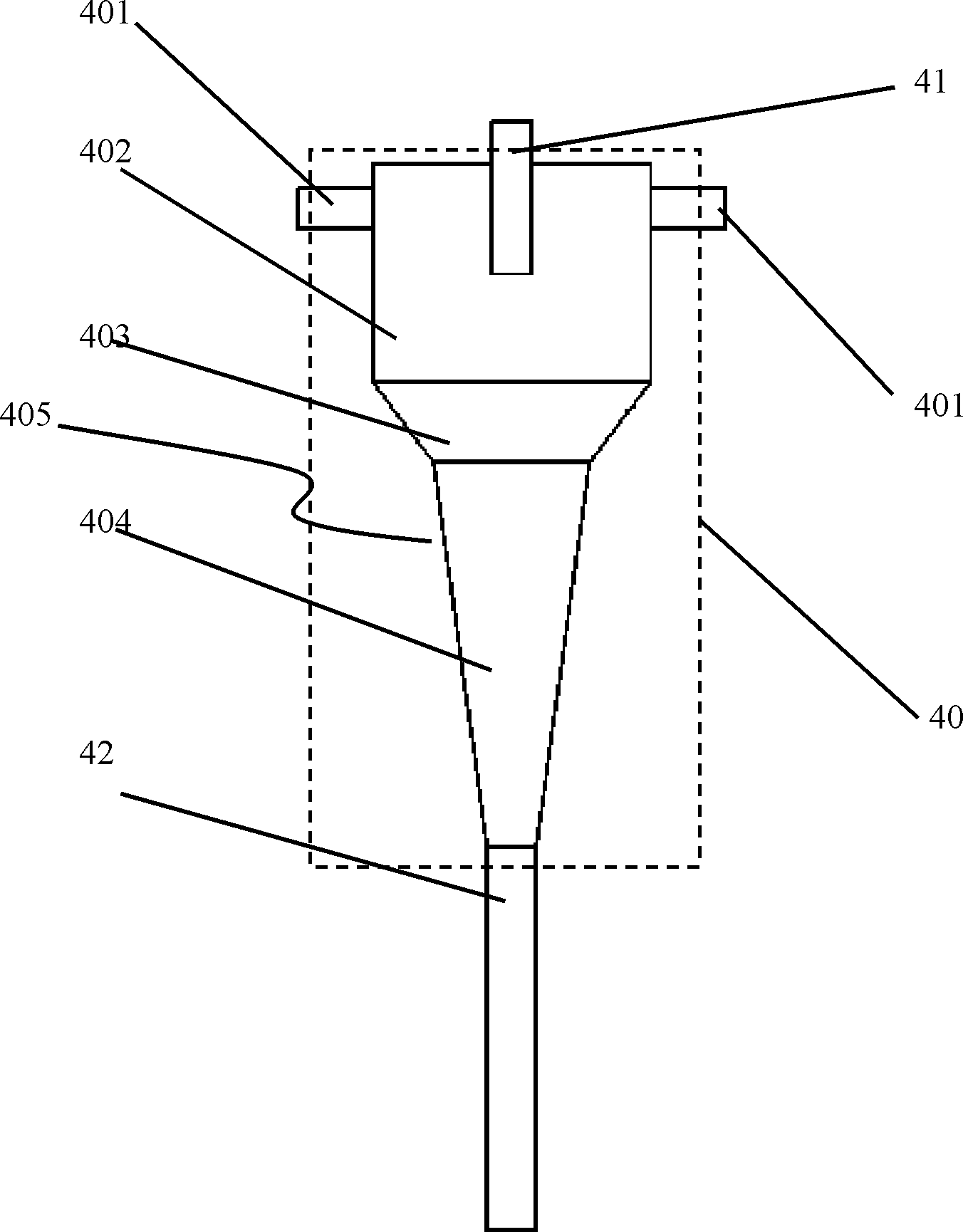

[0129] During the cyclone separation process, the first stage cyclone separator 4 ( Figure 4 shown) includes a water inlet pipe 401, a swirl pipe 40, an oil overflow pipe 41 and an underflow pipe 42, wherein the swirl pipe 40 is composed of a cylindrical pipe 402 and a conical pipe 405' that are sequentially connected from top to bottom and connected internally. . Wherein, the oil overflow pipe 41 is arranged in the cylindrical pipe 402, communicates with the cylindrical pipe 402 and extends to its top along the height direction; the water inlet pipe 401 is provided on the side wall of the cylindrical pipe 402; The bottom of 405 is connected, and the water flow after cyclone separation is exported.

[0130] The oil overflow p...

Embodiment 3

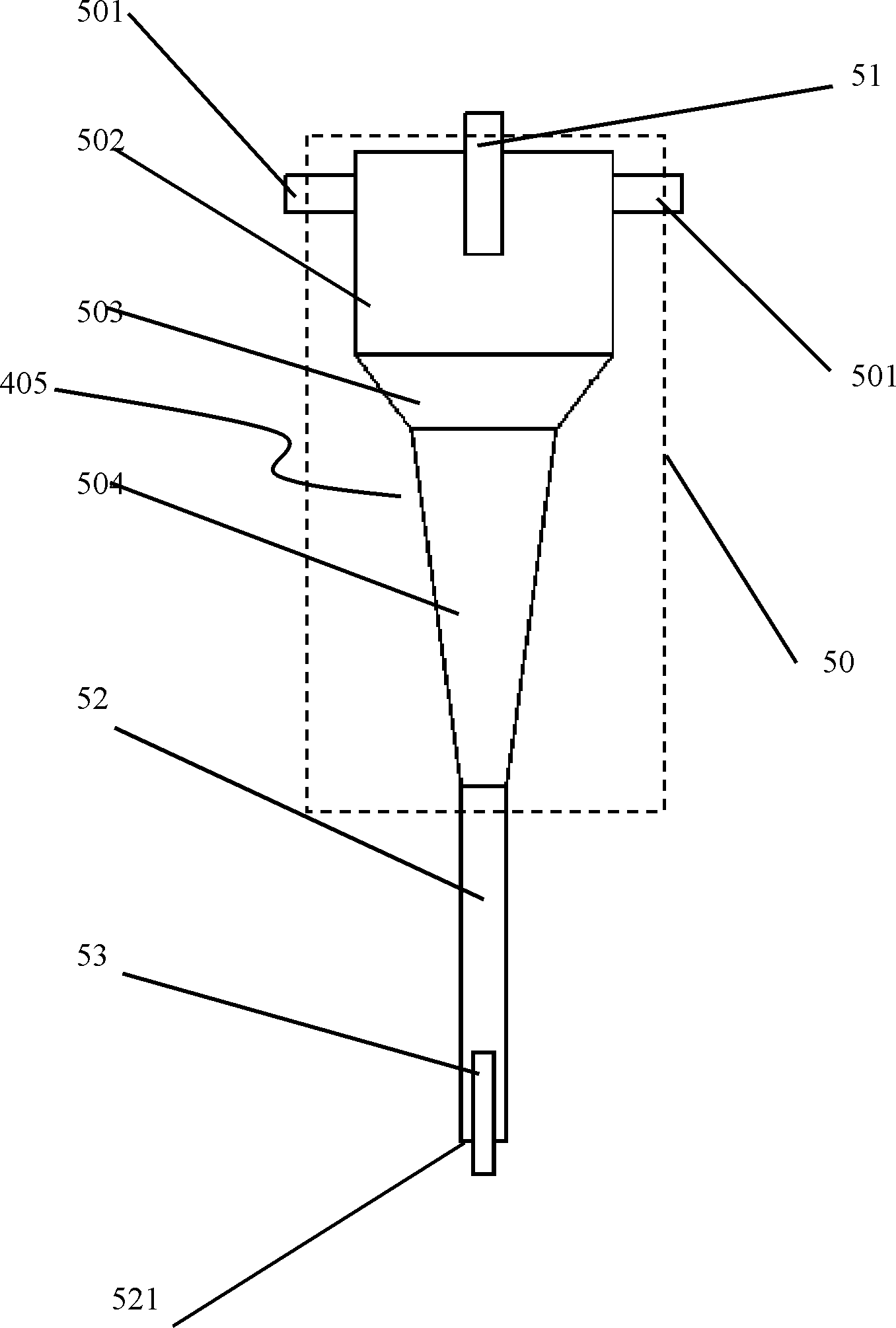

[0138] Except that the inlet pressure of the first-stage cyclone separator 4 is 150kPa, the oily sewage with higher density flowing out from the bottom flow pipe 42 of the first-stage cyclone separator 4 enters the second-stage cyclone after being treated by a booster pump. Separator 5, except that the control inlet pressure is 150kPa, all the other are identical with embodiment 1, adopt infrared spectrophotometry method to detect its oil content through the water after filtering, and oil content in water is 4.9mg / L, and oil removal rate is 99.8 %.

[0139] The oil content in the water filtered by fiber balls is less than 5mg / L, which meets the "Recommended Water Quality Standards for Injection of Clastic Reservoirs" (SY / T5329-1994), and can be directly used for oilfield water injection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com