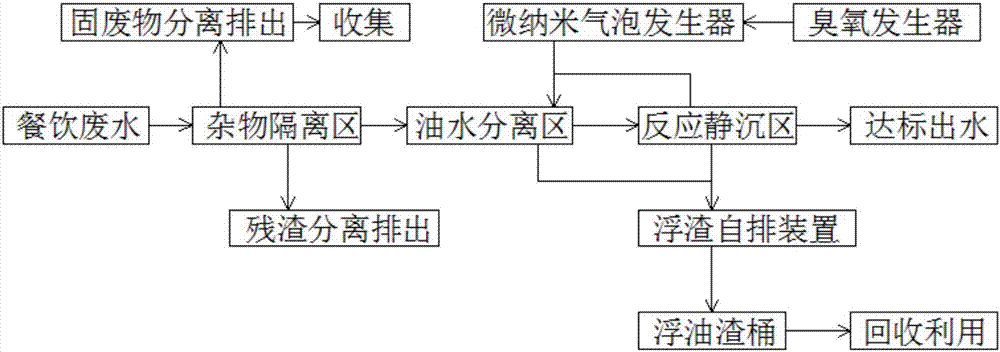

Micro-nano catering waste water pretreatment process

A catering wastewater and pretreatment technology, which is applied in the direction of water treatment parameter control, adsorption water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of short residence time, substandard water quality, high failure rate, etc., and achieve the goal of improving the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take the pretreatment of catering wastewater containing vegetable leaves, bones, vegetable roots, meat pieces, pork skin, rice grains, rice grains, broken bones, fish bones, and noodles as an example

[0023] Specific steps are as follows:

[0024] (1) After the kitchen and catering wastewater is collected, it will be discharged into the debris isolation area by gravity, and the large particles such as vegetable leaves, bones, vegetable roots, meat pieces, and meat skin in the wastewater will be separated and removed, and then the large particles will be sent to domestic waste. Collection point, centralized treatment at the transportation garbage station;

[0025] (2) Fine grains of rice, rice grains, broken bones, fish bones, and noodles in the waste water sink naturally along the 30°cone bucket, and are discharged to the residue storage tank with the help of vacuum suction, and the small particles in the residue storage tank are removed After crushing and drying, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com