Landscape lake water in-situ circulation treatment process

A recycling treatment and landscape technology, applied in water treatment parameter control, runoff/rainwater treatment, biological water/sewage treatment, etc. The effect of ecological restoration and saving maintenance and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

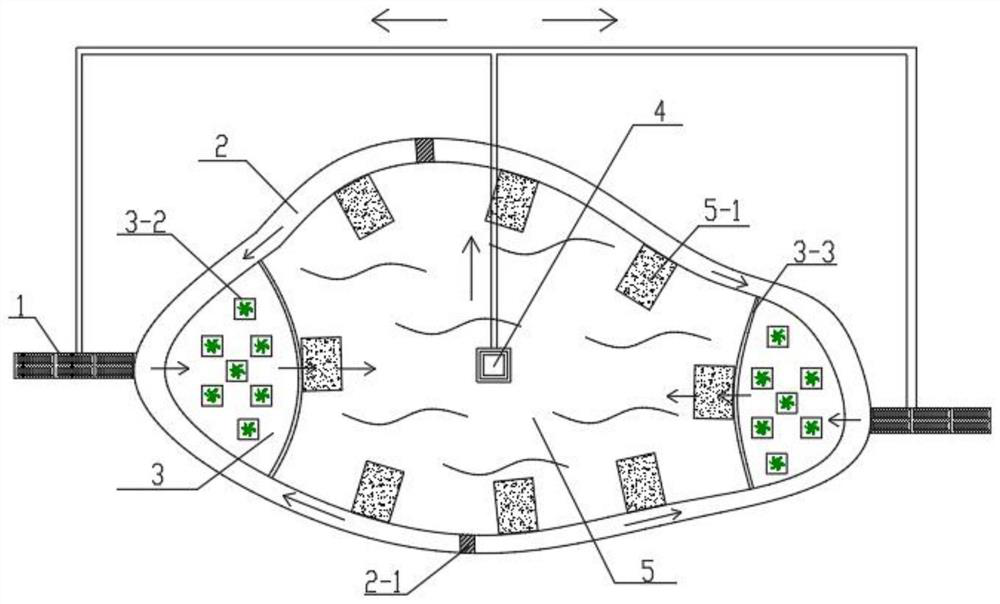

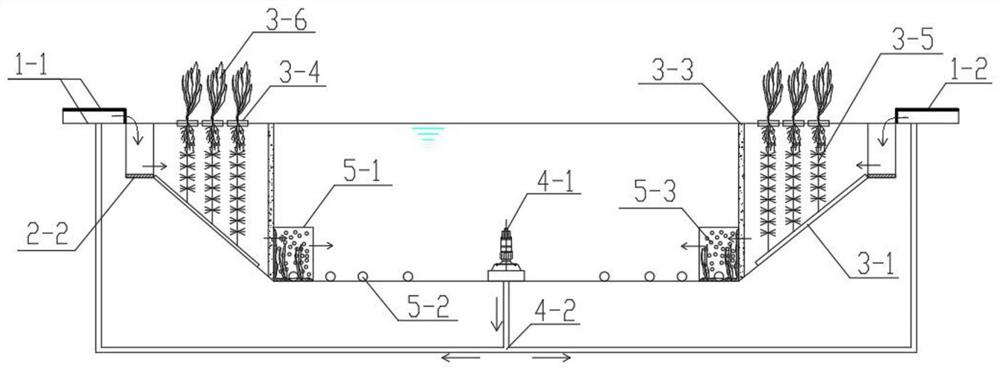

[0025] An in-situ circulation treatment process for landscape lake water is composed of a surface runoff collection tank (1), an ecological infiltration tank (2), an enhanced purification unit (3), a circulation power system (4) and a landscape lake main water area (5). The surface runoff collection tank (1) is located at the lowest point around the landscape lake, and is connected with the ecological infiltration tank (2). The ecological infiltration tank (2) is located in the outermost circle of the landscape lake, and an enhanced purification unit ( 3), the circulation power system (4) is located in the center of the main water area (5) of the landscape lake.

[0026] The surface runoff collection tank (1) is composed of a canal body (1-1) and a cover plate (1-2); the canal body (1-1) is made of sponge concrete, and the permeability coefficient is 1mm / s; Said cover plate (1-2) is made of stainless steel material, and specification size is 400mm * 500mm, and thickness is 20m...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is:

[0035] The ground runoff collection tank (1) is composed of a canal body (1-1), a cover plate (1-2) and a filter screen (1-3); the filter screen (1-3) is made of stainless steel, The size is 400mm×300mm, and the thickness is 10mm. The filter screen (1-3) is installed at the interface between the surface runoff collection tank (1) and the ecological infiltration tank (2), and its purpose is to intercept large-diameter stones or gravel impurities. Preliminary reduction of turbidity in surface runoff.

Embodiment 3

[0037] The difference between embodiment 3 and embodiment 1 is:

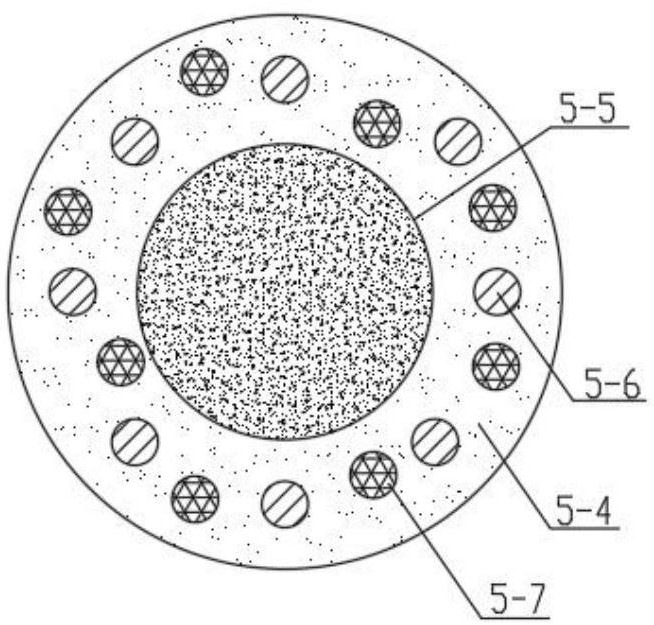

[0038] The raw materials for preparing the sponge concrete and their weight fractions include 120g parts by mass of aggregate, 15g parts by mass of cement, 5g parts by mass of binder, 0.5g parts by mass of foaming agent, 1g parts by mass of anti-cracking agent, Microbial agent is 1g mass part, water is 10g mass part; Described anti-cracking agent and microbial inoculum quality all increase to 1g from 0.5g; The increase of described anti-cracking agent quality can improve the intensity of sponge concrete, prolongs the strength of sponge concrete Service life; the increase in the quality of the microbial agent can speed up the water body treatment efficiency, effectively reduce the SS, ammonia nitrogen and other indicators in the water, and have more significant deodorizing and inhibiting algae breeding effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com