Marine oily water disk aggregation and separation device

A technology for gathering, separating, and oily sewage, applied in water treatment devices, ship parts, shipbuilding, etc., can solve problems such as emulsification, inability to realize oil droplet aggregation, separation, backflow of oily sewage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

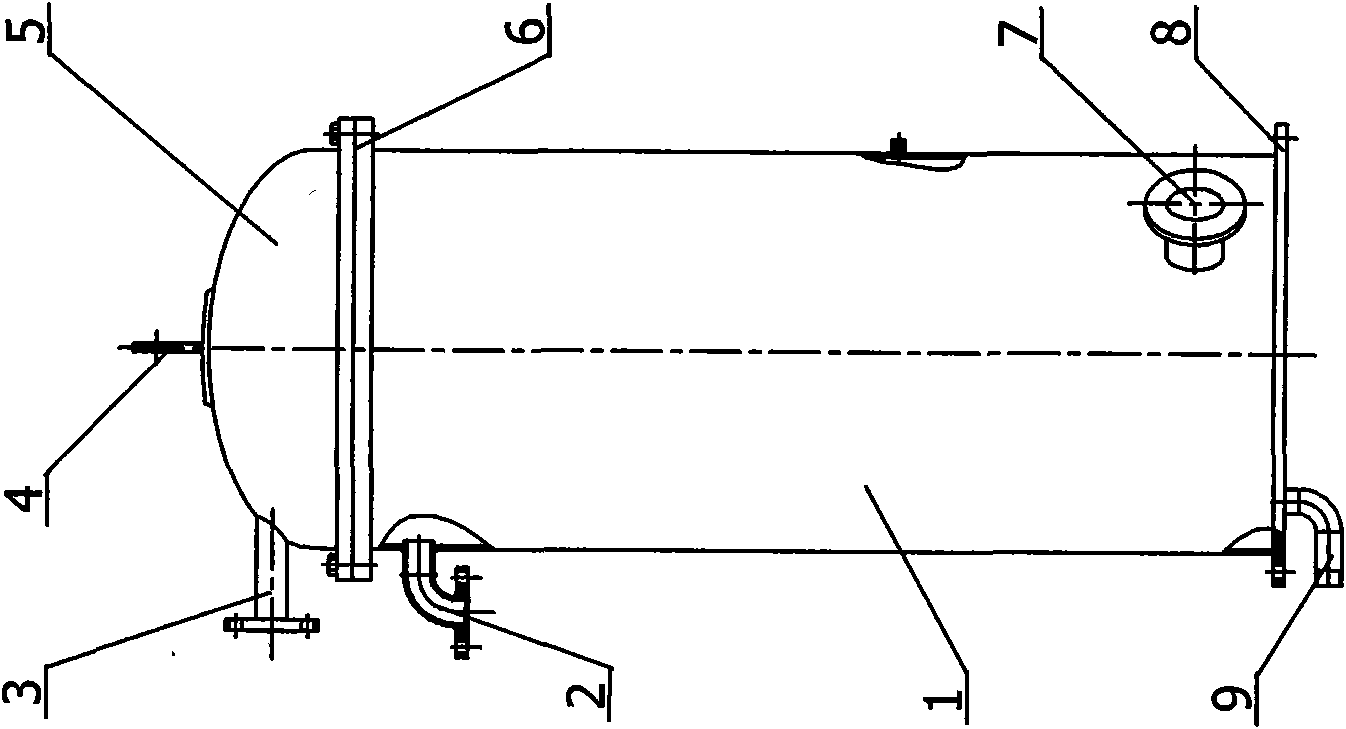

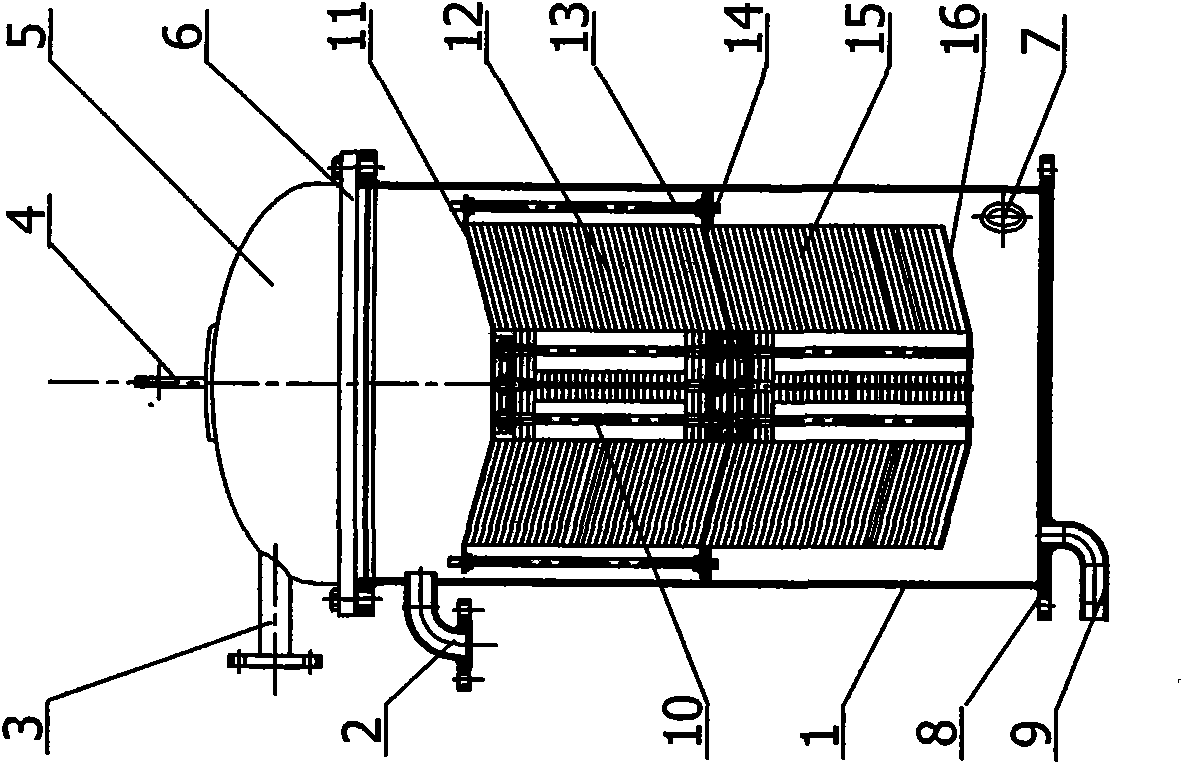

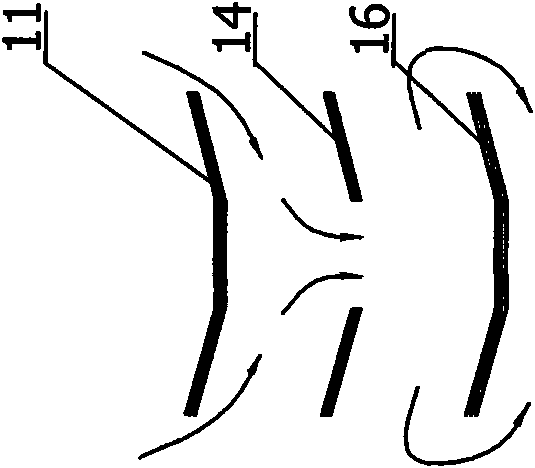

[0025] figure 1 In the marine oil-sewage stacked disc aggregation and separation device shown, the cylinder body 1 is cylindrical, and the material is made of high-quality carbon steel; the cylinder bottom plate 8 welded to the cylinder body 1 is a circular plate structure, and several mounting screw holes are provided on it. A sludge discharge port 9 is arranged on the bottom plate 8 of the cylinder, and the discharge port 9 is used to discharge sludge, particulate impurities, etc. deposited on the bottom of the cylinder to keep the cylinder relatively clean. The top of the cylinder body 1 is connected with a cylinder cover 5 through a connecting flange 6, and the cylinder cover 5 is in a spherical crown structure, and the waste oil discharge port 3 is arranged on the cylinder cover 5 in a spherical crown structure. Certainly cylinder body 1 can also adopt other shapes except adopting cylindrical cylindrical structure, and this cylinder cover 5 then should adopt other cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com