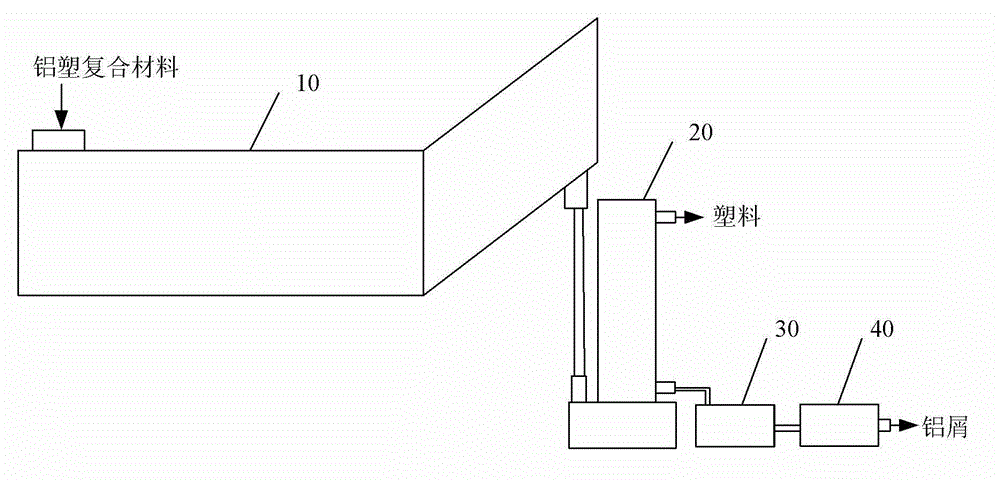

Shaftless spiral vertical-type continuous separation treatment system of aluminum-plastic compound package material

A technology of aluminum-plastic composite and packaging materials, applied in plastic recycling, recycling technology, solid waste removal, etc., can solve the problems of poor material processing capacity, material blockage, and high cost of waste water treatment, so as to reduce production and avoid blockage , Improve the effect of separation processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

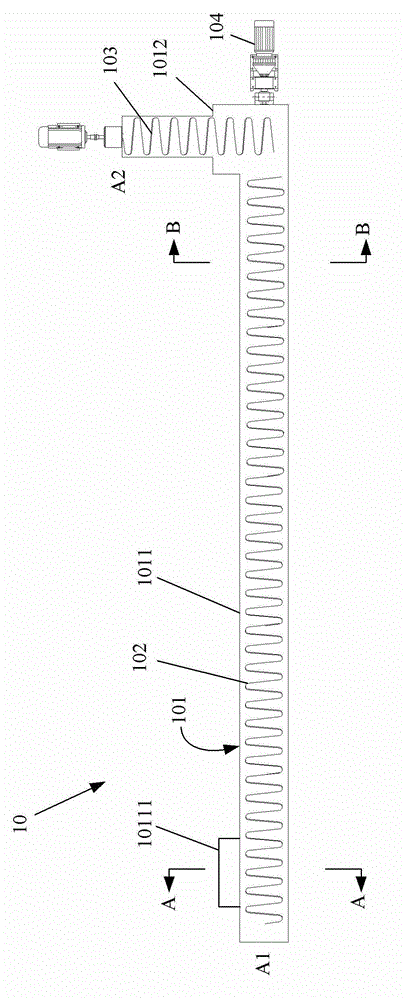

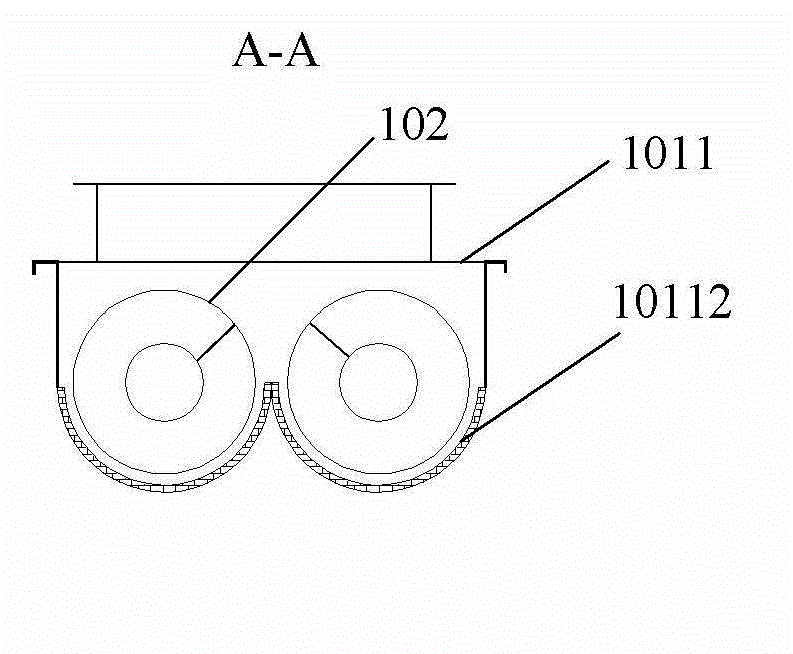

[0027] In view of the problems of poor material separation and treatment capacity, easy material clogging and large waste water generation in the existing separation system, the present invention provides a vertical continuous separation treatment system for aluminum-plastic composite packaging materials using a shaftless spiral type. By adopting a separation reaction device with a shaftless spiral structure and a vertical separation and drying device that can simultaneously dry and separate the chemically separated aluminum-plastic composite packaging materials, the processing efficiency of aluminum-plastic composite packaging materials can be effectively improved. Continuity, reduce the loss of separating agent and aluminum chips, reduce the amount of waste water, and improve the separation and treatment capacity of aluminum-plastic composite packaging materials. The technical solution of the present invention will be described in detail below with specific examples.

[0028...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com