A high-efficiency condenser and a washing machine with the condenser

A technology for condensers and washing machines, which is applied to washing machines with containers, household clothes dryers, household appliances, etc. It can solve the problems of increasing equipment complexity and the failure of the spray mechanism to operate normally, so as to avoid the decline of heat exchange efficiency and avoid Bacterial growth and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

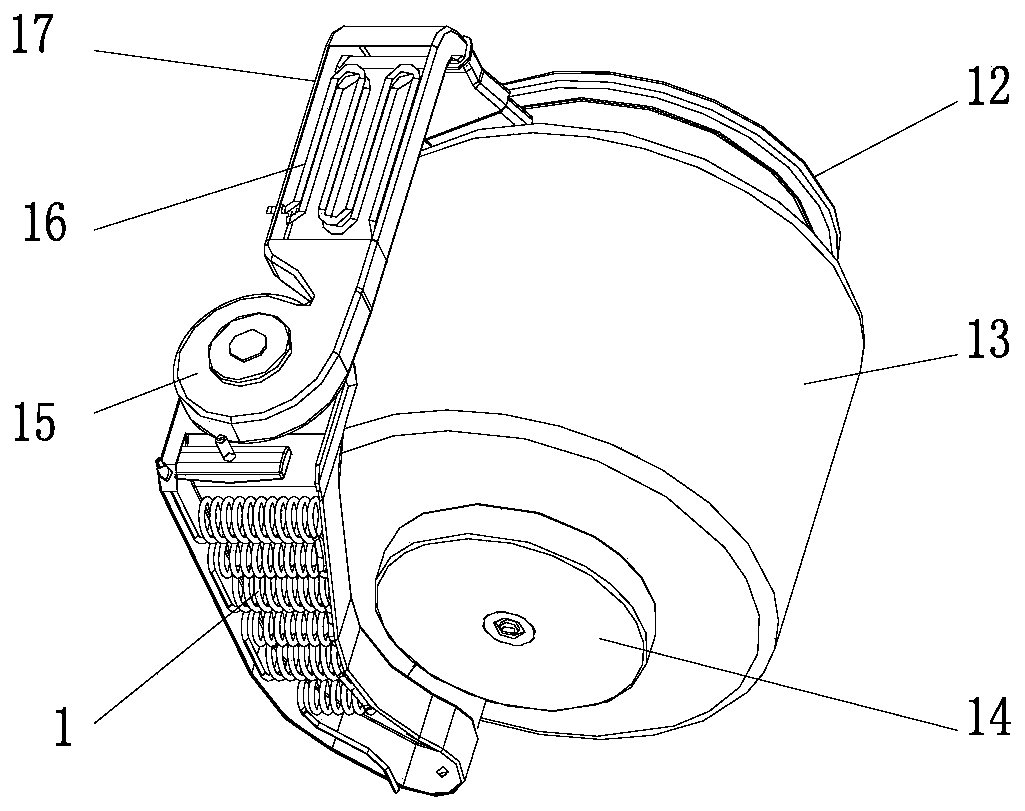

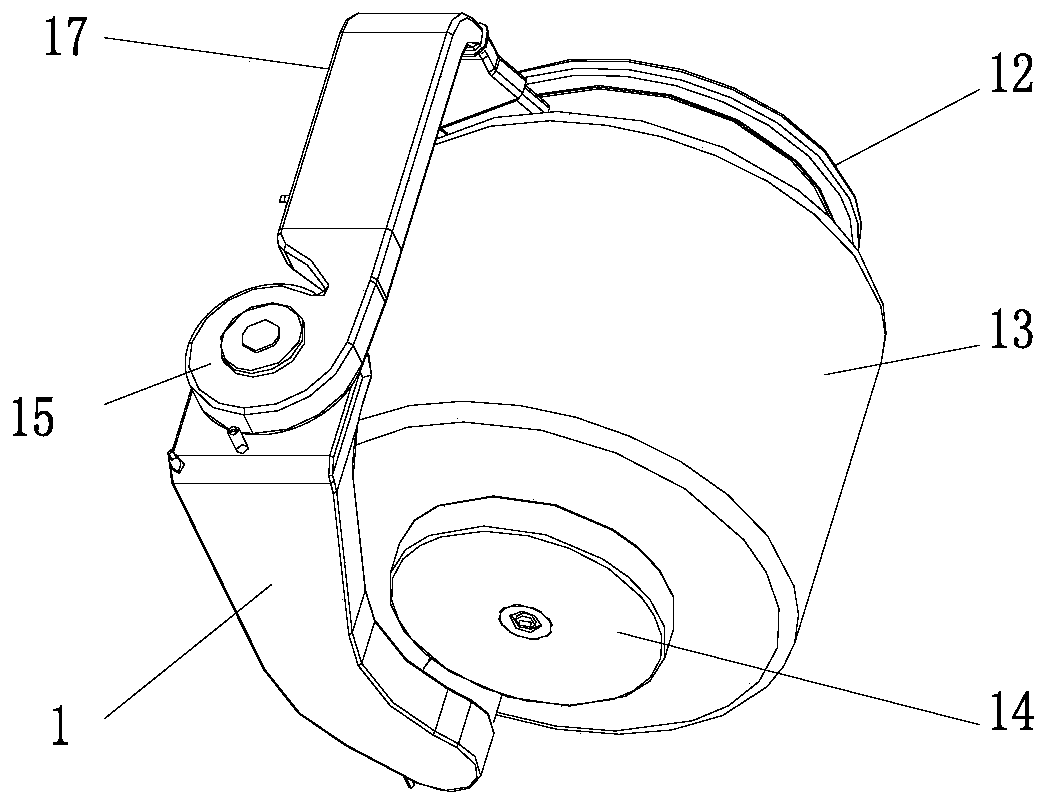

[0044] Such as Figure 1 to Figure 5 As shown, the high-efficiency condenser 1 in this embodiment is applied to a washing and drying machine. The condenser 1 is a cavity structure with a wide top and a narrow bottom, and the lower part is bent to one side, including:

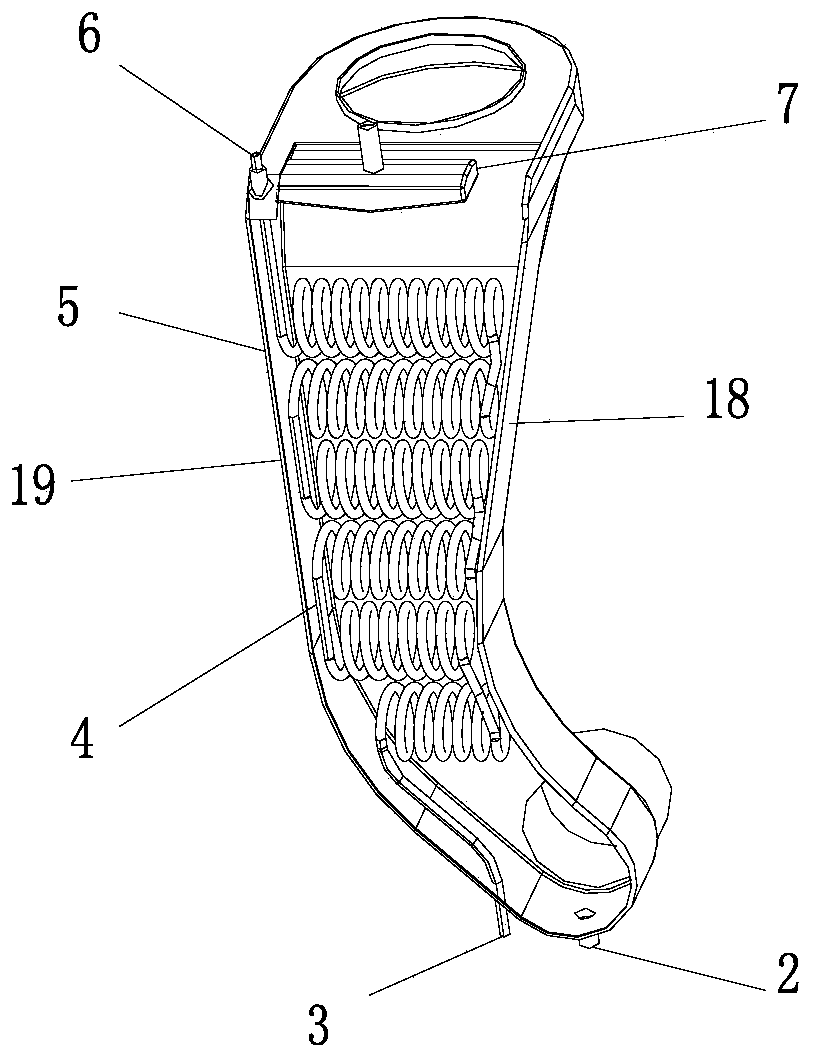

[0045] The shell 5 has an air inlet 8 on the lower part to connect with the washing machine outer cylinder 13, and an air outlet 9 on the top to connect with the fan 15 in the drying air duct 17, and the side where the curvature radius of the lower part is located is the inner side 18. The side with the larger radius of curvature is the outer side 19;

[0046] The heat exchange tube 4 is arranged in the shell 5 to exchange heat with the hot and humid air. It is hollow and wound into multiple rows of cylindrical spring-shaped heat exchange tubes arranged in multiple rows up and down. The liquid inlet 6 of the heat exchange tube 4 is located at the condensation The upper end of the condenser 1 is connected to the...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that the pitch of the cylindrical spring-shaped heat exchange tubes 4 in the same line remains unchanged, the thickness of the heat exchange tubes remains unchanged, and the outer diameter of the heat exchange tubes gradually decreases from the outer side 19 to the inner side 18 .

[0059] Although the pitch of the cylindrical spring-shaped heat exchange tubes is not changed by adopting such a distribution mode of the heat exchange tubes 4, since the outer diameter of the heat exchange tubes 4 gradually decreases from the outer side 19 to the inner side 18, not only the cylindrical spring shape The gap between two adjacent turns of the heat exchange tube 4 near the outer side 19 is smaller than the gap between two adjacent turns of the heat exchange tube 4 on the inner side 18, so that the density of the heat exchange tube 4 near the outer side 19 is greater than The density of the heat exchange tubes on the inn...

Embodiment 3

[0062] The difference between this embodiment and the above-mentioned embodiment is that the pitch of the cylindrical spring-shaped heat exchange tubes of the heat exchange tube 4 in this embodiment remains unchanged, the outer diameter of the heat exchange tube 4 remains unchanged, and the inner diameter of the heat exchange tube 4 changes from Downlink and uplink gradually decrease.

[0063] Such as Figure 1 to Figure 5 As shown, when drying clothes, the heater 16 is used to heat the air, and the hot air is driven by the fan 15 into the washing tub and heats the residual moisture on the clothes into water vapor, and the water vapor is driven by the fan 15 along with the hot air from The air inlet 8 connected to the air outlet of the outer cylinder 13 at the lower part of the condenser 1 enters the condenser 1 . At the same time, the cooling water flows into the heat exchange tube 4 through the liquid inlet 6 on the upper part of the condenser 1 and is drained from the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com