A kind of ultra-thin flat heat pipe and its manufacturing process

A flat plate heat pipe and manufacturing process technology, applied in the field of ultra-thin flat plate heat pipe and its manufacturing process, can solve the problems of inability to meet the integration and miniaturization of electronic devices, occupy a large volume, and be difficult to industrialize, and achieve good practicability and applicability. high performance, strong heat transfer ability, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

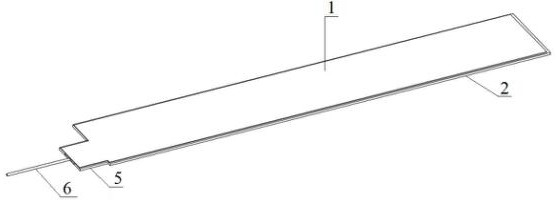

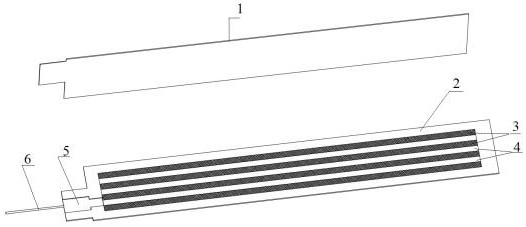

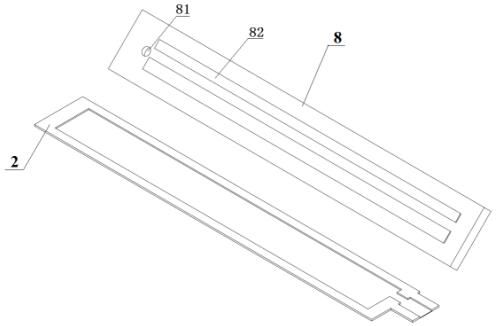

[0041] Such as Figure 1 to Figure 5 Shown is the first embodiment of the ultra-thin flat heat pipe of the present invention, which includes a base plate 2 and a cover plate 1 snap-fit package, the base plate 2 is provided with a concave cavity with a number of capillary structures arranged in parallel, and the adjacent capillary structures A gas flow channel 7 for the flow of the working fluid of the heat pipe is formed between them, and the capillary structure includes several liquid flow channels arranged in parallel.

[0042] When this embodiment is implemented, the setting of the capillary structure can provide greater capillary force on the one hand, and can be used as the internal support structure of the flat heat pipe on the one hand to prevent the heat pipe from collapsing and deforming; the setting of placing the capillary structure in the concave cavity can Reduce the thickness of the flat heat pipe; the gas working medium flows in the gas flow channel 7, and the...

Embodiment 2

[0047] This embodiment is an embodiment of the manufacturing process of the ultra-thin flat heat pipe, comprising the following steps:

[0048] S10. Etching a concave cavity on the base plate 2;

[0049] S20. Place the screen in the concave cavity of the base plate 2, and press it with a graphite plate after spraying alcohol to make the screen closely fit the base plate 2, and place it in a sintering furnace filled with an inert gas for primary sintering;

[0050] S30. After naturally cooling the bottom plate 2 sintered in step S20, fill it with sintered powder, and place it in a sintering furnace filled with inert gas for secondary sintering to form gas flow channels 7 and liquid flow channels;

[0051] S40. Put the cover plate 1 and the base plate 2 opposite to each other and package them;

[0052] S50. Vacuumize the heat pipe and fill it with working fluid, and seal the tail of the liquid-filled pipe 6 .

[0053] Wherein, in step S10, the depth of the concave cavity is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com