Deep cold loop heat tube

A loop heat pipe, cryogenic technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as difficulty in starting the cryogenic loop heat pipe, and achieve the effect of stable working performance and large heat transfer limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

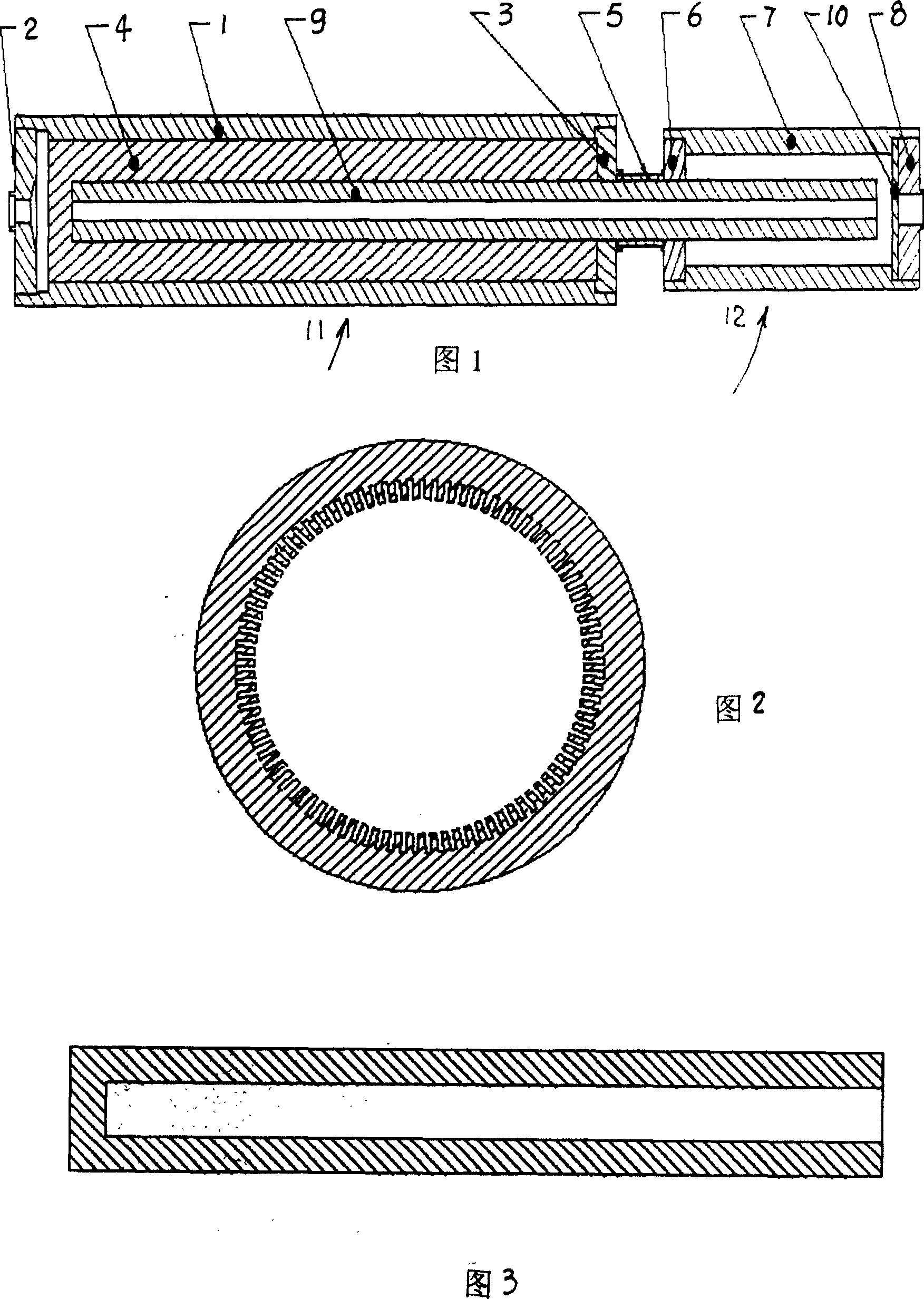

[0027] Fig. 1 is a schematic structural view of the present invention; Fig. 2 is a schematic cross-sectional view of the main evaporator shell 1; Fig. 3 is a schematic structural view of a cylindrical main liquid-absorbing core 4; as can be seen from the figure, the cryogenic circuit heat pipe provided by the present invention includes :

[0028] a main evaporator 11;

[0029] A liquid reservoir 12; the main evaporator 11 and the liquid reservoir 12 are integrated in series through a connecting pipe 5;

[0030]The main evaporator 11 includes a main evaporator tube shell 1, a main evaporator left end cover 2, a main evaporator right end cover 3 and a main liquid-absorbing core 4, and the main evaporator tube shell 1 is cut with a shaft on the surface of the inner hole. The hollow stainless steel tube facing the channel, in which the cylindrical main liquid-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com