Gas-liquid separation evaporator

A gas-liquid separation and evaporator technology, used in evaporators/condensers, refrigeration and liquefaction, refrigerators, etc., can solve the problems of large vapor-liquid two-phase resistance, low refrigeration efficiency, etc. Large heat transfer coefficient, the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

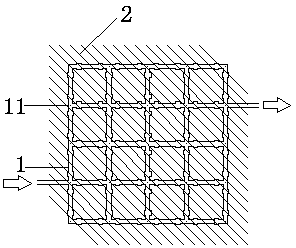

[0013] exist figure 1 In the first embodiment shown, the gas-liquid separation evaporator includes a transmission pipe 1 and a cooling fin 2; wherein, the transmission pipe 1 forms a multi-communication network structure composed of a large number of squares, and the nodes between the transmission pipes are formed by The multi-way connectors 11 are connected, which not only facilitates assembly, but also ensures the tightness of the mesh structure.

[0014] Refrigerant enters the evaporator from the left side, and is divided into two parts: vapor and liquid due to gravity. The gas passes through the upper part of the multi-communication network structure quickly, and the liquid flows into the lower part of the multi-communication network structure. Evaporation is realized under constrained conditions; since the gas and liquid are completely separated in this structure, the resistance of the gas-liquid two-phase flow is greatly reduced, which effectively improves the efficiency...

Embodiment 2

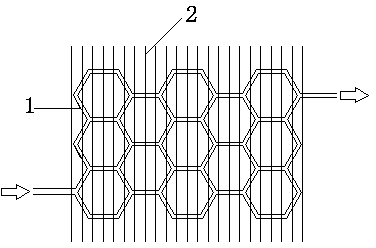

[0018] exist figure 2 In the shown embodiment two, the difference from the first embodiment is that the multi-communication network structure of the gas-liquid separation evaporator is honeycomb, and the connection nodes between the transmission pipes 1 are also connected by multi-communication. The head 11 is connected; compared with the first embodiment, the specific structure of the transfer pipe is changed, and the gas-liquid separation can also be realized. The inner and outer surfaces of the transfer pipe can be wrinkled, and the heat transfer area can also be increased to achieve the same effect.

[0019] In addition, the multi-communication network structure formed by the transfer pipes 1 in the evaporator may also be a three-dimensional grid structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com