New method for dividing water injection layer sections of offshore water injection well

A technology for water injection wells and water injection layers, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc., and can solve the problems of large difference in water absorption between layers, low qualification rate of layers, uneven advancement of injected water, etc. Simple application and clear technical ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below in conjunction with the drawings, which are described in detail as follows.

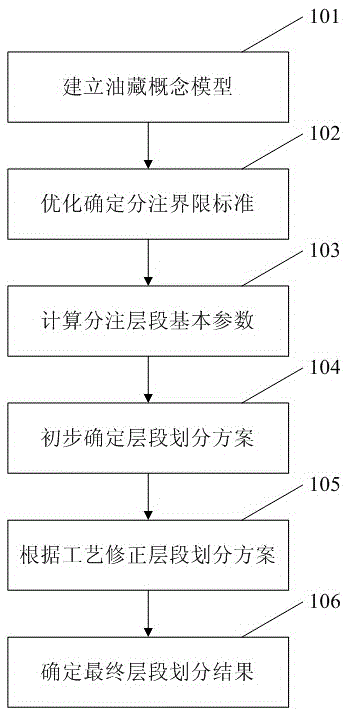

[0014] Such as figure 1 As shown, figure 1 It is a flowchart of a new method for dividing water injection intervals of offshore water injection wells of the present invention.

[0015] In step 101, the basic parameters of the reservoir are collected and a conceptual model of the reservoir is established.

[0016] In step 102, the numerical simulation method is used to study the influence of the permeability difference, the thickness difference, the number of small layers in the section, the degree of flooding of each layer and the pressure difference on the uniformity of water injection well, and the sensitivity analysis of each factor is performed. Determine the separate injection limit standard for water injection wells.

[0017] In step 103, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com