Viscous damper based on piezoelectric variable friction

A viscous damper and variable friction technology, which is applied in the field of viscous dampers, can solve the problems of the damper not reaching the damper, less energy dissipation, and increasing the structure, so as to achieve energy reduction, regular shape and size, and good energy consumption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

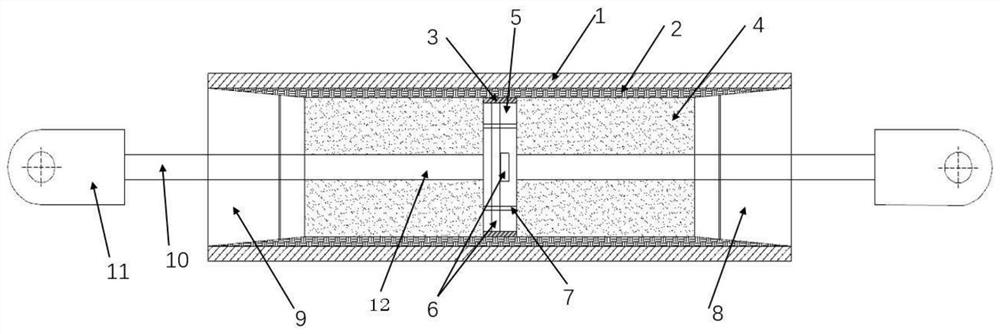

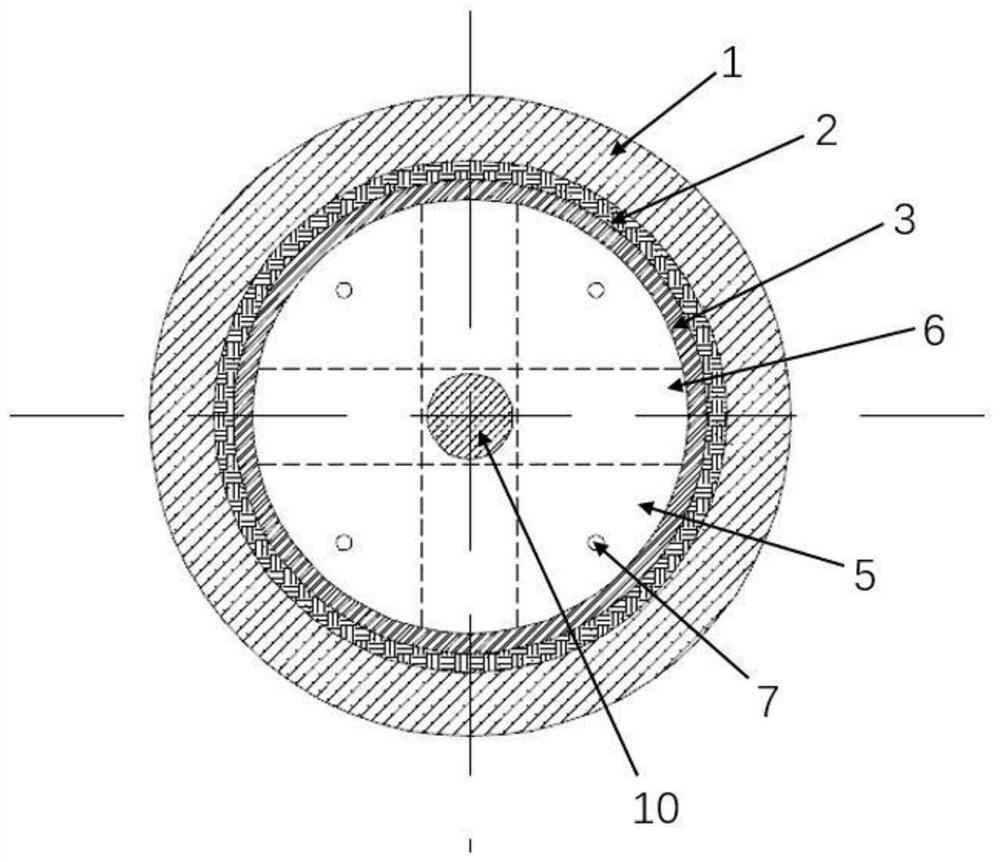

[0034] refer to Figure 1-3 As shown, a viscous damper based on piezoelectric variable friction provided by the present invention mainly includes a cylinder 1, a piston 5, and a laminated piezoelectric driver 6, and the cylinder 1 surrounds the piston 5 to protect the piston 5 Not damaged by the external environment. The inner wall of the cylinder body is evenly coated with friction material 2 , and a friction plate 3 is also arranged between the piston 5 and the cylinder body. The friction plate 3 is in an annular structure and matches with the friction material 2 . Due to the influence of the pre-pressure of the laminated piezoelectric driver 6, the friction plate 3, the cylinder 1 and the friction material 2 are tightly combined.

[0035] The inside of the cylinder 1 is filled with a damping medium 4, and the damping medium 4 is a fluid with a moderate viscosity. The piston 5 in the cylinder 1 is connected with the piston 5 rod, and the inside of the piston 5 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com