Water-cooling chassis for casting large steel ingot and using method

A water-cooled chassis and steel ingot technology, which is applied in the field of casting, can solve the problems of shrinkage and porosity in the core of large steel ingots, and achieve the effects of improving cooling strength, promoting uniform advancement, and reducing shrinkage and porosity defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

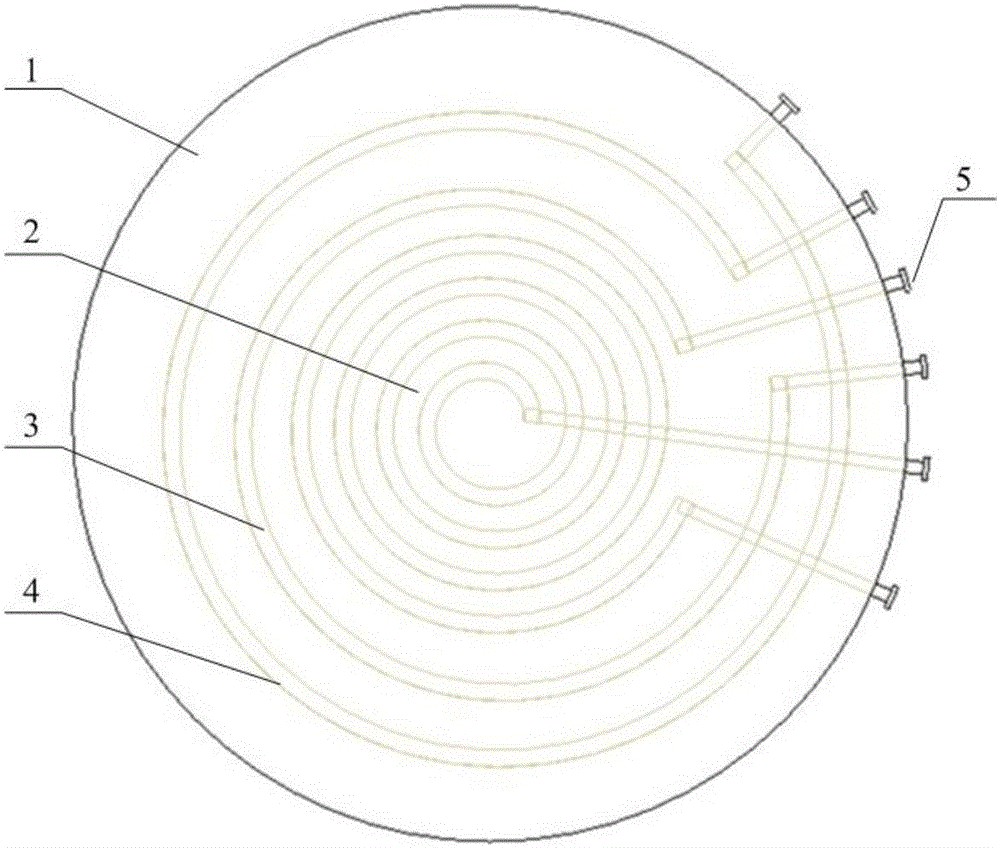

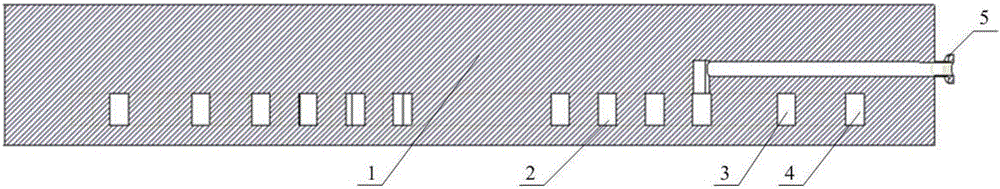

[0019] A water-cooled chassis for casting large steel ingots, such as figure 1 , figure 2 As shown, it includes a chassis 1, a primary cooling ring 2, a secondary cooling ring 3, a tertiary cooling ring 4 and a flange 5. The chassis 1 is circular or rectangular, and the cooling rings 2, 3, and 4 at all levels are correspondingly circular or rectangular. The primary cooling ring 2 is distributed and densely within a certain range in the center of the chassis 1, and the secondary cooling ring 3 and the tertiary cooling ring 4 are sequentially distributed around the periphery of the primary cooling ring 2, which is relatively sparse relative to the primary cooling ring 2. The inlet and outlet ends of the cooling rings 2, 3 and 4 at all levels are provided with flanges 5 for connecting the cooling water system.

[0020] The method of using the water-cooled chassis for casting large steel ingots includes the following steps:

[0021] 1) After swinging the mold, connect the multi-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com