Anisotropic two-dimensional visual sand filling model in simulation layer and two-dimensional visual seepage experimental device

A technology of heterogeneity and experimental equipment, applied in the field of experimental equipment for simulating fluid seepage in reservoirs, can solve the problems of inability to seepage changes in heterogeneous porous media, inability to simulate formation overlying pressure, and inability to observe directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

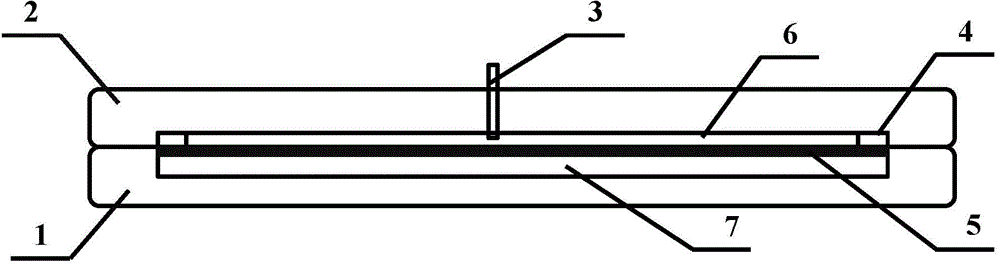

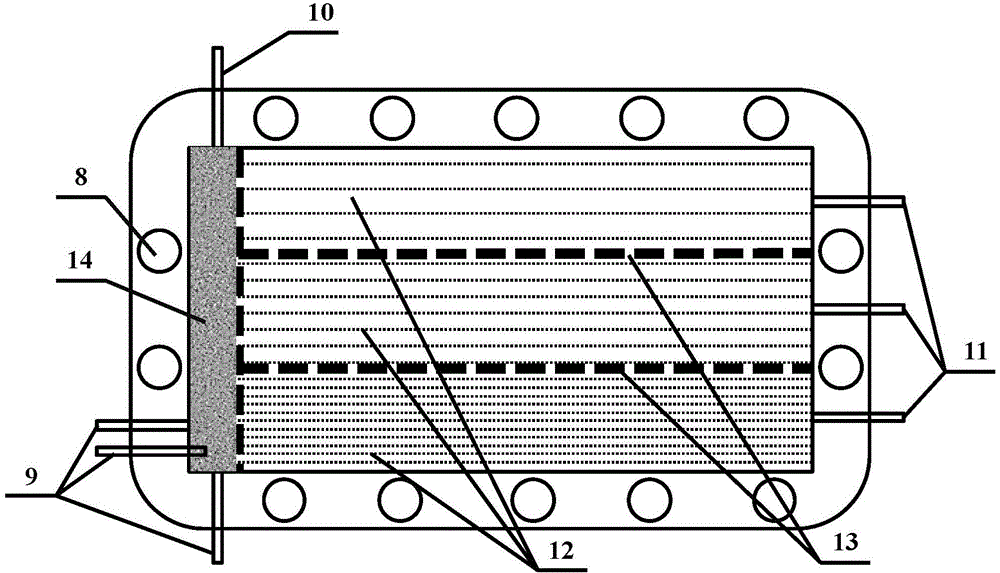

[0038] Such as figure 1 with figure 2 As shown, the two-dimensional visible sand filling model for simulating layer heterogeneity provided by the present invention includes a bottom plate 1 and a cover plate 2, both of which are rectangular PMMA panels. The base plate 1 and the cover plate 2 are tightly fitted by bolts (the threaded hole 8 is provided on the base plate 1). A sealing ring 4 is provided between the base plate 1 and the panel 2 in order to make the two seal fit.

[0039] Such as figure 1 As shown, a sealing rubber pad 5 is provided between the bottom plate 1 and the cover plate 2, a confining pressure chamber 6 is formed between the sealing rubber pad 5 and the cover plate 2, and a filling space is formed between the sealing rubber pad 5 and the bottom plate 1. Cavity 7 can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com