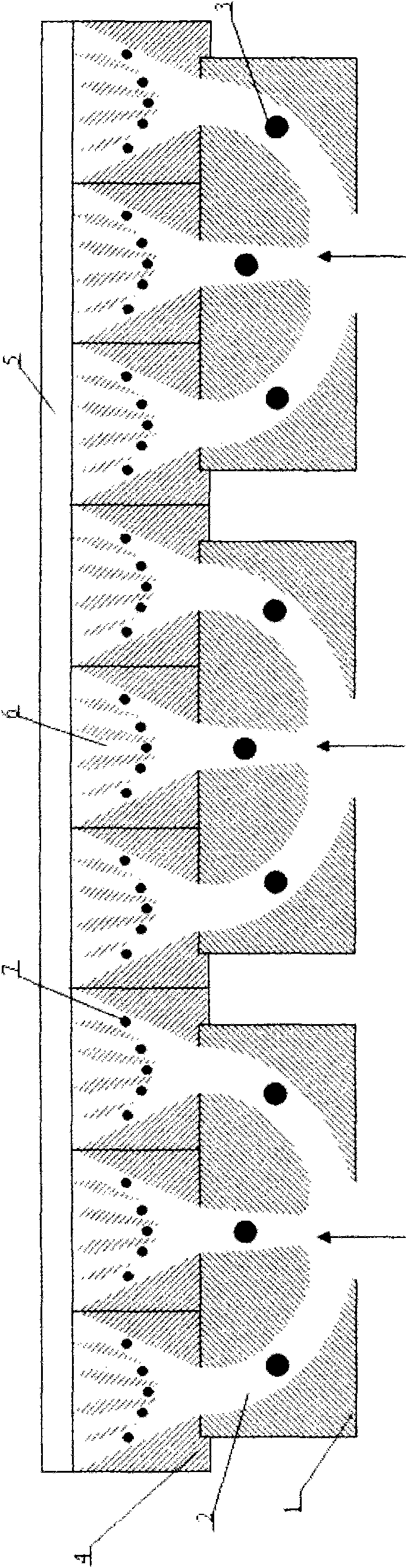

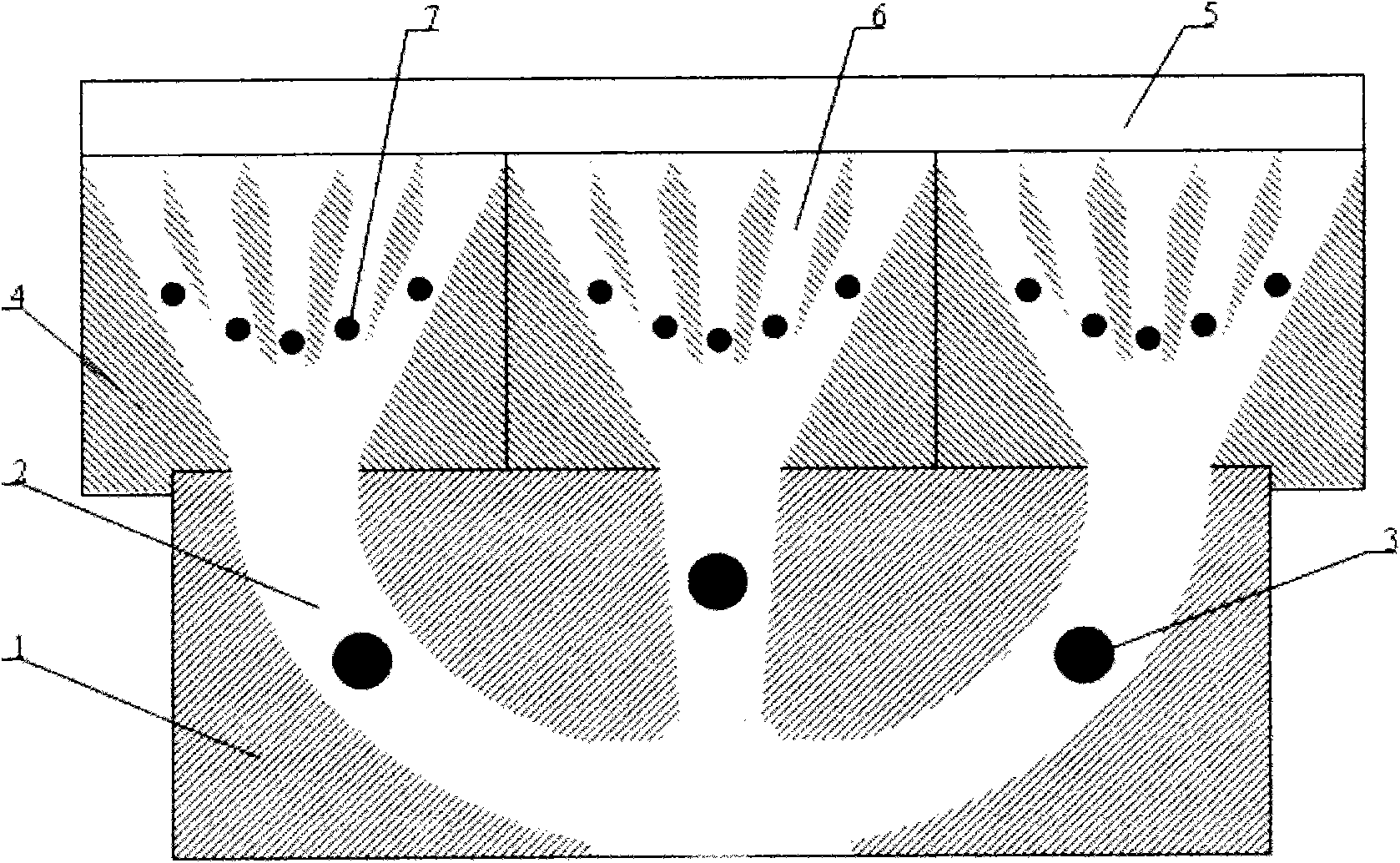

Extrusion die for producing high molecular weight polyethylene sheet material with breadth between 500 and 2,000mm

An ultra-high molecular weight, extrusion die technology, used in household appliances, other household appliances, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

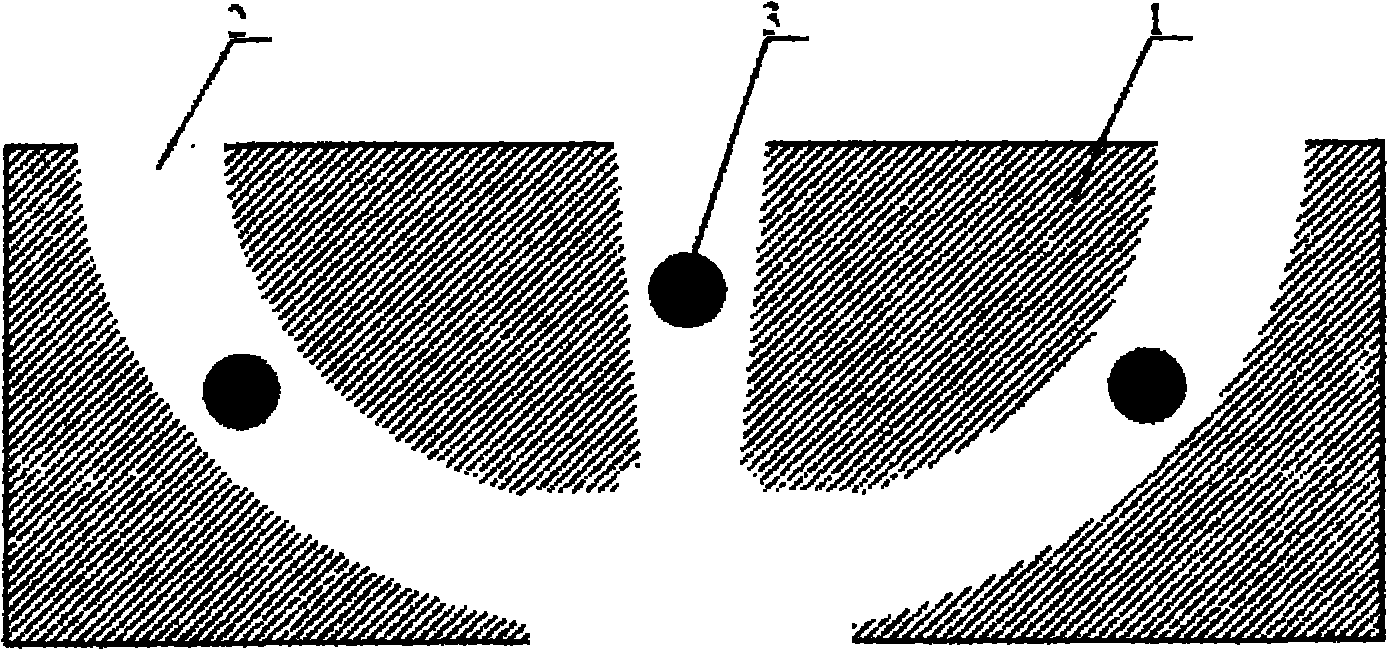

Method used

Image

Examples

Embodiment 1

[0015] Use 100 parts of Ticona GUR4150 ultra-high molecular weight polyethylene resin (molecular weight 9,200,000-ISO standard), 5 parts of composite processing aids, enter single-screw extruder after being mixed by high-speed mixer, in the present invention width 1000mm * 10mm machine head The UHMWPE sheet is continuously extruded on the top, and the appearance is smooth and smooth.

Embodiment 2

[0017] Adopt 100 parts of M3 type ultra-high molecular weight polyethylene resin (molecular weight 300-350 ten thousand-GB standard), 5 parts of composite processing aids, enter twin-machine co-extrusion single-screw extruder after high-speed mixer mixes, in the present invention The ultra-high molecular weight polyethylene sheet is continuously extruded on the machine head with a width of 2000mm×10mm, and the appearance is smooth and clean. Attached table: Properties of ultra-high molecular weight polyethylene sheet

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com