Concrete uniaxial tension load and test device and use method thereof

A technology for testing devices and concrete test blocks, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of complicated test operation process and difficult centering of concrete test pieces, and achieve simplified test devices, effective continuous load, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

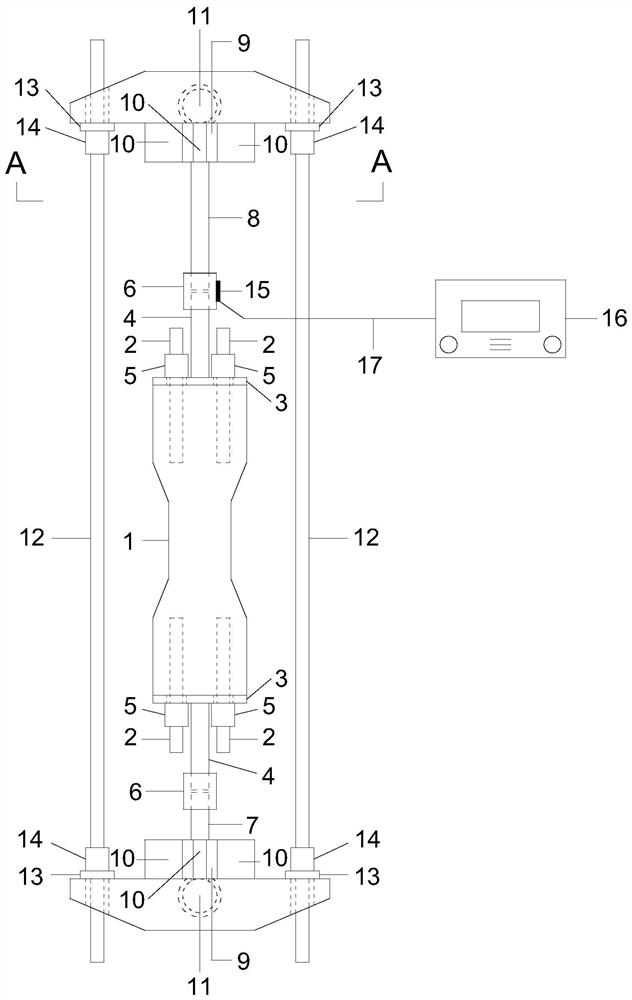

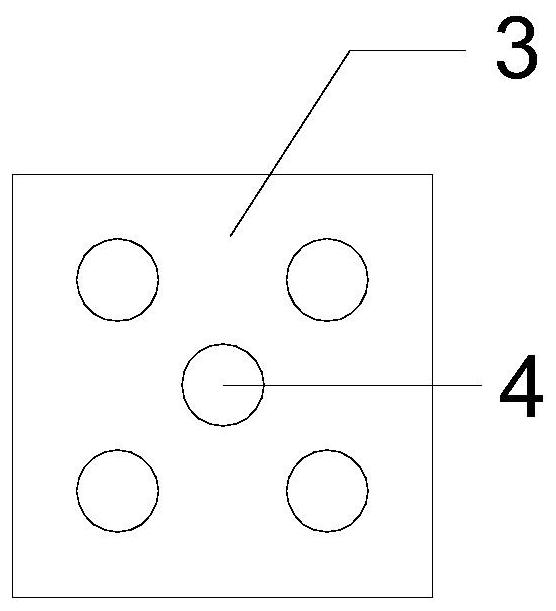

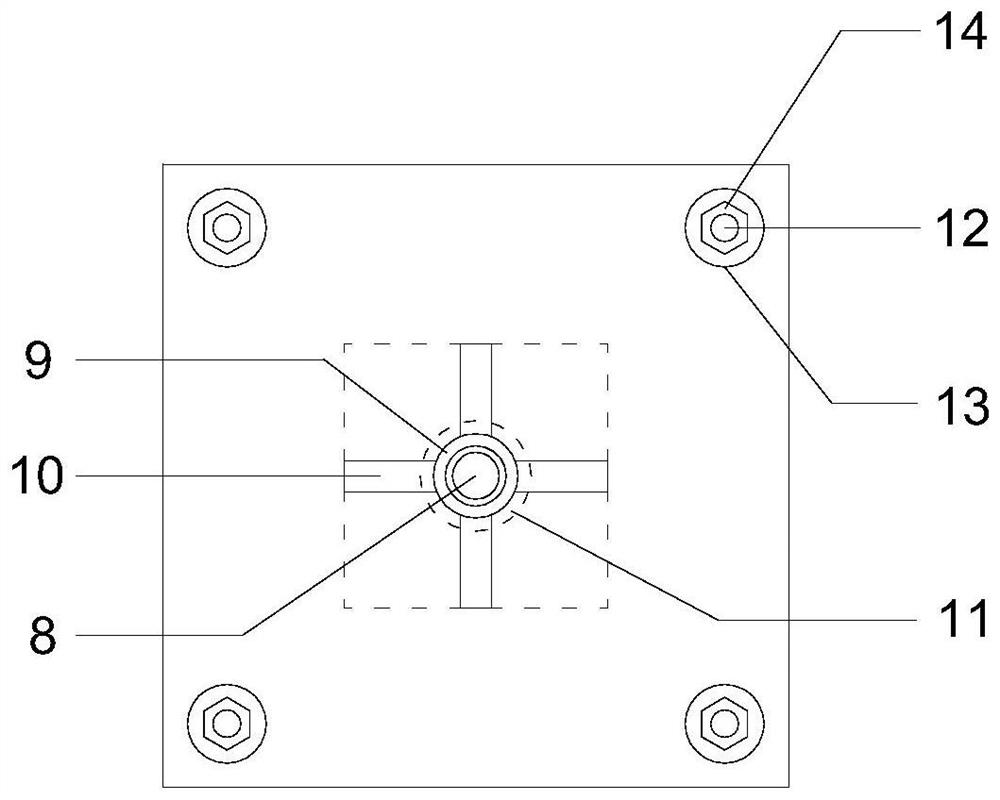

[0037] Such as figure 1 As shown, a concrete uniaxial tensile load test device includes a concrete test block 1, a finish-rolled threaded steel bar 2, a square anchor plate 3, a prestressed finish-rolled threaded steel bar specification-4, a finished-rolled nut specification-5, a connection Sleeve 6, ordinary connecting rod 7, extended connecting rod 8, reinforced round steel pipe 9, rectangular stiffened steel plate 10, ball hinge 11, prestressed finish-rolled threaded steel bar specification 2 12, steel washer 13, finish-rolled nut specification 2 14, Strain gauge 15, resistance strain gauge 16, connecting wire 17. The concrete test block 1 (120mm×120mm×400mm) is a non-standard type. Considering the effect of reducing the stress effect at the end and ensuring that the tensile failure occurs in the middle part, the area of the middle part of the test piece is reduced, and a self-made steel mold is used. To complete the pouring and molding of the test piece, remove the form...

Embodiment 2

[0053] Such as Figure 5 As shown, a concrete uniaxial tension test device takes out the load-bearing device in the erosive environment simulation device, and adds a square steel plate 18 and a through-core puller 19 on the basis of the load-bearing device. Two new square steel plates 18 are added, one of which is placed between the upper part of the connecting sleeve 6 and the rectangular stiffener steel plate 10 to support the upper through-hole drawing instrument 19, and the lower steel washer 13 and finish rolling The nut specification two 14 is fixed, and the other one is arranged on the top of the through-heart drawing instrument 19 to withstand the rectangular stiffened rib steel plate 10; the rectangular stiffened rib steel plate 10 is arranged as a rectangle to facilitate the support of the square steel plate 18 below; The core-through drawing instrument 19 is arranged on the square steel plate 18 for applying tension; as Figure 6 As shown, the steel washer 13 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com