FRP rib and concrete bonding performance load holding and testing device and using method thereof

A bonding performance and testing device technology, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems that it is difficult to ensure the axial tension of the reinforcement, and achieve the effect of simple structure, small space, and not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

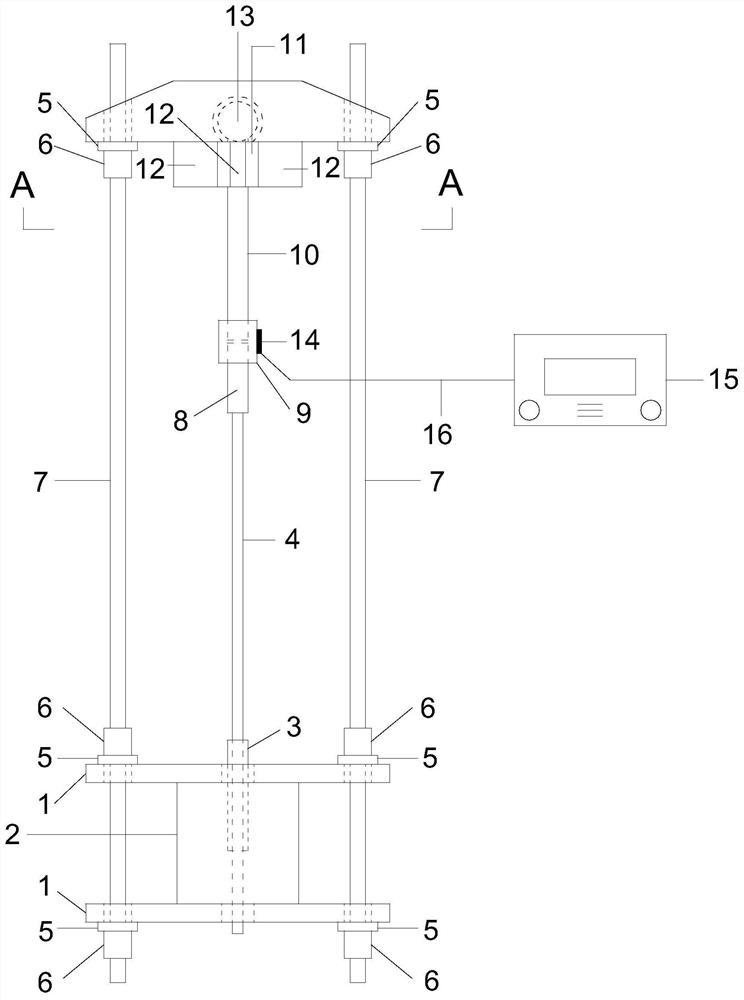

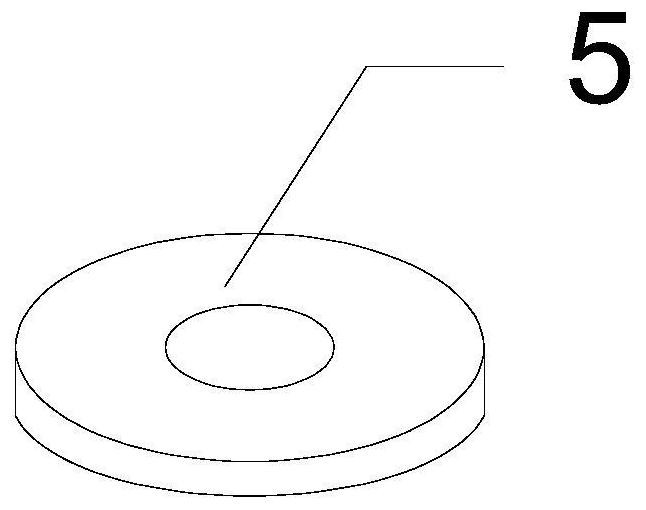

[0035] The present invention is used as FRP bar and concrete bonding performance load-bearing test device, as figure 1As shown, it includes square steel plate 1, concrete cube test block 2, PVC pipe 3, FRP bar 4, steel washer 5, finish-rolled nut 6, prestressed finish-rolled threaded steel bar 7, bonding sleeve 8, connecting sleeve 9, Connecting rod 10, reinforced round steel pipe 11, rectangular stiffened steel plate 12, spherical hinge 13, strain gauge 14, resistance strain gauge 15, connecting wire 16. The end of the ball hinge is a variable-section steel plate with circular reserved holes at the four corners, and a groove is reserved in the middle of the variable-section steel plate for rotational contact with the ball hinge. In order to avoid becoming bulky due to the large thickness of the steel plate, the steel plate on the top is designed as a variable-section steel plate.

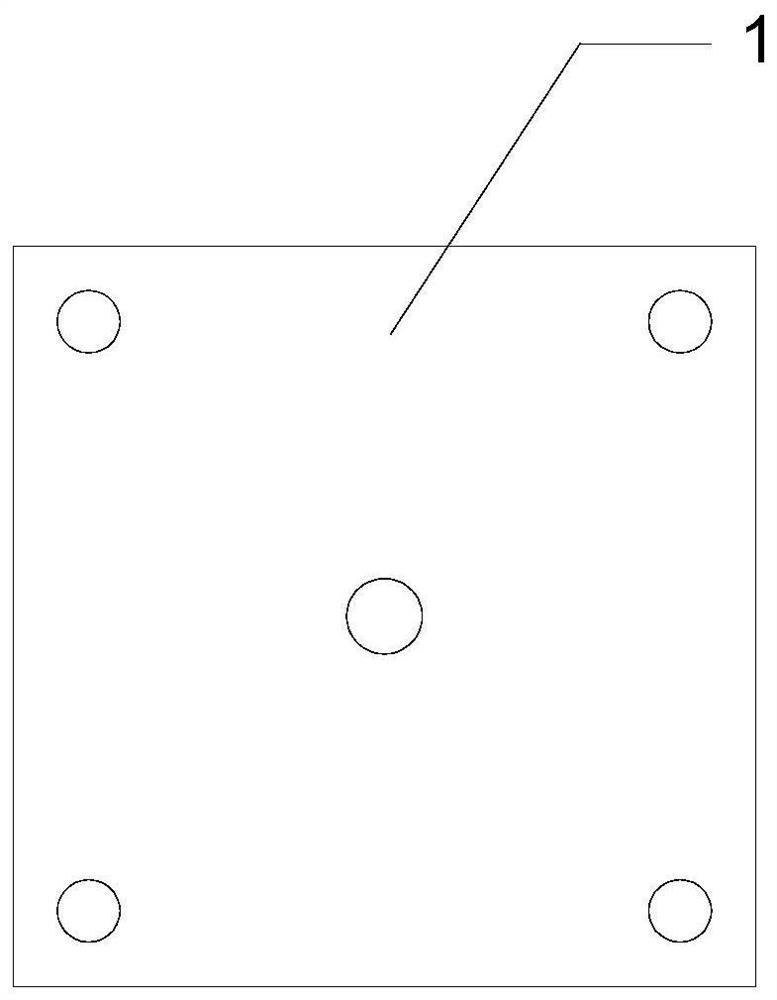

[0036] Such as figure 2 As shown, there are five reserved holes on the square steel plate 1,...

Embodiment 2

[0045] The present invention is used as FRP tendon and concrete bonding property testing device, as Figure 6 As shown, on the basis of the load-bearing device, a newly added through-type drawing instrument 17, a displacement gauge 18, and two square steel plates in the middle, one of which is placed between the connecting sleeve 9 and the rectangular stiffener steel plate 12 The center-through drawing instrument 17 above the support is fixed below it with steel washers 5 and finish-rolled nuts 6, and another steel plate is arranged above the center-through drawing instrument 17 to withstand the rectangular stiffener steel plate 12; Described rectangular stiffener steel plate 12, is arranged in the square steel plate 1 below rectangle conveniently withstands; Described piercing type drawing instrument 17 is used for applying drawing force; Described displacement meter 18 is respectively arranged on piercing type drawing instrument 17 above the square steel plate 1 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com