Rock core oil washing instrument

A technology of oil washing instrument and core, which is applied in the preparation of test samples, etc., can solve the problems of reduced cleaning efficiency, large energy consumption, and slow cleaning effect, and achieve the goal of improving automation, reducing use cost, and improving oil washing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

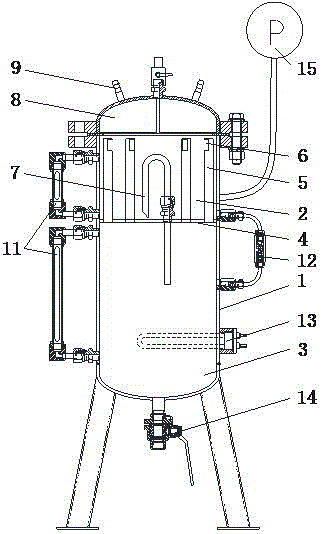

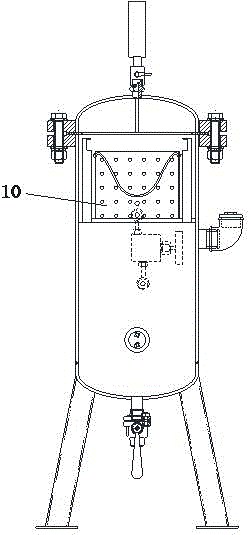

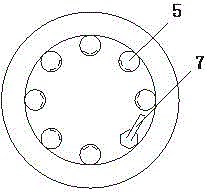

[0014] Such as Figure 1-3 A kind of core oil washing instrument shown, comprises main body 1, and main body 1 is divided into rock core chamber 2 of upper part and the heating chamber 3 of lower part, and rock sample basket 10 is placed in rock core chamber 2, and rock sample basket 10 surface There are through holes, and the core chamber 2 and the heating chamber 3 are separated by a sealing partition 4, and seven steaming pipes 5 are evenly distributed on the sealing partition 4, and the opening below the steaming pipe 5 leads to the heating chamber 3, and the steaming There are gas outlets 6 above the tubes 5. After the liquid in the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com