Scraped automobile preprocessing method and production line thereof

A technology for scrapped cars and pretreatment, which is applied to the recycling of scrapped vehicles, the removal of solid waste, and motor vehicles. Dismantling efficiency, effect of improving displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

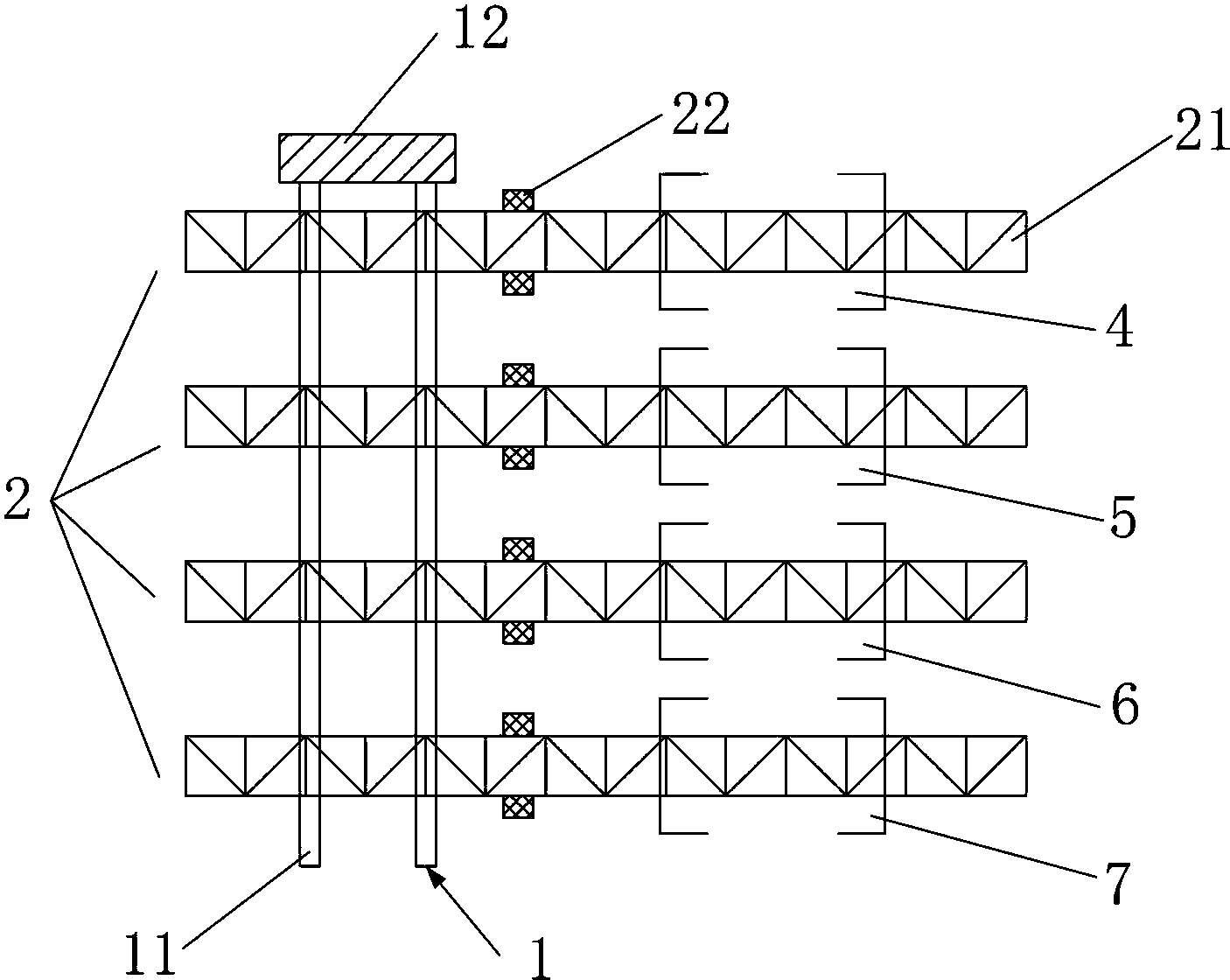

[0028] refer to Figure 1 to Figure 5 , a pretreatment method for scrapped automobiles of the present invention, comprising: a, pre-dismantling process; b, vehicle body dismantling process; c, power system dismantling process; d, packaging process.

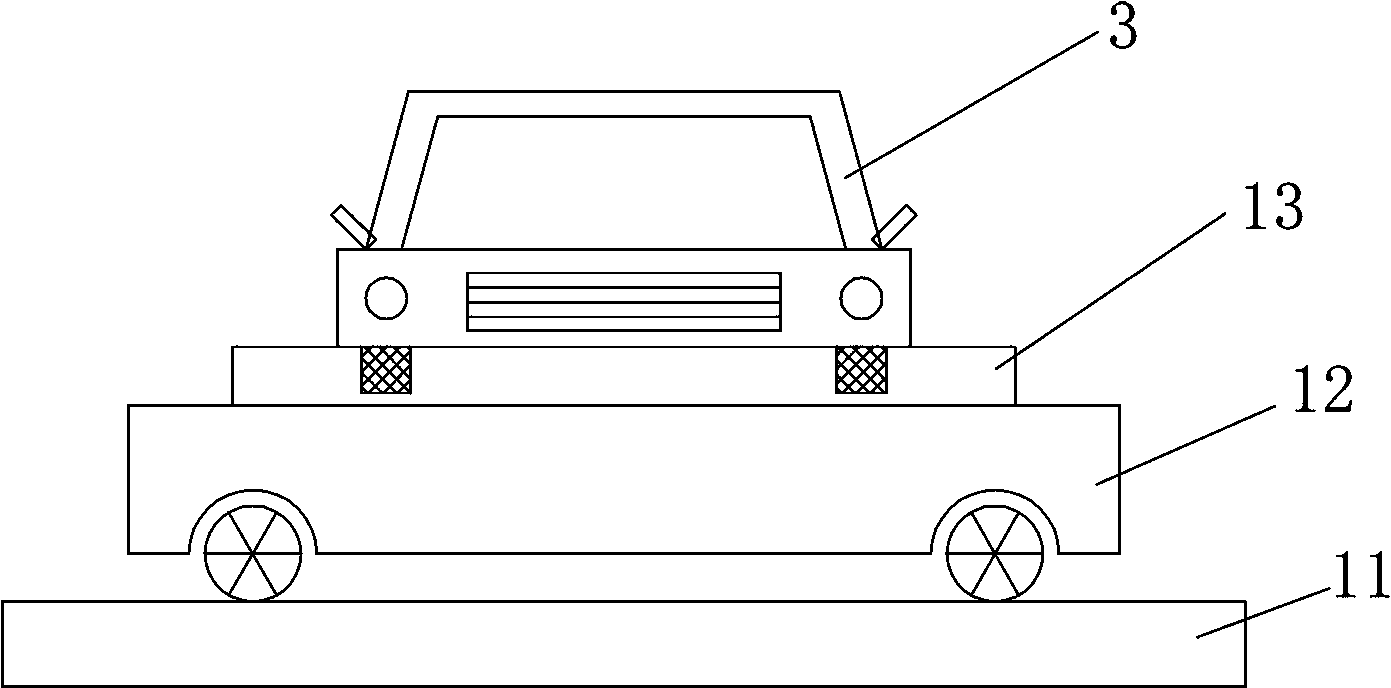

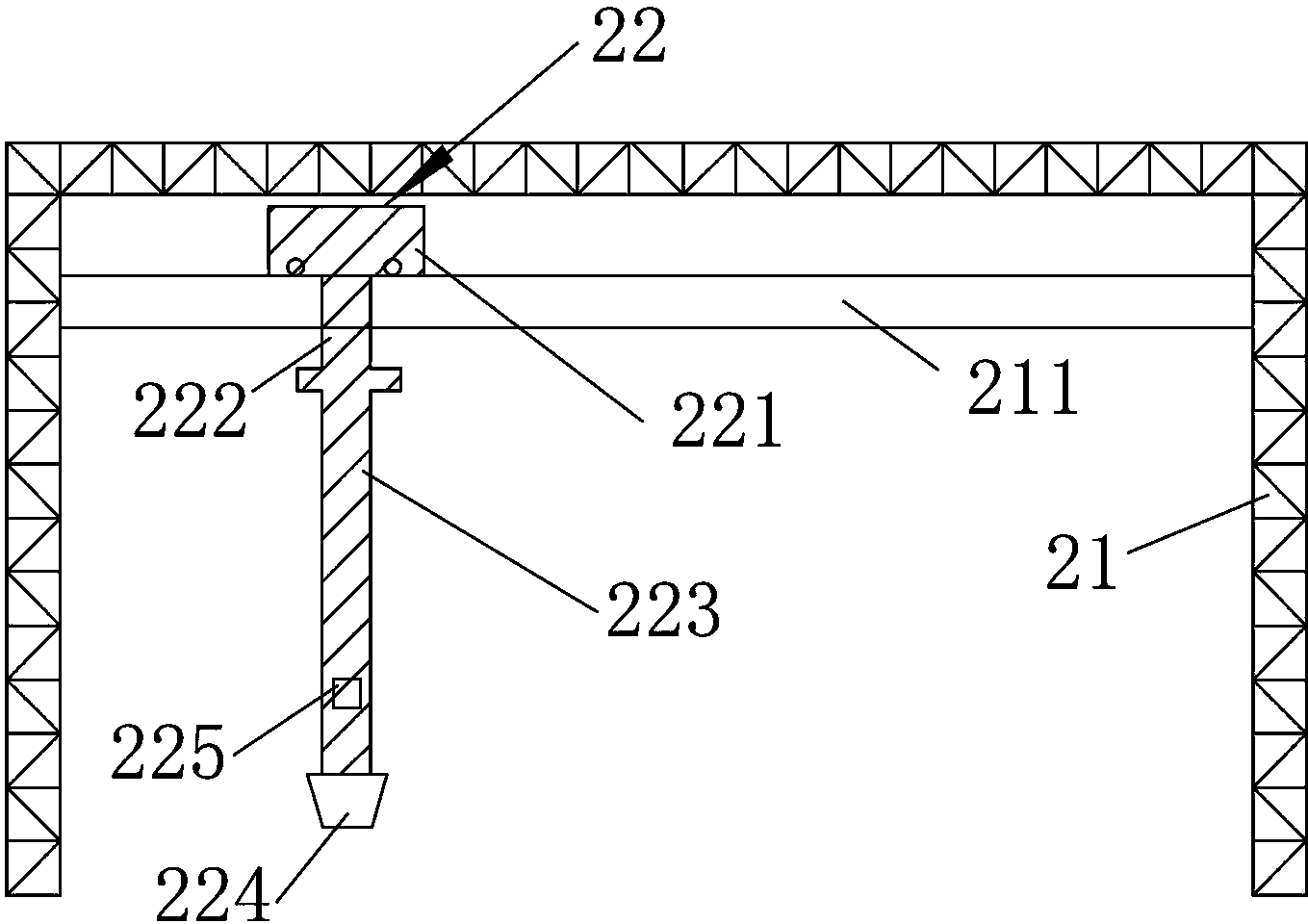

[0029] First, use a forklift to place the scrapped automobile 3 on the conveying trolley 12 of the main conveying line 1, move the conveying trolley 12 to the pre-dismantling station 4 directly below the conveying branch line 2, use the spreader 22 of the conveying branch line 2, and transfer the The scrapped car 3 goes to the pre-dismantling station 4. In the pre-disassembly station 4, the engine cover is opened, and the battery is removed; the conduits connected to the drain device 42 are respectively inserted into the various pipes in the engine box, and the waste liquid is sucked; the airbag detonator 41 is used to connect the airbag, and Detonate; disassemble the wheel and front and rear lights; use the lifting device 44 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com