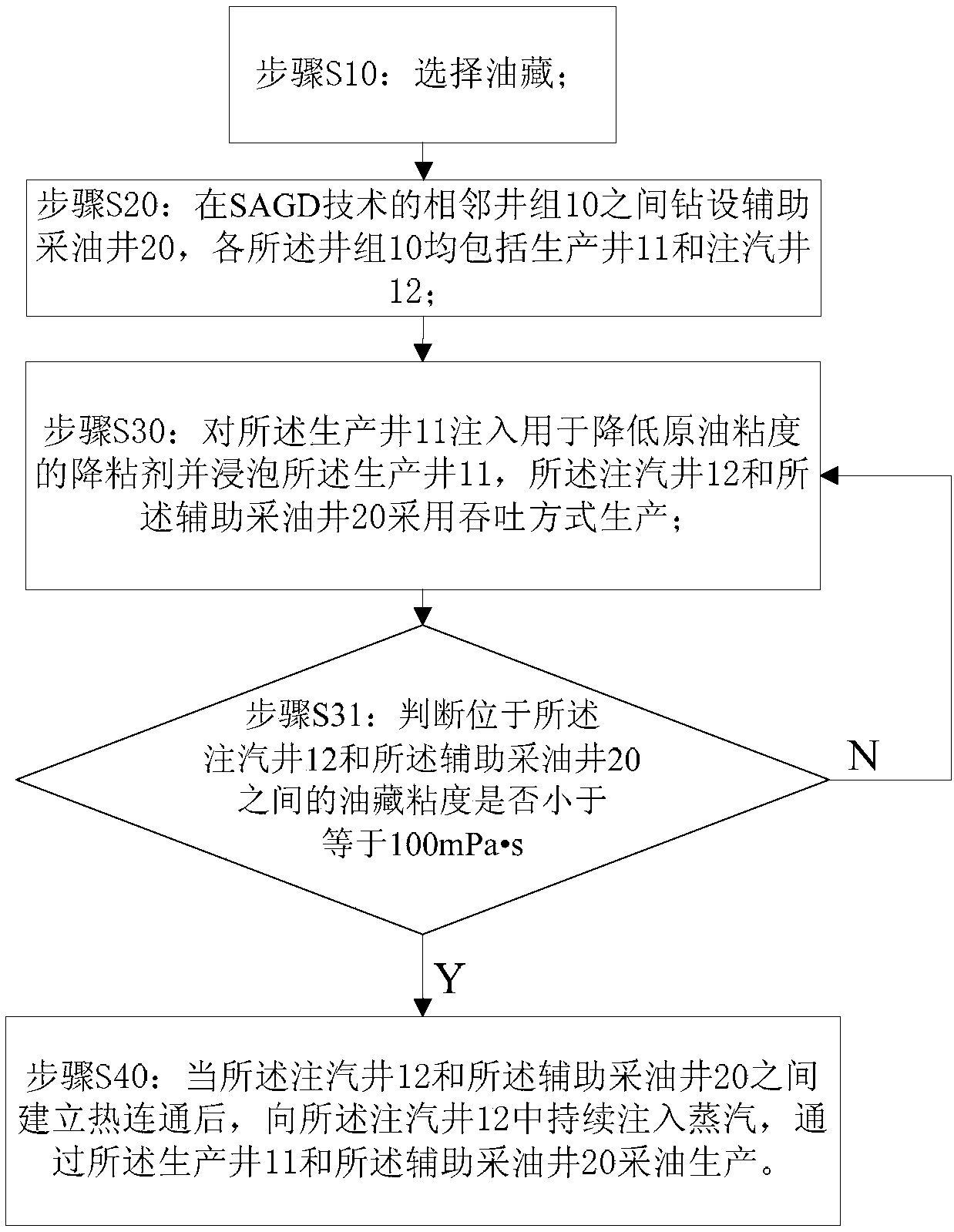

Method for exploiting super heavy oil through combination of auxiliary oil exploiting wells and steam assisted gravity drainage (SAGD)

A technology for super-heavy oil and oil production wells, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., and can solve the problems of difficult crude oil production in triangular areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] (1) Reservoir screening, the selected oil layer is 580m below the surface, the thickness of the continuous oil layer is 22m, the porosity of the oil layer is 0.31, the horizontal permeability is 1200md, the ratio of vertical permeability to horizontal permeability is 0.7, and the oil saturation is 0.72, there is no continuous mudstone and shale interlayer developed in the oil layer. The viscosity of degassed crude oil at 50°C is 45,000 centipoise.

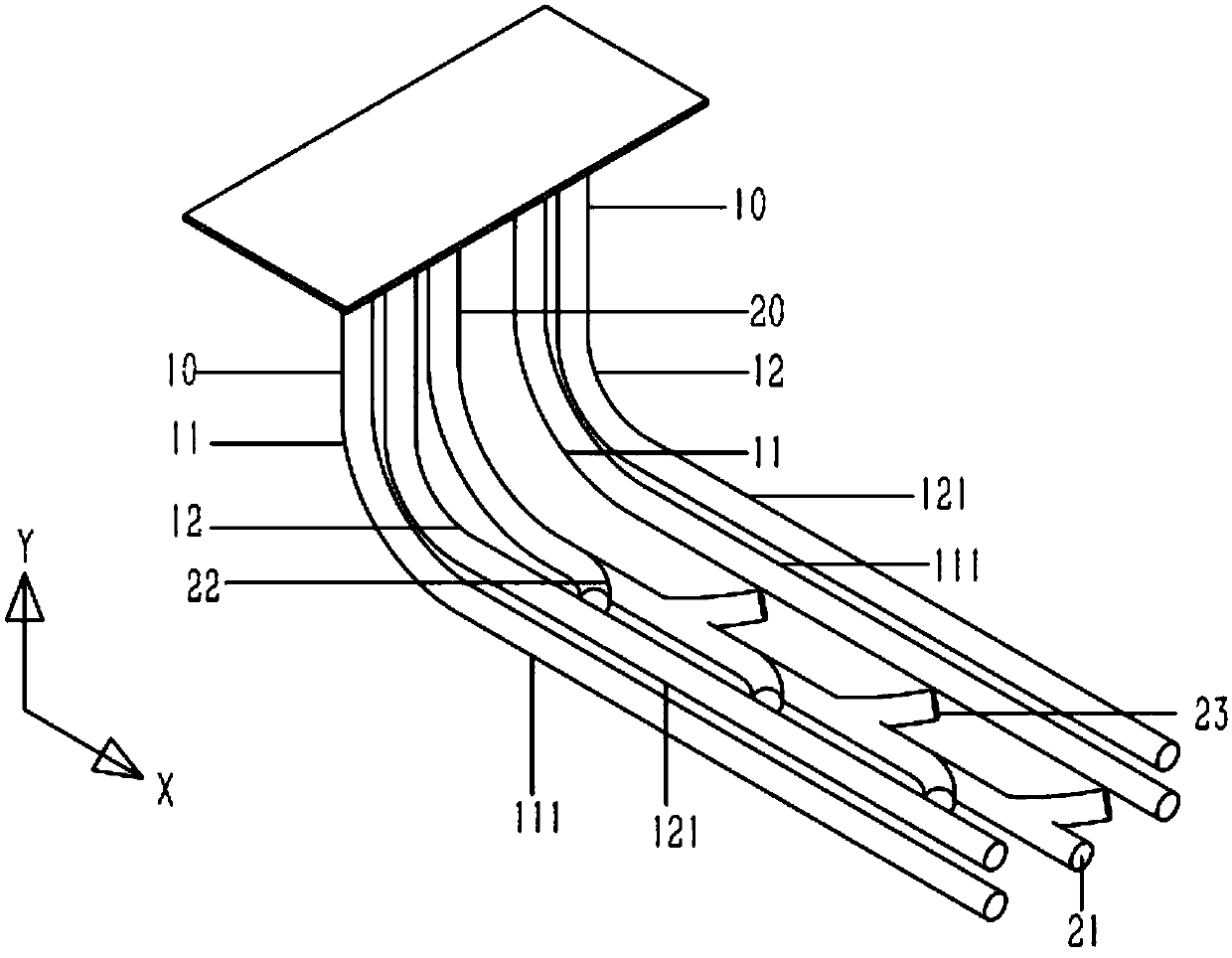

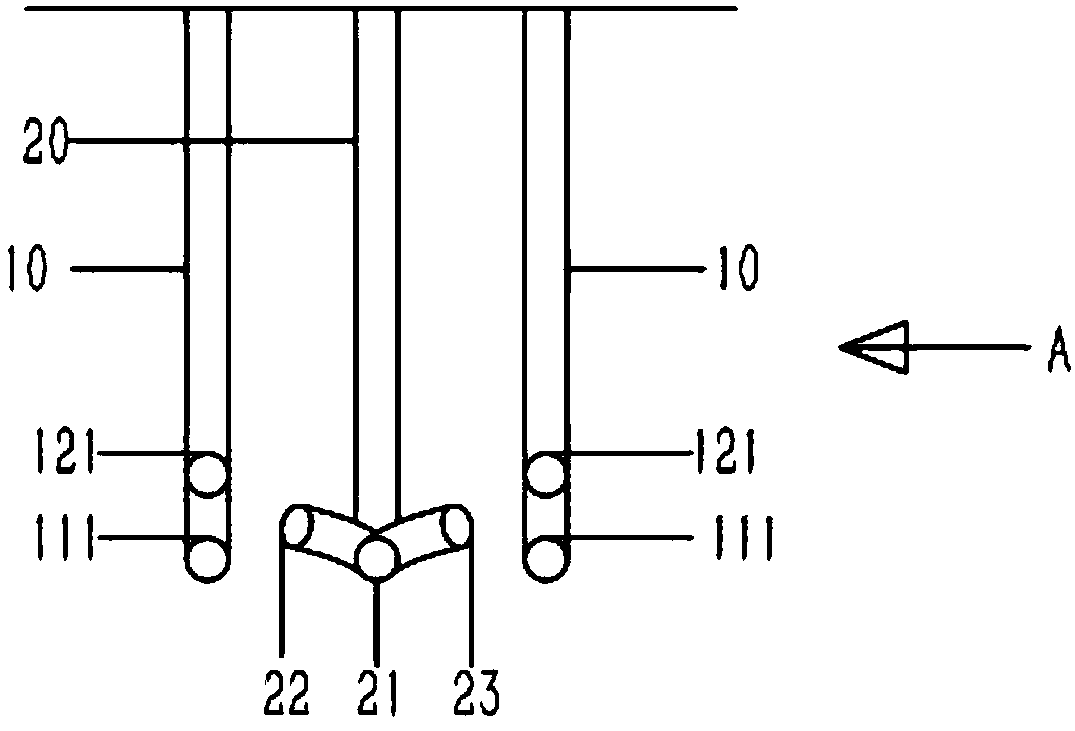

[0071] (2) The distance between adjacent well groups in this reservoir is 70m, and the lengths of the first horizontal well section 111, the second horizontal well section 21 and the third horizontal well section 121 are all 500m. In the vertical direction, the production wells The first horizontal well section 111 of 11 is 2m away from the bottom of the oil layer, and the distance between the steam injection well 12 and the production well 11 is 5m; an auxiliary oil production well 20 is drilled in the middle of the two wel...

Embodiment 2

[0076] (1) Reservoir screening, the selected oil layer is 470m below the surface, the thickness of the continuous oil layer is 20m, the porosity of the oil layer is 0.29, the horizontal permeability is 986md, the ratio of vertical permeability to horizontal permeability is 0.65, and the oil saturation The viscosity of degassed crude oil at 50°C is 49,000 centipoise.

[0077] (2) The distance between adjacent well groups in this reservoir is 70m, and the lengths of the first horizontal well section 111, the second horizontal well section 21 and the third horizontal well section 121 are all 500m. In the vertical direction, the production wells The first horizontal well section 111 of 11 is 2m away from the bottom of the oil layer, and the distance between the steam injection well 12 and the production well 11 is 4m; an auxiliary oil production well 20 is drilled in the middle of the two well groups. In the vertical direction, the second water well 20 of the auxiliary oil producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com