Method for developing deep-layer heavy crude reservoir by carbon dioxide auxiliary steam driving

A technology of carbon dioxide and auxiliary steam, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., and can solve the problems of dryness difficult to meet steam drive requirements, low recovery factor, low oil-steam ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

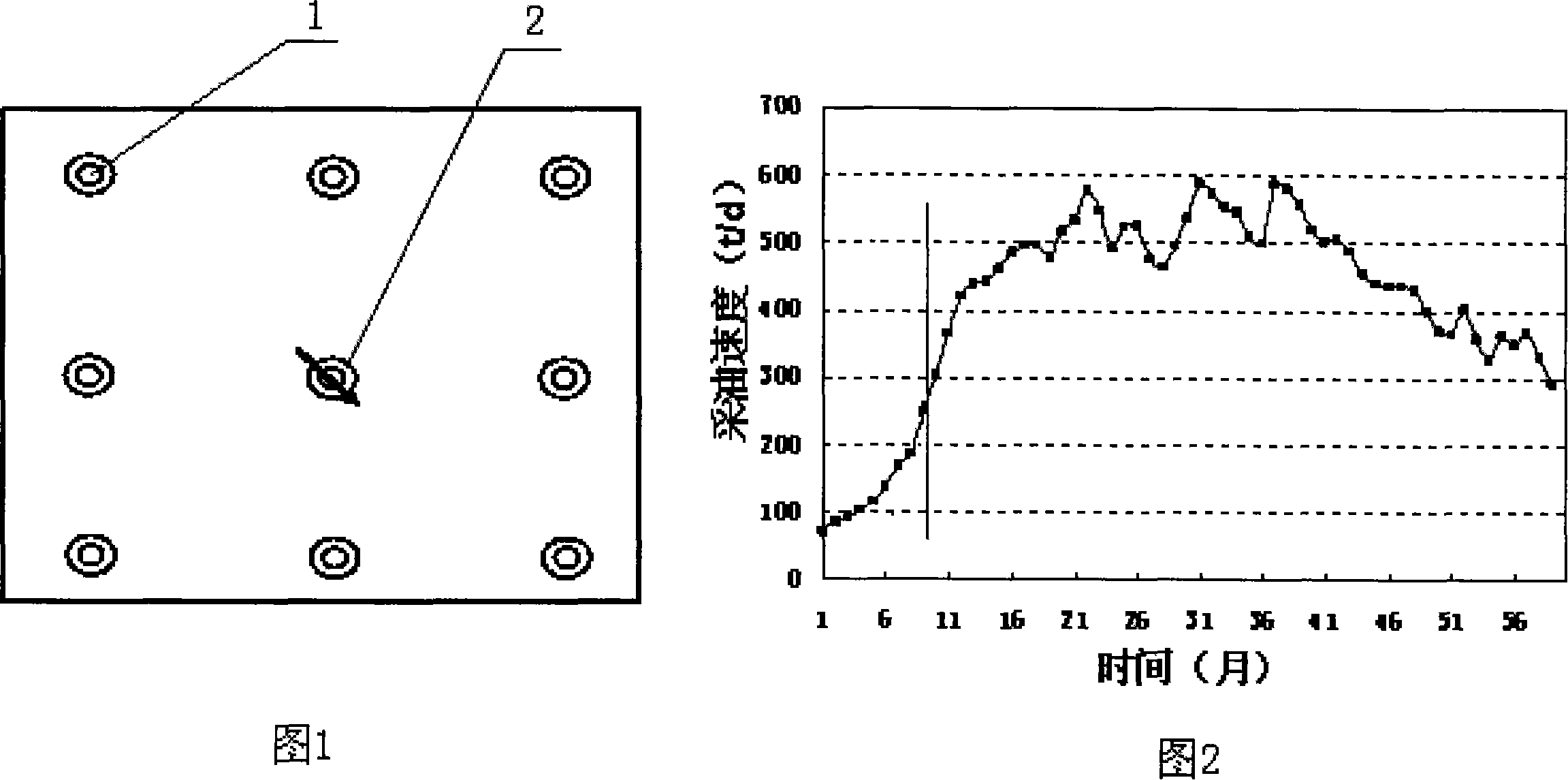

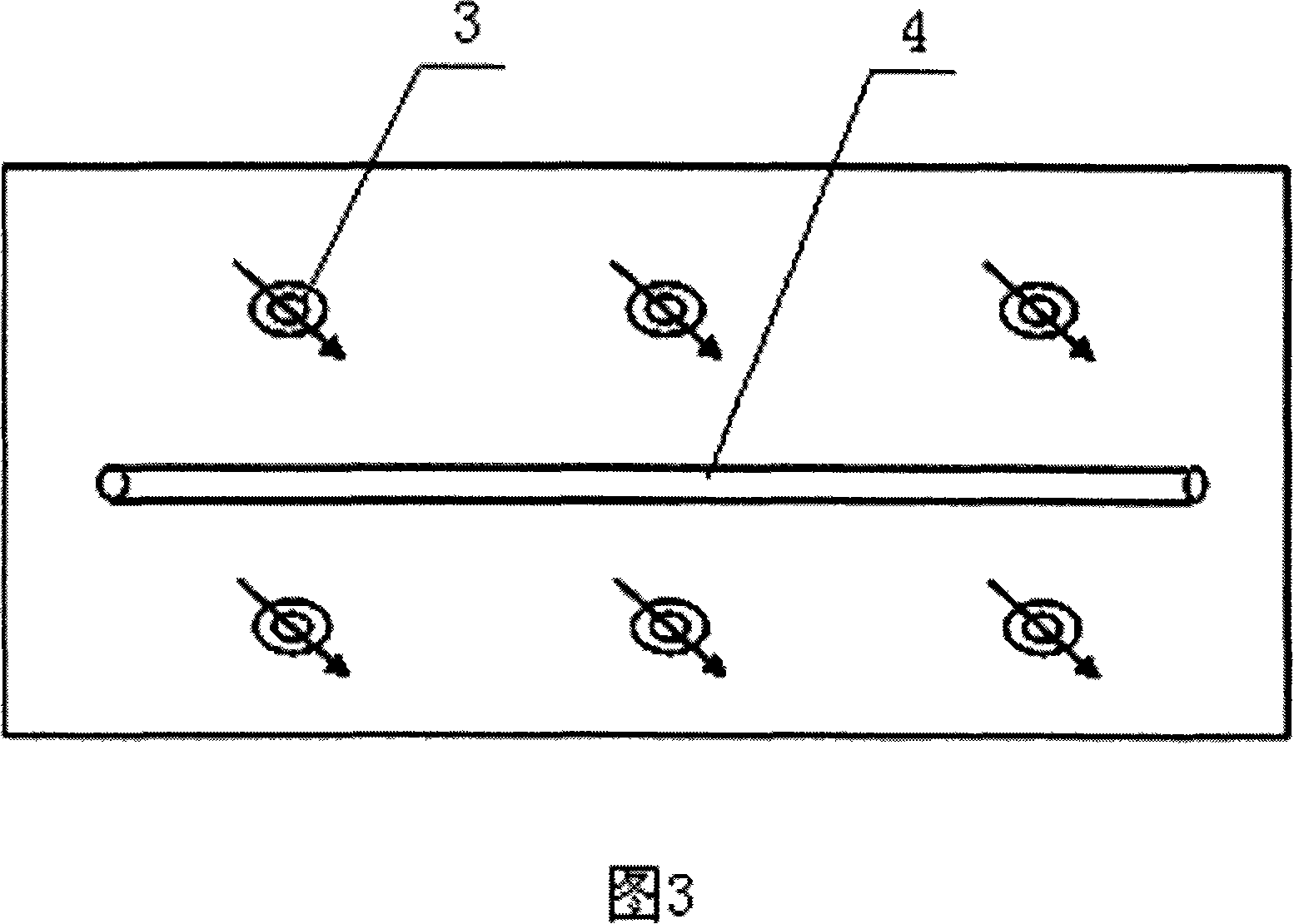

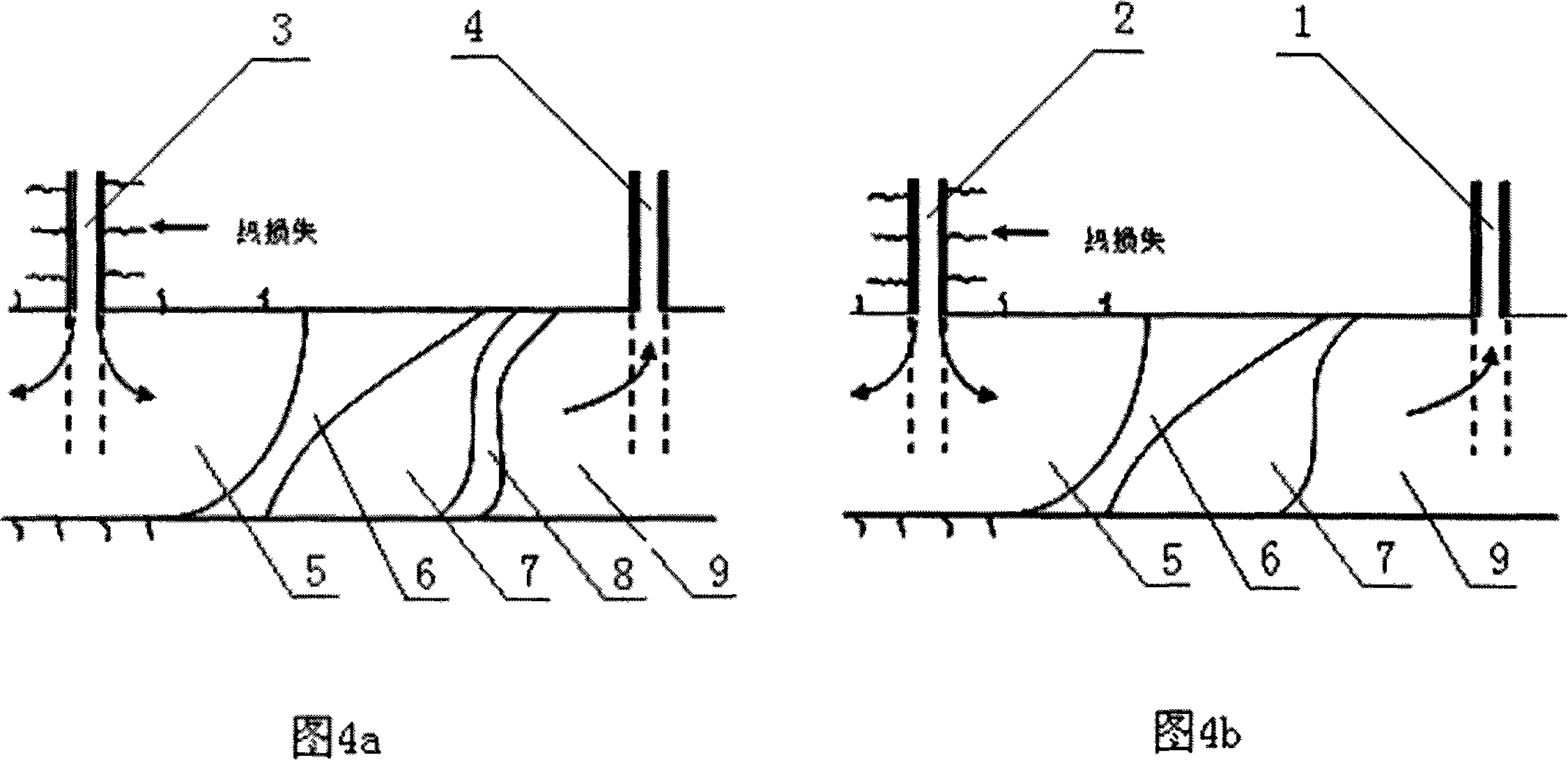

[0036] Embodiment 1: refer to accompanying drawing 3. The method for developing deep heavy oil reservoirs by carbon dioxide assisted steam flooding of the present invention has been tested in an oil field. This oilfield is suitable for the development of combined steam flooding of vertical wells and horizontal wells assisted by carbon dioxide injection after high rounds of steam huff and puff in deep heavy oil reservoirs. After long-term steam stimulation, the pressure has dropped below 3MPa, and the remaining oil is mainly distributed in the interwell area, which is suitable for the steam flooding development method of replenishing energy to the formation. Therefore, if an infill horizontal well is drilled between wells with abundant remaining oil, first huff and puff for 2 to 3 cycles, and after thermal communication with the vertical well is established, it can be transferred to the vertical well to inject carbon dioxide and steam. .

[0037] The specific method is:

[0...

Embodiment 2

[0054] The buried depth of an oilfield reservoir is 1300m, the effective thickness of the oil layer is 30.0m, the net total thickness ratio of the oil layer is 0.65, the average porosity is 22.0%, the average permeability is 1000md, the coefficient of variation of permeability is 0.60, and the viscosity of crude oil under the oil layer conditions is 400- 500cp. The oil field has been developed by steam stimulation for 15 years, the formation water content is relatively high, the recovery degree of the steam stimulation stage is 20.0%, and the formation pressure is 4-5 MPa. Carbon dioxide assisted steam flooding was used to develop deep heavy oil reservoirs in this oilfield.

[0055] A. Selecting reservoirs suitable for CO2 assisted steam flooding

[0056] According to the geological characteristics and development status of the oilfield, rough screening of the oilfield is carried out. Reservoirs suitable for carbon dioxide-assisted steam flooding meet the following condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective thickness | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com